Premeditation is planning on a higher plane. It considers the nuances not only of the step before and the step after, but every tangential influence known or supposed. It is forethought sufficient not only to commit the act of airplane building; it is the prudent plotting that leads to its ultimate achievement.

For Paul Collins, house hunting was the inaugural step in his first homebuilding project. “We told the real estate agent we needed a house with a big garage to build an airplane. The house can be nice, but we’re more particular about the garage itself,” he said. “So we found a great place, six-car garage with its own HVAC.”

As soon as Collins and his wife, Amy McPartland (a professional figure skater, former director of the Ice Capades and Dorothy Hamill’s understudy, now president of The Next Ice Age, “A Dance Company on Ice”), closed on the house in Gambrills, Maryland, he ordered a Backcountry Cub PA-18/L-21C kit (www.supercub.com) and started work in April 2009. When the kit became a flying airplane in July 2016, they put the house on the market. Downsizing to a smaller garage was the final item on the building plan.

In itself, the airplane was part of a larger life transition for Collins, who retired from the U.S. Army after 20 years as a warrant officer and helicopter pilot. Upon retirement, he began a full-time cyber security position with the Department of Defense in Washington, D.C. “I worked on the airplane every day,” said Collins. “I may not have turned a wrench every day, but I’d think about how I would proceed that night or that weekend.”

This premeditation often resulted in procedural checklists that made the most of his hands-on time. “When I went out to the garage, I knew exactly what I wanted to do. That morning, before work, I’d lay out the tools I’d need that evening.” Reviewing his checklist during the workday, “I could go right to the garage and start working.”

Uniform Challenge

Covered with wrinkle-free Ceconite, the Super Cub wears a flawless charcoal gray uniform favored by special operations aircraft. “It’s a holdover from my military days,” Collins said. On the tail, a solder equipped for a HALO (high altitude, low opening) parachute insertion holds the Piper Cub logo, Special Operations Edition. “I found the HALO soldier on the internet, added the Cub logo, and sent it to AeroGraphics with the size I wanted,” and they tweaked the art and produced four vinyl decals.

That was the easy part. Covering and painting the airplane was the project’s greatest challenge. Collins helped his father recover the wings of a Cessna 120 in the early 1970s, so he had some experience there. He learned that attention to detail—and patiently working out the wrinkles—is the secret to tailoring any airplane’s Ceconite uniform.

Painting the airplane was a different story, said Collins. A first-timer, it “took me almost eight months to paint the airplane.” He did not build a paint shed in his garage shop because the plastic sheeting most builders use is a ready source of static electricity, which attracts dust like a magnet. To avoid the health and environmental hazards of two-part epoxy paint solids carried by volatile organic compounds, he chose waterborne Stewart Systems.

“You can’t use the same tactical mindset as Poly-Fiber or Stits. It doesn’t work with Stewart Systems. If you follow the instructions to the letter, you’re going to have a good product. I’d never painted before, so I followed the instructions,” Collins said. “The challenge was setting up the spray system to eliminate moisture; drying out the compressed air took a lot of planning.” This is important, he explained, because spraying Stewart Systems with moist air can trap moisture under the paint, “and it will bubble up months later.”

Stewart Systems needs a lot of pressure—35 psi coming out of the gun—to push the waterborne paint solids, and that requires more thorough preparation, Collins said. “There are a lot of parts, and when painting them you have to secure them top and bottom, and sometimes diagonally, with safety wire so the gun pressure doesn’t push them around. If you don’t, you’ll never get them painted.”

Given the prep and setup time involved, Collins only painted on weekends, “because I wanted to do it right. I didn’t want to build a nice airplane and have a secondary paint job. So I took my time.”

Fresh Air Flyer

To passersby at EAA AirVenture Oshkosh 2017, Collins explained the Cub’s special ops paint job as “a hangover from my Army career.” He’s logged time in all of the service’s rotary-winged flying machines but spent most of his time with his hands on the cyclic and collective “of the Bell Jet Ranger and MD-500,” mentioning the civilian equivalents of the military helicopters. During his career, Collins was “an instructor pilot in OH-58 Scouts with multiple deployments in cavalry units, attack helicopter battalions, and the schoolhouse at Fort Rucker, Alabama.”

In these helicopters, “we flew a lot with the doors off,” he said, and that was an important factor in deciding what airplane to build. Flying low and slow with the doors open is Collins’ ideal aerial experience, and the Backcountry Cub not only has an optional left-hand door (Collins went with the split door instead of the swing-up version), it can fly up to VNE with both doors open.

Beyond the affordable replication of the low and slow fresh air flight of a helicopter, the Cub closes the circle on Collins’ aeronautical birth. “My dad was in the Air Force, and we spent four years at Kincheloe Air Force Base [in the Upper Peninsula of Michigan] south of Sault Ste. Marie,” in the early 1970s, he said. Joining the local EAA chapter, its members gave him rides in the J-3s and Super Cubs that later taught him to fly.

Collins met the Backcountry Cub during his Oshkosh recon in 2007. “I saw this kit at the north end of the field.” It was a straight PA-18 with “Alaska mods, like 3-inch extended gear, and it just stood out as a brute of an airplane,” he said. Liking its looks and the left-hand door option, his future was pretty much set when he settled into the cockpit. “It just felt like I was sitting in one of the helicopters I used to fly.”

When Collins ordered his kit two years later, the left-hand door wasn’t his only option. The base kit comes with a welded steel-tube fuselage and assembled all-metal wings, and Collins had them respectively powder coated and lacquered. Considering that the helicopters he flew had skids instead of wheels, he opted for heel brakes.

“I was leery of the toe brakes because I didn’t want to inadvertently get on them while I was working the rudder, particularly while landing or taking off,” he explained. “I like the heel brakes because they give me a more positive transfer of control from the rudder pedals to the brakes. I know I’m on the brakes because I’m moving my heels as opposed to hitting a brake with my toe, which is still on the rudder pedal. The other factor was that the toe brake option required indentations in the firewall that reduced the working room in the engine compartment.”

The optional left-hand door is one reason why Collins picked the Backcountry Cub. He installed larger 8.50×6 tires because they give the airplane a more proportional look and better performance on grass strips.

Power and Panel

Having turned a wrench or two as the crew chief on an Army UH-1 Huey before he went to flight school, Collins said assembling the kit was straightforward. Backcountry delivered assembled wings, except for mounting the aileron and flaps and their control systems; installing, grounding, and plumbing the two 24-gallon fuel tanks; and fitting the LED landing and navigation lights. From there it was a matter of bolting the various components to the fuselage.

Backcountry didn’t provide any plans or specific drawings, but “every chapter of the instruction manual was well done, with great pictures and guidance,” except for firewall forward and the instrument panel. The kit came with the conical engine mount, but the rest of it—how to cowl the gap between the composite nose bowl and the stainless steel firewall, and where to puncture that firewall for the controls and connections that pass through it—was up to him.

With his typical premeditation, Collins investigated and photographed these aspects of every Super Cub he saw during his annual research trips to Oshkosh. And he probed the institutional knowledge of the sages he met on SuperCub.org. With an effusive shout-out to the online builder’s group he said, “If I had a question, I could post it online, and in about 10 minutes, a guy in Alaska would respond and say, ‘you need to do it this way.'”

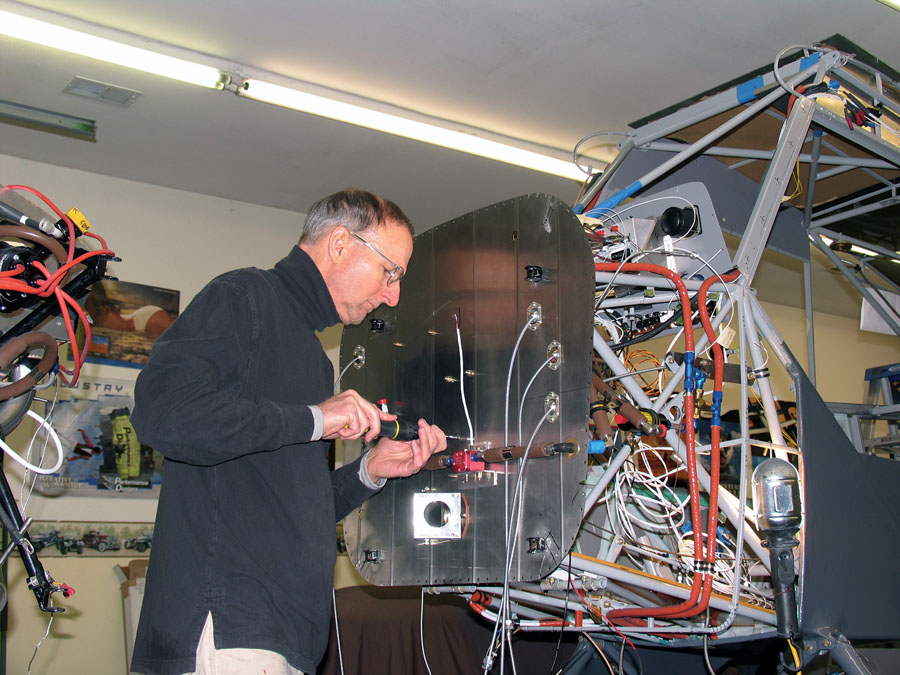

Before puncturing the blank stainless steel firewall, Collins first mapped each hole on a cardboard template and then built a Plexiglas firewall to adjust and confirm the proper placement of every aperture. “Once I got the idea for the Plexiglas, it was a simple process to maintain clearance within the engine compartment, particularly the exhaust system, working around the cockpit tubing, routing the electrical wiring, and meeting the recommendations for the fuel flow angles and cables.”

The cowl’s jowls are essentially flat sheets of aluminum connected to the airframe with piano hinges. They cover a 180-hp Lycoming IO-360 that is one of the last few TMX 360 engines Mattituck built for the experimental market. “I got it from them about two years before they closed up shop,” said Collins. “Their follow-up and back-end support has been great, and they supported the warranty even after they closed up shop.”

Collins is running a fixed-pitch prop because he “didn’t want to go through the extra time and expense of a constant speed,” and he was concerned about the weight and balance. “Initially, I thought it would make the airplane nose heavy, but I don’t have that issue. I’m super lightweight; I only weigh 165 pounds, so when I have a big load in the cargo compartment or a big person in the back seat, I’m just a little aft CG, so I just have to pay attention to that.”

In creating its version of the venerable Super Cub, Backcountry stressed it for 180 hp and a 2300-pound maximum gross weight by making the necessary components, like the wing spars, more robust. Empty, Collins’ Special Operations Edition weighs 1274 pounds. He traded some of the useful load for bigger main tires because the 8.50x6s not only give the Cub a good proportional look, “They are good on all the grass strips that I visit.”

To accommodate his desired avionics, Collins built a bigger panel. With the plan made and tested with a cardboard template, he ordered the flat stock from Aircraft Spruce and cut holes in it to mount a Dynon FlightDEK D-180 EFIS and Garmin SL40 com, aera 510 portable GPS in an AirGizmo mount, and a GTX-327 transponder. Arrayed around them are the necessary switches and circuit breakers, an analog altimeter and airspeed indicator, and a PS Engineering PM1200 intercom.

A FreeFlight ADS-B unit was on his Oshkosh 2017 shopping list until Garmin announced its new GDL 82 ADS-B unit during the event. Upon receiving it, Collins installed it, as he’s done with all of the airplane’s avionics and electrical systems. Not well versed in things electrical, he said that when he couldn’t figure something out, he turned to his library of KITPLANES magazines to find the article and diagram he needed. “I love you guys; you saved my life with really great, easy-to-read and understand articles that present material that’s easy to follow.”

A Stratus II ADS-B In receiver drives his iPad mini equipped with ForeFlight. “I fly with paper charts as a backup, and I don’t rely on the iPad all the time,” because, he explained, “I’m looking outside. If I need a position fix, or I’m getting close to congested airspace, close to DC, Chicago, or Oshkosh, I pull out the iPad and look.” Collins keeps his Cub at the Essex Skypark Airport (W48). With parallel 2200-foot paved and grass strips, the publically owned non-tower airport and seaplane base is in Baltimore County, Maryland, just outside the dome of protective airspace that covers Washington, D.C.

Upset Prep

Collins prepared for his first flight with the same care and premeditation he invested in building his airplane. He enrolled in Marianne Buckley’s unusual attitude course and, even though he was grandfathered by the date of his initial civilian training, earned a tailwheel endorsement. Flying Buckley Aviation’s 150-hp Citabria from Maryland’s Potomac Airfield, “We did loops, rolls, hammerhead turns, and lots of spins,” he said. “It was a great situational awareness builder, and it definitely increased my confidence before my first flight. I didn’t want to fly a new airplane for the first time without the upset training. I didn’t want to take the chance of getting into a situation that I didn’t know how to get out of. I’m really happy I did that.”

His first flight, he said, “was almost perfect: hands off, feet on the floor, the ball was almost in the center.” With the fuel-injected Lycoming, he had a 40-hour Phase I test period, which he designed to meet the requirements of Lycoming’s break-in instructions. “The airplane flew perfectly, the oil consumption settled down around 25 hours, and I didn’t have to make any adjustments.”

By the time he returned to his hangar at the Essex Skypark from Oshkosh, Collins had logged 180 hours in the airplane. His parents live in South Carolina, and Collins has flown in to visit them four or five times. He and his wife also winged their way to the Boston area for a Next Ice Age fundraiser there. “I like low and slow,” he said. “If I want to go 300 knots, I’ll take Southwest. Or maybe, one day, I’ll build an RV-8 or something like that. But right now, this is great fun! It is worth every penny and every hour I put into it.”

Am I missing something? That special forces soldier on the tail is from the video game HALO not the real US Army. I would assume the retired Army vet knew this and the write up is just incorrect.