Here’s a rhetorical question we might ask skydivers: “Why jump out of a perfectly good airplane?” And we could add, “Why cut the trip short?” or “I like to keep my takeoffs and landings an equal quantity.” But we as airplane designers, builders, and pilots do like to have a backup plan; we think about the “what if.” Take a look at many of our instrument panels with multiple gadgets, all running independently to keep us from getting lost or flying the airplane toward dirt. But what if something went wrong that our iPad won’t replace? Is there an app for a failed elevator control coupling?

A Trip to Arlington, Washington

Last summer I flew to Arlington, Washington (KAWO), for the Pacific Northwest’s largest annual fly-in and airshow. There I met Dan Tarasievich, owner of Para-Phernalia, the maker of the Softie line of emergency parachutes. Dan is a pilot, flies a Super Cub, and is currently building a Carbon Cub. In fact, when I asked him if he had time to show me his parachute shop, he begged out because he had a ride offer over the hill to CubCrafters, in a plane big enough to pick up his wing kit. You can’t get in the way of that special trip, so we set another day, and I had a good excuse to fly again later.

On the ramp at Arlington, Bruce Eicher snuck his RV-8 next to the other guests. Para-Phernalia owner Dan Tarasievich bought the vintage Ford Mustang fastback brand new when he was 18.

As the tour date rolled closer, I asked a friend and RV-6 pilot, Scott Kelley, to join me. Scott is active in the International Aerobatic Club (IAC) and is starting to learn aerobatics in his RV-6. I don’t have immediate plans to compete, but have experience doing “gentleman’s aerobatics” consisting of rolls, loops, and such. As you may know, IAC requires an emergency parachute be worn for their activities. And the FARs tell all occupants to wear parachutes when doing aerobatics, unless you are flying solo (Read FAR 91.307(c) for details). So both Scott and I have a need for parachutes if we want to share the fun with a passenger or to pursue aerobatic competition. I thought it would be good to get two opinions on the parachutes we want. Also, if we both owned one parachute, we could lend them to each other for the occasional passenger ride.

On a Monday we played hooky from other responsibilities and flew back to Arlington in my RV-8. Para-Phernalia is located in a large box hangar on the northeast side of the main runway. In a call before departing, office administrator Holly Sampson told us to park next to the B-25 and P-51. OK, why not? So today the ‘chute shop was very easy to find because of these special visitors. She told me it is not uncommon to see interesting airplanes out front, and even my little Hula Girl got a few walkarounds on the grass here.

The minute we arrived we were greeted by Dan. He was participating in a photo shoot of the warbirds, along with a couple of four-wheel-type Mustangs. Dan purchased a brand-new Ford Mustang fastback when he was 18, and he still owns the like-new vintage auto. What a lot of eye candy and go-fast machines to look at. But we needed to get back on mission, so Dan invited us into his shop. Here is a summary of what we learned.

Para-Phernalia’s Mission

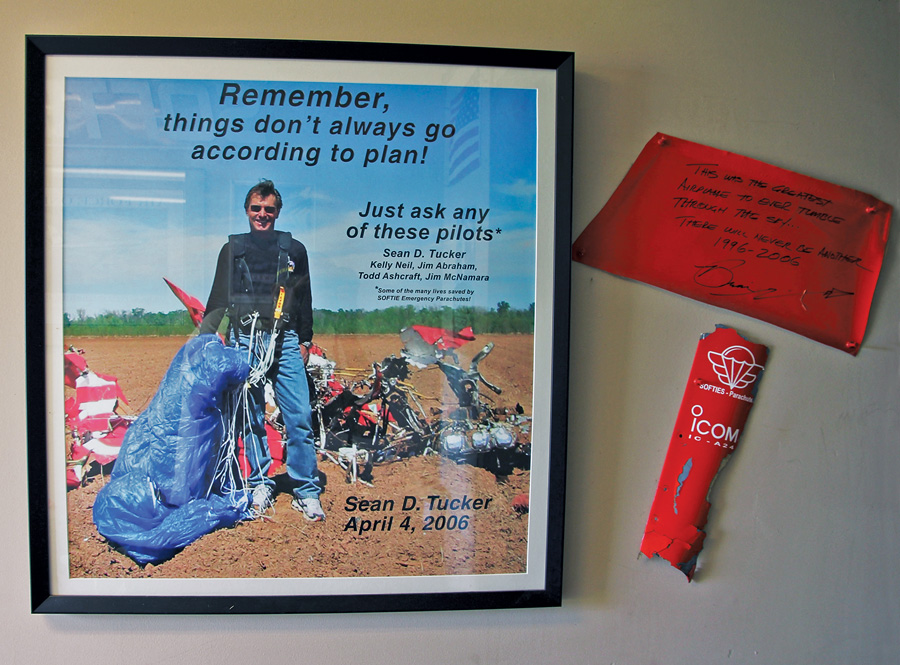

The moment we walked into the huge hangar, it was obvious that Softie parachutes are about saving lives. The walls throughout the office, walkways, and production areas were covered with posters, letters, and thank-you notes from happy clients. There were even some small scraps of airplanes tacked up next to an autographed photo of a crash. But posing in the photo was a happy client holding a wadded-up parachute.

Throughout the shop you’ll find the walls covered with airplane pictures, thank you notes, and scrap parts of airplanes demonstrating why you would want to wear an emergency parachute.

A dozen or more workstations, most with sewing equipment, lined the largest room. Jamie Culler was at one of the many workstations stitching up web harnesses on a heavy-duty sewing machine. Along the full length of one wall was a parachute packing bench. We also met Jimmy Culler, Jamie’s father and production design manager. He has been with the company since 1980. In the office was Holly Sampson, office Administrator since 2007.

Founded in 1979, Softie parachutes have saved 36 lives in 36 years, including four lives in the first half of 2015. Dan purchased Para-Phernalia from the original founders in 1984. The company is focused on emergency parachutes only, rather than recreational jumping or skydiving equipment. But skydiving is in the history of Para-Phernalia. Dan has many years of experience in parachutes and skydiving with over 2000 jumps in his logbook.

Dan explained how an emergency parachute system is quite different than the skydiving type. Skydiving ‘chutes skip comfort because they are worn for a short period of time. They are built for rugged use with multiple jumps and repacks. On the other hand, a properly designed and fitted emergency parachute system will be comfortable for several hours of flying time in your aircraft. A comfortable parachute system that’s proven reliable sums up what Dan’s company is all about.

In a newspaper interview, Holly was asked about her job. She said, “The best part is when you get that one phone call and the customer says, ‘Thanks to your parachute, I’m having coffee right now with my family. Without it, I probably wouldn’t be here.’ You don’t put a price on that. The value of your job becomes very different at that moment. This is why we do what we do.”

Scott Kelley (left) watches Para-Phernalia’s Dan Tarasievich select three parachute rigs for trial fitting in Bruce Eicher’s RV-8.

Choosing a ‘Chute

Three major components make up an emergency parachute system: the parachute itself, the container that the ‘chute is packed into, and the harness that will strap the system to you. You can further break down the parachute component to the shroud lines, the parachute canopy, and the pilot ‘chute. This parachute assembly will carry its own serial number and manufacture date, and the harness and container will have a serial number and manufacturing date of their own.

Parachute manufacturing is done under the watchful eye of the FAA. Para-Phernalia holds a manufacturing TSO for their harnesses and container systems. The Softie line uses round-shaped parachutes manufactured by Free Flight Enterprises in California. These parachutes are specifically designed for emergency parachute systems and the Softie line uses two sizes to cover different pilot weights. Be sure to pick the right size for your weight. The round ‘chutes are steerable by pulling toggle-handled shroud lines—pull left to go left, right to go right.

Dan shows Scott how to buckle and adjust the aerobatic-style harness. Snug but comfortable was his recommendation.

You have several choices to make when choosing an emergency parachute system. Each system will be made to order for you in Dan’s shop. First, there are two canopy sizes, a smaller one for people up to 180 pounds, and a slightly larger one for up to 240 pounds. A smaller ‘chute will fit in a smaller container, but you have to choose based on weight limit. Today’s modern canopy design allows for smaller sizes, but still descends slowly as compared to older, much larger military ‘chutes.

After picking the canopy, the next choice is the style, shape, and size of the container. The container shape will dictate to a large degree how the ‘chute will be packed and positioned between your body and your airplane’s seat. The backpack style puts the whole system against your back and is available in a couple of different sizes and shapes. The chair style is longer and spreads down your back and under your buttocks. And last, the seat style puts the majority of the system under your buttocks.

Bruce Eicher (left) and Scott Kelley are ready to strap on the airplane. Bruce is wearing a parachute with a conventional harness and Mini backpack container, while Scott has the aerobatic harness and Wedge backpack.

Dan told us many consumers try to select a parachute system from a list of recommendations or descriptions on a web site, but he cannot endorse a one-size-fits-all approach or even a one-size-fits-a-specific-airplane approach. He explained, “It is a combination of what fits your particular airplane, your body shape and size, plus a preference of sitting positions.” Scott and I both quickly discovered this is true when we got to demo a few systems.

The gray Mini Softie container gives you about 2 to 2.25 inches of pack thickness. The red Wedge style puts much more of the ‘chute at the bottom, reclining you more in the cockpit.

The last choice is the harness; you can pick from the standard or aerobatic style. The aerobatic harness places the buckles away from your lap belt to prevent the hardware from digging during heavy negative-G maneuvers. Dan suggested it is more of a personal preference, and with Scott’s or my airplane, we would not be experiencing the high negative Gs compared to his clients that fly high-performance aerobatic aircraft to their full potential. And aside from many colors, there are also a couple of buckle release types to choose from.

The E-Ticket Demo

Dan pulled three ready-to-sell parachute systems from the shelves: a grey Mini backpack with standard harness, a longer red Wedge backpack with an aerobatic harness, and a tan Seatpack with standard harness. We carried these out to my airplane parked on the grass in front of the shop’s hangar.

Dan helped Scott and me put on and secure each ‘chute. We had both a standard and an aerobatic harness. The difference was not noticed yet, but I would have buckled mine wrong if it was not for Dan’s help. In just a few minutes, we were ready to strap on the airplane. Dan had us try both the front PIC seat and the back GIB seat with each parachute. For the backpack styles, we removed the airplane’s seat back pads. The parachute becomes your back pad. And likewise, for the seatpack we removed the airplane’s seat cushions. Getting into the airplane wearing the seat padding took a little more effort, not due to weight (these rigs only weigh about 15 pounds), but because the added bulk made it difficult to get my long legs under the panel. But with a few times in and out, we adapted well.

The seat pack raised Bruce more than he liked, even though he removed the RV-8’s stock seat pad. His head almost touched the canopy without any headset. It also put the stick too low between his knees. Bruce is 6 feet 1.

Once in, Dan instructed us to buckle up and try the controls. He even instructed us to close the canopy. You don’t want to rush this with just a quick sit; you really need to operate your airplane and get a good feel and sight of what is changing. Leg distance, even with my 6-foot-1-inch height, was a small change that could easily be compensated with rudder pedal adjustment. But sight and reach distance to the panel, and reach to the control stick and throttle, was different with each parachute container system. In the case of my tandem-seat airplane, adjusting reach for the pilot’s front seat was much more critical than the back seat. Headroom was also important, especially when wearing a thick padded headset or helmet. I suspect with many airplanes and the right parachute, you could get back to your normal, before ‘chute seating position by removing the right amount of seat padding or making other adjustments. In my airplane, to wear a ‘chute full time, I would rebuild my pilot seatback frame a little wider to fit the pack. Dan mentioned he would have liked being part of Van’s seat dimension design from the beginning.

As far as the harness differences, the aerobatic harness made putting on the lap belt less cumbersome, with less hardware down low. I also think in an emergency, and in a hurry, reaching low to the lap to unbuckle your airplane might make you less apt to unhook the parachute harness instead.

With the RV-8’s seat backs removed, Scott tries each ‘chute in both the front and back seat. It takes a little more care getting in and out, but should get easier with practice.

Of the container pack types we tried, the Mini felt the best to Scott and me in both seats. It gave us a neutral or “near without ‘chute” seating position.

The Wedge gave us a more relaxed, laid-back seating position, which wasn’t bad. Laying back gives you a longer arm reach and a shorter leg reach. Some say reclined seating also puts less pressure on your spine in high-G maneuvers.

The seatpack put me too high, but a shorter pilot might benefit with better visibility. I would hit the canopy in turbulence.

Dan also explained how you can have him or your parachute packer position some of the folded parachute more in some areas than others to custom fit the backpack for you and your airplane. A common request is a little more thickness placed in the bottom Mini backpack container. This gives you lumbar support, but without as much reclining as the Wedge container.

One note of expectations about replacing your seat padding with an emergency parachute of any design: Parachutes are harder. As much as Dan or others strive to make them as comfortable as possible, they are denser and won’t compress under G loads of 1 or 10.

The bottom line is, trying the different systems yourself is the only way to get a feel for the different variations. Even better is to try them with your own airplane, if possible.

Once in with ‘chutes on, close the canopy, buckle up, and check seating position, arm reach, legroom, headroom, and comfort. Ask yourself if you are always going to wear this; if you’re not sure, try another style.

How Does It Work?

I jumped out of an airplane once, just to say I did it. I don’t think I will ever forget the intense feeling of letting go of the strut and stepping off the plane’s tire. At that time I could not tell you how my parachute worked; I was just glad it did. Skydivers and pilots coexist, but don’t always follow the same path, especially back to the airport. I’ll continue to take the long, slow way down, thank you.

According to Dan, most of his customers are not experienced jumpers. When Scott said the old phrase, “Why jump from a perfectly good airplane?” he answered, “There is no such thing as a perfectly good airplane.” Now, Dan is on our side as a pilot and a homebuilder, but also believes one should always have a backup plan. And he was willing to show us just how this backup plan works.

Dan gathered Jimmy and had him don a ready-to-go parachute rig. We were going to witness a zero-AGL emergency parachute deployment! Out on the big lawn, we were camera-ready, expecting a big show. Jimmy added to the suspense with verbal and facial expressions suitable for jumping from a falling airplane. Gripping the ripcord handle with both hands, he pulled outward. If I did not have my camera shutter set to continuous action, I would have missed the spring-loaded pilot ‘chute pop out the back of Jimmy like an escaping alien being. It fell to the grass a few feet directly behind Jimmy.

Jimmy Culler demonstrates a zero AGL parachute deployment with a chair style container. It takes less than 22 pounds of force to pull the ripcord at your left chest, which releases the spring-loaded pilot ‘chute you see shooting out his back.

OK, I know that little ‘chute is not all. Dan described the entire process while holding the pilot ‘chute still connected to Jimmy.

Once clear of the aircraft, deployment of the Softie ‘chute starts with a firm pull of the aluminum handle attached to the ripcord. This pulls a cable out of some pins that hold the spring-loaded, compressed pilot ‘chute on the pilot’s back. The pilot ‘chute catches air and pulls out the canopy. At this point, the canopy is held shut at the skirt by rubber bands and a few inches of shroud lines. As the lines stream up and out, the full length of the lines are pulled from the container. Then the rubber bands release and allow the canopy to open.

Dan explained how this deployment type (the only method his parachutes use) helps prevent shroud line entanglement and canopy malfunctions. From ripcord to open canopy, about 2 to 3 seconds will elapse, and you will fall 300 to 500 feet.

Dan, acting as the wind-filled pilot ‘chute, pulls the canopy from the seat container. Only when all the shroud lines are out and tight does the canopy open, to help prevent shroud-line tangle.

At this point in my jump (many years ago), I recall waking up from almost a blackout adrenalin rush. I had no ripcord to pull because it was an instructor-assisted deployment, meaning he was in the airplane, holding and tossing the pilot ‘chute as I jumped. The feeling of relief as the parachute canopy opened and slowed my fall to a seemingly floating speed brought me back to real time. As in an emergency jump, all that was left to do was to reach up for the steering shrouds to direct myself to a safe landing spot, then make an upwind landing with proper body position and landing roll.

With the help of a good breeze, we have a full canopy! Hard to see in the photo, but three screen panels are in the back of the canopy allowing air to escape, which provides forward motion and control.

Dan offered to display this sequence in slow motion (and safely on the ground). He acted as the wind in the pilot ‘chute, pulling the rest of the parachute canopy and shroud lines out of the pack Jimmy was wearing. As if we ordered the wind, it caught the canopy, which gave us a full show of its colors and purpose in life, or more importantly, yours.

So now in a real jump, you would take a big sigh of relief, look up at that beautiful canopy full of air, grab the toggle handles of the steering lines, and pull in the direction you wish to float. There are three screen windows toward the back of the canopy that allow air to escape, giving you forward motion. The pulling of a steering shroud line closes the respective window, turning you and the parachute. Forward speed will be 3 to 5 mph.

This description is not intended to teach you how to safely jump from an airplane. Much more detail of what to expect and how to plan for such an event can be found on Para-Phernalia’s web site, softieparachutes.com.

Jamie Culler stitches harnesses. Each rig is built to order, with customers choosing the container style, buckle and harness type, and colors.

When Would You Wear a ‘Chute?

As with any purchase, we want to know we will get our money’s worth. Like an expensive leather jacket, a parachute won’t earn its cost hanging in a closet.

In addition to aerobatics, more and more homebuilders are participating in air races where we need to be wearing a parachute. Experimentals also perform at most airshows, so that might be another good time to wear a ‘chute. Thinking about more homebuilding scenarios, what if something goes wrong on our maiden flight, or during the testing phase? An absolute backup plan might be nice. Cross-country flight over hostile terrain could also be less stressful with a safety net for the pilot (and passengers).

As we become more aware of the risks of all activities, we have become accustomed to protecting ourselves. For instance, as a kid I never wore or owned a bike helmet, or used one for snow skiing or boarding. Now, most folks are wearing such protection for these activities, and it is part of the normal gear—even fashionable.

Like any safety device, a parachute will do you no good if you aren’t wearing it. You could elect to wear a parachute every time you fly, as an added safety device. That would get the most use out of your investment, plus you can look cool wearing it. It shouldn’t surprise you that Dan agrees. He said, “Most airplane owners won’t hesitate to buy a new radio or some other instrument. For about the same amount, you can have a life-saving device. It’s inexpensive insurance considering the cost spread over twenty years.”

Care and Maintenance

Back in the shop, Dan pulled another parachute out, stretching it down the long repacking worktable. He showed us how the whole system is inspected for damage, wear, or aging. He said the most common damage is caused from sun and strongly recommended that the parachute not be stored in an airplane outside. Stored in the bag it comes with, and in the hangar or at home, would be just fine. Also keep it in a well-ventilated area and away from possible chemical spills.

Your harness and container should be inspected before each flight, just as you would preflight your airplane. The instruction manual that comes with the system does a good job of explaining this.

Dan stretches out a ‘chute on a long table and demonstrates an inspection and repacking that the FARs require every 180 days. Para-Phernalia will inspect and repack your ‘chute, or you can contact an FAA-licensed parachute rigger at a sport skydiving center.

Emergency parachutes need to be opened, inspected, and repacked every 180 days by an FAA-licensed rigger, no matter how many times it may have been worn. You should seek out a rigger as part of your purchase plan. You will find one or information at sport parachuting centers. A record is kept in a pocket of the container, and it is illegal to wear a non-compliant parachute. Dan said the cost of each inspection and re-pack is about $50 or so.

Two parachute canopies, pilot ‘chutes, and shroud-line assemblies made by Free Flight Enterprises in California.

Parachutes can also be subject to service bulletins, just like other components of your airplane. Check with your manufacturer, and your rigger should also be up on possible bulletins for your make and model. Some older ‘chutes no longer made (but seen on eBay) are grounded out of service. Before you buy, ask someone who knows, like a good rigger. Para-Phernalia puts a 20-year life on their products. Dan clarified that after 20 years, many riggers won’t repack any parachute for liability reasons. Dan also sells internationally, and other countries require a life limit on his products, so he made it universal for all countries.

Dan gives Scott a tour of Para-Phernalia’s large hangar shop. More than a dozen workstations with sewing machines, layout benches, and product racks fill the space, along with a long repacking table running most of the length of the hangar.

Thank You Para-Phernalia

Dan, Jimmy and the rest of the crew were very kind to show Scott and I their business and products, and we learned a lot. Thank you for your time. If it becomes necessary, I will be equipped to jump—and then I hope to be home that evening, sipping a drink with my family and calling to say thanks again.

For more information visit softieparachutes.com