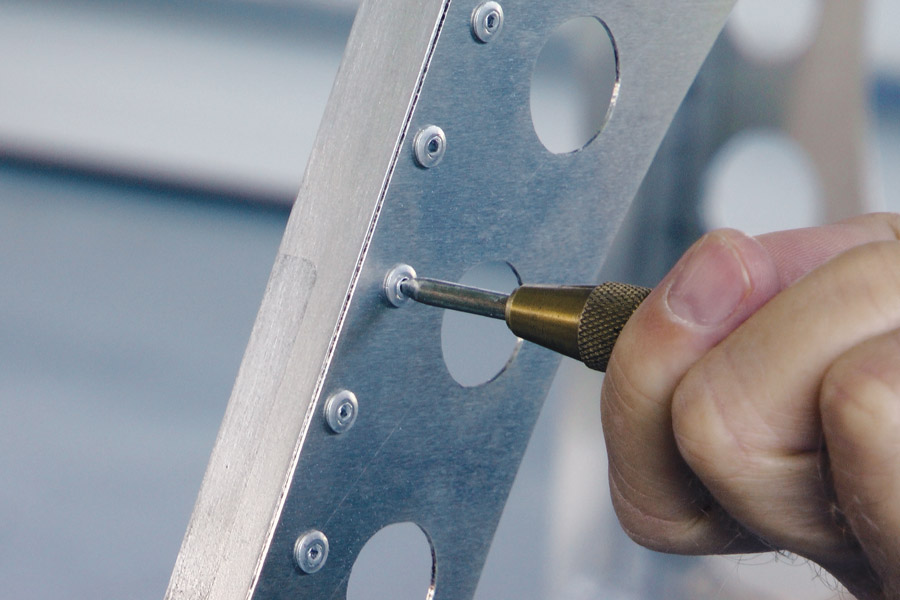

A drill is used to remove just the head of the rivet, using a circular motion to help pry the head off.

Blind rivets, pulled rivets, POP rivets—all are names for the same permanent fastener used in many homebuilt and kit aircraft projects. “POP” is a brand name, “blind” refers to the fact that you do not need access to the backside for installation (as a solid rivet requires), and “pulled” refers to the process used by a tool to set the rivet in place. This type of rivet is fast and easy to install, and comes in a variety of sizes and material composition (aluminum and various steel materials).

Although these rivets are permanent, it is very common to need to remove them due to mistakes while building or for required repairs. Removing these permanent fasteners is easy—but extreme care must be exercised if you do not want to damage the hole during the removal process. A not-so-obvious obstacle will challenge your ability to keep the original rivet hole from becoming enlarged while drilling the rivet out. At all costs we want to keep that rivet hole unchanged so that it can be used again with a new rivet and maintain maximum strength.

To remove a blind rivet, a drill bit (the same size as the original hole or a little smaller) is used to remove the rivet’s head. While the dimple in the head guides the drill bit perfectly down the center, problems often occur when the tip of the drill meets with the rivet “stem” hiding just below the top of the head. This stem was used by the rivet gun when setting the rivet, and it breaks off just below the head during installation. While designs of rivets vary, many rivets need this stem fragment to remain in the rivet to add extra strength. When drilling to remove, the tip of the drill contacts the top of the stem. What happens invariably is that the drill is pushed off center and the hole becomes distorted. This all happens in a split second and is then too late to remedy.

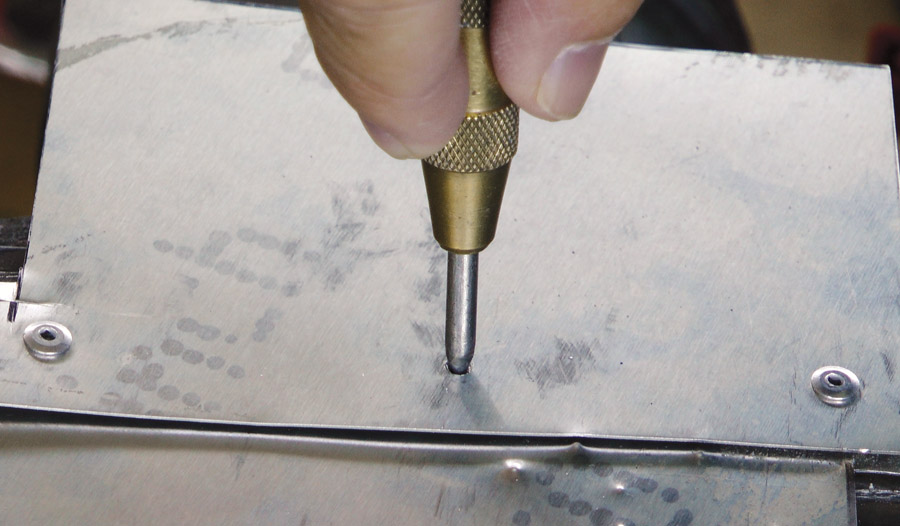

The solution is to simply remove or displace the stem prior to drilling. Two options are available: a pin punch or a spring-loaded automatic punch. Finding a punch that fits inside the rivet head dimple is the key. Depending on the rivet sizes you are working with, it is important to find one or more punches that can reach into the dimple and contact the top of the stem.

Using some good judgment with a manual pin punch, the right amount of tapping with a hammer (don’t damage your airplane!) will move the stem down. The stem does not have to be completely removed—just enough to give the drill bit a little more room.

My favorite stem remover is the spring-loaded punch (from Amazon or Harbor Freight). No tapping is needed; you simply press until the internal spring unloads its stored energy and creates a mild impact at its point. This can be repeated rapidly several times in a row if needed. We just need the stem to move a little bit! The problem with this spring punch is that the tip is too large for the popular 1/8-inch rivets found in many kits. A one-time effort of grinding the tip a little thinner on the bench grinder is all that is needed. It can also then be used for larger rivet sizes. Works like a charm!

With the stem out of the way, the rivet head can be quickly drilled off using the dimple in the head as a guide. I like to use a slight circular motion with the drill to help pry and break the head off while drilling. Do not drill the rest of the rivet out! Sometimes stainless steel rivets can start to spin while drilling. If this occurs you need to prevent this motion by pinning them down until the head is removed.

Next, using the spring-loaded punch again (or manual punch), the rest of the rivet body can usually be easily pushed out. If you have access to the other side of the rivet, side-cutter pliers can be used to pull the remaining rivet fragment from the hole.

Using this process and always making sure the stem does not disrupt your drilling precision, blind rivets can be removed very quickly and easily, leaving the original hole practically untouched for reuse.

![]()

As the founder of HomebuiltHELP.com, Jon Croke has produced instructional videos for Experimental aircraft builders for over 10 years. He has built (and helped others build) over a dozen kit aircraft of all makes and models. Jon is a private pilot and currently owns and flies a Zenith Cruzer.

Great tip, I have a flaperon that I need to open back up and fix something.