Over the past months I’ve learned a lot about magnetos on half VW engines. Much of it has been scattered over various threads on the Internet, but I thought I’d summarize it all in one place. Some of it is specific to my engine, a Mosler CB-40, but much applies to any half or full VW engine.

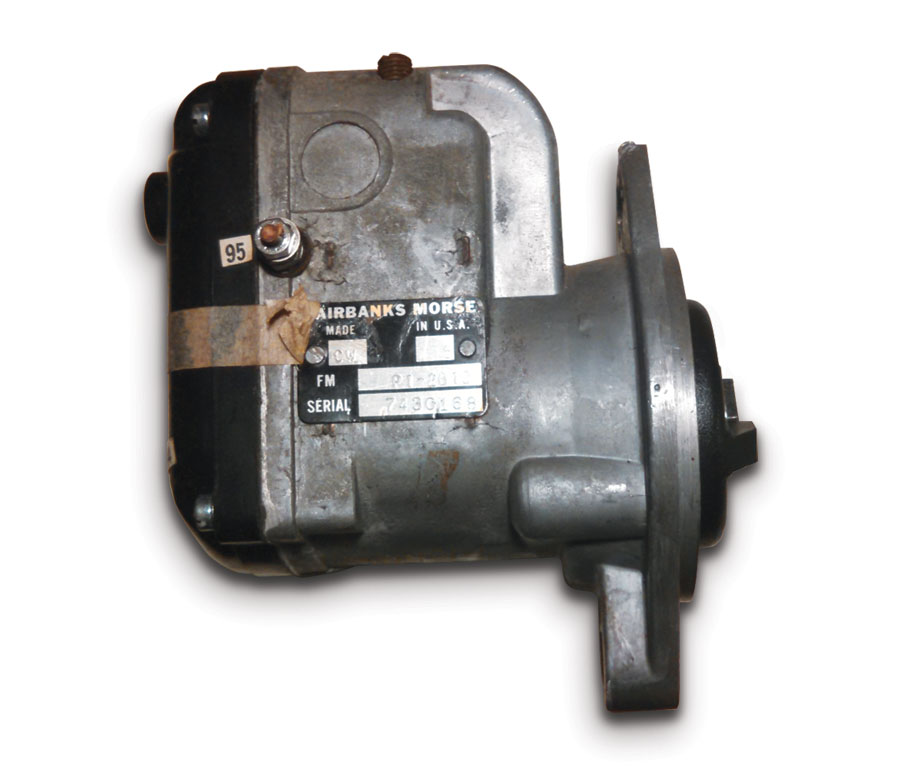

My engine originally came with a Fairbanks-Morse (F-M) tractor magneto. This commonly used magneto uses unshielded automotive-style spark plug wires. At about 200 hours, the original builder of the plane experienced hard starting and eventual complete magneto failure. He believed the failure was due to the use of resistor plugs and resistor wires, something not anticipated in the magneto’s original tractor application. Having never used it, I can’t say much more about it.

Because Fairbanks-Morse parts are hard to find, he replaced it with a new Slick 2316 magneto. The 2316 (no longer available) was based on the 4316 four-cylinder magneto, but with a different distributor cap with two removable wires and the other two connections shorted out with springs against the blank points on the special two-cylinder cap. He adapted the Slick distributor cap to unshielded solid wires with the typical rubber automotive spark plug boot. It did require an adapter plate to mount it on the engine crankcase designed to accept the F-M magneto, but as far as I know, no modifications to the engine itself were necessary. The Slick is longer than the F-M, which might be a problem if your engine is very close to the firewall.

Other Options

Another popular magneto is the government surplus 2220 magneto (and the similar 4220 mag for four-cylinder engines). This magneto is virtually identical to the 2316 except for the army-green paint, slightly different mounting dimensions, and the fact that the impulse coupling has 15 lag instead of 25. The reduced lag can cause kickback during hand propping. Some people have ground the impulse pawls to get 25 lag (see this).

These magnetos are readily available on eBay ($60 as of this writing) and include the shielded spark plug wires, one 21 inches and one 31 inches long, with 5/8-inch spark plug connections. The harness (distributor) cap is the same as the 2316, with removable wires. Although new or government depot rebuilt with (then) new parts, these mags are 30+ years old, and it’s generally recommended to replace at least the capacitor (condenser) with a new one (Slick p/n K3984). If you buy a 2220 from Great Plains Aircraft Supply Co. or Hummel Engines (Scott Casler), it will have the mounting face machined to fit your engine and a new capacitor installed…and will cost more.

Finally, there is the 4316 magneto, still in production (but usually with lead times of a month or more) and expensive at over $1,000 list price. This mag, with 25 lag, is the standard magneto for four-cylinder VW applications, but can be used for a half VW with two of the spark plug connections shorted out, the same as the 2316. The harness (Slick M2266) must be purchased separately. The M2266 is a four-cylinder harness. For two-cylinder applications, two of the wires must be removed and provisions made for shorting the unused connections. Slick no longer makes a two-cylinder harness.

The internal parts on all of the Slick magnetos are mostly interchangeable, except as noted below.

In my conversations with Slick (now part of Champion Aerospace), they advised me not to use the 2316 “because it’s so old and many parts have been highly upgraded since it was made in the early 1990s.” They also said that the surplus mags “should not be used on any aircraft since they were made from rejected aircraft parts and sold cheap to the government.”

Whether that’s true or not, many people are successfully using the 2220s on their aircraft, and some others in the business say the 2220 is better made than the later mags. Regardless, although most of the parts are interchangeable, the 2220 distributor and rotor gear are slightly different and lighter than the corresponding parts in the 2316. I haven’t disassembled a 4316, but its distributor block, at least, has larger output bosses than the earlier mags; perhaps this is one of the upgrades.

Spark Plugs

The plugs you use depend on the engine. I believe that stock VW heads require 1/2-inch reach (thread length) plugs, while my Mosler engine, with its Scat heads, and possibly the earlier Global heads, require a -inch reach plug. Most people use standard automotive plugs. Some have used an aircraft-style shielded plug (Champion REL3B) on half and full VW conversions with standard VW heads where the 1/2-inch reach is appropriate. The aircraft plugs are expensive at $40-$50 each. The only shielded aircraft plug I could find with a -inch reach is the Champion REN30S. Apparently some certificated motorgliders with VW-derived engines use these, but I don’t know where to actually buy them (nobody has them in stock), so I’ve never tried them. Autolite makes a 2304 shielded plug with automotive style electrodes, which is probably the plug used on the generators the 2220 mags were used on. The 2304 is a -inch-reach resistor plug in the same heat range as the recommended plugs and works with the 2220 plug wires. I’m not aware of a 2304-style plug with 1/2-inch reach. The 2304s are about $8 each at the local NAPA auto parts store, while standard unshielded auto plugs are $2-$3. The only difference is that the recommended plugs are “projected tip” (which according to NGK “provides higher ignitability and improved performance”), while the 2304 is not.

Great Plains makes a shielded spark plug adapter that fits over the standard automotive plugs and accepts the shielded wires of the Slick M2266 harness (note the Great Plains adapters do not fit the surplus harnesses or the Aircraft Spruce house brand M2266 harness; only a genuine Slick harness will fit). Some people have expressed concern about the Great Plains adapters staying on, and they do look a little shaky (they snap over the porcelain insulator on the plug and then are secured with a set screw), but I haven’t heard any reports of them actually coming loose in flight. Safety wiring them in place is a good idea.

Mag Failure

As I said, my plane came with the 2316 magneto, which was working fine until the A&P who was doing my annual condition inspection wanted to inspect the points (unnecessarily, as it hadn’t reached the 500-hour service interval) and removed the harness cap (which doesn’t give access to the points anyway). Then the cap was reinstalled incorrectly, without the shorting springs installed. This led to internal arcing, which caused the magneto to fail quickly (within a couple of hours). The symptoms were hard starting, followed by complete failure, fortunately on the ground. Magnetos must never be operated without all spark plugs installed and connected or shorted, or the P-lead shorted to the magneto case (ignition switch off)!

Because of the unknown level of damage and because new Slick parts are quite expensive, I bought a surplus 2220 magneto and used all of the internal parts (coil, points, distributor block, and rotor) and a new Slick condenser to rebuild my 2316, which was easier than modifying the impulse lag and machining the 2220 mounting face to match the 2316. I did have to modify the surplus distributor block mounting holes slightly, but all the other parts were drop-in interchangeable. If the magneto internal parts are replaced, it must be done in accordance with the Slick L-1363F overhaul manual. There are torques, clearances, etc. that must be given close attention, though of course, the manual also disclaims the use of used parts. In particular, setting the point gap is not enough; the “E-gap” must be set as well. This is critical! I also used the shielded wires that came with the 2220, along with the Autolite 2304 shielded plugs. This worked well at first, but I started to experience an intermittent missing at full throttle when the engine warmed up to over 180F oil temperature.

Since I had originally only set the point gap, not the E-gap, I took the mag back off and apart and set the E-gap properly (a special tool is needed, though it can be easily made from 1/16-inch aluminum). This initially cured the missing, but it started doing it again after an hour or two. Although the temperature on the magneto case itself was below the rated maximum 175F, the Slick representative believed the surplus coil may have been a little weak, starting to break down at a lower than normal temperature, and he again advised me to get rid of it. I suspect the combination of the incorrect E-gap and the slightly weak coil caused the missing. Fixing the E-gap apparently cured it for a while, then as the coil continued to deteriorate the problem came back.

Fixing It Again

Getting a good deal on a new 4316 mag, I decided this was the way to go; all new parts are a comforting thing on a single-ignition engine. I immediately ran into problems. The larger bosses on the 4316’s distributor block mean that the surplus or 2316 harness caps wouldn’t fit. Of course, I failed to discover this until I had already removed the old mag and installed and timed the new one, so off came the new one and back to the old one (I was still flying, cautiously, since it was temperature dependent and it took a while to warm up to the point where I had a problem). I then modified the 2220 cap to fit on the new 4316 magneto. All looked good, and I installed the 4316 on the engine again, only to discover there wasn’t enough wall thickness left and it broke when I tried to install the plug wires. Again I removed the 4316 and reinstalled the 2316. I was getting really good at installing and timing mags by this point!

The standard harness for the 4316 is the M2266, which has the wires permanently installed in the distributor cap, rather than the screw connections in the surplus mags. I ordered an Aircraft Spruce aftermarket M2226 harness. It was in stock, while the genuine Slick harness was not (and again with the typical long lead times). The M2226 harness does fit the new magneto (it fits the surplus mags as well), but it didn’t fit the 2304 spark plugs I was using. Accordingly, and since I wanted to see if the projected-tip non-resistor plugs worked better, I ordered two of the Great Plains adapters, only to discover that the Aircraft Spruce aftermarket harness doesn’t fit the GP adapters either. I probably could have modified the ACS harness to fit the adapters, but I wasn’t overly impressed with its construction anyway, so I returned it. Since nobody had a genuine M2266 in stock, and I didn’t want to lose any more of the flying season waiting for it, I separately ordered an M-1569 distributor cap and a pair of M6202-72 single lead wires to assemble my own harness (NOS parts from eBay, less than half the price of a new M2266 assembly). The -72 indicates the length in inches; 72 inches is obviously too long, but it’s what was available. They can be cut, and shorter lengths are also sold. Any other late-model four-cylinder harness (for 4000 series mags) with 5/8-inch plug ends and long enough wires could be used (with two wires cut off and shorted, of course). Used harnesses are often available cheap on eBay, but buyer beware as far as condition goes.

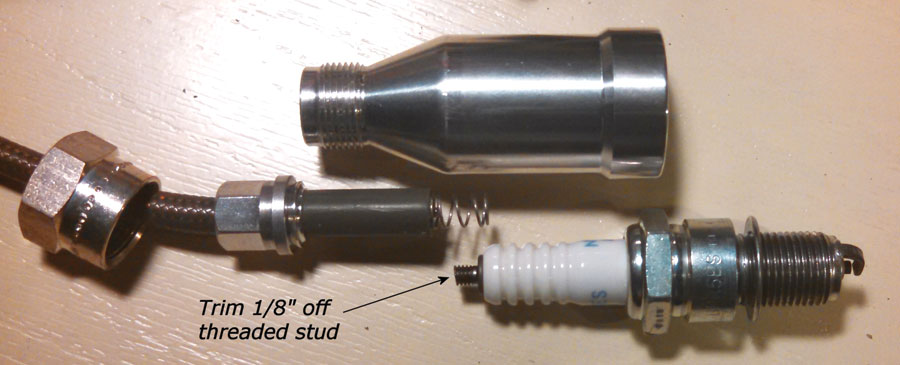

The next wrinkle is that even the genuine Slick lead doesn’t quite fit in the Great Plains adapters; the “cigarette end” is slightly too long. Great Plains said the screw-on tip on the spark plug should be removed (something not mentioned in the instructions), which helps, but even that wasn’t quite enough. In the end, I was able to make it work by removing the tips and cutting about 1/8 inch off of the threaded studs.

Moving Forward

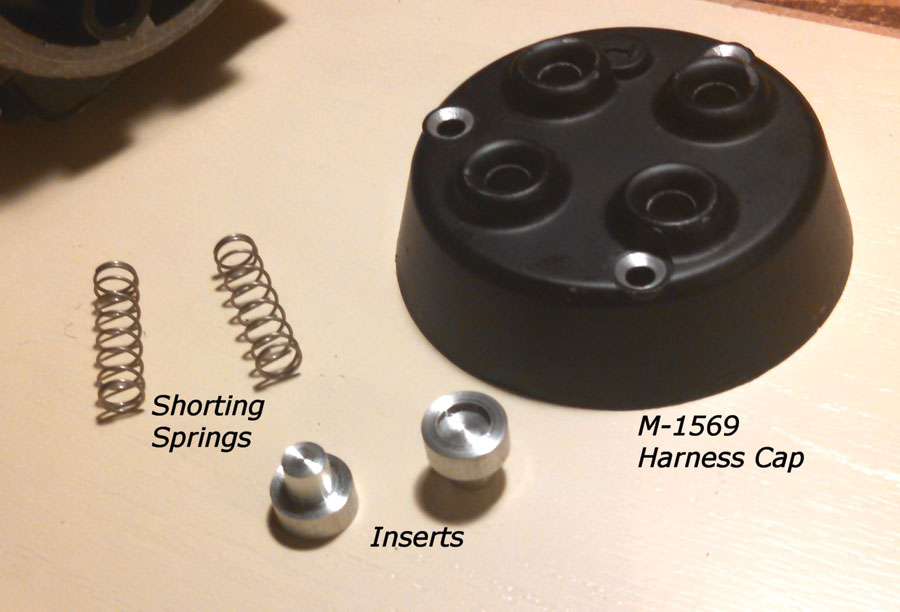

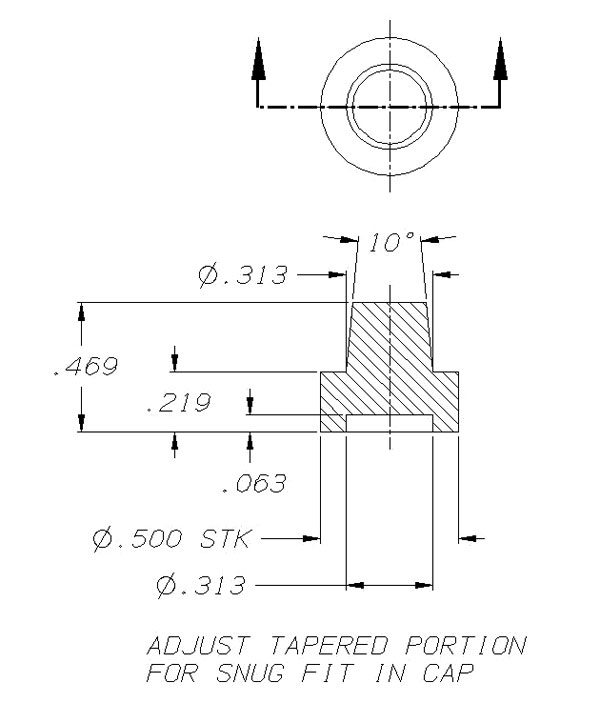

Once I got through all that, assembling the new harness was fairly straightforward following the instructions in the Slick L-1499B harness manual (the special tools listed can be easily improvised). The plug ends are already installed on the M6202 lead wires. The other ends should be cut to the appropriate length for your engine before connecting it to the magneto end. Thirty-six inches was a good length, allowing a clean routing on my engine, and by cutting the 72-inch leads exactly in half, I have a spare pair of wires. The #1 and #3 wire locations are used, and the #2 and #4 connections are shorted. I made inserts to plug the unused wire holes in the cap and bear against the shorting springs. I suppose you could cut the wires to a short length and ground them somewhere instead, but shorting them internally is neater. I used the shorting springs that came with the 2220 magneto (if you need to find some, they’re 5/16-inch diameter, 11/8 inches long, .027-inch wire diameter, 7 coils with closed ends) and made the plugs so the springs are compressed the same amount as on the 2220. The inserts are a snug fit inside the distributor cap and a dab of epoxy (on the outside only; there must be metal to metal contact) sealed them and kept them from falling out during installation.

Installation

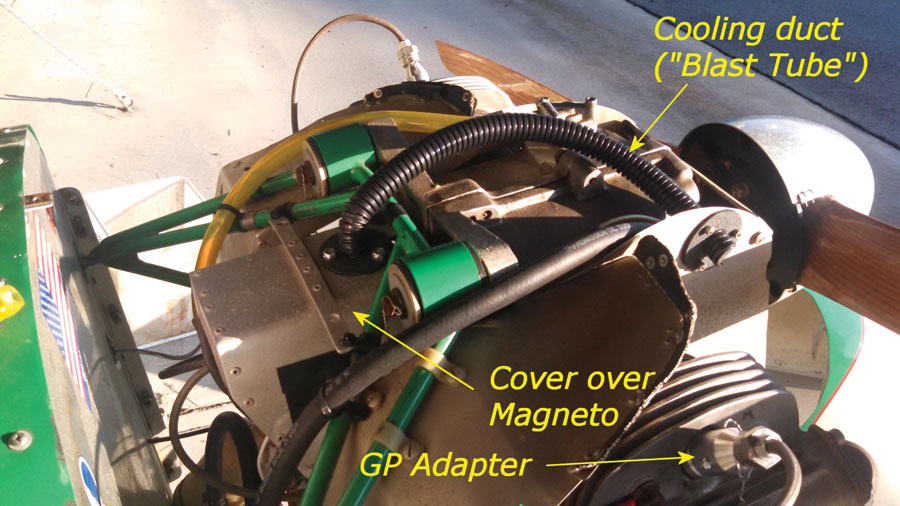

It’s important to keep the magneto cool. Use a thin gasket between the magneto and the engine case; I cut one from 1/32-inch rubberized paper. This helps to insulate the magneto from the engine heat. Many people also install a blast tube, i.e., a duct to direct cool air from the front of the cowling over the magneto.

Timing

This is fairly easy. You set the timing pin (supplied with the magneto, though a piece of 3/32-inch rod can be used as well) into the “R” hole in the distributor block and carefully rotate the magneto backwards until it drops into the hole, then mate it to the engine with the #1 cylinder at the firing position, 28 before TDC on the compression stroke. (#1 is usually the left-hand cylinder; actually the wiring is neater if you call the right-hand cylinder #1, the mag doesn’t care which is #1.) The reason for rotating it backwards is you don’t want to trip the impulse coupling and get a spark while it’s not connected to anything, and you don’t want it to snap the internal plastic gears around while the pin is in the way. Then remove the pin and fine adjust the timing with a buzzer so the points just open at 28 BTDC. You can buy fancy magneto timing boxes, but a 9-volt battery and a piezo buzzer from Radio Shack wired in series between the magneto P-lead and the case works just as well. The buzzer will change tone slightly when the points open or close.

Success at Last

When I finally got it all together after eight months of struggling, the engine started easily, ran smoothly, and turned about 100 rpm more than before at full throttle. Whether this is due to the all-new components or using the recommended projected-tip plugs (NGK BP5ES) instead of the unprojected-tip Autolite 2304 plugs, I don’t know. There was quite a bit more ignition noise over the radio. Switching to BPR5ES resistor plugs helped a lot. Although there’s still more noise than the true shielded plugs, I can live with it. I did safety-wire the covers in place, though I’ll try to work out a more easily removable arrangement than twisted safety wire.

Maintenance

Slick recommends a 100-hour external inspection and timing check, and a 500-hour overhaul. The magneto should not have to be opened up until the 500-hour overhaul. Supposedly they’re designed so that the points and cam wear at the same rate, canceling each other out and meaning that the timing should not change; if it does, there may be a problem.

Slick Service Bulletins

There are three that I’m aware of, which apply to certain serial numbers. SB2-08 applies to premature wear of the breaker point cam. No disassembly is required, but the timing should be periodically checked and anything more than 4 drift requires replacement of the cam. SB3-08 applies to premature wear of the carbon brush on the distributor gear. However, the Slick representative told me that even though my magneto is included in the affected serial number range, most problems were on the 6-cylinder magnetos. He said the problem is so rare on the four-cylinder mags that there’s more risk in disassembling and reassembling it, so I should leave it alone and just keep an eye out for any trouble (in particular, misfire or timing drift). The last service bulletin applies to the coil; any orange coils with certain manufacture dates (which includes the surplus mags) should have the coil inspected for cracks around the high-voltage contact. If no cracks and the resistance measures within spec, it’s OK to use (though mine inspected OK and still had a problem). Later mags have black coils, which aren’t subject to the problem. I never saw an official Slick document on this, only an airworthiness bulletin from Limbach, who makes VW-derived engines using Slick magnetos.

There you have it. With an engine running well and 100% new ignition components, I’m hoping I won’t have to worry about the ignition for quite a while.

Thanks to Joe Logie at Champion and Marty Roberts at Great Plains for valuable advice.

Great Information . I bought up a batch off the Green Slick surplus mags in the late 90s. I have used the internals in my slick mag I bought for $79.99 from Rand Robinson, in the late 70s.