Weight! Before you carpet the cockpit of your Ultra Pup, read this.

Every airplane has two weights that determine how much people, petrol, possessions, and GoPro cameras it can carry aloft: the airplane’s empty weight and the design’s gross weight. Your goal while building is to keep these weights as far apart as possible, as you would your mom and your dad’s wife at your kid’s birthday party. When items that aren’t necessary for flight are added to an airframe, the airplane’s useful load is whittled away one upgrade, beef-up, and do-dad at a time. These additions also affect where the remaining useful load can be carried. What’s more, every added item impacts building time and cost, the airplane’s performance, and the airplane’s ongoing maintenance burden—if it isn’t there, it can’t break, need service or cleaning, or be in the way of something that does. By resisting the temptation to add items that aren’t necessary for flight, each builder has control over their aircraft’s empty weight, increasing the odds the aircraft will carry the load it was designed to carry. The aircraft’s gross weight, however, is determined by the designer, and we builders have no say in it. Yet, we do.

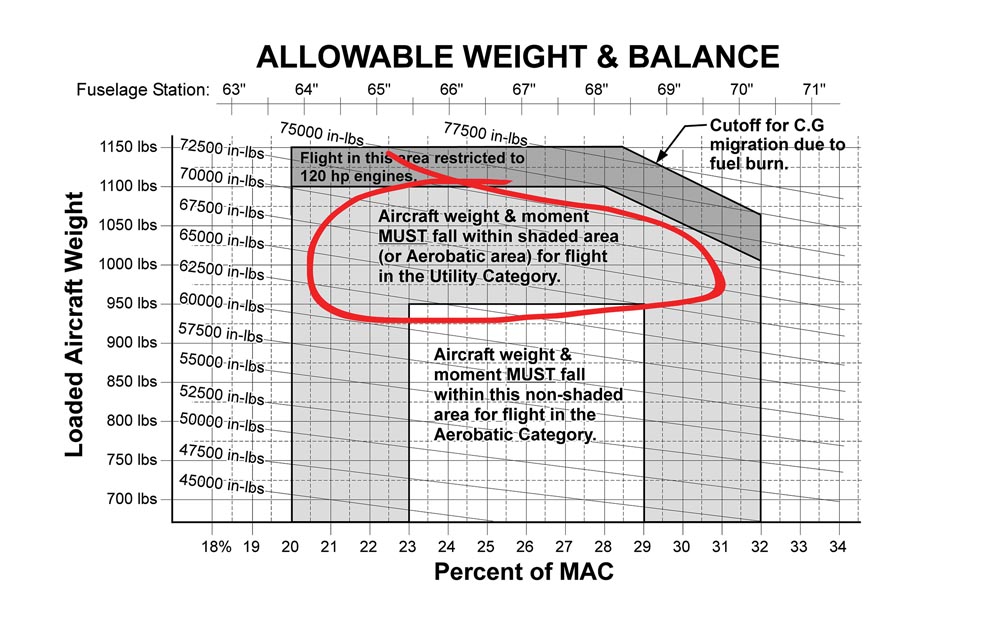

There is no getting around the fact that an aircraft is a teeter-totter and must be flown within its center of gravity range, from takeoff to landing, regardless of its licensed gross weight. This often means you have to leave people, petrol, or possessions behind when you “build heavy.”

More than one builder has been surprised by the empty weight of their aircraft and disappointed to find they turned a two-place airplane into a single-place airplane by adding unintended (well, unintended by the designer) weight to their airframe. Upon discovering they built a heavy airplane, some builders have licensed their airplane above the design’s gross weight. It’s their way to claw back, at least on paper, the useful load they sacrificed with cup holders and mahogany instrument panels. It’s a mask, not a fix. FAA inspectors get wedged between a rock and a hard place when an airframe they are licensing lists a gross weight in excess of the design’s gross weight. Because the aircraft is being licensed in the Experimental/Amateur-Built category, the inspector cannot reject the increased gross weight out of hand. The inspector knows the aircraft was not designed to fly at that weight, therefore the safety margins built into the design shrink. An aircraft flown at an increased gross weight stalls faster than intended, climbs slower than intended, and has a lower tolerance for G-forces than intended. Does the builder—who is about to become the pilot—also understand this?

You, of course, would never license your aircraft heavy. But if you run across someone who has, encourage them to record the reason for the gross weight increase in the airframe’s logbook. It is an important part of the airframe’s history. If you are shopping for a used homebuilt, be familiar with the design’s gross weight specification and recognize that an airframe licensed above that weight was done so against the designer’s wishes and (somewhat) beyond the FAA’s authority to prevent it.

Licensing an aircraft at a higher gross weight may get someone off the legal hook for overstuffing their aircraft, but it doesn’t free them from the potential handling consequences of overstuffing the design. Building a heavy airplane also impacts the aircraft’s center of gravity (CG), and this comes as a bigger surprise to some builders. There is no paperwork work-around for this issue. An airplane is a teeter-totter that must balance within a narrow range of the wing’s mean aerodynamic chord (MAC). This safe range of balance, the CG envelope, doesn’t change regardless of the aircraft’s empty weight, licensed gross weight, or flying weight on any given flight. Space for people, petrol, and possessions is allocated early in the design process and drives, and is driven by, every major design decision and more than a few small ones. That is why a casual decision to add a beefed-up tailwheel becomes a double-edged sword. It adds weight, which reduces the useful load, it upsets the airplane’s balance, and it changes where a portion of the remaining useful load can be carried. Three extra pounds of tailwheel may decrease the baggage area capacity by 9 pounds. Surprise! You may get away with licensing—even flying—your aircraft 100 pounds heavier than intended, but physics will smite you if you fail to place that extra weight in a manner that keeps the teeter from tottering from takeoff to landing. Remember scooting toward the fulcrum when your mom forced you to teeter-totter with your little sister? Remember getting bruised when the kid on the other end of the teeter-totter suddenly jumped off? Flying out of balance is much worse. You probably won’t remember it.

Airplanes, like pilots, grow heavier as they age. When a small tool kit and some spare parts get tossed into an airplane’s baggage area, they tend to stay there—their two pounds never subtracted from the useful load and not accounted for in the empty weight. A spare quart of oil adds 1.5 pounds. Three pounds of spray cleaner, rags, tie-downs, and gust locks take up permanent residence after the airplane’s first fly-in. The incidentals add up and become particularly threatening to the well-being of a pilot who has already chosen to fly an airplane at a heavier weight than the designer intended. Remember to account for these extras in your preflight weight and balance calculation. Remove whatever you can whenever you can.

Homebuilding abounds with clever, weight-related sayings and rightfully so: “Add only lightness.” “Ounces equal pounds.” “Throw it in the air. If it falls back to earth, leave it off.” Make wise weight decisions from the moment you begin building. Carpet or spouse? Auxiliary fuel tanks or a change of clothes when you get to your distant destination? Joyous aerobatics or straight and level? Ounces equal pounds, pounds equal consequences. Before every addition, ask yourself, “Do the benefits outweigh the costs?”