The squeaky wheel gets the grease, but it is better if everything that needs it gets the proper grease before it begins to squeak. If you consistently use the correct lubricant for your airplane’s various parts, you will go a long way toward preventing problems that could leave you stranded.

While Experimental airplane owners may use any grease they like, greases made for aircraft work better. Just as you won’t find the best aviation hardware at your favorite home-improvement store, you won’t find the best grease for your airplane at the auto parts store. It’s not that automotive greases aren’t suitable. They are simply designed to meet different needs.

For this article, we will focus on aviation greases available in tubes to fit the standard grease gun. This covers the vast majority of greases that the owner of an Experimental aircraft would likely consider. We also look at the places where they are best suited.

Making the Grease

Different types of grease are formulated to provide better performance in specific situations. Since different users have different needs, we get a variety of greases tailored to those needs. Helicopter main and tail rotors see different kinds of loads than light-plane wheel bearings. Airliner wheel bearings see higher loads than those on light planes. Amphibious floatplane wheel bearings need a high degree of corrosion resistance. Thus, there is no one grease best for everything.

Grease is mostly oil, either mineral or synthetic. Oil makes up 80 to 95% of grease. The rest is thickening agents and performance-enhancing additives. Thickening agents can include calcium, clay or lithium. Calcium is a popular thickener for mineral-based greases, with lithium being more common among synthetics. Thickeners are there primarily to provide mechanical stability and resist water washout. Performance additives may be included to increase corrosion resistance, wear resistance or resistance to high pressures.

Wheel Bearings

Unless your airplane is on straight floats or skis, you will have wheel bearings to maintain. If your plane lives on wheels, you will need a general-purpose grease such as AeroShell 5 or 6—both economical and widely available. AeroShell 22 is a good synthetic grease that will match or exceed the performance of AeroShell 5 and work over a wider temperature range. Mobil 28 is a fine choice if you prefer a synthetic grease, but is slightly more expensive and not as widely available.

If you spend a lot of time in wet conditions or, if you have amphibious floats that have wheel bearings under water much of the time, you will want to lean toward AeroShell 22—this is a product that carries the specific endorsement of Wipaire, Inc., maker of Wipline floats. AeroShell 5 is a good choice if you can’t find AeroShell 22, but avoid AeroShell 14 and 33 for wet environments.

Wheel bearings are typically serviced at the time of the yearly condition inspection, but hard use or extreme wet conditions may dictate a shorter service interval. Remember that when servicing wheel bearings, they need to be clean before you repack them. Pushing out the old grease with new grease does not ensure that the wheel bearing is free of contamination. The effectiveness of any grease will be compromised by contamination, so no cutting corners here.

The actual greasing process can be messy and tedious, but it isn’t too bad once you get the hang of it. Take a glob of grease, about two tablespoons, in one hand and grasp the bearing cone in the other with the narrow end facing up. Place your thumb on top of the bearing and press it repeatedly into the grease until it begins to squirt up through the rollers. Then rotate the bearing and do another section until you have completely gone around the bearing. While you are at it, apply a thin coat of grease to the race. It is a little easier to say than to do, but you will get good at it with practice. Low-cost bearing packers have not worked well for me and higher-priced ones are just not worth it for once-a-year use. The hand method has the advantages of being well-proven and cheap. A pair of disposable nitrile gloves makes the job less messy.

In all cases when servicing wheel bearings, be mindful of safety, both when jacking up your airplane and when using flammable solvents for cleaning.

Tailwheels

Tailwheels should be greased annually or every 100 hours if you are fortunate enough to fly that much. To grease a tailwheel, first make sure the grease fitting is clean. Any dirt or debris on the fitting can end up on the bearing surfaces and cause damage. If possible, cover the grease fitting with a protective plastic cap. Attach the grease gun to the clean fitting and pump in a few squirts of grease. Keep an eye on the grease seal to ensure you do not push it out of place with too much grease. As soon as you notice any movement, stop pumping. Be sure to use a grease that is recommended by the tailwheel manufacturer. Some tailwheels use sealed wheel bearings, so they obviously do not need to be greased, but the pivot joint will still need servicing.

Propellers

Typically, constant-speed propellers are serviced once a year at the time of the condition inspection. If you fly more than 100 hours per year, you should consider servicing the prop every 100 hours. Be sure to consult the prop manufacturer’s maintenance guidelines for greasing recommendations.

Hartzell traditionally asked you to remove the trailing-edge grease fittings on each blade and pump grease into the leading-edge grease fittings until grease squirted out the trailing-edge holes. However, after an enthusiastic mechanic pumped two full tubes of grease into a King Air prop, waiting for grease to come out the other side, they changed their recommendations. They now say to pump not more than one ounce of grease—about five squirts—and call it good. Excess grease can get into places where it doesn’t belong, leading to removal and teardown of the prop in question.

Propeller manufacturers all assemble their propellers with grease that they think will sufficiently lubricate and protect their products. They want you to service their props with the same grease and not mix greases. In the past, they gave you some choices. That does not mean you could choose to use any approved grease at any time. It means pick one and stick with it. Mixing greases, especially mineral and synthetic, is not allowed.

As of January 2020, Hartzell assembled their props with NYCO GN 3058 grease, and they expect you to service any prop made after that date with that grease. It is not yet widely available, but Ottosen Prop and Hartzell will sell it to you. Hopefully, other vendors will offer it soon. Propellers made before this year can continue using the grease they have been using. Do not switch to NYCO grease if you are currently using some other grease. Needless to say, if you have a constant-speed prop made by another manufacturer, you should consult them for the most current recommendation on products and procedures for greasing your prop.

If you are currently using a factory-approved grease in your constant-speed prop, it makes good sense to use the same grease for everything else in your plane. That way, you don’t accidentally put the wrong grease in your prop. As an alternative, you can have a dedicated grease gun for prop maintenance and use whatever you like for other things.

Other Applications

What grease you should use for any particular application will depend on the conditions under which it will operate. Choose a grease that best fits the requirements. For example, AeroShell 5 and 22 are particularly good in hot environments, whereas 7, 22 and 33 are the best in extremely cold situations. Among the AeroShell choices, AeroShell 5 and 22 are best in wet conditions. Helicopter mechanics widely use AeroShell 14 for its superior anti-fretting properties. With the information available on the internet, it is pretty easy to do some detailed research if you have a particular need.

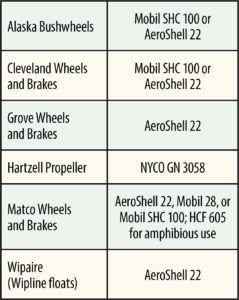

Recommended Greases

Here are the grease recommendations of some popular manufacturers. Note that Mobil SHC 100 is not available in tubes from Aircraft Spruce, but Amazon carries it. The smallest quantity available is a 4.4-pound tub for $83.

Here are the grease recommendations of some popular manufacturers. Note that Mobil SHC 100 is not available in tubes from Aircraft Spruce, but Amazon carries it. The smallest quantity available is a 4.4-pound tub for $83.

As you can see, AeroShell 22 is a popular choice among manufacturers. That said, AeroShell 5 also has a good track record. AeroShell products are widely available from aviation vendors, making them a popular choice among mechanics and aircraft owners. Matco recommends BG Products HCF 605 for wet uses and amphibious aircraft. It is available from SkyGeek. Mobil 28 is also popular as an alternative to AeroShell products, and Mobil SHC 100 is widely used by manufacturers during initial assembly. Since it is not available in tubes, it is much less popular with aircraft owners.

Some Takeaways

Use a grease that is approved by the maker of the part you are greasing. The people who make your parts know best what works well for their products. In just about every case, that will mean using an aviation grease. Follow the lubricating procedures recommended in the manufacturer’s service literature. There are right and wrong ways to do most things. Do not mix greases—and especially do not mix mineral and synthetic greases. If you want to use a different grease, thoroughly clean the part before applying a new type of grease. Mixing greases can lead to corrosion and other negative consequences.

Popular Aviation Greases | |||

|---|---|---|---|

| Brand | Type | Price/tube | Use |

| AeroShell 5 | Mineral | $12.80 | Wheel bearings and engine accessories |

| AeroShell 6 | Mineral | $10.75 | General purpose |

| AeroShell 7 | Synthetic | $19.50 | General purpose |

| AeroShell 14 | Mineral | $9.95 | General helicopter grease |

| AeroShell 22 | Synthetic | $12.50 | General purpose, amphibious (Wipaire) |

| AeroShell 33 | Synthetic | $17.50 | General purpose |

| AeroShell 64 | Synthetic | $21.50 | General purpose |

| HCF 605 | Synthetic | $10.76 | Amphibious (Matco) |

| Mobil 28 | Synthetic | $14.75 | General purpose |

| Mobil 33 | Synthetic | $17.95 | General purpose¹ |

| Mobil SHC 100 | Synthetic | $83.00/tub² | General purpose |

| NYCO GN 3058 | Synthetic | $27.00 | Hartzell props |

| ¹Mobil 33 grease not recommended for wheel bearings ²Mobil SCH-100 not available in tubes, only 4.4-pound tubs or larger | |||

[This article has been updated with the correct NYCO grease type and Mobil small quantity availability.]

Note on Mobil SHC 100 not being available in tubes, you can buy it in tubes on Amazon for $13.99. Been using on my RV-12 wheel bearing for several years.

What an awesome article. I’m just about to the point of building up my RV wheels and Kitplanes never fails to have the article I need right at the time I need it.

Hi Dave, great article, I represent NYCO in North America, manufacturer of the NYCO Grease GN 3058.

The product is available at multiple vendors accross the USA. I will be happy to support any of your questions, please reach out to me at: [email protected].

Great article on ingredients of grease Dave. Buy stock in Amazon but, buy your tube of Mobil SHC 100– at graingers.com under $8. Sorry for being late to the party.

GREAT article although if you’re not up on post Covid supply shortages, Aeroshell 6 is in very short supply. If you’re fortunate enough to have magnanimous friends, you have a source, otherwise happy hunting!

V/R

Smokey

Not going to lie. My EXPERIMENTAL Wheel Bearings get packed with a marine trailer wheel bearing grease. High retention, doesn’t spin out and the rollers and races don’t pit or corrode. It’s a quarter of the price of anything that says “aero” on it. My AP doing the Condition Inspection always comments the bearings and races look like new. So does the grease. Live in a coastal tie down outdoors.

Elsewhere – I use as recommended by the component maker.