One of the big differences between gyroplanes and helicopters is the landing gear. That’s because helicopters don’t need landing gear, other than skids to rest a while on the ground. After all, the big advantage of a helicopter is its powered rotor, which gives it the ability to lift off vertically to a hover and then build forward speed for a climb.

On the other hand, the gyroplane with its free-spinning rotor needs a takeoff roll. The takeoff roll allows the gyroplane to take advantage of the relative wind to build rotor speed for takeoff. The transition from ground to flight in a gyroplane is actually a lot more similar to an airplane than it is to a helicopter. So all you airplane builders—stick with us!

Wheels Aren’t Glamorous

Unfortunately, on a gyroplane wheels are often looked upon as a necessary evil. Actually, to be honest, wheels are all-around seen as rather boring. There aren’t too many kids going to college to earn a mechanical engineering degree in order to design wheels. That lack of excitement doesn’t take away the importance of wheels, steering, and shock absorption in aircraft design.

In fact, gyroplane wheels have to be far more versatile than the wheels on your car. True, a gyroplane is designed to fly, not to taxi around, but taxi it must. The wheels don’t have to be able to endure thousands of miles of road wear, but they do have to be lightweight. Even more important, gyroplane wheels have to make the transition from rolling to flying and back to rolling again. And preferably they should make the transition without trying to force the gyroplane off the side of the runway!

With so much attention being focused (and properly so!) on flight stability, ground handling may have been given short shrift. With the industry and pilots beginning to understand the physics of flight stability, it is time to look at the lowly landing gear. After all, there seems to be a disturbing trend of aircraft getting involved in incidents after executing a landing. Some of this can be addressed with training, but part of training is understanding the machine and its systems.

Lesson number one is that gyroplanes handle differently on the ground. This generally varies make-by-make since often the same landing gear designs are used on similar models, even if other things are changed. Our focus with this article will be on the front gear of tricycle-style gyroplanes, which are far more common. In tricycle-geared aircraft, the one pivoting wheel is at the nose of the aircraft. With a tailwheel aircraft, the trailing wheel is the one that pivots.

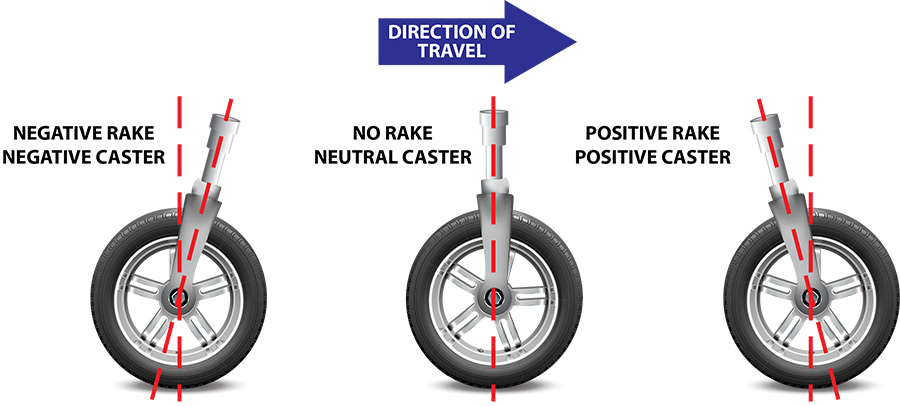

Caster can be affected by the rake of the fork. Positive caster is when the steering axis extends in front of the vertical. Positive caster creates a lot of align torque (the force that straightens the steering when you taxi forward), which improves straight-line stability of the gyroplane. Negative caster is when the steering axis extends behind the vertical. Aircraft do not use negative caster. It will lighten the steering effort, but decreases steering stability.

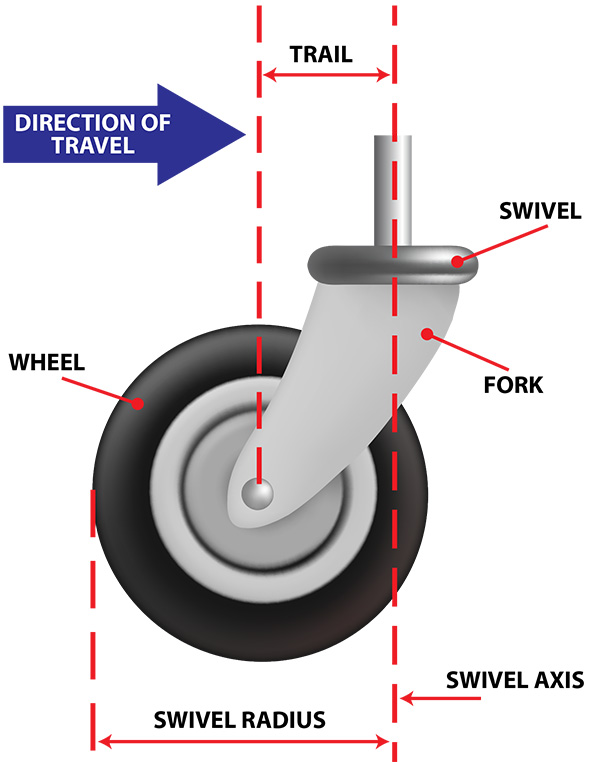

For smaller wheels, offsetting the rolling axis from the swivel axis is an effective way to achieve caster.

Caster, Rake, and Trail

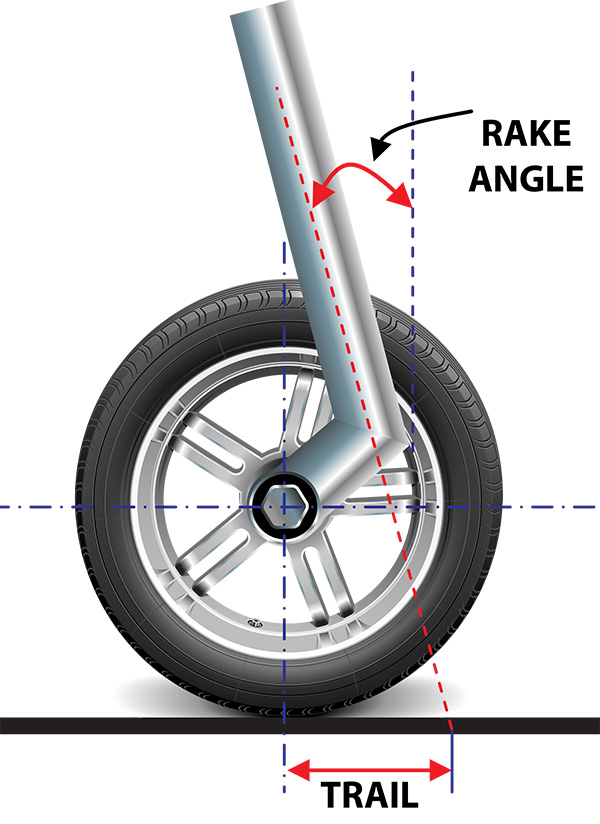

The first thing to understand about front landing gear is caster. Caster can be positive, neutral, or negative. An example of positive caster can be found on the front wheels of a shopping cart. The caster is achieved using a displaced axis. The displacement is called the trail and is also a typical tailwheel design on airplanes. The measure of the caster in this instance is the amount of the displacement or the trail. No displacement at all would be a neutral caster. If somehow the wheel swings around in the other direction, that would be negative caster and very unstable. A wheel with neutral caster will shimmy even at low speeds. That’s why the good folks at the grocery store invest in castering wheels that automatically pivot to a positive caster!

Another way to achieve caster is to angle the pivot axis of the wheel assembly. This angle is called rake. As the steering axis is tipped forward, then some positive caster is achieved. That’s because again the pivot axis of the wheel assembly is forward of the turning axis of the wheel. In this case the trail is a function of the steering pivot angle from vertical and the diameter of the wheel. If you have a large wheel like those on a bicycle or motorcycle, you can achieve a lot of trail using this method. But with the smaller wheels found in light sport aircraft, there are definite limits to the amount of positive caster you can achieve by just tilting the pivot axis. And too much tilt can cause problems of its own.

What positive caster does for the gyroplane is that it works to steer the front wheel back to center. The larger the trail, the greater the centering effect. This really helps on landing when the front wheel may not be lined up with the direction of travel of the aircraft. As soon as the front wheel touches down, a properly castered nosegear will work to pull the wheel into alignment with the direction of travel. Since presumably the direction of travel is directly down the runway, this is definitely a good thing!

The good news is that most all gyroplanes have at least some positive caster. The bad news is that normally there isn’t nearly enough forward caster. This is clearly indicated by the number of gyroplanes—both modern designs and not so modern designs—that dart off of the runway after landing at higher speeds.

The questions become how much caster is enough, how do you achieve it, and can there be too much?

Before addressing those questions, it is important to first talk about the downside to positive caster. The biggest downside is that as you increase positive caster, you also increase the amount of force needed to turn the front wheel. It is the classic tradeoff between maneuverability and stability. But since most of us prefer stable landings, it is a trade-off worth making.

Tilt angle on the nosegear is defined as the angle in a vertical plane between the wheel axle and the local surface on which the tire is operating. These views from the front of the wheel show that when a wheel with rake is turned, the tilt angle increases also. The greater the rake, the greater the tilt angle effect.

Three Variables

There are three variables that designers can use to achieve positive caster. Those are: rake, wheel diameter, and offset.

Yaw angle for a wheel is defined as the angle in a horizontal plane between the wheel axle and a line perpendicular to the direction of motion of the wheel axle. These views from above show a wheel with no rake in a turn. Below that is a view of a wheel in the same turn, only with exaggerated rake.

All three are part of the geometry that can increase the trail of a castering wheel, which is what ultimately improves the caster in a nosegear design.

Rake is the most common way of increasing castor in bicycles, motorcycles, and even motor vehicles like cars. It is also common in aircraft design, including gyroplanes. However, there are limits to how much rake you can introduce into wheel geometry before you start increasing side loads.

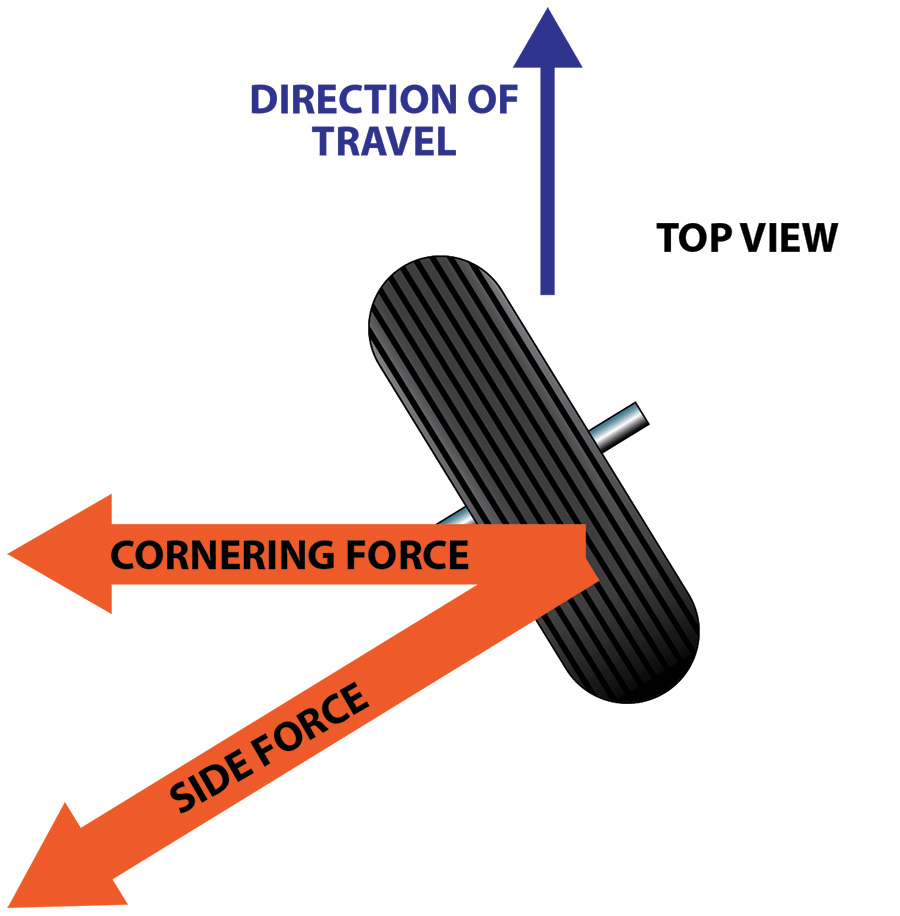

This is because as you increase rake, you also increase the tilt angle of the wheel when it is turning. Small tilt angles are acceptable, but large tilt angles introduce large side loads on the wheel, which can actually counteract the positive forces of the caster.

Side loads already exist on a nosegear wheel on touchdown if the wheel is not aligned with the runway. This force is called cornering force. Even while caster properly works to straighten the wheel out, cornering force tries to pull the wheel farther into the direction the wheel is turned. As rake is increased, the effect of cornering force can overcome the self-centering effect of the caster and pull a gyroplane further and faster to the side.

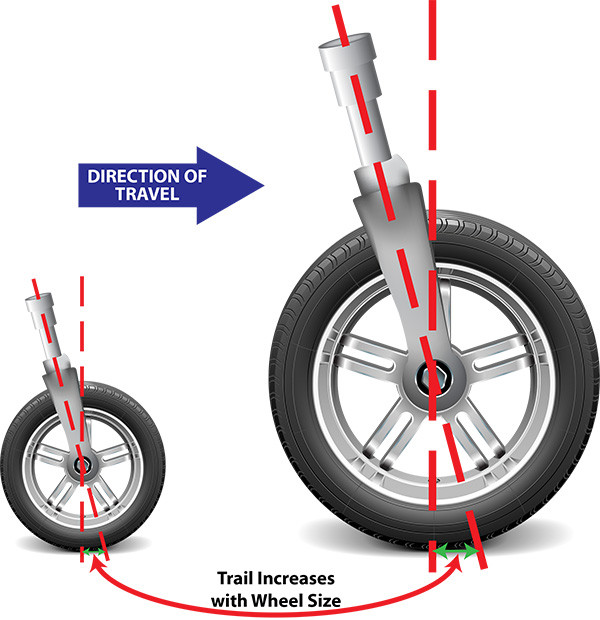

Wheel diameter, along with rake, is what actually determines trail in wheels that rely on rake for caster. As the wheel gets larger, the trail also increases. After the practical limits of nosegear rake have been reached, designers often use larger- diameter wheels to increase caster.

Larger wheels are what makes smaller rake angles work for automobiles, motorcycles, bicycles and even airplane nosegear.

However large wheels have limits in aircraft design, too. Larger wheels typically weigh more. And landing forces on narrow and tall tires that aren’t aligned with the runway are extra damaging because of the moment arm between the surface of the tire touching the runway and the axle.

When a tire touches the runway, there is a force to the rear that acts to begin turning the wheel. But when a wheel touches down and it isn’t aligned with the runway, other forces also come into play. These forces tend to pull the gyroplane to the side that the wheel is already turned. Side force is defined as a force in the tire footprint parallel to the wheel axle. Cornering force is defined as the component of the side force that is perpendicular to the direction of motion.

Gyroplanes have another issue with tall front tires. Taller tires usually mean raising the center of gravity. It isn’t necessarily true, but design aesthetics also come into play.

Offset works by simply moving the wheel axle behind the steering axis without using rake. Offset works with wheels of all sizes, which means that it is particularly well suited for the small nosewheel sizes used in gyroplanes. Another advantage of offset is that it works without any of the disadvantages created by rake.

Putting It All Together

Remember, the point of caster in the first place is to straighten out a nosewheel when it touches the runway. There are three tools in the toolbox. We already know that rake and wheel size work together to achieve trail. However, designers can also integrate offset along with rake and wheel size. This is not uncommon in aircraft design.

Steering

As mentioned earlier, steering a high-castering nosewheel is more difficult than a low-castering nosewheel. But there are ways to get the job done.

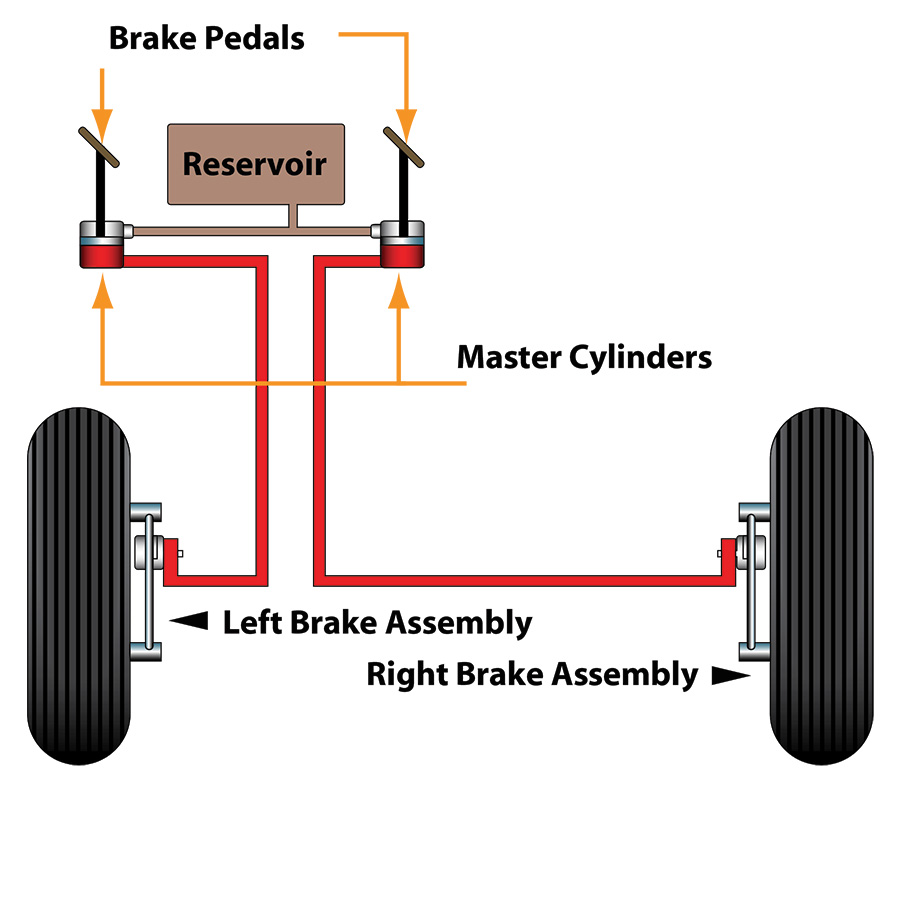

One solution to steering a gyroplane with a lot of caster is to allow the nosewheel to freely caster and steer with differential braking. This is again similar to a shopping cart or many tailwheel airplanes. Instead of incorporating any kind of steering mechanism to the castering wheel, the pilot just pushes on one side of the aircraft and pulls on the other to make it turn.

Of course the placement of the push (prop thrust) can’t be changed, so steering is accomplished by slowing one wheel down by braking and allowing the other wheel to turn. The moment created between the pushing on the center of the aircraft and the pulling of the brake on one wheel usually has little problem overcoming any caster.

This method requires two separate braking systems (since presumably you want to turn left and right, as well as slow down), along with the expense and mechanical complication that comes with such a system. However, it is very effective.

Another solution is to steer by turning the front wheel, knowing that steering is going to take more force as the caster is increased. This is the solution that is used by a lot of gyroplane manufacturers. The differences lie in how much caster is designed into the front wheel.

An analogy for motorcyclists is the rake of the front fork. Generally, the greater the angle of the front fork of the chopper, the more stable the freeway ride. However, what comes along with that is a more difficult time turning and cornering. European and Japanese bikes value cornering more, so you generally see less caster. Luckily with a gyroplane, pilots aren’t as concerned about cornering abilities, well, at least while taxiing.

Ultimately, some designers want to make the ground steering manageable while incorporating as much caster as possible. But it isn’t just about the strength of the pilot. Steering assemblies have to be strong enough to take the higher turning inputs from the pilots.

Dual Purpose

For most gyroplanes using a steerable nosewheel, that nosewheel is steered using the same foot pedals that are used to steer the rudder. After all, most pilots only have two feet. This is not a problem while taxiing and not a problem when flying.

However, the dual purpose of the steering mechanism can create problems for a pilot during a crosswind landing when the direction of the rudder needs to be different from the direction of the runway and the front wheel.

This is where a significant positive caster shines. At the moment of touchdown, it becomes more important to have a front wheel rolling straight down the runway than anything a rudder can do. A positive caster allows the runway to grab the front tire and straighten it out as soon as the wheel touches down. The greater the caster, the greater the effect. So, for a manufacturer who wants to design an aircraft that is controllable at different touchdown speeds, this is a big advantage.

Shimmy

Front wheel shimmy is an unfortunate byproduct of a steerable nosewheel. Everyone has had the unfortunate experience of pushing around a shopping cart with a shimmying wheel. That experience is annoying, but not dangerous. On the other hand, a shimmying nosewheel can be damaging to the entire airframe since it is a violent form of vibration, akin to flutter in flight controls. Like flutter, it may only appear at higher speeds. Also like flutter, it should not be accepted as normal.

Shimmy prevention is part good design and part good maintenance. Steering and the wheel itself should be tight, with no undamped movement (other than rolling of course!). Damping can be achieved in a lot of different ways. Friction can be used as a damper and there are even specific shimmying dampers, which are similar to shock absorbers and are used in some applications.

From a pilot’s point of view, it is important to know that shimmy is just not acceptable.

Issues for Builders

It is important for homebuilders, and even manufacturers, to focus design concern on the undercarriage of gyroplanes. No matter how well an aircraft flies, they all have to land regularly. Making that landing a stress-free event for both the aircraft and for the pilot is important. Many nosewheel designs are simply not up to the task, and that is something that manufacturers should address.

Issues for Students and Instructors

The main thing here is to know your aircraft. If you are shopping for an aircraft, take into account how it taxis and how it transitions from flight to landing. If the design is not optimum, you are simply going to have to increase your skill set. A workaround for gyroplanes with little caster is to land at very low speeds and to avoid crosswind situations as much as possible.

Instructors have a bigger challenge, as should be expected. Not only do instructors have to understand their training aircraft, they should educate their students on the differences in landing gear. This is especially important if the student is planning to transition to a different model of gyroplane than the one being used as a trainer.

Wheels may have been around for over 5,000 years, but that doesn’t mean that they are any less important or should be taken for granted.