Next time you’re hanging out on the FBO porch with the boys, casually announce your intention to install an oil separator with a sump return line. Chances are at least one will swear it’s a bad idea, and offer a dire warning about returning water to the engine along with the captured oil.

Is he right, or wrong? Let’s look at the details.

Blow-by-Blow

Crankcase outflow originates in the combustion chambers. The piston rings don’t seal perfectly, and some of the hot combustion gas leaks past them into the crankcase. We call this leakage “blow-by,” a nicely descriptive term. Without some way to escape, blow-by would increase crankcase pressure until it became high enough to blow out an oil seal. The escape path is the crankcase breather outlet.

The hot combustion gas is, not surprisingly, similar to ordinary exhaust outflow: in ballpark terms, about 71% N2, 14% CO2, 13% H2O, with the remaining few percent being NOX, CO, unburned hydrocarbons, and trace compounds. The rings also leak on the compression stroke; compression blow-by is mostly ordinary air spiced with gasoline. The resulting “crankcase atmosphere” is hot, so constituents with high vapor pressures (notably water and fuel) are in the form of a gas, not liquid.

The crankcase is full of whirling parts and flying oil droplets. Lubricating oil has a very low vapor pressure and thus does not easily evaporate, even at high temperatures. In consequence, although the oil droplets get smacked and smashed until broken down to aerosol size, they remain in liquid phase. The result is a breather outflow consisting of tiny liquid oil droplets floating in a hot mixture of gases.

In a traditional aviation installation, the breather outlet is simply vented overboard at the base of the firewall, and the liquid oil tends to spread itself along the belly. If the outflow temperature remains high enough, water and fuel remain in the vapor state and pass to the atmosphere. However, if outflow temperature is reduced to the respective dewpoints of the water and the fuel, they will condense into liquids within the breather hose. Normally both re-evaporate when released into the atmosphere, although ice formation (and blockage) at the end of the hose is a distinct possibility if outside air temperature is low enough.

Separators

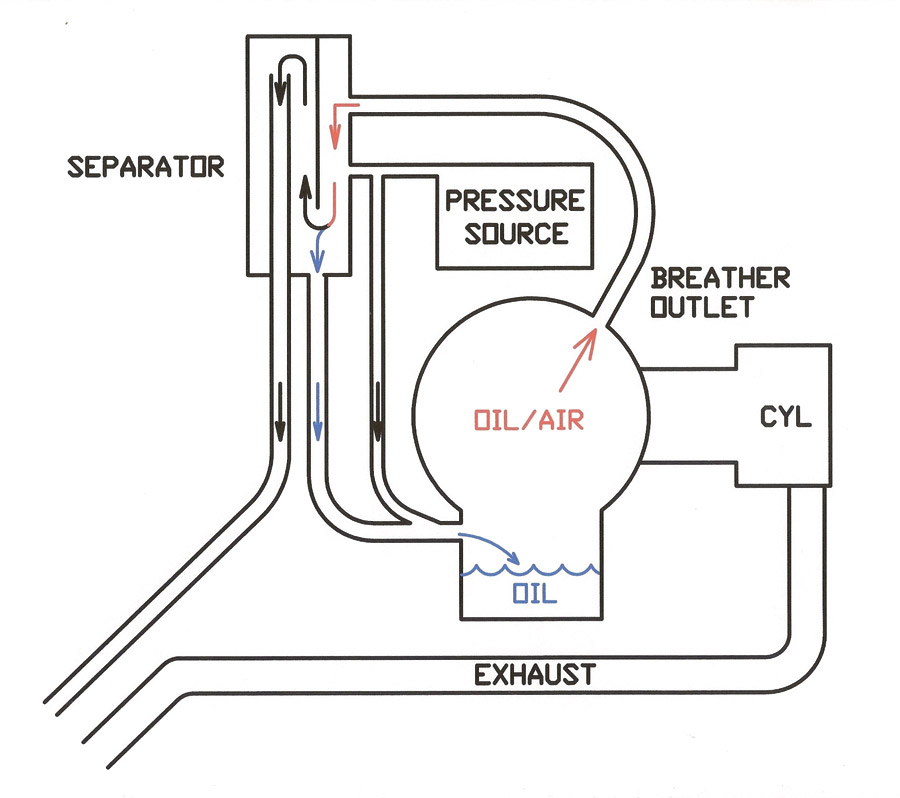

Let’s add an oil separator. Traditional aviation separators generally work by directing the breather flow against the inside surfaces of a can, then vertically to an outlet. The oil droplets, having mass, can’t follow the rapid changes of flow direction. They splatter on the surfaces, coalesce into larger drops, drain to the bottom of the can, and exit via a drain line. In a simple system the hot outflow gases continue overboard as before, but now without the liquid oil.

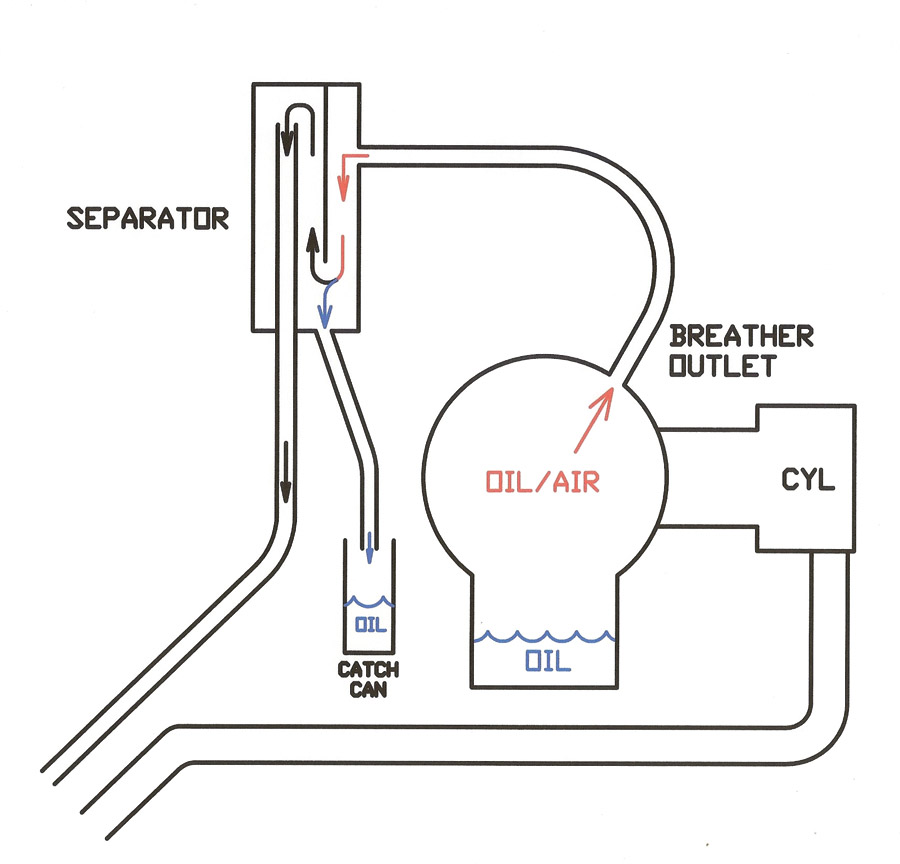

Almost everyone likes a separator. The debate centers on what to do with the oil drain line. Quite a few separators have been installed with a catch can intended to store the separated oil until drained at some maintenance interval (Figure 1). Owners and mechanics often report that the can collects a milky emulsion of oil and water, usually described as “slime.” The condensed water generally includes some miscible acids and oxidizers; the reported pH is in the range of 4.6 to 3.85, which is about the same as ketchup, canned peaches, or a Bartlett pear. Regardless of content, it’s not attractive. Owners don’t like the idea of returning slime to the engine sump.

However, slime isn’t universal. Other operators report nothing but oil in their catch cans. The slime faction figures them for tall tales and white lies (they’re pilots, right?), but that’s unfair. It is far more likely that the slime-free installations simply operate at higher temperatures.

Remember, when the engine is operating, the crankcase outflow is hot…usually somewhat hotter than indicated oil temperature. At that level all the volatile liquids (water, some acids, and fuel) are in vapor phase. If they remain in vapor phase, they pass right through the separator with the other gases; only liquid droplets collect on the walls. To maintain the vapor phase, the separator and its associated plumbing must be kept at some temperature above the dew point of the vapor constituents.

With that in mind, there are two causes for water in a catch can. The first and most obvious is that the breather hose and/or the separator housing is being chilled enough to act as a condenser. The cowl may be the type that is largely open to the air stream (think J-3 or similar), or includes several blast tubes, or is just poorly sealed. Leaking baffle seals can allow a lot of cool air into the accessory area; NASA Report CR 3405 reported 38% of total cooling mass flow bypassed the engine fins in a relatively new installation. That unheated leakage significantly lowers temperatures in the firewall area.

The second cause is accumulation following cold start. When the engine is started after a period of inactive storage, liquid water droplets condensed inside the crankcase are blown out through the breather in the same manner as liquid oil droplets. Since both the initial outflow gas and the separator system are cold, the liquid water cannot reach vapor phase, and is thus collected by the separator and drained to the catch can. Note that if cold-start liquid water is returned to the engine, it evaporates as the engine reaches normal operating temperature, and is ejected as vapor in due course.

Temperature Considerations

It is physically impossible to return water to the crankcase if breather gas temperature is held above the dewpoint until downstream of the separator can. Dewpoint is dependent on percent water saturation (or relative humidity, to use a common term). The quantity of H2O in the breather gas is a function of combustion chemistry (fixed by the number of available hydrogen atoms in the fuel) and the contribution of atmospheric water in the intake air. I wasn’t able to obtain research literature that specifically measured breather gas H2O saturation. However, there is no shortage of information about exhaust gas constituents, including water content, and the dewpoint calculations can be borrowed from flue gas engineering. The resulting dewpoint appears to be between 125 and 145 F.

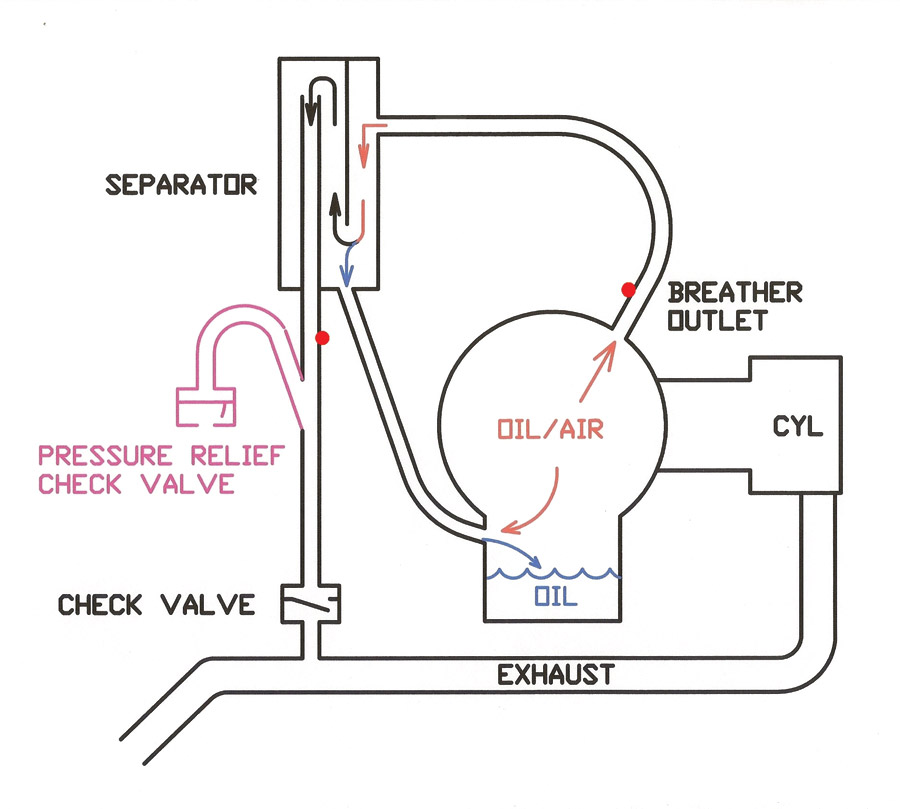

My RV-8 is equipped with a pair of very useful roving temperature sensors (National Semiconductor LM135) on long leads in the engine compartment. In order to establish operating temperatures, one sensor was inserted into the main breather line just outboard of the accessory case port, and the other into the outflow line just after the separator (red dots, Figure 3).

The resulting measurements are interesting. Breather outflow at the accessory case averaged 200 F, or about 15 F higher than indicated oil temperature. Separator outlet temperatures averaged 40 F less than breather port temperature. A 200 F average breather outflow and 160 F separator outflow are enough to stay above the assumed dewpoint.

However, a similar separator system may run colder under certain circumstances, and there is no downside to increasing the margin between separator outflow and dewpoint. So, the next step was to insulate the breather system and re-check temperatures. Surprisingly, breather can insulation (1/16-inch Fiberfrax felt under aluminum foil tape) didn’t change outlet temperature very much. However, insulating the breather hose with a length of ordinary firesleeve raised the separator outflow to between 170 and 175 F, a nice increase in margin over dewpoint.

Oil Analysis

Several aircraft owners were kind enough to forward their recent reports from Blackstone Laboratories, the very popular oil analysis firm. The reports show no change in water content after the addition of a sump return separator. The systems were installed on RV-type aircraft, which, being fully cowled, tend to maintain moderate to high under-cowl temperatures. However, there was no effort to insulate the separator systems and increase dewpoint margin.

Bottom line? It appears that warnings about returning water and slime to the sump have basis in physical reality, but only if the owner/installer fails to ensure adequate operating temperatures. The apparent physics do not allow water return to the sump when the breather-separator system is operating above the dewpoint. If you’re not sure about separator outflow temperature, measure it. One measurement can be worth a great many front porch opinions.

I have been researching “catch cans” for a number of weeks now as my girlfriend recently purchased a 2016 Ford Edge Sport, with the 2.7L Ecoboost, a twin turbo, GTDI v6. I have absorbed many, MANY academic and journal papers, studies, opinions and “facts”, stories and a plethora of slimes collected by various separator systems. This article is, by far and away, the most helpful and informative on the subject I have come across. Just wanted to express my appreciation for this article and I will be sharing it everywhere I can! Cheers!