Our Creative Homebuilder has made many specialty yokes over the years, both for general service and highly specialized uses. Very little machine work, mostly simple welding, is involved in any of these yokes, making them good candidates for construction by home hobbyists. This month, we share several of his Make-Your-Own (MYO) creations, which we hope will inspire your own designs. We also share his design for an MYO adjustable squeezer ram.

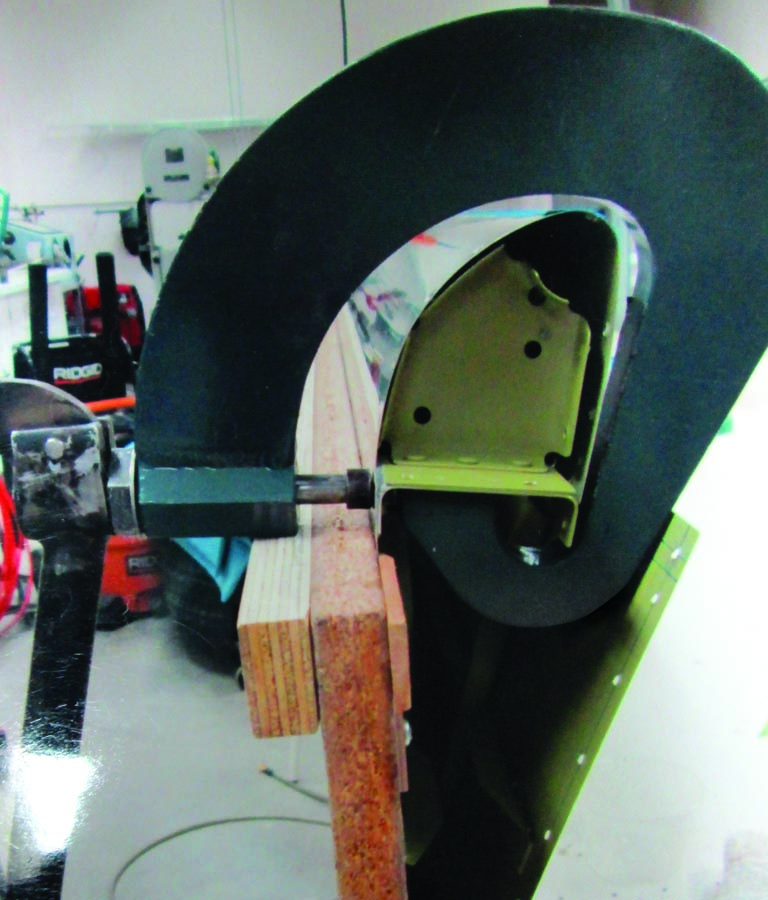

One of our Creative Homebuilder’s MYO specialty yokes. This one was made for unique conditions on his RV-3 aileron top spar rivets.

Aileron yoke in use on an RV-3 aileron top spar. The bottom “flat” on the coupling nut used to connect the yoke rests on the plywood jig shown in the picture. By adjusting the aileron up or down before “fixing” it to the backing plate, the operator can simply slide the squeezer along the rib while clearing the nose of the aileron, and then squeeze the rivets without abusing the aileron. The Creative Homebuilder notes that with 0.016-inch skins, it doesn’t take much contact to result in damage, so he designed the system to be as simple to use as possible while avoiding contact with any portion of the aileron except the rivet locations.

MYO yoke specially designed for the Creative Homebuilder’s RV-3 flap top spar rivets. Also note the handles that have been re-indexed from vertical to a 75-degree offset for added ergonomic benefit.

A general “specialty” yoke welded up in about 15 minutes from individual pieces of key stock in inventory when a special need arose.

The Creative Homebuilder’s biggest MYO yoke to date, “Big Mama.” The yoke has a 30-inch throat, 4.5-inch depth, and a 5000-pound pneumatic head. It is made out of A36 mild steel, with two 3/4-inch laminations skip welded around a 1.5-inch core. With an adjustable lower mandrel, very sensitive adjustments can be made relative to dimpling or setting rivets. Big Mama resides on a rolling stand with adjustable height so that the working height can be changed for convenience when necessary.

MYO yoke made for spar production within certain dimension parameters. With a 6000-pound tandem squeezer driving the rivet, the Creative Homebuilder calculates about 0.004-inch flex during operation. This yoke is also made of laminations of mild steel and weighs about 60 pounds.

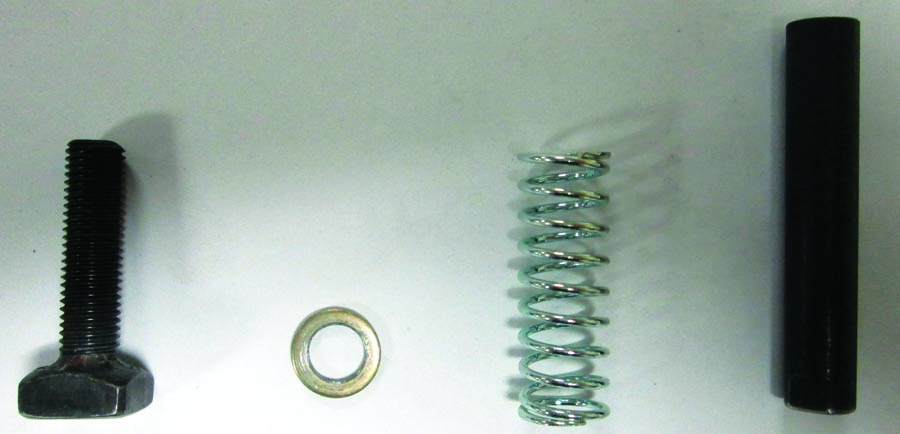

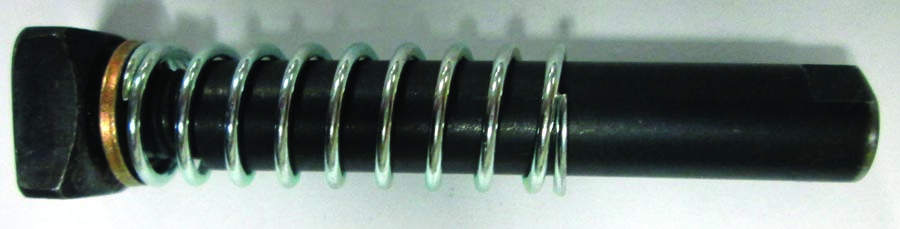

Parts for an MYO adjustable squeezer ram. From left to right: 5/16-24 B7 all thread tapped and welded into a -inch square nut, AN960-4 washer bored to 5/16 inch, a compression spring, and a factory-made (sold by ATS) adjustable ram sleeve ($8.25).

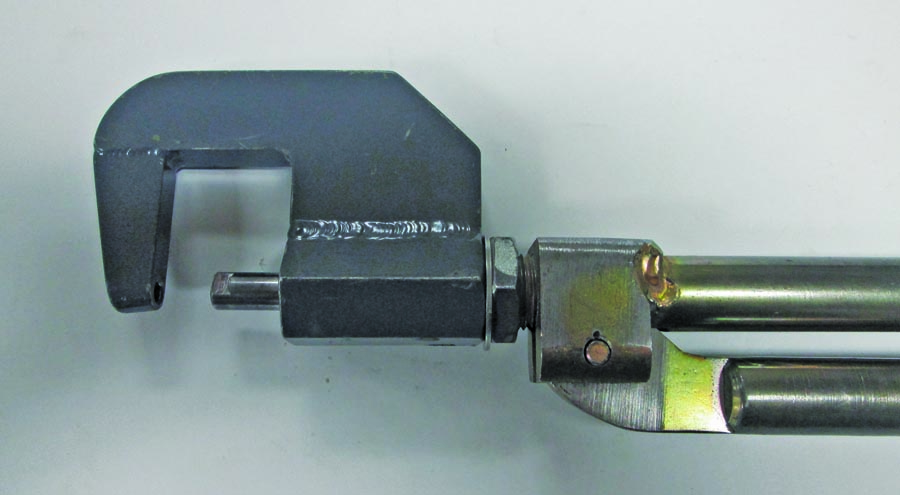

Close-up of the assembled squeezer ram. Total cost was about $12 for the entire set—much cheaper than those manufactured and sold commercially.