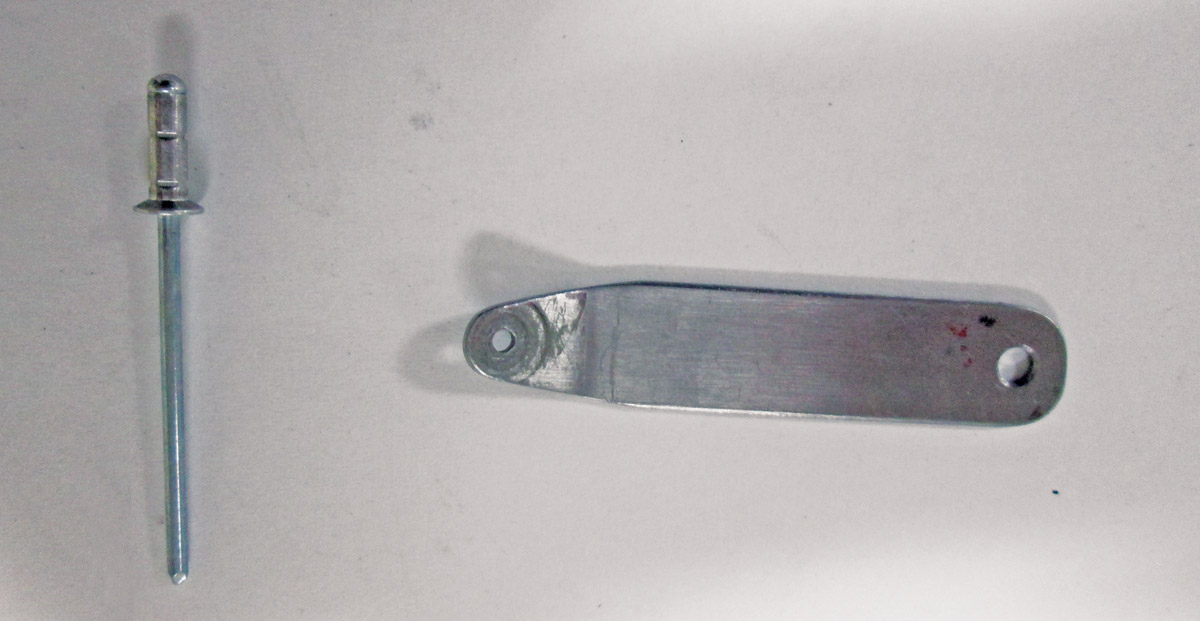

When setting an aluminum pull (or “pop”) rivet, sometimes the hole in the pulling head is a little too large and a “feather” of aluminum is pulled into the hole, leaving a slightly rough surface at the rivet’s face. In order to get an absolutely smooth finish, our Creative Homebuilder made a little handle. The hole at the tip is as close to the mandrel diameter as possible, and a little bend to the handle accommodates ergonomics, putting the handle at a convenient angle when pulling a rivet. As the rivet is pulled, no aluminum can be “cold worked” into the original hole in the pop rivet gun, guaranteeing a smooth surface.

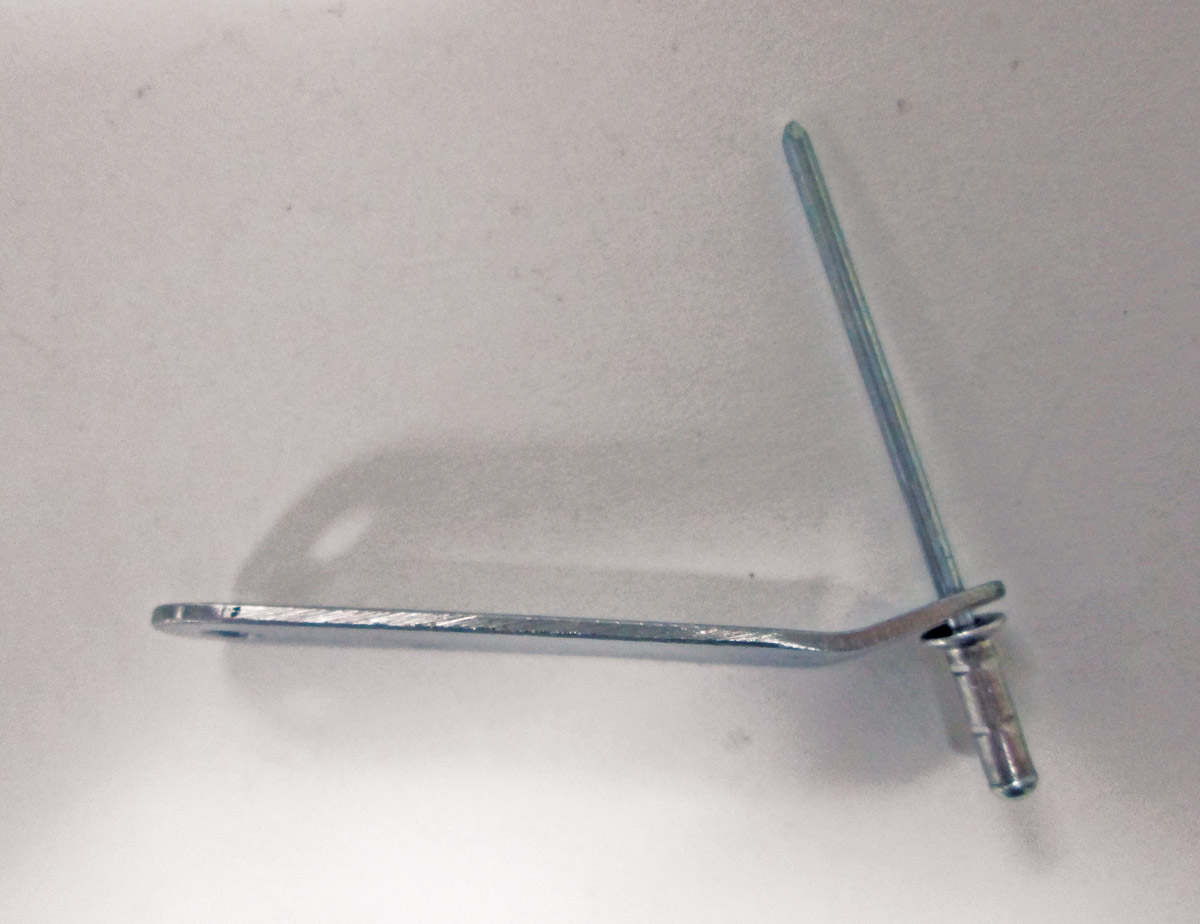

While pop rivet angle adapters are familiar to many, our Creative Homebuilder has been using them for 30+ years and picked up a few tricks along the way. Take a quarter-inch round rod, cut one face square and cut the other face back at an appropriate angle to provide relief from interference with the nose of the riveter. Then drill a rivet-shank size hole in the center of the adapter and paint the adapter a bright color to facilitate recovery of the small piece. Once the paint dries, place the adapter over the rivet and bend the rivet shank until it is square with the angled face. Finish by pulling the rivet. This technique also lessens the “feather” issue mentioned above.

Pop rivet angle adapter is painted red to facilitate recovery when the stem breaks and the gun separates from the skin surface.

Close-up of the pop rivet angle adapter placed in a pop rivet gun and ready to install a rivet. A similar technique is to use a small piece of AEX wedge in place of the beveled round rod.