Building an airplane can be an expensive hobby, and if your plane starts as a kit, you need a big chunk of that cash early in the process. For many would-be builders, this can mean putting the dream on hold for years.

In any airplane project, though, there is at least a year’s worth of work that can be done before plunking down any money at all. Here are 10 ways to start your aircraft project today—without spending any money.

1. Do the deep research.

You have already looked into what planes are available, examined the costs and specs for each one, figured out what your mission is and narrowed the options to the perfect airplane for you. Now it’s time to research this plane in depth. Connect with online and local builders’ communities for that specific model. Get old copies of builders’ newsletters (free online or borrowed from other builders) and read them all. Find all the past articles about your future aircraft in homebuilt-aviation magazines—the archives are often available online and access is free to subscribers. (You are a subscriber, aren’t you?) Read the blogs of other builders and see what problems they overcame. Spend the next year learning everything you can about the decisions you’ll need to make during the construction process.

You may need to figure out which engine to use, what fuel capacity you’ll need, whether to install a vacuum system, how much redundancy will be in the electrical system, whether you want fixed gear or retractable and whether the canopy will lift or slide open. What modifications have other builders found worthwhile? What seemed like good ideas to previous builders that just didn’t work? There will be hundreds of these decisions to make. Sure, you could wait until you have the aircraft kit in your garage to start thinking about these things, but most of them can be researched just as easily without a pile of aluminum displacing your car.

2. Start a research log.

Get a three-ring binder and some dividers or go high-tech with electronic notebooks like Evernote, Springpad or Microsoft OneNote (which comes with some versions of Office). Make sections for Airframe, Engine, Control System, Electrical System, Painting, Modifications, Workshop Setup, etc. Whenever you come across some worthwhile information, tear it out of the magazine, print the web page or scan it into your research log. Later, when you are actually building, you can quickly turn to the relevant section and find all of your ideas organized. Working on the brakes this week? Flip to the section on Landing Gear and you’ll find all the forum posts, newsletter articles, kit or plans changes, failure reports, builder recommendations, brand reviews and anything else that’s been written about brakes on your make and model of aircraft.

You should have a section in the builder’s log for everything, including avionics. But while it may be fun to peruse the latest high-tech glass gizmos or ultralight Belite instruments, you don’t want to lock yourself in to a given product early on. Aircraft designs and engines don’t change much, but avionics are going through a revolution, and products may vary dramatically from year to year. Whether you’re planning on installing a top-of-the-line IFR-approved glass-stravaganza or going for the eBay scavenger prize, by the time you need to fill a panel, the options will have changed. Avionics should be one of your last decisions, and while it’s valuable to know the history of avionics for Experimentals, any research you do today may be outdated by the time you need it.

3. Build the airplane in your mind.

Get a copy of the entire builder’s manual. (For some models, you can find these online. For others, you may need to borrow a physical copy from a local builder who has completed his plane.) Read it quickly to get a feel for the whole process. Then read it again, slowly, imagining each step and how it fits into the whole project. Construct a mental image of where each fuel line, circuit breaker, torque tube, trim spring and air duct goes.

If you have a thorough understanding of the whole process, when it comes time to build you will feel like you’ve done it all before. You will also make better decisions about any customizations that deviate from the plans. Thorough comprehension is the best way to avoid the dreaded cascading alterations (I moved the seat aft 2 inches, then I realized that the sump tank wouldn’t fit, so I made a taller and skinnier tank, which got in the way of the…). The time you spend building the aircraft in your mind will save you countless dollars and hours of head scratching and reworking later.

4. Become familiar with FAA Advisory Circular 43.13-1B and 43.13-2B.

These are the FAA “handbooks” on the acceptable methods, techniques and practices for aircraft inspection, repair (1B) and alterations (2B). They are free downloads from the FAA (just search for “FAA 43.13”), and they’ll tell you everything from the difference between a shear load and a torsion load to the inspection requirements for an engine subject to sudden stoppage. You don’t need to memorize every page, but it is good to be familiar with the wealth of information that is in these documents. Later in the building process, you’ll save time and money by knowing how to quickly answer your own questions from these reference materials.

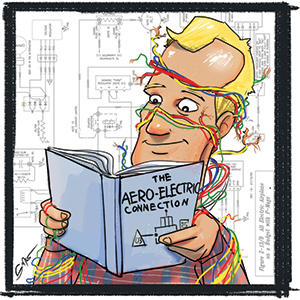

5. Read The AeroElectric Connection.

If your aircraft will have any type of electrical system, this book is a must-have. Bob Nuckolls, the author, has generously made it available as a free download. Nuckolls discusses everything from how to wire a simple electric starter, to the most complex dual-battery, dual-alternator, fully redundant, no-vacuum aircraft. He teaches not only the best practices, but why some things work and others don’t. He’s a fan of the simple-means-safe principle, so he doesn’t make anything more complicated than it absolutely has to be.

6. Finish the honey-do list.

At some point before buying the plans or kit, you’ll have to convince your family that you can build an airplane. This will be a tough sell if there is a long list of unfinished projects around the house. You can mentally gear up for these by counting them as part of the building process. There will undoubtedly be many boring, labor-intensive stages in building your aircraft, and you’ll get through them because you know they’re necessary to get to that exciting first flight. Think of those to-do items around the house as the first steps in your process and you’ll find renewed energy to tackle them.

7. While you’re doing things around the house, get the family involved.

The airplane project will be more fun, get built faster and receive more support if it becomes a family project. The best way to get them involved in your future project is to help them with their projects today. Tell your wife, “You know, your closet doorknob has been broken for a long time. Saturday, let’s go to that antique show you’re always talking about and find a replacement knob and then install it together.” Do this for a year and you’ll build the good will that could have her helping you buck those hard-to-reach rivets.

8. Work on the domestic marketing.

It’s one thing to have the family support your dream. It’s something special, though, if you can get the whole family dreaming of flying. Figure out how an airplane would help your wife achieve her goals. Does she want to spend winter weekends in Arizona instead of Idaho? Go to big cities to see Broadway shows? Be able to travel with her dogs? Take aerial photography? Drop in on the grandkids who are 300 miles away? Whatever her passion, there is a reason to own an airplane. (You’ll have to build one with at least two seats, though!)

9. Get working on your shop.

Many builders buy a kit and then spend the first six months setting up their workshop. Get that done now! Clean out the garage or basement. Organize your tools. Take that pile of scrap wood and build a workbench. Turn that old armoire or refrigerator into a heated epoxy cabinet. Read the workshop section of your aircraft manual and create the space you’ll need. If you are resourceful enough, you can scavenge sufficient wood, metal and hardware to construct storage shelves, a wing stand or even a fuselage jig. Ask the builder community what you’ll end up needing, and get building.

10. Start the airplane fund.

Open a separate savings account specifically for the airplane. Put a little away each month. With all of the above pro-jects on your plate, you probably won’t have much time for TV, so drop back to basic cable and put the difference in the airplane fund. If you’re tackling more projects around the house, that’s a lot less money being spent on plumbers and appliance repairs. Put it in the airplane fund. You can get spousal support for this idea by making it a dual-purpose savings account. Agree that when there’s $3,000 in the account, you’ll buy a new dining room table (or whatever your spouse wants) and the empennage kit.

All of this work has to be done at some point, and for most people, it will take a year or more. Get it done now and it will certainly save you more than a year of work between when you order the kit and your first flight. Even if you can’t spare a penny today, you can make 2013 the year you started your dream.