Paul’s latest completion was the Dream Tundra (below), a bush plane used for exploring the wilds of Nevada. Although it and his collection of RVs are metal, he has also restored tube and fabric aircraft and dabbled in both wood and composite. His latest projects are a Xenos motorglider and a soon-to-be-started SubSonex personal jet.

Choosing a new set of plans, a new kit, or a finished airplane that is new to you is an important decision—one that is full of excitement as well as a big financial and lifestyle commitment. At KITPLANES, we maintain a directory that is as broad as we can make it, listing airplane designs that are new and those that are old so that you have the big picture of experimental craft. Giving you this broad perspective is important; we want you to know as much about your choices as possible so that once you have settled into the cockpit of your new aircraft, the excitement never goes away.

This year, we decided to show you our own choices. We have many regular contributors to KITPLANES, all of whom have gone through the process of choosing an aircraft to build and fly. You read their work here every month—but what did they go through to get here? What choices did they make, what requirements were they trying to fill? Our authors fly a variety of airplanes, which reflects the variety of needs, opinions, and desires of a diverse group of people. What do they have in common? A love of flying and all things aviation!

As you peruse this year’s guide, we hope that you dog-ear the pages looking for your own dream project and plane, just as our authors have found theirs. Enjoy their stories and use the guide to inspire yourself. Aviation is a personal journey, and building an aircraft is something that will change your life. Follow the process others have taken to get to their perfect airplane—and we look forward to seeing what you got when we see you at the airport!

—Paul Dye

Editor in Chief

Visit the online Buyer’s Guide.

Once Is Not Enough

Ken Scott

Back in about 1987, I was 36 years old, with very little money and a logbook with about 180 hours in it. The preceding three years had contained one wrenching experience after another, and I was ready to do something, anything, positive. I decided to build an airplane.

N207KS was the 207th RV-6 kit sold out of more than 6000. It first flew on December 26, 1993, and Ken still owns it.

I had no idea what I was getting myself into.

I ordered info packs for three different airplanes ($5.00 to $8.00 each…I really had to think about that) and tore them open eagerly when they arrived. My choices? The Beachner Special, the Durand biplane and the Polliwagen. I think a total of seven or eight of those airplanes—combined—were ever finished. I grew up building surfboards and had helped a friend rebuild a few VW engines, so when the Q2 came along, I was all over that. Foam, fiberglass, and a VW motor? Perfect. Until I stood next to one and realized I’d never fit in an airplane I could step over.

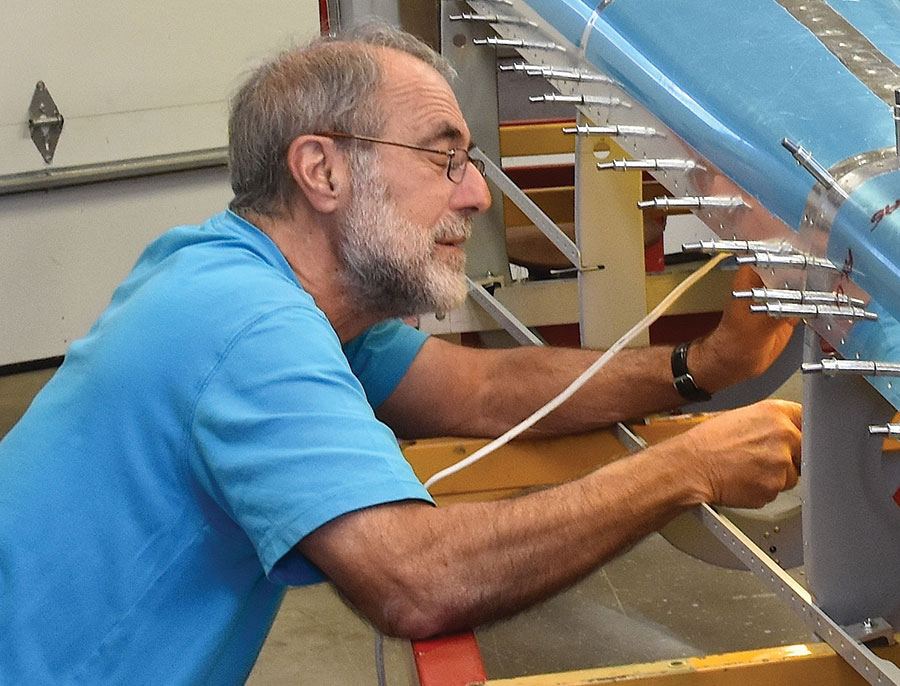

Ken Scott works on the tail feathers of the scratch-built Bearhawk LSA. Now known as the ForeverHawk, it is expected to fly in 2019.

I live near Portland, Oregon, and one Dick VanGrunsven was building a small but successful business nearby. I thought his airplanes, with expensive Lycoming engines, were out of my financial reach. Besides, I knew nothing about rivets or sheet metal. Then Carl Battjes took me out in his Chard 6, and suddenly I understood what all the RV zealots were raving about. I wanted something that flew like that, and if I had to learn the skills to build it, so be it. I rode my bike out to Van’s Aircraft and placed my order for their newest design, the RV-6. I received builder number 20207.

I finished that airplane and made the first flight on December 26, 1993. I have it still. Over the next couple of decades, I partnered with Ken Krueger to build an airplane he designed, a small VW-powered single-seater we called the KK-1. It was a five-year project, but the result flew very well. In 2008, Van’s came out with the RV-12. I enjoyed flying the company airplane and needed some way to occupy my hands and mind, so I spent 18 months building one. It lives in Georgia now.

Knowing that I’d be retiring in a couple years, I consulted my wife, The Violinist, about ways that I could avoid becoming a living room vegetable when I no longer had to go to work every weekday. Naturally, I suggested another airplane. I took the resulting eye-roll as permission. What to build? I already had an RV, and after three sheet metal airplanes, I was ready for something different.

I’d spent a lot of time at Oshkosh watching airplanes go by. Some looked OK, some looked…well, not so OK, most were just blah…and a few caught my eye as just looking right. One guy who seemed to get it right was Bob Barrows, designer of the four-seat Bearhawk. I liked his tandem Patrol even better, and when he came out with the LSA version, I liked it best of all. The Violinist surprised me with a set of plans for Christmas. I convinced a couple of airpark neighbors to join me, and in 2013 we formed the Pudding River Bearhawk LLC. The resulting airplane, now known as the ForeverHawk, should fly in 2019.

As a way to stay busy, learn new skills, and enjoy working with a couple of good friends, it’s been a great project. As a way to obtain an airplane, it’s just dumb. I now know why so few scratch-built airplanes are finished by the original builder—it’s a ridiculous amount of work. There’s no doubt that the Bearhawk LSA flies and performs well. I recently had a chance to fly one, and now I’m really looking forward to getting ours done. If it does what you want to do, it’s a good choice.

But after spending the majority of my adult life building and flying experimental airplanes, my advice is that if you want to build an airplane, buy a kit. There’s a world of satisfaction and pleasure in building a kit aircraft, without the grinding grunt work. There are a lot of choices out there. Figure out what you’re really going to do with an airplane, find one that does it, and get to work.

Building Another GlaStar

Dave Prizio

Twenty years ago, I started on my first airplane project, a Stoddard-Hamilton GlaStar. I had toyed with the idea of building a Starduster Too, but the impracticality of an open cockpit bi-wing airplane turned me in another direction. I test flew an RV-6 but found its cockpit dimensions and useful load inadequate for hauling around my large frame, even though it was undeniably fun to fly. Then I tried the GlaStar, and I knew it was the plane for me. Good useful load, good speed, lots of room inside—it just fit me.

Wind the clock forward 20 years and here I am again, taking on another GlaStar project as my fourth airplane building adventure. I had looked longingly at a Carbon Cub, and I do truly love that plane, but in the end two things moved me away from it toward another GlaStar. The Carbon Cub is rather narrowly focused on the single mission of backcountry flying, which means that it does that very well but other things not so well. It is also expensive enough that to afford it, I would have to sell my Sportsman, leaving me with a plane—a very nice plane to be sure—that would not be well suited to the cross-country flying that I often do.

The GlaStar seemed to be a good compromise between backcountry and cross-country capabilities. It is also affordable enough that I did not need to sell my current plane to purchase the kit and components. Who knows? I may still build a Carbon Cub somewhere down the road, just not today.

I bought a GlaStar project that was some 20 years old from a nice guy who had just run out of good health and motivation to complete it. It was a sad development for him but gave me the opportunity to pick up a project with a lot of high-quality work already done at a good price. The thought was that this would save me time and money. Whether or not that actually happens remains to be seen, but it is a good theory.

Dave Prizio (left) and Ed Zaleski assemble a Sportsman flap for their new GlaStar project. The Sportsman flaps should be an improvement over the original GlaStar flaps, but require extra effort to make them work.

To enhance the GlaStar’s backcountry performance I have invested in some extended heavy-duty landing gear, some bigger tires, and a T3 tailwheel setup. I have also built some Sportsman flaps to replace the less effective GlaStar flaps. That has been more expensive and more technically difficult than I expected, but experimental aviation is all about education and recreation. Let’s just say I am getting an education now in hopes of some future recreation.

These modifications are not ones I would recommend to a first-time builder, at least not the flap change, because such changes tend to complicate and extend the building process. My previous planes were all built according to the plans, although I did later switch my first GlaStar to conventional gear from its original tricycle configuration. It is only now, on my fourth project, that I am customizing things from the beginning. With the experience gained from my previous projects, I am confident that my end result will be what I want, but I am not so sure I would have been ready to try this before. Certainly, every builder can find his or her own path, even on the first project, but sticking to the tried and true is a pretty good idea until more experience has been gained.

As you consider an airplane project for yourself, look for something that will meet the majority of your flying needs, be affordable to you, and be fun to build and fly. After all, if it isn’t fun why do it?

Would I Buy It Again?

Bob Hadley

My regular flyer since March 2014 has been a Jabiru J250-SP. The how and why of that acquisition was detailed in “To Launch a Light Sport-Redux” in the May 2015 issue of KITPLANES, so I won’t go over the details here, except to say that it was built by Bob Fritz, who started the “Home Shop Machinist” column.

So, instead of answering if I would build it again, I’ll change the question to, “Would I buy a Jabiru again?”

All things being equal, yes, I would buy another Jabiru. But if all things weren’t equal, maybe not.

With a baggage area measuring 39 inches long by 42 inches wide, the Jabiru J250’s baggage compartment will hold a full-size pro racing bike (wheels removed) with room to spare.

Like, for instance, I like the Quest Kodiak: awesome payload, STOL performance with 170-knot cruise, turboprop, etc. But at $2 million a pop, it’s never going to happen.

So that brings me back to the Jabiru. For $60,000 (used, in good condition) it’s reasonably fast, affordable, and if cargo space is a measure of utility, the Jabiru 230/250 is the one of the best, if not the best, two-seat aircraft for cross-country flying.

Oh yes, that cargo area! At about 30 cubic feet, it’s not only enormous for a Light Sport Aircraft (LSA), it’s enormous for any two seat airplane. As one might expect, the space is, shall we say, density sensitive. Gross weight and center-of-gravity limits are obviously governing factors. Still, I have about the same area for cargo at my disposal as my neighbor’s Cessna 182T. Yes, I know you can put up to 200 pounds in the Cessna, while the Jabiru, with two people and less than a full load of fuel, holds maybe 30 or 40 pounds of cargo (your results may vary). That said, if there were a contest for two-seaters to see which one holds the most popcorn or ping-pong balls, the Jabiru would win hands down.

How the Jabiru has all this space came about because the factory down-spec’d a four-seater, the J430, to meet the LSA category rules. Call it serendipity, or fluke, or whatever you want, you have to admit they were smart to do a simple reconfiguration rather than a complete redesign for entry into the LSA market.

Obviously, the 1320-pound LSA maximum gross weight limit and CG considerations are determinative factors as to what you can and cannot haul, weight-wise, but the sheer volume available opens the door (literally, there’s a separate cargo door) for a number of items that would be impossible in most LSAs. Think sleeping bags and camping tents, a bicycle (a racing bike, not a beach cruiser), snowboards, etc.

Is the Jabiru perfect? No. The company has had its ups and down, but it’s still here. The latest engines represent 20+ years of production experience, and the airframe 25+ years. As for my J250-SP, the flight characteristics are extremely docile, especially in stalls. In fact, when I’m due for a biannual review, I make sure to remind my flight instructor, Daniel Wotring, not to expect any kind of break, just a descending nose-up mush and the stall horn blaring.

One thing Jabiru in North America is known for is hosting engine seminars. This is something every engine manufacturer should do. The seminar I attended in 2015 covered everything from tuning to cooling, as well as complete teardown and assembly. One of the most interesting topics was the revision history and design philosophy of Jabiru. In particular, engine failure analysis was a big part of the discussion. This, I should add, is very similar to Brain Carpenter’s Rainbow Aviation LSA repairman/inspection class, except their focus is Rotax engines. In both cases I came away more knowledgeable and with a healthy respect for the factory guidelines.

In mid-2018 longtime Jabiru North America sales agent Pete Krojote retired. New USA airplane sales were taken over by Scott Severen of U.S. Sport Planes in Texas, while USA engine sales were taken over by Nick Otterback of Arion Aircraft, in Shelbyville, Tennessee (which was next door to Jabiru North America).

According to Otterback, “We are continuing the seminars…I actually did give the seminar for several years.”

As far as spare parts and support, Otterback added, “Arion has bought all inventory that Jabiru North America had. This gave us no downtime on orders. We continue to maintain a very good stock of parts, and we order new stock every Friday from Australia to keep the shelves full.

“Jabiru is not new to our company; we have used the Jab since 2006 in our Lightning sport aircraft. I moved here from Wisconsin with Pete in 2004 when we set up shop in Shelbyville. So we have many years’ experience with the engine line, and our A&Ps do as well. We have also taken over the service work as well. This includes anything from annuals to complete overhauls on Jabiru engines.”

Someday I might own another airplane. It might not be a Jabiru. But I’m pretty sure that whatever it is, it’ll have room for a normal, non-folding bike. On that point the Jabiru has me spoiled.

How Kelli Girl Came To Be

Sid Mayeux

In April 2015, I launched Kelli Girl, my RV-7A, on its first flight, which culminated a seven-year journey of inspiration, education, and, after 1560 hours of logged labor, exhilaration. An aircraft named Kelli Girl was always going to take flight. I mean, a decades-old itch constantly reminded me that I would build an aircraft someday, and that I would name that aircraft Kelli Girl after my beautiful wife.

Sid Mayeux’s wife Kelli poses with Kelli Girl. It’s her RV-7A, but if Sid does the maintenance, she lets him borrow it.

But the itch never manifested itself until 22 years into my Air Force career. While assigned to Kirtland Air Force Base in Albuquerque, I was suddenly exposed to two different E/A-B kits, both under construction: first, the Titan T-51 Mustang, then the Van’s RV-7A.

I don’t recall how I became aware of the Titan T-51 Mustang kit, but I do remember suddenly spending a ton of time online reading and studying the aircraft…and what a kit! Dude! It’s a -scale Mustang! Aerobatic, 6 G’s, retractable, reasonably nimble, and with an available V-6 “Mini Merlin”! For a South Texas farm boy who spent countless hours pushing Varsol-soaked mops under the (now) Commemorative Air Force’s warbird oil drips in Harlingen, I was ecstatic: I simply could not wait to build my own Mustang.

I studied the Titan website and poured over the online T-51 forum, learning, estimating costs, concocting a build space plan. My middle-school-aged younger son Houston took a keen interest in the project, further warming me up to the notion of pulling the trigger. But as the “real” cost numbers started to jell, I simply had to yield to an overriding real-world priority: Houston’s older brother Chase was about to start his freshman year at Texas Tech. This project must wait. I was disappointed, and I did catch Houston trying to hide a silent tear.

I kept abreast of the T-51’s developments as I dreamed on. However, one of my fellow USAF officers introduced me to his Van’s RV-7A project. I had not looked at any kit other than the T-51, but was immediately impressed by the RV-7A when he showed me the build, plans, construction, and designer’s performance specifications. When Houston and I visited Paul “Bugsy” Gardetto, two of his sons showed Houston and me how to shape, work, and rivet Alclad…our very first aircraft pieces.

The look on Houston’s face proved to me that if ever there was a time to build an amateur-built aircraft, it was now. He was less than half a decade away from leaving the nest, and I wanted this to be a family affair. Find the way…

…Which returned me to a question I had previously answered for myself without realizing I hadn’t actually asked myself the question. Which aircraft kit shall we build? I knew which aircraft I wanted to build…the T-51. However, is that the aircraft I should build?

For context, you should know that I was nearing the end of my tour as the USAF’s chief of flight safety at the Air Force Safety Center. Risk management, in all its forms (fiscal, safety, mission, etc.), was a key part of my job, and I carried it forward that year to my new assignment as Air Combat Command’s director of safety.

I considered the T-51 against the Van’s fleet line (RV-7, -8, -9, etc.). The price difference wasn’t intolerable, nor did I see any relevant safety risk between the Titan and Van’s lines. Aesthetically, the Mustang’s looks beat the RV’s hands-down.

However, one fundamental logistical risk stood out: the chances of a successfully completed build to first flight. For my first attempt to build and fly an E/A-B, I chose the aircraft line with the higher percentage of successfully completed projects. To me, that meant more support, a better build experience, and, well, a greater odds-on chance that Houston and I would fly the thing. I decided this scale tipped in the RV’s favor.

Let me be clear. I’m not saying the RV is a better, or worse, aircraft than the T-51. An RV project was simply the right choice for my situation. The T-51 is a great kit, and I still hope (plan?) to build one.

So that’s how we chose to build an RV, but which one? First of all, I wanted the kit to help the builder (me) as much as possible: Match-drilled parts make the day, so I ruled out the RV-3, -4, and -6. Then we looked at the mission: sport flying (gentleman’s aerobatics and formation) plus speedy VFR cross-country. RV-9s aren’t really suited to aerobatics, I didn’t need a four-seat RV-10, and I’m just not a Rotax guy. That left the RV-7 and -8.

My wife Kelli settled it for me when I asked her if she had anything in mind for her aircraft (if I maintain it, she lets me borrow it). Among her inputs, Kelli gave me two key “requests” (which I dutifully understood were actually “requirements”).

• “Side-by-side seating,” she said. “Sid, you flew over 2000 hours in the back seat of F-4 Phantoms. I will not be your backseat wizzo.” Got it. RV-7 or -7A.

• “No surprises,” she said, to which I asked for further clarification. “Sid, I want you to build out of this airplane the chance that it’ll make you say, ‘Oh, sh%$.'” After deep thought, I figured a ground loop counts as an Oh sh%$ moment, so a taildragger just wouldn’t do.

That settled it. We built an RV-7A. The canopy choice (slider versus tip-up) was easy for me. After 2069 Phantom backseat hours with zero forward visibility, the RV tip-up canopy’s totally unobstructed forward view was heavenly (proven to me when Joe Blank took me up for a factory demo ride in their RV-7A).

The rest is history. Now, after several big mods (constant-speed prop, IFR upgrade, dual P-MAGs), we have logged over 550 Hobbs hours in just over three years and are preparing for our third trip to Oshkosh. I still feel that itch, but scratching it has been an absolute blast.

“Do You Think You Could Build Something Faster?”

Dave Forster

Wham! A bolt from the blue. You’ve got to love a wife who asks for an airplane to be built. Like any dutiful husband would, I quickly agreed, before she had time to change her mind.

Until that moment, we had been flying an airplane that on a good day would do 90 knots. On lunch fly-outs, we would be the first to depart and the last to arrive. It would not be a challenge to find something faster.

When his wife asked if he could build something faster, Dave Forster decided to build this F-1 Rocket.

However, as we built our wish list for a new airplane, speed was not the only criteria. It had to have at least two seats (of course) and enough baggage space for a week’s camping at Oshkosh. I had grown fond of our bush plane’s short-field capability and appreciated a strong climb rate. Altitude more quickly meant more options sooner. It had to be capable of landing on grass, with handling characteristics that wouldn’t bite a weekend pilot. I was aware that off-airport survivability drops significantly with increasing stall speed (energy is the square of velocity), so a reasonably slow stall speed was desired. The build time had to be short enough to fly prior to my hair commencing its migration, and metal was preferred. A previously built kit car taught me that fiberglass resin and sandpaper are not two of my most favorite things.

Armed with the list, our search for a suitable aircraft commenced. It didn’t take long for the F1 Rocket to come to the top of the list. The next step was to go to one of the big experimental aviation shows, talk to the manufacturers, and ensure nothing new was about to change the equation. A trip to Sun ‘n Fun and meeting with Mark Frederick of Team Rocket Aircraft helped reinforce our impressions and, as it turned out, he was from our home state of Texas, which made it easy to schedule a visit to check out the factory and go for a test flight.

For someone not used to small kit aircraft manufacturing, the “factory” was a bit underwhelming: a single hangar filled with Rocket parts and the promise of flight. However, the real kicker was the test flight.

One of the things I really enjoy is flying around puffy white clouds (at a legal distance, of course!). With our old Falconar Avia Maranda, this really did mean flying around them. The Rocket opened a whole new dimension: the ability to simply pull back and fly over the top. The climb rate was impressive, especially for someone used to the kind of performance where planning over the clouds required a sectional and E6B.

However, regardless of how impressed I was, the critical hurdle in the buying decision came next—the wife’s ride. As I stood nervously on the ground, they took off. Have you ever had a time when you knew the next 15 minutes were going to set the course for a substantial impact on the rest of your life? This was it.

I knew she would probably like the airplane and was hopeful that a nice, quiet flight and gentle landing would provide a green light. After a while, the airplane came back into view, entered the pattern, and set up for a nice, gentle landing. However, before the wheels touched, the power came back, it soared up into the sky, and commenced doing something that shouldn’t be described in writing. My heart sank and I saw the future unfolding with a steamed wife and evaporated Rocket dreams.

But when the plane came back for a landing, she bounded out of the cockpit and declared, “Wow! That was better than sex!”

I wrote a check on the spot.

Stardusted

Tom Wilson

In a life less planned than others, the Starduster came to me more by being at the right time and place than by sober reflection. Having eagerly worked my own way to a Private while in high school, but sidetracked by racing cars and motorcycles, my early piloting years were spent in rented Cessnas as I indulged the car habit and made a career of writing about them. But early on, I also put in several years working at the local airport, in part at Aberle Custom Aircraft, where besides having certified oil run down my arm, a minor parade of Pitts, Stardusters, and racing biplanes got my attention. Biplanes were more popular in those pre-RV, canard, and bush plane days, and the then prevalent Greatest Generation owners saw the biplanes as natural sport planes, and it seemed so to me, too.

Tom flies his Starduster Too over north San Diego County, California. With its O-540 Lycoming, it climbs at 2500 fpm, cruises at 150 mph, and has a 350-foot takeoff roll.

By my early 40s, airplanes were renewing their appeal, and my wife and I had just barely accrued the discretionary income to consider the long-dormant dream of owning one. Possessed of only modest fabricating skills and buried under magazine deadlines, two kids, and a mortgage, there was no hope of building my own plane. I had been around plansbuilt sport plane construction enough to know there was no way I was going to survive 6000 hours of that. I also never considered a certified plane; they were too boring, and you could always rent one if you needed four seats. And then the Starduster Too came on the market right there at my local airport.

The airplane was well known to me (and I bought it anyway) as it had been maintained its entire life by Aberle Custom Aircraft, which tamed some of the usual angst about how it had been built (elsewhere) and maintained (in my hometown). In any case it was a mess, looking like it was hurriedly built in a dark room by a guy welding without a mask and upholstered in an upstate Nevada sporting house, plus it had spent the last seven years standing motionless in a tin shed hangar. I knew better…but it had a 540 up front that I swore I could hear breathing when I stuck my head in the hangar. It wasn’t anywhere close to boring, Aberle Custom Aircraft was there to help, and the price was set to sell—now.

Never mind that I had no tailwheel endorsement or loggable time in anything more challenging than a 172, the Starduster promised adventure. With its fast climb and 150-mph cruise, cross-countries were reasonable expectations. A confirmed convertible freak and yet to be deflowered romanticist, I didn’t mind sitting outside, either.

Even if this particular Starduster was down on its luck and eventually proved to have a 50 percent availability record the first decade—the first annual took 14 months and brother there were some dragons hiding in the shadows—buying a used homebuilt is so incredibly time and money saving over rolling your own that I was able to hang onto the plane—my plane—on a writer’s salary. Eventually, the demons were expunged, the engine and prop overhauled, so that while today the plane is still scruffy, it’s stronger and more reliable than ever.

As for the Starduster design, it’s been perfect for me. Undervalued, the Starduster was financially possible, unlike a two-seat Pitts. I roll and pitch aggressively on nearly all flights but don’t need tiddlywink aerobatics. Zooming up and over the clouds on sunset flights is glorious, and the big engine means you don’t have to look at your watch to see if anything is happening when you lay on the loud lever. Cross-country stability is excellent, and the world looks great framed by those two wings and crossing stainless steel wires. Yes, storage room is challenging, and you must accept both heat and cold (sometimes simultaneously), plus wind noise, the sun always on your face, and a “say again” attitude toward radio procedures, but airline captains give you thumbs up when you taxi by, and every gas stop is a social event. You wear a leather jacket without affectation.

Now older, I sometimes wish for a plush, sit-inside cross-country ride, and whenever gas gets toward $5 a gallon, I think of my buddies with Rotaxes. But then I remember the 350-foot takeoff roll, the 2500-fpm climb, and the immediacy of being out in the sky rather than passing through it. Then I zip my jacket all the way to the fur collar, point the nose into the wind and go.

An RV-3B? Really?

David Paule

I didn’t plan to build an RV-3B. In fact, the RV line wasn’t on my radar at all. I’ve got a very nice, reasonably fast, four-seat airplane and a capacious hangar in which to keep it. If ever I were going to get another airplane, it would be a Kolb Xtra or a Curtiss Junior, for the visibility. And I couldn’t really say that I needed either of those; after all, I’d sold a Kolb precisely because I wasn’t flying it.

And as for a project, I did, admittedly, enjoy building aluminum airplanes, having had the construction of one as a college job. But then again, I knew well the labor involved.

David Paule rivets the left-hand skin of his RV-3B. He finds building to be both fun and challenging, and he haven’t gotten bored yet.

What’s more, I’d sold my fast composite trimaran sailboat. Yes, after sailing for a decade, I gave it up; the ocean was too far away from the mountains of Colorado. But the sailboat taught me something pertinent: I preferred non-engine activities to engine ones. The best part of any day on the water was when I got to shut the motor off.

So a friend built a motorglider and started flying it about 90 minutes per day. He’d climb for about 15 or 20 minutes, shut down that motor, and soar. It was a kit that he built. I could buy one of those and have the fun of shutting down the motor, too. Tempting indeed. But the memory of him building those very long wings still made me think that it wasn’t for me. Wings are good things to have, to be sure, but that plane has an excessive length of them, and they must be built, every foot of them.

For that matter, the Curtiss Junior has seemingly long wings, too. This led to wondering if I could homebuild a Junior, keeping the airplane’s grace and, yes, the span, but with slightly better visibility and a more recent engine. No, I decided, I didn’t need a project of that magnitude at all. A simple little airplane kit at my age would do nicely.

Around that time I discovered www.VansAirForce.net, and Paul Dye and Louise Hose were discussing the construction of their RV-3B, and this got me interested in that airplane. About this time also, I got a demo ride in an RV-12 and was surprised by its superb handling and remarkable visibility. If only it were a taildragger! I have only minimal nosedragger experience and remain somewhat suspicious of them, an unfounded prejudice of mine, perhaps.

People say that the RV-3B handles well. I don’t know. I’ve never flown one.

People don’t say the visibility is outstanding, and I’m sure it isn’t. But it appeared as if a tall canopy and lots of seat cushions might improve that, anyway.

People say that the nice thing about the RV-3B is the quality of the social experience, knowing that it’s a single-seater.

People don’t say that the RV-3B is a thinking man’s airplane, which it most certainly is, at least during the construction. People should say that because it’s true. I ought to know because I decided to build one, mostly to have a fulfilling project, and it has been that and more for sure. My kits were delivered in 2012, and I’ve been at it since. And yes, it’ll have a full-time big engine, and it’ll make those loud engine sounds that I no longer enjoy.

To me, the difficulties inherent with the RV-3B made it a particularly attractive project. The skins didn’t have prepunched holes, for example, and some of the parts didn’t fit as well as they might have. But apparently the design has decent handling characteristics, and I look forward to that.

What’s it like to build? It’s an airplane from the ’70s, which means it’s not computer designed. A number of the parts need to be tweaked before they fit, and the plans, while sufficient, are not always well organized, complete, or ample. Some of the details are obscure at best. But two fuel tank arrangements are included and two canopy-opening designs. The airplane has been around long enough that its major design-improvement iterations are complete: the B model with wing tanks and a better spar being the major one. So far, factory builder support and replacement parts availability have been excellent. I’ve got the wings and tail done and am skinning the fuselage now. Building it is both fun and challenging, and I haven’t gotten bored yet.

Designing and Building the Facetmobile

Barnaby Wainfan

Building an airplane is a major undertaking. For most of us, it is the single biggest draw on our resources other than taking care of necessities and our families. To maintain the level of effort needed to succeed, you have to have a compelling reason to complete and fly that particular airplane. That motivation is as personal as the individual builder. For some, it’s the only way to get the machine they dream of flying. Others enjoy the act of construction itself or see the project as a personal work of art.

In 1994, Barnaby flew the Facetmobile to Oshkosh and it appeared on the cover of EAA’s Sport Aviation. (Photo: Courtesy of EAA)

The path that led to the Facetmobile started many years before actual construction. I am a designer and innovator both by profession and inclination. I remember getting my first issue of Sport Aviation when I joined EAA at the age of 16 and thinking that someday I wanted one of my designs to grace the cover.

I was driven by the excitement of creating something new and different. I had my own conception of what a personal airplane could be.

I wanted to do the experiment and prove that it worked. To do that I had to both design and build the airplane.

The seed of the idea was planted by the cover article on the Dyke Delta in the July 1972 issue of Air Progress. I was 16 at the time, and while I lacked the technical education to fully understand why the Dyke Delta worked, I was impressed by both its performance and radical look.

A year later, I passed my flight test for my Private Pilot license and started work on my mechanical and aerospace engineering bachelors degree at Cornell. I started sketching delta-winged light-plane concepts and used my newly acquired engineering knowledge to analyze their performance. Within a year, I set building such an airplane for myself as a life goal.

During my time at Cornell, I started building a KR-2 with my father, who suggested a plansbuilt project as a learning exercise before we started on the original-design delta. I now understand that my dad saw my still-developing engineering skills were not yet to the point where I could design a safe airplane. The KR-2 project was his way of supporting my long-term dream while postponing the delta project until I had the ability to do it right.

The KR-2 was never completed, although I moved the project with me twice after I left my parents’ house. I continued to work on it on and off for a few years and then lost interest. Its end illustrates what my motivations really were. For me it was not worth the effort to simply reproduce what had been done before. That partially built KR survives to this day and is used by a Southern California EAA chapter as a show exhibit illustrating wooden airplane construction.

As time went on, my fascination with the desirable characteristics of low-aspect-ratio configurations increased. I studied other such airplanes including the Arups, the NASA lifting bodies, and the Avro Vulcan and continued to work on my own designs.

By 1988, I had refined my ideas to the point where the detail design of what would become the Facetmobile started in earnest. We began cutting metal in early 1989, 17 years after the picture of N555A on the Air Progress cover first caught my attention.

N117WD first flew in April of 1993. In 1994, I flew it from California to Oshkosh, where it earned an EAA award for innovative design and became the cover story for the October 1994 Sport Aviation.

For me, the Facetmobile project was as much about the experiment and the exploration of a new design approach as it was about building simply to have the airplane. In that, it was a complete success, in spite of its relatively short flying life. I remember thinking after I flew it to Oshkosh that even if it never flew again, it had all been worthwhile. I used the knowledge I gained during the project in my professional life, and I am currently working on the design of the Facetmobile’s long-delayed successor. If fate is kind, perhaps it too will make it to Oshkosh someday.

Why I Chose the RV-8

Nigel Speedy

When it comes to choosing the right airplane, there are many considerations. Here is how I ended up building and flying a Van’s RV-8.

Back in the day, when I still wore a uniform, I had the opportunity to do a flying instructor course in the Pilatus PC-9, a 1000-hp tandem-seat turboprop. In hindsight I did not fly that airplane all that well, but I sure did enjoy going places fast—fast relative to the helicopters I had been flying up until then. I also liked the aerobatics and formation that we did in this course.

Nigel Speedy chose to build an RV-8 because it met the criteria that were most important to him: tandem seating, cruise speed, range, aerobatics, cost, and solid support for the type.

A few years later, I was in the USA, and one of my classmates in a test pilot course was talking about the rudder kit for an RV that he was building. You can build a plane in your garage? What a novel idea.

Fast forward a few more years, and I was back in the USA again and hanging out at the local airport display day. A chap there with a Sirocco (imagine a wooden RV-8, or as he likes to say, “The RV-8 is an aluminum Sirocco.”) tells me, “You need to start building now before you get married.” Hard to argue with that logic. The question was, what to build?

I want to explore my new home and mostly it will be on weekends, so I wanted a plane that is relatively fast, so I can cover some reasonable ground. I like doing gentle aerobatics. I want to replicate the tandem seat configuration of the PC-9. This was my first kit aircraft project, and I while I enjoy building stuff, I really wanted to be flying, so an aircraft with a good probability of completion in a reasonable time period was important. A stable company with good customer support and popular models also played into my deliberations.

After five years and 2500 hours of construction, the RV-8 does exactly what I wanted it to. Day in and day out, I get 177 knots TAS burning 7.7 gallons per hour. There are certainly many aircraft that are more capable in any one area (STOL, cost, speed, aerobatics, range, economy), but

I don’t think there are many that can outperform the RV-8 in all areas. I tell folks that the RV-8 is not the best at any one thing, but it is very good at most things—at least the things that are important to me.

After two and a half years and 500 hours of flying, I still marvel at the fact that it was built at home. If I were to do it again, I would use 10-inch displays rather than 7-inch ones that are a challenge with older eyes. I would not bother with an IFR GPS, given the amount of actual IFR I do. I would not bother with the aftermarket tip tanks; it can do around 1000 nautical miles on just the mains. I would go with electronic fuel injection and ignition for the tuning ability these systems offer. If a lot of cross-country time with a significant other had been part of the original plan, I would have considered an RV-14 instead for the larger panel space and more sociable side-by-side seating.

My advice is to build a plane within your means that does your mission well. Try to keep it as light and simple as you can. It’s worth the effort, and you’ll thoroughly enjoy the end result!

Why Build?

Dick Starks

When I was 14, my dad took me to see the award winning 1927 movie Wings with a live piano accompanist. That’s when the seed was planted in my mind that took another 39 years to finally take root and blossom.

That movie really burned itself into my soul. After watching it, there were two things written down on slips of paper and added to my bucket list.

Sharon Starks in her Airdrome Aeroplanes Morane-Saulnier “L” Parasol makes a pass with Dick Starks in his Graham Lee Nieuport 11 replica.

One, I’d someday own and fly some kind of warbird.

Two, I’d marry Clara Bow.

Well…It took 39 years, but the one about flying my own WW-I fighter plane finally came through.

In between those years, time was spent getting a degree, starting a career, marrying the girl of my dreams (Clara Bow was out of my reach, and besides, I got a much better deal anyway), restoring a 1946 C-120, and learning to fly the C-120. But I still didn’t have the brass ring—my own warbird.

During all those years, I went to many airshows and just stood in slack-jawed awe watching the warbirds being flown. The cost of owning and flying any kind of warbird was totally out of reach for a middle-school math teacher.

Then in 1985 I got hooked up again with a grade-school buddy, Tom Glaeser. We’d separated for several years while we were both starting careers and families. Tom became a machinist for TWA. He also had his pilot license. At his urging, I bought the pretty well beat-up 1946 C-120. I totally stripped it, recovered it, painted it, and learned to fly in it. I knew my dream of a WW-I plane had to be a taildragger, so it was the natural plane for me to choose.

Then Tom and I found an article about a “cheap-to-build, fun-to-fly” 7/8-scale WW-I Nieuport 11 replica fighter. In 16 months of part-time labor, we built two of them for the cost of $2,859 each, ready to fly. (Tom and I take scrounging to a new Olympic level. That’s much less than the cost of a set of main landing gear wheel bearings for a P-51 Mustang.)

That’s when life took off. When the word got out that we owned and flew WW-I replica fighters, the invitations to come to airshows all over the country (and world) started pouring in. We got more invitations to go to airshows than we could possibly make, even if we’d been retired.

For about five years all was well, but a sobering reality soon set in. Flying cross-country in an open-cockpit plane that only goes 60 mph in calm air is an unexpected adventure into sheer physical torture.

First, there’s always a headwind, going and coming. One memorable day, Tom and I got passed by a dump truck on a gravel road!

Second, weather is always a major concern. One year it took The Dawn Patrol—Tom, me, Mark Pierce, and Dick Lemons—nine days to get home from an airshow only 108 miles away. On the day the weather actually let us fly, it took two hours plus to get home (another headwind).

So, The Trailer Weenies were born. We all built trailers to get our planes to the shows and back home.

At every show we’ve been to since then, a scenario similar to this one repeats itself: I’ll be sitting in my folding chair beside my canvas falcon when an airshow attendee walks up.

“Does this thing really fly?”

“Yup…I’ve been flying it since 1986.”

“Did you fly it here?”

“Nope, we trailer to airshows.”

“Why didn’t you fly it here?”

“We only go 60 miles per hour. In this wind, we would never have made it.”

There is a long silence while he looks over the plane, then the other shoe drops.

“So, you don’t fly cross-country; your plane is too slow. It’s open cockpit, so you can only fly in good weather. And you have to trailer it to airshows…Why did you build it?”

Just about then, the pilot of the Navy F-18 Super Hornet flying in the show comes ambling by with all his flying gear hanging over his shoulder. He stops and reads the poster I display with the history of my plane.

I walk up to him and say, “Wanna try it on for size?”

His equipment hits the ground with a clank and 15 seconds later he is in the cockpit, stick and throttle in his hands, feet on the rudder bar, and he’s peering through my ring gun sight.

I explain the controls (or lack thereof) and what it is like to fly.

That’s when he says it. “You know, I’ve never wanted to fly a prop plane ’til right now.”

That’s why we build them. There’s a mystique about WW-I planes that will live forever.

So, to answer his question, “Why?”

Why not!