Consider the tapered-rod landing gear leg. Originated by race pilot Steve Wittman in the 1930s and now used on thousands of airplanes, it’s right up there with the atalatl and the baseball bat as an example of exquisitely simple design. There are no complicated shapes, no moving parts—just a round, tapered rod that fits into a round tube. An airplane goes on the upper end, a wheel goes on the lower end…and there you are.

Simple to use and even simpler to install…but not so simple to make.

The man who figured out how to make them in quantity, while maintaining accuracy and quality, is Harmon Lange. His company, Langaire Aircraft Parts LLC, operates out of a small shop in Warren, Oregon, some 20 miles northwest of Portland. But it started in Wausau, Wisconsin.

Davis DA-2A Gear Legs

In the late 1960s, Harmon was working in a Wausau machine shop, and in his spare time building a plansbuilt Davis DA-2A. Designer Leeon Davis had sourced the aluminum used to build the wing spars of the prototype locally, but other builders ran into problems finding it. Aluminum producers would make the material needed, but only if they were guaranteed a buyer for the entire “mill run.” Harmon organized Davis builders, and with the buying power of the group, managed mill-run buys. As more Davises neared completion, the tapered-rod landing gear became another issue. There just wasn’t a source of ready-to-install gear legs. For Harmon, as a machinist with a good understanding of metal, this wasn’t a problem. He simply lathed up a set of legs for his own airplane—and suddenly found himself on the other end of the group-buy scenario.

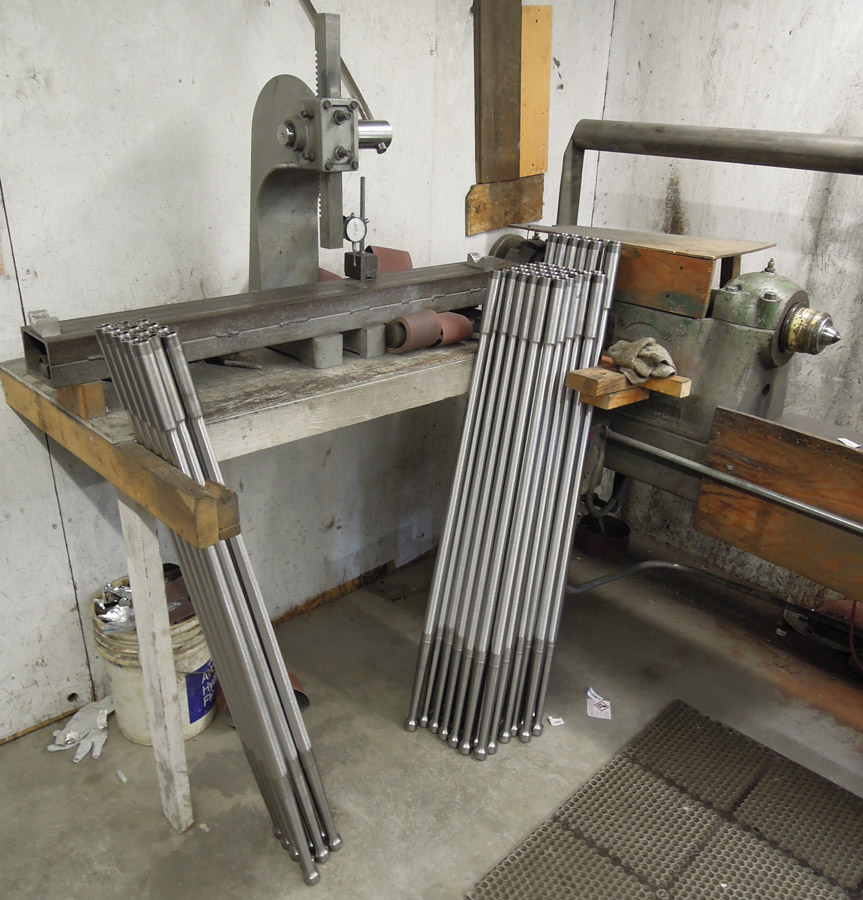

The process begins by cutting 20-foot 6150 steel rods into gear-leg lengths with a band saw. The sawed ends are squared up on a lathe.

“It was just one or two requests, at first,” Harmon recalls. “I rented some machine time from my employer and made sets for other Davis guys. Then the Wittman Tailwind builders heard about it, and orders for those started coming in. I decided I’d place an ad in EAA’s Sport Aviation magazine. I went down to Oshkosh and asked Steve Wittman for permission to use his name and advertise ‘Wittman-style’ gear legs. He was fine with it, and that ad ran for decades.”

Axles are hollowed out with a gun drill, then threaded for the wheel nut before the gear legs are bent.

In 1973 Harmon formed his own business. His main source of income was machine work for Enstrom Helicopters, but landing gear orders steadily grew and really took off when some guy in Oregon (who’d also formed a business around 1973) began ordering 12, 25, or even 30 sets at a time. “That was the first I’d heard of Dick VanGrunsven and his RV-3, but it was obvious he was on to a good thing,” Harmon remembers. “I needed another project as a break from long business hours, so when Van came out with the RV-4, I ordered a kit. I got serial number six. I finally finished it in 1989, and a few years later, I flew it from Wisconsin to the RV Homecoming on Van’s grass strip in North Plains, Oregon.”

That trip gave Harmon a chance to see a lot of country he’d never seen before. It stuck in his mind, and on his return, he realized that two decades of 14-hour days had given him a degree of financial freedom. He sold his machine shop to his son and moved west. He considered the beautiful Montana valley around Hamilton, but the heart of his business was in the Pacific Northwest. Glasair had introduced the GlaStar, which used tapered-rod gear legs, and Van’s Aircraft was shipping numbers never before seen in kit airplanes. He settled in between the two, in Scappoose, Oregon. Once he’d found a suitable property, he moved all the machine tools he needed to produce gear legs into a shop alongside his hillside home, hung out his shingle as Langair Machine, Inc., and went back to work. He soon hired a high school kid to help out, and in 2010 Richard Squires became a full partner in the renamed Langaire Aircraft Parts LLC.

This batch of gear legs is ready for bending. Note the threads for the wheel nut on the hollowed-out axle end of the gear leg and the mounting knob on the other end.

Visiting Langaire

LAP is just 20 minutes by RV-6 from my home, so I decided to pay Harmon a visit. I taxied across my backyard, took off from the neighborhood grass strip, and fifteen minutes later touched down on the tarmac of Scappoose, all on gear legs Harmon made 25 years ago. Harmon met me at his hangar (now filled with an RV-8A and an RV-12), drove me a few miles to his shop, and walked me through the process of making a tapered-rod gear leg.

Harmon uses 1.5-inch diameter 6150 steel rod as a starting point, so the first thing visible is a large pile of material piled alongside the drive. The material is not commonly available, so, just like in the Davis days, Harmon orders entire mill runs. The 20-foot rods are chopped into gear leg lengths with a serious band saw, and the sawed ends are squared up on a lathe.

Using muscle power, feel, and a digital level, the leg is bent to within one-tenth of a degree. The exact angle depends on what airplane and which gear arrangement the gear is destined to fit.

The tapers are turned on another, CNC-controlled, lathe. This step is a difficult one—the long leg gets progressively thinner as metal is cut away, and a long skinny rod is difficult to keep from “whipping.” Harmon has designed and built some additions to his lathe that prevent this, and keep the legs turning true. “The tools are simple enough,” he says, “but nobody else seems to have designed anything similar, and I’m not talking.” Hence there are no photos of the lathing process…suffice it to say that when the lathe is done, the product is recognizable as a gear leg. The mounting knob is there on the upper end, the tapers are formed, and the section that will serve as an axle for the wheel is turned. The finish is rough, but that is fixed on another lathe that is fitted with belt sanders using carborundum and Scotch-Brite belts.

After axles are hollowed out with a gun drill and threaded for the wheel nut, the gear legs are bent. The bending step is the closest thing to an “art form” in the whole process—the axle end of the gear leg is preheated in a simple furnace made of firebrick and fueled with natural gas and compressed air from the shop compressor. Legs are taken one at a time from the furnace and clamped into a steel fixture where the bending point is heated further to a bright red/orange with a torch. Then, using muscle power, feel, and a digital level, the leg is bent to within one-tenth of a degree. The exact angle depends on what airplane and which gear arrangement the gear is destined to fit.

After the gear legs are hardened and sandblasted by a heat-treating shop, they are examined for stress risers and cracks using magnafluxing.

At this point the gear legs are taken to a heat-treating shop in Portland where they are hardened and sandblasted. “Sandblasting delivers a benefit we didn’t anticipate,” Harmon explains. “We’ve done a lot of testing, and we found that the sandblast acted almost like shot peening. It made the legs measurably stronger as well as cleaning off all the scale from the heat treating.”

A clean gear leg is necessary for the next step—magnafluxing. After heat treating and sandblasting the legs go back to LAP, where each one is examined for stress risers and cracks. Very few flunk the test—but every once in a while one does, so Harmon considers the step essential.

The last process before completion is grinding the knob and gear leg surface that contacts the gear mount to an exact diameter. In years past, this step had to be done before the gear leg was bent and heat treated. The heat, however, changed the dimension of the gear leg. The changes were very slight, but the exacting nature of the fit between leg and mount meant they could not be tolerated. If the gear leg could not be held to an exact dimension, the mounts had to be honed to match the specific gear leg. This extra step added significantly to the cost of production and meant that a damaged gear leg was difficult to replace.

Harmon overcame this by learning to grind the hardened, bent, gear legs. This is accomplished with a massive grinder, spinning a 20-inch wheel. The gear leg is held in a lathe-like tool that spins the gear leg accurately, despite the axle bent on the end.

The last process before completion is grinding the knob and gear leg surface to an exact diameter. This lathe-like tool spins the gear leg accurately, despite the axle bent on the end.

Harmon still gets excited by this grinder. “I appreciate good tools, and I love this thing! It was produced for a government program back in the ’50s. They were storing machine tools deep in salt caverns so they could be used to rebuild the country after a nuclear war or something. Nobody blew us up, so after a few decades they were auctioned off. When I bought it, it was essentially brand new. Using it, we can grind a perfectly round surface on a gear leg, accurate to within one or two ten-thousandths, without damaging the heat-treated surface. That means we can make standardized gear legs that are truly interchangeable. We hone the sockets just as accurately, so the whole extra process of matching the sockets to individual gear legs has been eliminated. If someone bends a gear leg—we’ve got a pile of some impressively bent ones out back—we can ship a drop-in replacement.”

Langaire Aircraft Parts’ well-organized shop is located in Warren, Oregon, about 20 miles northwest of Portland.

Beyond Tapered-Rod Gear Legs

Walking around the shop reveals that tapered-rod gear isn’t LAP’s only product. Aluminum hexagonal wheel nuts, used in many airplanes besides RVs, are produced in a multi-tooled CNC mill. Stacks of steel leaf-spring gear legs for the RV-8 taildragger and the RV-14A lie on pallets, as do aluminum leaves used in the RV-12. In their way, leaf springs are just as involved as the tapered-rod gear, and Harmon and Richard have learned their intricacies as well.

As I photographed piles of shining new gear legs, I wondered aloud just how many of these things Harmon had made in his lifetime.

“I thought you might ask me that,” he smiled. “I tried to look it up, but I only have figures from 1996, when I moved to Oregon, so I can’t count the first 20 years. For the tapered-rod gear—not counting the leaf-spring stuff—the best number I can come up with is 34,313.”

Thirty-four thousand and change…but that was last week. Harmon and Richard come to work every day. There’s no telling what the final number might be…