Scrounging, once the fiscal staple of experimental aircraft construction, is not so highly valued in this age of super-complete airplane kits. After all, if every last tool and rivet is a mouse click away, there’s less call for the ability to spot opportunity in that pile of dusty stuff in the back of so many hangars.

But for those working with plansbuilt designs, the advantage is all sorts of fallow parts and assemblies are useful fodder for the craftsman. And so it was when Scott Thomson, late of Uncle Sam’s C-17 and U-2 cockpits, found himself lined up for a second career shepherding 737s and an interest in pylon racing.

Co-owners Eric Scheppers (left) and Scott Thomson take a moment with their new racer. Both are Air Force veterans, Scheppers for a four-year stint and Thomson for a first career. Scheppers, an AirVenture Lindy winner, has numerous builds to his credit and with a move to full-time building soon should have many more. Thomson has C-17, U-2, and U-2 instructor piloting experience.

The racing had started innocently enough. After the Air Force, Scott bought a 172 and was making the fly-in rounds when in 2014 he came across a gorgeous Glasair at Marysville, California. “The build quality was so amazing,” said Scott, that he hung around the airplane until the owner, Eric Scheppers, showed up. The two became friends, and ultimately partners in the Glasair, which not quite incidentally, won a Lindy at AirVenture in 2017 thanks to Eric’s handiwork.

Second Hand finished a close third in the Gold race in its debut event. Teething issues were surprisingly few; the left cylinders could run cooler, and as visible here, the lower cowl shape deforms at speed. Straight on the ground, it’s distinctly concave here. Eric says this slab-sided lower cowl shape was an expedient anyway, and he’ll replace it with a slightly convex—and slightly larger—exit. (Photo: Courtesy of Bradley Haskin)

Also not incidentally, both Scott and Eric are based at Rio Linda Airport, hard under the Class B of Sacramento International. Dubbed “the fastest little airport in the world” by Scott, Rio Linda is a hotbed of experimental, and especially pylon racing, activity. This includes Jeff Rose, the Biplane Gold winner in 2016, whose Mong Sport lost its corroded tail as documented in “A Cautionary Tail” in our September 2018 issue. Other Rio Linda Sport racers are Lee Ulrich with the world’s fastest RV-7 (turbo) and Dan West with the similarly fastest RV-8 (supercharged).

In 2017 Scott raced Jeff Rose’s stock Pitts, and the die was set such that at the awards banquet Scott was thinking out loud about his next step. He figured he could put his own Pitts racer together in a few years when Eric started mentally counting Pitts parts he knew were lying around Rio Linda hangars and came up with just about everything except the fuselage weldment and a set of wings. Before the night was over the game was on—Eric and Scott would build a Pitts for next year. Eric would bring an engine, propeller, and his building expertise while Scott would write checks and contribute what building he could.

“Simplify and add lightness” is the hallmark of all performance machinery as exemplified by Second Hand’s cockpit. The curved seat back shows here although the similarly curved seat bottom is not so obvious. All electronic boxes are along the side of the right footwell; hydraulics and engine controls are on the left. As for the light glowing through the fabric in the right corner, it’s due to the AirTech process. It has UV protection in the primer that Second Hand currently wears, so there’s no light-blocking silver coat. Once the team is convinced all airframe speed mods are in place they’ll add paint.

To find the fuselage truss and wings, a want ad was placed on Barnstormers, and “Luckily, a lot of people have Pitts parts in their hangar,” said Scott. The fuselage truss was located in the San Francisco Bay area, and a set of unfinished Pitts S-1C wings turned up in Van Nuys, California. By late October the Pitts was under construction.

Second Hand’s angry clock graphic, designed by team friend Jesse Barrasoso, draws attention from one of the plane’s excellent features: completely removable fuselage skins in the forward cockpit area. This panel covers the electronics located in the cockpit footwells and is removable, thanks to nut plates and countersunk machine screws around its perimeter (Second Hand has no exterior buttonhead hardware). This was achieved by cutting off the lower several inches of the standard Pitts panel and riveting it in place so the wing root would not cover the removable portion of the panel. Anyone who’s serviced anything at the bottom of a typical biplane cockpit will applaud this arrangement.

As construction began in Eric’s hangar, the project goals were defined. “We aren’t doing an IAC work with it,” says Scott, “but we want to race and do well, and also use it as an aerial motorcycle.” That is, they wanted a comfortable, day VFR sport plane with a strong emphasis on racing. Eric and Scott are not interested in thin airfoils with hair-trigger stall habits, so the stock Pitts S-1C M6 airfoil was retained. In fact, Eric had a set of S-1C plans to check dimensions on, so that was what the plane was built to.

In any case, Scott knew the build would be to Eric’s exacting standards, but to a budget. With no major sponsor other than Scott’s wallet, some things would have to wait such as a hot rod engine, but there was no limit on crafty thinking and nifty details.

Eric Dienst of Rev’d Up Composites blew this perfectly clear, distortion-free canopy for Second Hand. Eric mated it to the airframe with a carbon fiber skirt. It’s one of relatively few carbon parts on the biplane, other notable pieces being the spinner Eric splashed off an RV piece, the cowling, wheel pants, and gear leg fairings.

Naturally the effort snowballed with the Rio Linda crowd. While Eric was the chief builder, others made significant contributions. Jeff Rose was critical to the build, supplying endless parts plus doing all the fabric work, much of it in his living room. Lee Ulrich handled the wiring and installed the Dynon avionics. Dan West came by every day after work and put hours into Second Hand—typical quitting time in Eric’s hangar was 11 p.m. and weekends were 16-hour days. Scott characterized himself as the administrative guy and found keeping the FAA inspections coming was a task unto itself. Because the build was so fast paced, admin tasks normally spread over five or more years were squeezed into just a few months. Everyone constantly had their calendars out, and talk was often about the schedule.

Eric and the Second Hand crew went to considerable lengths to provide a well-streamlined spring gear. The gear legs from Jeff Rose have been wrapped in an aluminum fairing riveted at the trailing edge; the wheel pants are Dimension Three units wrapped around the 5.00-5 rolling stock that came with the fuselage weldment.

Fuselage

Of course there was a lot more than talk going on. The fuselage weldment was configured for bungee gear, but Eric had a more streamlined spring aluminum gear handy, so the frame went to Chico, California, where Josh Phillipson holds forth as Dimension Three, a Formula One and biplane racing-oriented fabrication shop. Josh’s pro welding skills soon had the bungee gear attachments gone and the lower longerons/gearbox reinforced for the spring gear, along with the bushings necessary to capture the spring gear’s U-bolts. This gear change is critical as the loads are distributed completely differently between a bungee and spring gear, so the work calls for reengineering the fuselage, along with competent welding.

Aviation Products, Inc. built this tailwheel and spring assembly, and Flyboy Accessories made the single-arm RV Rocket steering link. Scott reports a pleasant, positive action and that the first tire (old) shredded on the second flight, so it was replaced. Scott said the noise when the tailwheel failed and the spring hit the pavement “was like being inside a gramophone.”

Other Dimension Three framework included removing existing tabs so the Second Hand team could weld on their own former fittings.

To lower the upper fuselage height and thus make a larger airway under the upper wing, plus lower the canopy, the seat was dropped 2 inches, along with the fuel tank. Furthermore, the typical slab back and bottom Pitts seat was curved on both surfaces to form a sling-like support. Eric did this by simply rolling the aluminum seating surfaces, thus forming a recess for a seat-and-back emergency parachute, along with a much more comfortable shape. Both Eric and Scott rave about how comfortable the seat is, and when queried about any cramping or loss of legroom from the lowered seat and fuel tank, Scott said not at all. At nearly 6 feet 2 inches tall, he finds no constraints in Second Hand’s cockpit.

Simple, battleship-strong wing tips speeded wing construction. Mad Ink is the printing company that provided the team with graphics.

Behind the cockpit Eric formed the lower-than-stock turtle deck from 3/32-inch thick mahogany skin over -inch plywood formers. Again, because the Pitts is plansbuilt, this wasn’t even much of a modification, just another builder option.

Underneath the mahogany skin Eric placed the GPS antenna, plus glued his homemade 1/2-inch copper tape com antenna. He’s big on this design, which he got from Jim Weir’s column in KITPLANES, saying, “It’s amazing how well this stuff works. With the right tape width for the bandwidth [it works great]. We were 20 miles away in Lincoln, and I could hear him on a handheld! I’m telling you, it’s pretty cool.”

As for the engine mount, it was donated by Jeff Rose, who had it in his hangar. As Scott said, “It was one of these things that looked like it should have been in a scrap heap. But we blasted it and checked it, primed it, and are using it.”

Streamlined stainless steel wires are an expensive part of biplane construction today; luckily veteran biplane racer Jeff Lo had a used set available through Jeff Rose. The javelins stabilizing the wire intersections were fabbed from old carbon fiber archery arrows.

Wings

Because the wings came to Second Hand as pretty much just spars and ribs, it was relatively easy for Eric to finish them as desired. Overall he describes them as “just clipped standard S-1C wings.” Saying it “looked draggy,” Eric closed “the semicircle in the upper trailing edge where the handhold is…so the trailing edge aluminum just goes straight across. And I got rid of the laminate bow at the tips…there’s just a rib there.”

Eric also removed the standard Pitts 1.5-degree positive incidence on the upper wing, setting it flat relative to the lower planes. As the incidence is partially set by the cabanes—which were already welded to the fuselage—Eric did this with new intermediate brackets on the triangle attach plates inside the upper wing. Because the wings and fuselage came from separate homes, it seems some sort of accommodation might have been necessary anyway.

Rushed to Reno, Second Hand was light on paint and a few finishing details. Empty weight at Reno was an admirable 738 pounds, a bit less than most Pitts, thanks to a well-focused build as a day VFR sport plane. The pireps for Second Hand say it’s a comfortable little plane with surprising stability and docile handling.

Looking to reduce drag, Eric built the aileron coves much tighter than normal Pitts practice. At the upper and lower edges, the cove-to-aileron gap is a mere 1/16 inch, and this is sealed with tape at the races.

Because of the clipped wings, the aileron’s trailing edge also had to be straightened at the outboard ends. He did the same with the wing tips, which are 9/16-inch-thick birch. “You can smash your head into them!” says Eric. “They’re really strong. I got them from a guy remodeling a house; they’re old door jambs, about 20 years old, aged, and cured so they’ll never change their shape. I just milled them…they’re perfect.”

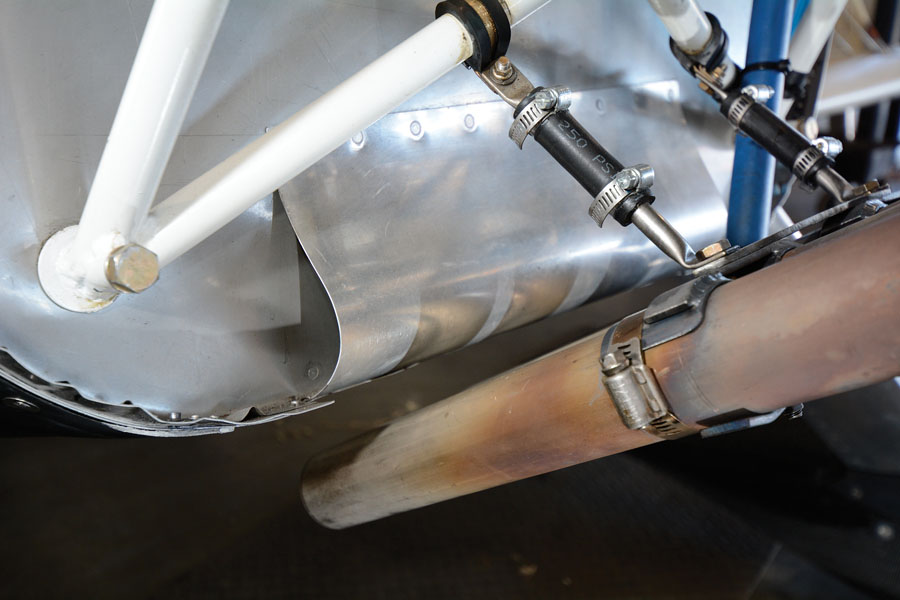

Biplane racing rules allow extensive engine hot-rodding within the 360-cubic-inch limit, but Second Hand’s IO-360 Lycoming has so far remained relatively stock due to finances. In this view the cooling air plenum cover has been removed. The plenum cooling system is Van’s RV-6,-7, -8 system cut to fit by Eric. At $290 it’s an easy choice to begin with. The two round-to-rectangular inlet ducts are custom by Eric.

Engine

If cost containment is reasonably possible during airframe construction, engine building offers few such opportunities. Therefore, the starting point for Second Hand’s engine was a stock O-360 off of a Beechcraft Duchess. This was the same wrecked Duchess Jeff Rose bought both engines off of to power his Mong Sport, as reported in our September 2018 article. Jeff had given the engine to Eric for work he had done on the Mong, and for duty on Second Hand, Eric prepped the engine with a mild cleanup using 10:1 pistons, Bendix fuel injection overhauled by Airflow Performance, and a Superior cold air sump. Furthermore, Eric says everyone at Rio Linda happily runs Light Speed ignitions, so a pair of Dual Plasma IIIs was a given. With no magnetos and a glass panel, he also needed plenty of reliable electrical power, so he fitted a 25-amp B&C alternator to the vacuum pump pad. A tiny backup alternator was originally considered, “but they just don’t charge enough,” says Eric.

Eric did not skimp on oil cooler size for Second Hand, and the installation runs cool enough. Besides the expected lightweight accessories, the Lycoming sports a custom individual runner exhaust system from Vetterman. Clint Buseritz at Vetterman asked Eric for just two basic measurements, then supplied this perfectly fitting exhaust.

Likewise, the Catto propeller had previously been given to Eric from Jeff. In fact, this engine and prop combination had been raced on Jeff’s Mong in 2014, which did give the team an interesting baseline for the new Pitts. Between the engine and prop is an 8-inch spacer that belonged to Eric Zine for his upcoming Pitts racer but was appropriated by the Second Hand crew in their rush to get their plane flying. “We’ll buy him a new one,” says Eric.

One reason everything electric, even the starter and master solenoids, is mounted in the cockpit is to keep the firewall absolutely clean to improve cooling airflow. Eric borrowed the curved fairing above the cooling air exit from an RV-8, but even so thinks Second Hand could use a touch more cooling air exit area.

Second Hand Flying

Most amazing to everyone was how well Second Hand handled right out of the box. Eric’s voice was still a bit incredulous when he said, “Two minutes into the first flight, Scott put both his hands in the air. What? He was just showing us it would fly hands off. I figured I got lucky on that! We had put the rigging boards on it, and it should have been close, but we didn’t touch a thing.”

“Jeff and I and Scott have flown it,” says Eric. “It breaks straight out [of the stall] at 69 mph indicated. It doesn’t matter at different weights, it’s the same mph. It breaks straight, it’s amazing. I thought it would be twisting wings or something, but no.”

It looks large here, but Second Hand’s tail group is standard Pitts size, as are the ailerons. It’s the shorter wings that make the ailerons look so long. Aileron linkage fairings will be added by the next race.

At its debut at Reno in 2018, Second Hand qualified at 202 mph and averaged 192 mph in the Gold final. Alternatively, Scott reports straight and level at 7000 feet density altitude, Second Hand clocks 230 mph. Considering the mildly hopped-up engine, that’s a testament to the airplane’s inherent aerodynamic cleanliness. It also fits the racer’s rule of thumb where straight-line speed at 7000 feet density altitude minus 10 percent is what the plane will average around the pylons. “We’re within three percent of that,” notes Eric.

The only issue to date is cooling the left-side cylinders. At Reno this was a limiting factor as Scott had to richen the mixture after a couple of laps as the engine heated up. This allowed John D’Alessandris in the RB Special to sneak around Scott in a heat race, and for second in the Gold race behind Andrew Buehler in the untouchable Phantom. The Second Hand team never had time to balance injectors or fully investigate cooling airflow before the 2018 race, but is definitely working on a solution for 2019.

Another area for improvement is the propeller. The borrowed fixed-pitch Catto unit runs smoothly, but turns “just” 3000 rpm instead of the 3250-rpm target speed. Either more power or a different prop seems indicated. The cowling was designed and the plug made in Chico, California, by Josh Phillipson at Dimension Three using digital measurements, SolidWorks software, and a CNC mill. Eric made the mold followed by the carbon fiber cowling using scrap material from Jeff Rose’s all-carbon racer at Rio Linda. Eric was amazed by the accuracy and ease of obtaining the plug. “When they gave it to me, it was darn near done. I just sanded it a little and primed it.” All the hard shape and clearance work was done in the computer.

In fact, while no one is going to beat a healthy Phantom in a conventionally configured Pitts, we detected a distinct competitive urge from the Second Hand crew. They certainly have an excellent little racer for not much outlay and a lot of labor. A bit of tuning and tapping into the Lycoming’s hot rodding potential should do the rest.

Great article, Tom.