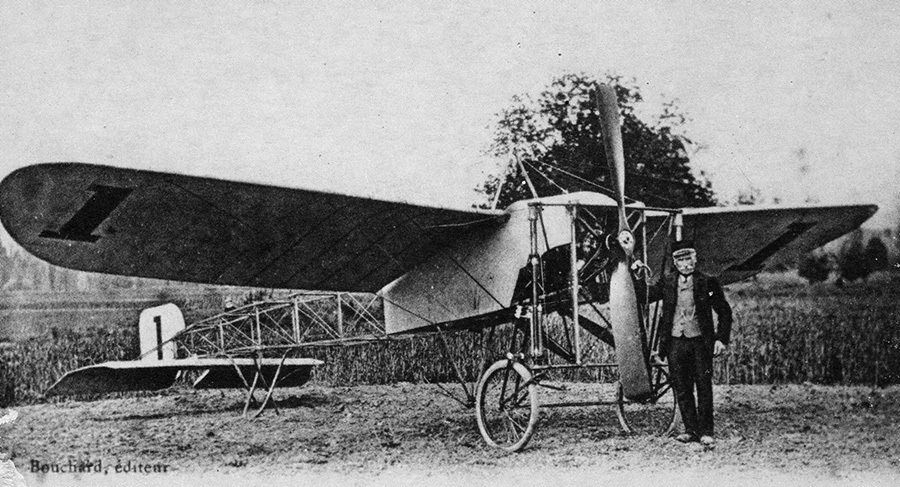

Blériot replicas have graced museums for many decades, but those replicas that fly, especially with original and contemporary era engines, are few and far between. Building a full-scale replica of this iconic 1909 aircraft is probably the ultimate in plansbuilt aircraft construction. At Corning, Iowa, aircraft restorer and propeller manufacturer Chad Wille has completed construction of a near exact replica and flies it from his base at Brodhead (Wisconsin) Airport when the weather conditions are favourable.

“Learning to fly a Blériot is a bit like the Wright brothers and Louis Blériot himself,” Chad told me, because they are single-seat aircraft and very few 21st-century pilots have any sort of experience flying such antiques, or knowledge of the wing-warping process that pre-dates the use of ailerons. However, Chad was already one-up because a few years back, he was chief pilot at Old Rhinebeck Aerodrome in New York State and had accumulated time in their Blériot, #56.

Flown in memory of Chad’s late wife Betty, who helped with much of the initial inspiration, planning, and constructional work, he now keeps the Blériot XI (N453) alongside his 1936 Waco YKS-6 in the Brodhead hangar. The project started in the spring of 2002, following a visit to the San Diego Air and Space Museum where a replica, originally a flyer and fitted with a Continental A-40 and built by Walter Bullock, is displayed, suspended from the museum’s ceiling. At the end of that visit Betty said to Chad, “I’m going to build one of those,” and added a follow-up suggestion that it would be great to celebrate the centenary of Blériot’s historic July 25, 1909 first English Channel crossing by flying their replica of the Blériot XI.

Original Drawings and Materials

Chad and Betty used blueprints for construction and sourced some original parts, making dimensional sketches in areas where the blueprints were lacking. Charles Rozendaal had rendered drawings in the 1911 German magazine Der Motorwaggen, and these were the basis of the project. Noted Chicago-based Blériot builder Gary Karner, who has visited and photographed most surviving Blériots worldwide, provided a continuous source of guidance and help. In 2004 Chad and Betty went to work at Old Rhinebeck, where Chad flew their example and Betty got to taxi it. Betty, a medical technician by profession, was also a qualified pilot and flew a Corben Baby Ace. Unfortunately early in 2005 Betty died at the age of 49, a victim of cancer. Chad decided to complete the project, which was well advanced in the loft of their barn back in Iowa, in Betty’s memory; it was another seven years of work.

Using exact original materials and to the original drawings, the homebuilt to end all homebuilts took shape. The “Traverse Le Manche” Blériot XI was a one-off, differing from others with the same designation because of the location of the wing height on the fuselage mounting and the shape of the rudder. Chad told me, “I believe our Blériot XI is the most accurate replica XI ever built.” Ash and poplar were used for the wooden fuselage, but they soon realized that it is a long aeroplane (over 26 feet, greater than the wingspan). They also realized that the structure was “a thing of beauty, with the French curves of the longerons and carefully streamlined-shaped uprights.” All of the bare-wood structure was carefully varnished, they had to manufacture a woven cane seat, and opted for the crossed sprung cane and hooped tailskid to retain authenticity. In one of the few deviations from the original, Chad used modern Nicopress swaged ends on all the flying and landing wires, rather than the tuck splices of the original. The undercarriage shock absorber is a bungee cord, which swivels like the original, and today is commonly known as a crosswind gear. For accuracy and looks Belgian linen was used to cover the airframe, donated to the project by aircraft restorer Forrest Lovley, with a couple of coats of nitrate and butyrate dope, typical of the 1910-15 period. Chad studied the original covering system, fearing it may add unnecessary weight to the aircraft, but concluded that there is virtually no difference between this early 20th century method and modern covering systems. The finished look and colour of the Blériot was also important, and this could only be reproduced with the correct sheen and straw colour in daylight by using the Belgian linen and dope.

Airframe Construction

All construction was hardwood ash or poplar, the one-piece wooden spars being routed for lightness. Chad manufactured and installed internal drag and anti-drag bracing wires within the wing structure, which weren’t shown on the plans, probably because the original Blériots were not expected to last very long. A spanwise batten between the leading edge spar and front spar is also fitted, as per the original, to stop top-surface fabric from dipping between the wing ribs, which have an extreme curvature—the leading edge has rolled aluminum and was one of the hardest parts of the original to get correct. The wing ribs close to the wingroot are also reinforced, illustrating Blériot’s care and understanding of airframe engineering. Before covering in June 2011, Chad made the first trial wing attachment. Due to the considerable undercamber of the wing’s “Eiffel 13” airfoil, Chad rib-stitched the fabric to the wings, sucking it tightly to the underside. The original covering was held tightly with tacks, but shrinking dope on the fabric, a process that goes on over months, long after the work is complete, could shrink the fabric too tight and affect the wing-warping process. Chad must have done it correctly because he reports, “The wings warp easily with little stick resistance.”

Engine Installation

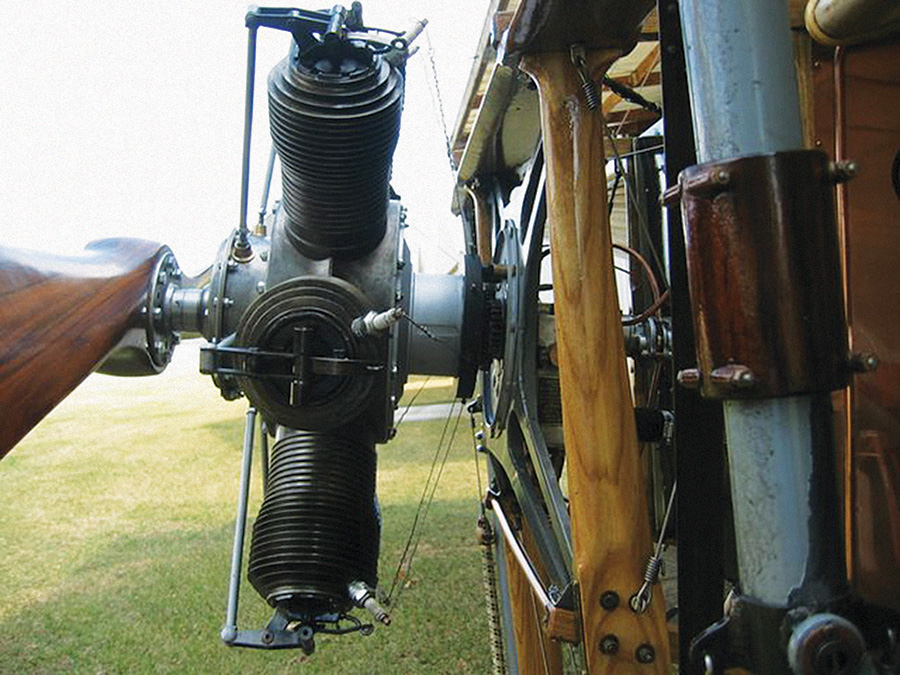

Engine installation and the engine(s) themselves deserve an article in their own right. Chad was lucky enough to be able to test two original 1909-era engines on his Blériot, initially a restored 1910 Anzani three-cylinder, air-cooled, semi-radial fan-type engine rated at 22/25 hp and loaned to him by Gary Karner, and more recently, the currently fitted 1908 Gnome Omega rated at 50 hp. Chad is an accomplished propeller maker and carver, running a small business doing this since 1977 in their Iowa barn; so thanks to his craftsmanship, an 89-inch (2.23-m) diameter, hand-carved propeller was fitted. When the Gnome was substituted, a new 98-inch (2.50-m) prop was made and fitted.

The Gnome requires separate manually adjusted air and fuel flow, and the familiar (to engines of this vintage) blip switch to prevent full rpm until ready for full power and takeoff. Springs, counterweights, and centrifugal forces control the air intake, and the engine will only operate properly down to a certain rpm. Chad established that 600 rpm was the slowest speed from which he could then speed the engine back to maximum revs on the ground using the air and fuel levers. The Gnome has the benefit that Chad could start it without assistance: Prime and set a cylinder in the correct position for the booster magneto to fire it, walk around to the cockpit, spin the booster, and the engine runs. It doesn’t throb either, like larger rotary engines, thanks to its lower compression ratio. The change from the Anzani required an adaptor plate so no airframe modifications were necessary, but other connections weren’t as straightforward—a larger oil tank supply line for the larger Gnome pump was required, larger vents had to be fitted in the oil tank, fuel lines and controls for the Tampier metering valve needed to be modified and a cockpit control had to be installed to adjust fuel flow to the carburetor. A booster magneto was also installed on the only available floor space in the cockpit to help with easier starting. As the Gnome installation was about 25 pounds heavier than the Anzani, the bungee suspension had to be adjusted and, to prevent the gear from sagging, an additional chord installed on each side.

Chad stands in the Blériot cockpit, control stick in hand, and surveys the route along which he’ll taxi to the runway. Once started, with no brakes, the aircraft transitions from taxi to takeoff without interruption.

Operation of the Blériot with the Gnome is “very pleasant” according to Chad, but “the feeling is, sadly, more modern in terms of performance and feel because the delicate balance on the very edge of powered flight is lost!” But the Gnome provides smooth power and plenty of it, a whirring of seven cylinders whose sound is spun outward to the wind, which blends as a continuous drone.

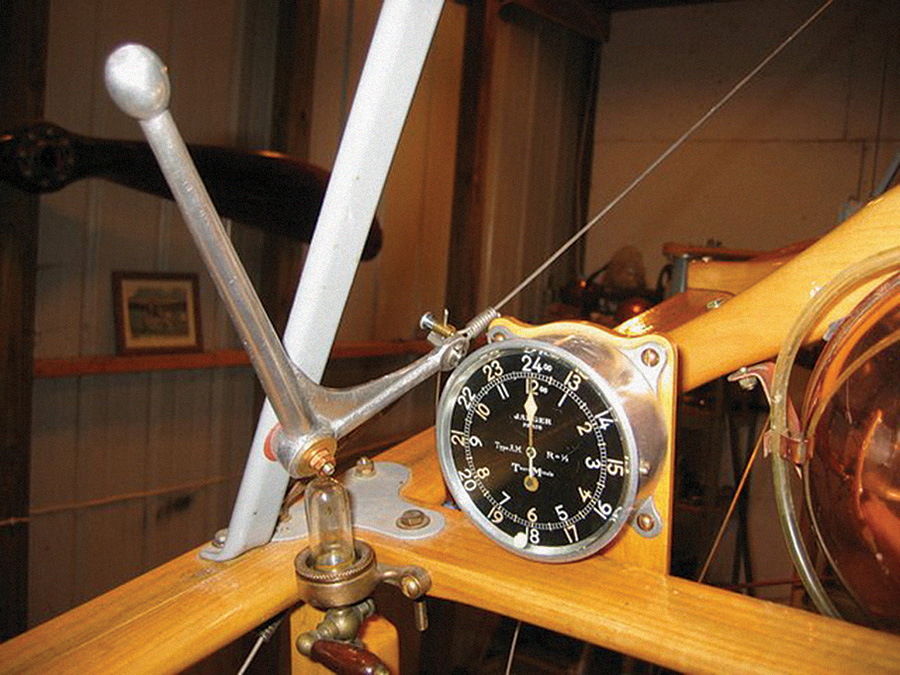

Long handle is the spark advance (primitive throttle), pulsometer glass to show flow of castor oil, and original Jaeger tachometer.

The Gnome is much thirstier than the Anzani, and the one-gallon oil tank has to be frequently topped off. It produces only about 7 hp each time a cylinder fires, and its extra power doesn’t so much translate into extra speed, but does assist in being able to fly in windier conditions.”

Attention to Detail

According to Chad, “The building was not only a means to an end, but rather the incredible beauty of all the parts was an end in itself. The French believed that every part of an aeroplane must itself be a thing of beauty, sanded, polished, and painted—and every piece added was something to be admired for its own unique artistry. I particularly like the look of polished copper, so I went to some lengths to build a copper fuel tank and to use original copper-plated turnbuckles, securing them for safety with copper wire. I also used bronze nuts and bolts where possible and paid much attention to finer details, such as the few period instruments fitted.”

First Flight

Transported by truck from Iowa to Brodhead for final assembly in August 2011, the first tentative “hop” was made during taxi trials on September 1—the official first flight was on September 9. The next year the center cylinder of the Anzani blew, and Chad took this opportunity to replace it with the Gnome Omega that’s still fitted. The Anzani, owned by Gary Karner, has since been repaired and will be fitted to a Blériot replica he’s building.

In calm, damp air, Chad says his Blériot is stable and solid in turns, with no adverse yaw or tendency to bank over. Cruise speed is a slow 40 mph, established with the chase pickup truck running alongside the runway, but Chad comments that the whole sensation is one of “impossibility” that forward flight can be so slow. Any puff of wind is much more noticeable at these speeds than with faster aircraft. Climb is about 36 mph and a dive 48 mph.

Although the elevators are sensitive, they are extremely effective. The rudder feels normal, the wing warping responsive, but it can catch you out in turbulence as the aircraft tends to run out of lateral control. It is also much harder work flying in gusty weather, even though the aircraft remains fully controllable; at such slow speeds wing-warping makes perfect sense, with ailerons only practical at higher speeds. The Blériot responds well to rudder input for roll control, probably due to the large, 8 dihedral of the wings. With no brakes fitted, once the rotary engine is started the aircraft moves off, so there is little time to preflight, only on the short taxi to the runway end. Takeoff distance is about 100 feet, and Chad has taken the Blériot to 200 feet. He says, “A readjustment of thinking about space is required since the speed is so low, the turning radius is quite small, and I can fly for what seems a very long time toward my turn point before ever getting there. The flight paths and approaches I’ve known for decades at Brodhead flying more modern and faster aircraft are different and revised, and in the Blériot it becomes a new place to fly.”

Chad usually limits endurance to 10- or 15-minute flings, the engine spewing out castor oil because there is no cowling to contain the spray. This all leads to a lengthy post-flight cleanup, but it’s well worth the effort. After all, there aren’t many airplanes that can take you back to 1909.

The author would like to thank Chad Wille for his generous help and contributions, without which this article would not have been possible.

beautiful build, i truly enjoy the simplicity of the Bleriot XI, i would love to see a flight video of your Bleriot, is there a video footage?

I have many models RC models of the Bleriot XI, but seeing your scale full size build, i am quite envious. thank you

What an ambitious project! But why do you spell the name Blriot (without the ‘e’)? That’s not how Louis Bleriot spelled his name. I found it distracting from an otherwise fine article. And I know a little about this, having helped rebuild the fan-type Anzani on the Shuttleworth Bleriot XI in England more than 40 years ago. We had two engines to work with and discovered that literally ZERO parts were interchangeable between them. Not even the crankcase castings were standard, with differing angles between the cylinders!

Somewhere in the process of migrating content from the old Kitplanes website, the “é” had fallen into a dark hole. Fixed now – thanks for the notice.