After a very steep approach, the gyroplane flared just above the grass and gently settled to the surface without any landing roll. That really got my attention. The pilot then spun up the rotor, applied power, and departed in about 100 feet of ground roll—impressive, since I have spent the last forty years modifying Cessna airplanes, trying to achieve very short takeoffs and landings with good results, but nothing that short. This took place “down on the farm” at Oshkosh several years ago, and it made enough of an impression that it became my next project.

The gyroplane is a rotary wing aircraft, but not a helicopter, since it does not power the rotor and thus cannot hover. The rotor is powered by the air traveling up through it, as it is always tilted somewhat back as the gyro is propelled forward by a pusher engine. The gyroplane is not affected by wind nearly as much as a fixed-wing aircraft because of the high wing loading (rotor loading), which takes you through the thermals without the big bumps.

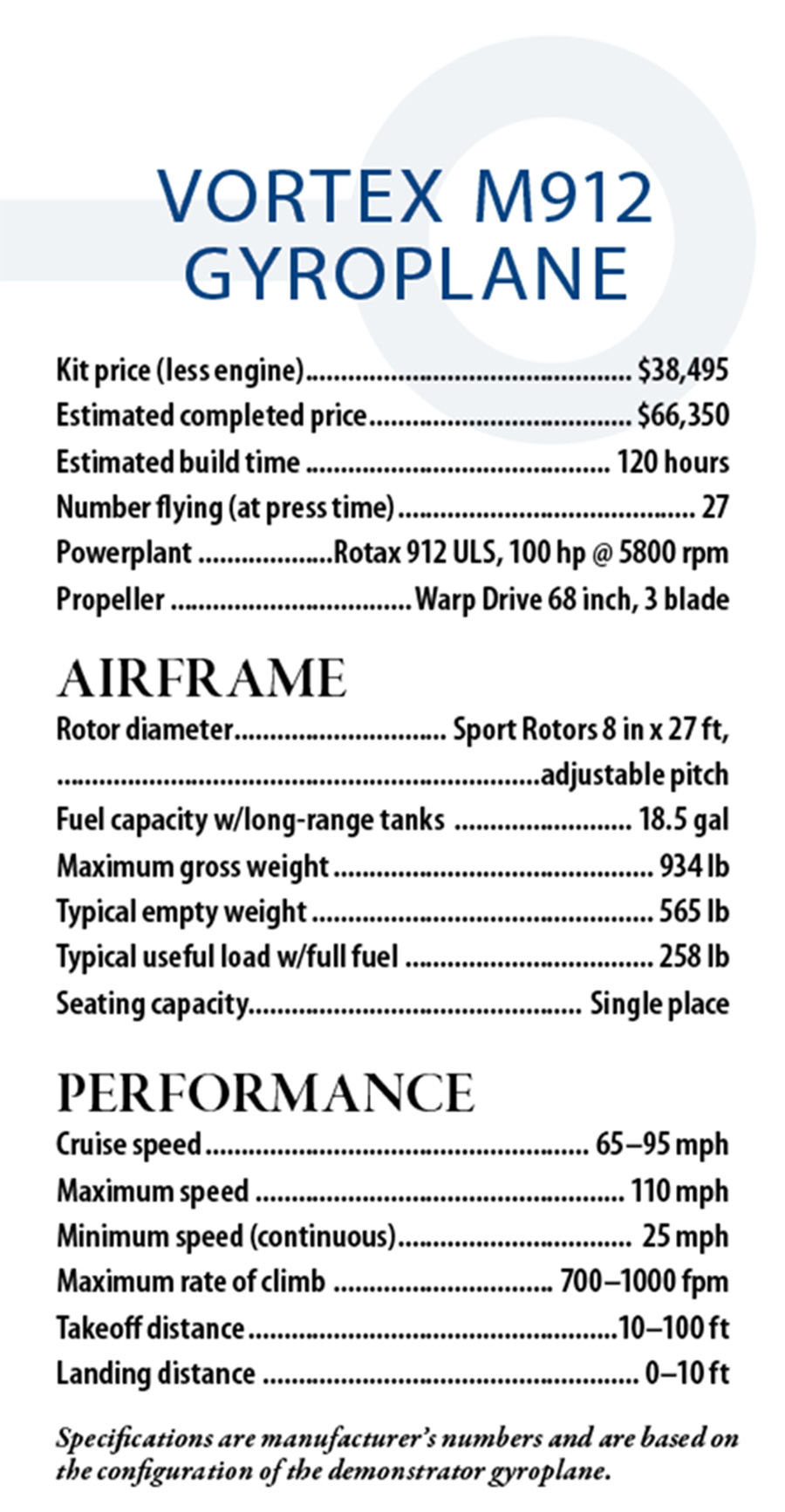

The wind always blows in my part of the country, so being able to handle wind is important to me. Landing into the wind with zero ground roll is the clincher. I was hooked, especially when I realized that I could get into a gyroplane for under $60,000. That is a lot cheaper than a helicopter.

The Vortex kit is complete and well organized—individual small parts are shrink-wrapped on cards and easily identified.

My Choice for Off-Roading

Talking to knowledgeable people in the rotary-wing community lead me to Sport Copter of Scappoose, Oregon. Their kit is extremely well designed and every part is powder coated or otherwise protected from corrosion, making it a quality product. Also, they provide flight instruction to their customers, which is extremely important. If you want a long life, do not train yourself.

The Vortex M912 is a completely redesigned Vortex model that came about while Sport Copter was designing a gyroplane that could handle the rough use dished out by Australian ranchers. To accomplish this, the Vortex M912 is designed with a state-of-the-art suspension system. It has 11 inches of travel and rate-sensing shocks with heavy-duty springs that can handle fast rates of descent with safe recovery. The tailboom is extended to place the horizontal stabilizer farther back to handle the extra torque from the 100-horsepower Rotax engine. The large rudder, plus the large end plates on the horizontal stabilizer, provides great stability and directional control.

The author hangs the new Rotax 912 on the frame of the gyro. Building the gyro involves little fabrication—the majority of the work is assembly.

Putting it Together

The kit arrived in January. Unpacking shipping boxes revealed that all the small parts were shrink-wrapped on cardboard squares. Every bolt, nut, cotter key, washer and all small parts are all on these squares. The squares are marked to correspond with a page in the construction book. This book contains a lot of pictures that aid in understanding exactly how to assemble a part. The kit is all assembly, no fabrication, so it goes together very fast.

I was concerned about meeting the 51-percent rule since the gyroplane kit is just assembly, so I downloaded the FAA checklist for determining compliance from the Popular Rotorcraft Association web site (www.pra.org). After filling it out, I knew I had easily built more than 51% of the kit, but I still felt the need to meet with the FAA district office to see if they agreed. It would not be a good day if they determined that I did not meet the rule, so I scheduled a face-to-face meeting. This turned out to be a good idea, if for no other reason than peace of mind. To my relief, they agreed that according to my information, I met the 51-percent rule and they would be glad to do the airworthiness inspection.

If a builder wants to build at the factory, they are happy to make that happen for a price. Doing this means that you will never have to wait for missing parts and will quickly be flying your own reasonably-priced STOL gyroplane.

The instrument panel of the M912 is simple, but provides everything the author needs in a compact package.

Training to Fly

My Vortex gyroplane was basically completed by the middle of May, so I traveled to Scappoose, Oregon to get the training I needed to be a safe gyro pilot. On arrival, I found out that being a longtime tailwheel pilot is a big help. Ten days later, I was on my way back home to finish the gyro and get it inspected.

Part of the pre-flight ritual is to clean the bugs off the leading edges of the rotor blades with a mixture of water and wax.

Flying the Vortex M912 is very much like flying a fixed wing—but with a few very important differences. The stick (called the cyclic) tilts the rotor to provide control response the same as a like movement in a fixed-wing aircraft. Pulling the stick back tilts the rotor back, thus you go up. The rotor takes the place of the elevator and ailerons. Preflight includes cleaning the rotor blades with rotor wash (a mixture of water and wax), in addition to checking the oil, water, and giving all fasteners a good look. Then you mount up, strap in with seat belt and shoulder straps, and release the rotor brake. Master on, ignition switches on, choke applied, then engage the start switch to bring the Rotax to life. The throttle is not cracked as that will not allow the choke to engage. The 100-hp Rotax starts instantly, the choke is slowly disengaged, and the throttle is moved off the stop to secure a fast idle. The two Bing carburetors on the Rotax 912 are altitude compensated, which eliminates a mixture control. Primary steering input is accomplished by independent, toe-operated hydraulic disc brakes. To taxi to takeoff position requires light taps on the brakes because the nosewheel is free castering.

The gyro features a large windshield, but wide open sides keep you in constant touch with the air and your surroundings.

Getting Airborne

Once the engine is at operating temperature, the prerotator is engaged at about 2000 engine rpm. The prerotator is operated by a belt on the prop shaft to a pulley on a flex shaft, which goes up the mast to a Bendix. When tension is applied to the belt, the Bendix kicks in to engage the ring gear on the rotor. The whole craft shakes as the belt slips to get rid of some torque. Then, as the rotor gains speed, the belt is tightened more and everything gets smooth. At 250 rotor rpm, the prerotator is disengaged, the power comes up to full, brakes are released, the cyclic (stick) is held full back, and within seconds, the nosewheel comes up. The stick goes forward a little to stop over-rotation, and off it flies. Level-off in ground effect to allow the gyro to gain speed, and then start the climb. At 4000 feet msl, the Vortex climbs 700 feet per minute at 45 mph indicated. The process just described is for a short-/soft-field takeoff technique that is used to depart from rough ground.

Sport Copter president Jim Vanek adjusts the rotor tracking on the author’s M912 during a factory visit.

Cruising

Level at cruising altitude (typically the legal minimum), the power comes back to 5000 rpm (75%), which results in 60 mph showing on the airspeed indicator and 350 rpm on the rotor tach—and I can start breathing again. The wow factor is off the charts. Every powered parachute and trike pilot knows what I am referring to. In the Vortex, as with many gyros, I am sitting behind a windscreen, but very much out in the open and that makes you feel very alive. Wind comes in from the open sides. A slight vibration is felt coming from the rotor, giving one the feeling that they have a hold on a living machine. The controls are not oversensitive. They feel just like a fixed-wing aircraft: not too light or too heavy.

Cruise flight (65mph) is slow enough to have plenty of time to look at everything on the ground—and I mean everything. Passing an outhouse with an open door, I see that it is occupied, so I wave. Passing a junk pile, I have to circle to see if there is anything that I could use. Low and slow is a world of joy.

Maneuvering

Maneuvering flight really brings out the difference between fixed wing and rotary wing. The gyro is very maneuverable, requiring a fraction of the turnaround space of a fixed wing; still it has a lot of drag with 27 feet of rotor spinning as it is being pushed through the air, so it takes a while for increased power to make a performance difference. The gyroplane will not stall, but sure will go into a sink at too low rotor rpm. I do a vertical descent by taking the power off. The gyro descends straight down in a level attitude with full control, but full power and nose-down stick are needed to stop the sink before reaching the ground—failure to do so might hurt. The rotor does not care which direction it is going, so the gyro will turn around in a tiny space. It does take a lot of power to keep the rotor rpm from decaying too much during the turnaround. The 100 hp Rotax really helps.

From a rotary-wing pattern of 500 feet msl, you can land a gyroplane much like a fixed-wing aircraft by keeping some power all the way to the landing, but I prefer the no-roll landing since I land off airport. I do that by removing all the power and establishing a 45 nose-down angle while maintaining 45 mph. The gyro is flared just inches above the grass as the rotor is tilted back and becomes a big air brake. The forward momentum stops, the rotor is making the wump-wump sound, and the gyro settles to the surface. If the wind is blowing, the gyro will go back up if you don’t level the rotor after landing.

Mod Time!

After I’d flown the gyro for a year, I began to get concerned about the rough treatment it received from all the off-airport landings, so I decided to have the experts look it over at the factory. The excuse for such a long trip was a gathering of Cessna pilot friends who are meeting at McMinnville, OR (home of the Spruce Goose) the last weekend in June. A few days with good friends is vital for good mental health, so I removed the rotor, loaded the gyro into a van trailer, and headed out to Scappoose, Oregon 10 days early. This would give me a week to work on my gyro, have the experienced factory people go over it, and add some upgrades. As I drove, I considered the upgrades I planned to install. Jim Vanek, owner of Sport Copter, has devised a simple rubber-clad extension on the prerotator belt engagement lever that applies a brake to the prerotator shaft pulley when the prerotator belt tension is released. This action kicks out the Bendix, making sure that the whole prerotator system does not stay engaged during flight. I have experienced the Bendix staying engaged during takeoff, which causes a lot of vibration. This simple idea solves that problem, so it is a must-have.

The author installed a smaller radiator with louvers (here, partially closed) to replace the large radiator that required duct tape to keep from over-cooling.

Also, greasing the shaft on which the Bendix travels requires removing it, applying grease, then reassembling. Safetying everything again is not a fun job, so Vanek solved this problem with a grease fitting in the top of the shaft with passageways to keep the area under the Bendix well-greased. I love it when my workload is reduced, so this was another must-have. The folks at Sport Copter never stop improving their products.

Sport Copter is working to integrate the Viking engine with the M912 airframe to provide about 10% more power than the Rotax.

Another reason for this trip to Oregon was to install a smaller radiator. A gyro pilot/rancher in Australia, who goes by the handle of “Birdy,” told me that my radiator was too big when I posted pictures on the Rotary Wing Forum. My cowboy solution to keep the oil temperature up was to close off most of the radiator’s excess capacity with duct tape. At the Oregon factory, I installed a smaller radiator with adjustable louvers so I can close them off as the weather gets cold. This replaces the need for duct tape, which actually works very well and is cheaper, but I am trying to impress my friends with this really cool idea of being able to change airflow through the radiator while in flight.

One day as I worked on my gyro at the factory, I noticed that Vanek was intently looking at my horizontal stabilizer. He told me to remove it because it did not look right. I removed it and using an electronic level on the spar, we discovered that I had bent the spar during one of my rough landings. After Vanek saw what I had done to the horizontal stabilizer spar, he changed to heavier tubing to make the spars stronger, which will withstand the heavy use a cowboy dishes out.

My want list for this trip to the Sport Copter factory also included the idea of adding a trim system to my gyro so I can use both hands to take pictures (and other legal things) and the gyro will fly hands-off. When I brought up the subject, Vanek told me about the trim system used on the Sportcopter II. So, in the near future, we will have a power-trim system on my gyro operated with a toggle switch on the stick, much like the fancier aircraft. He is also testing the idea of a damping system on the rotor to reduce vibration.

After a balancing test showed that I had not caused any damage to my 27-foot rotor by flying roughshod, the rotor was mounted on the mast and tracked. The experts at the factory do this with reflectors out on the end of each blade, so they can use a flashlight to see each blade’s track. If the reflections are not on the same path, they make adjustments to the hub bar to bring them in line. After adjustments, my machine has considerably less vibration then before, and with the new damper, it will be nearly vibration free and a great platform for taking pictures.

![]()

Karl Storjohann is a retired livestock nutritionist who used highly-modified conventional-gear Cessnas in his business to travel ranch to ranch for 40 years and some 6700 hours. He now regularly flies as a Sport Pilot in his aerobatic Sonex and Vortex gyroplane.

Karl Storjohann, Congrats for your details and experience. Excellent article.

nice job