In last month’s article (June 2017), I described the experience of having an emergency divert into a barren airfield after a catastrophic prop governor failure. This month I will pick up from the first return to my hangar after we managed to get the aircraft home.

After a good night’s rest and contemplation of how much worse chapter one of this story could have been, we returned to the hangar to begin the next chapter of the ordeal. After removing the cowlings, the next step was to drain the oil for examination. This oil was expected to be clean because we drained the remaining original oil in Tuba City, looking for contamination that wasn’t apparent. We replaced it with new, so this oil had less than two hours of engine operation on it. I strained the oil through two fine paint filters looking for debris. To my delight, the oil appeared to be pristine, and there was no indication of contamination. I took a sample to send in for complete analysis.

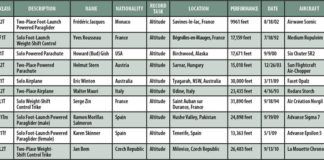

This chart from www.SavvyAnalysis.com shows the prop governor failing with a sudden drop in rpm about 1 hour and 40 minutes into the flight. Engine shutdown back on the ground occurred about 20 minutes later. (Chart: courtesy of www.SavvyAnalysis.com)

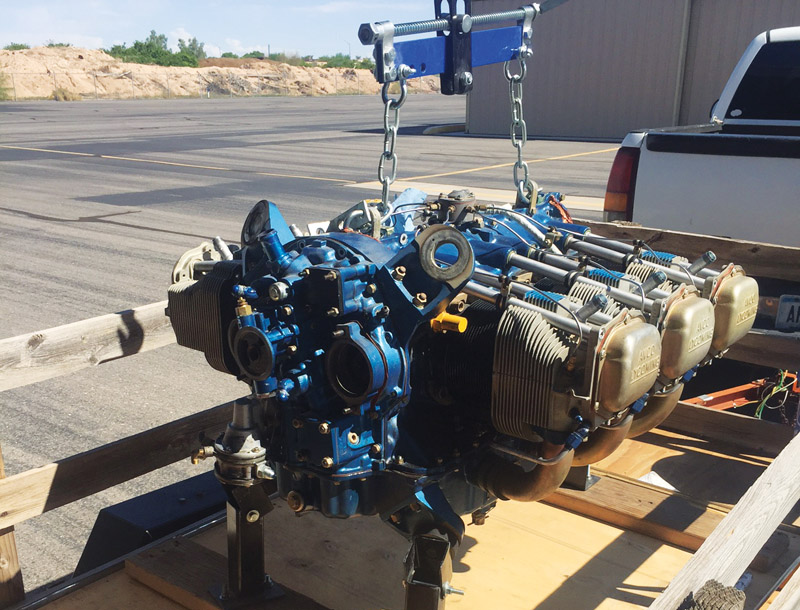

The next step was to remove and inspect the oil suction “finger” filter. As I was pulling it slowly out of its cavity, my heart sank. I could see shiny little curlicues trapped in the mesh, and more collected inside. Pulling, cutting, and unrolling the main oil filter confirmed the presence of metal. I called my engine builder, Allen Barrett of Barrett Precision Engines (BPE), and after sending him some pictures, he confirmed my initial fear that the engine would need to be removed, torn down, and inspected. It’s a good thing for me that nobody walked by at that precise moment with a few bucks in their hand as I might have taken it and run from the whole project. I asked Allen if, in his experience, he would expect an insurance company to cover the costs involved. His answer, in his distinctive Oklahoma accent was, “It wouldn’t be unheard of, but I couldn’t guarantee it either.” I realized that for the moment, there was nothing more to do at the hangar, so I went home to do some research.

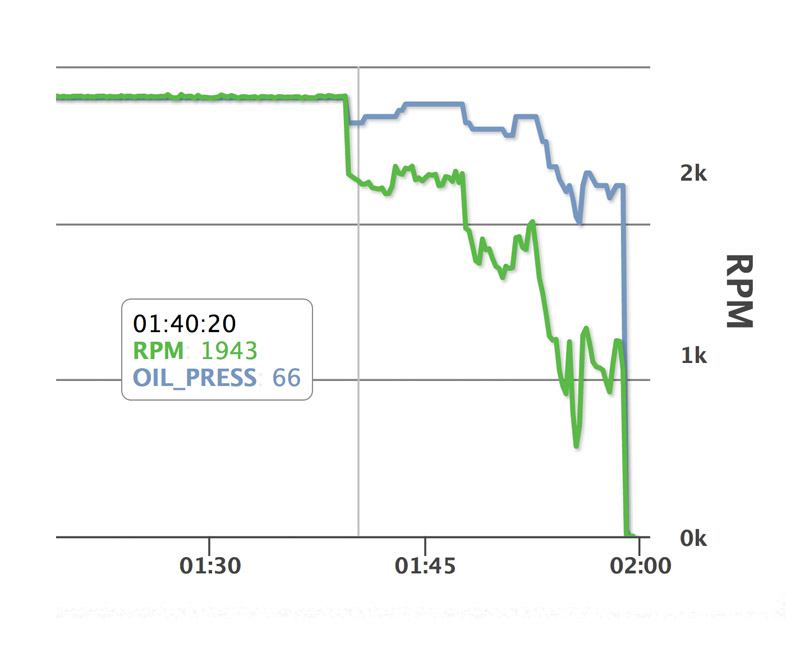

One of the greatest tools available to a builder/owner is the myriad of electronic resources available to the community, especially the online forums. Two of my favorites are VAF (www.vansairforce.net) and Matronics (http://forums.matronics.com/index.php), but there are several others. Like a lot of builders, I tried to keep quite current on the forums while I was building, but had kind of faded back a bit once I got flying. Big mistake. Had I been more current, I would have already known that there had been failures of my exact model of prop governor. They had all been the model MT P-860-3. I made posts alerting to the failure of my unit, and within minutes I had links to other threads of other failures, one whose thread title was exactly like mine, and another that had occurred exactly a week previous to mine to builder/pilot Todd Stovall. The forum banter and discussion became quite lively and active over the next few days as, with the addition of my incident, those who had been following along started referring to an alarming trend, rather than an odd coincidence. As those of us who had been directly impacted started comparing notes and answering questions from others, there was an oddity that arose: My failure caused the propeller to go to coarse pitch, while the others went the opposite to fine pitch and significant overspeed. A couple didn’t have the full breach of the case wall like mine did, but one in particular looked practically identical to mine. As of this writing, I know of three U.S.-based failures, plus one in Canada, and one (most likely the first), in Europe. So far, thank heavens, there are no known reports of casualties other than trashed engines and props. With high-pressure oil loss and/or extreme overspeeds of engine rpm, it certainly could have been a lot worse for all of us.

Myron Nelson’s prop governor (left) looks remarkably similar to Todd Stovall’s governor. The two failures occurred exactly one week apart. (Photos: Myron Nelson and Todd Stovall)

Insurance Anxiety

Having had visions of the financial collapse of my homebuilt dream, I decided it was time to call the insurance company. My first call was to my broker, Shanna Linton, of Gallagher and Associates. Gallagher, in general, and Shanna, in particular, are well known and respected in the RV community. Just spending a few minutes with Shanna on the phone dropped my anxiety level considerably. It was also reassuring to hear that they had already heard of similar incidences and already had claims started.

The basic concept of the insurance that most of us carry on our aircraft is simple. We generally carry insurance for “losses,” and losses are distinctly different than mechanical failures or breakdowns. Therefore, if something simply breaks or fails, it usually isn’t covered by insurance—only by warranty if such is in effect. However, if something breaks and then subsequently causes damage or losses to other parts of the aircraft, or worse, causes an incident or accident, then those related damages are often covered by insurance.

I know what some are thinking: If you have a failure, just make a crash landing and you’re good to go. Good for gallows humor perhaps, but nothing more. There is a process to follow. It’s a convoluted path, but at least it is a path. No experienced and responsible broker is going to make blanket claim guarantees at the start of a claim process, simply because there are so many things that can trip up a claim. However, Shanna, bless her heart, was empathetic, supportive, and reassuring that they would try their best to make me whole again.

The next step in the claims process was to meet with the adjuster from my insurance company, which is AIG. Fortunately for both of us, the company had an office nearby to my home hangar. The adjuster, Renee Bertolina, was extremely professional, knowledgeable, and thorough.

One thing I learned very quickly was that the first part of the process was a very thorough review of all of the documentation of myself and the records of the airplane. An insurance claim is not the time to get caught non-current or incomplete with medicals, training records, maintenance records, logbooks, licenses, registrations, etc. It is essential to have the full documentation package prepared and presented, as if the adjuster is a potential buyer for your aircraft (which sometimes, in essence, they are).

Once the documentation review was complete, I showed Renee the actual propeller governor and its obvious breach. After a walkaround of the aircraft and a couple of dozen photographs, she accepted my claim for the engine and propeller to be removed, shipped, disassembled, inspected, repaired, shipped, and reinstalled. She told me to begin gathering bids for the work that would need to be accomplished.

Words cannot describe the feeling of relief that came at that moment. From that point on until the first flight, there were delays and hiccups along the way, like there always are. However, I cannot be happier with how I was treated by my insurance company and my broker. Everyone I worked with had an affinity for aviation and a desire to get things going again when misfortune strikes. One gets what one pays for, and people are as important as product.

Looking for Clues

While the airplane was down, with the engine shipped back to BPE to be inspected and reworked, there were additional queries going on. Part of that was to figure out what exactly had happened and help prevent such an occurrence from happening again. One of the things I did was to download the data from my Dynon SkyView system and upload it to www.savvyanalysis.com. This impressive online platform provides free archiving and charting of digital engine monitor data for all models of engine monitors. Expert professional data analysis and analytical reports are available by subscription.

Although I am quite new to the workings of their product, I was able to fairly easily capture a graph of the exact moment that the governor failed. I must admit that while I knew what I saw and experienced in flight, there were some who questioned if I might have been confused because, in their mind, the failure should have gone to fine pitch, not coarse. I sheepishly concede that I was relieved to see that the data graph backed up what I had described, which was an immediate loss of roughly 500 rpm in about a second, even while at high-power, high-speed cruise. Deeper analysis showed four distinct upticks in rpm (that I never perceived in flight) over a few minutes’ time prior to the deep failure.

Another side discussion that erupted over these incidents was a topic for which I have found a lot of ignorance and confusion, that being the subject of narrow- versus wide-deck engines and their corresponding narrow- and wide-deck prop governors. The respective governors turn at slightly different gear ratios. A well-known vendor mistakenly listed the respective prop governor types in their catalog as being for carbureted vs. fuel injected engines, which in reality has nothing to do with the appropriate selection.

I’ve heard expert opinions that narrow should be with narrow and wide with wide, yet others say that it is no big deal at all. Representatives at both MT and Hartzell have stated that the core units of the governors are identical in respect to the narrow vs. wide determination. I am not an authority nor an expert, but as best as I have been able to determine, the slightly different gear ratios produce slightly different pitch changes for given movements of the controls.

As it turns out, mine were correctly matched, but the discussion itself initially caused a sleepless night until I verified it the next morning. I have discovered from personal research that there are a lot of installations in the marketplace that are not correctly matched, most having narrow-deck governors on wide-deck engines with no reported operational problems that I’ve been able to discover in my limited research. My advice to anyone concerned about this topic is to research your own installation, talk to an expert, then get a second opinion, and maybe a third.

Probable Cause

My failure happened on August 13 (of course), 2016. On August 29, MT issued service bulletin MT-SB-31 covering models produced within certain dates and serial numbers. While it is a positive step that they took that measure, it is frustrating and misleading that they included text in the body of the service bulletin that says it only relates to engines using electronic ignition and high-compression pistons. I was told by an MT executive that the aircraft involved in the European failure did have electronic ignition and high-compression pistons. But after communicating with the other victims, none of us here had either of those components installed at the time of our failures. The good news, however, is that MT appears to be covering all of the units within the serial number range regardless of the type of installation, at least by anecdotal experiences posted on the forums.

As the engine investigating process continued, the metal in the engine filters and cavities was traced back to the governor itself—the failed balance weight must have become, in essence, like the bit of a lathe cutting away the inside of the chamber until the wall was breached and the unit completely failed. Curiously, Lycoming had no reference for an overtorque inspection situation in a piston engine, so they advised BPE to conduct the same inspection checklist as they would for an overspeed. Several parts ended up needing to be replaced, including the crank, which suffered a crack at the base of the slinger component, which can occur in cases of rapid deceleration.

At long last the day finally came when our airplane was complete and ready to fly again. Even with 100% insurance coverage, there is still a cost and a toll in an event like this. I think I was honestly more nervous for this “first flight” than the original, but once the plane broke ground, the famous RV grin was back.

Myron Nelson soloed at 16 and has been a professional pilot for over 30 years, having flown for Lake Powell Air, SkyWest Airlines, and Southwest Airlines. He also recently started flying for the Flying Samaritans. A first-time builder, N24EV, his beautiful RV-10, won the people’s choice award at Copperstate 2016. He has also owned a C-150 and a Socata TB-9.