Against high-stacked odds, a company like Porsche is able to sustain its place in the automotive firmament and even expand its offerings into new categories for one big reason: The car we generically know as the Porsche 911, that ageless yet continually refined sporty coupe, remains steadfastly in demand. And while the nameplate edges to within two years of turning 50 this fall, the iconic coupe has remained fresh and desirable through the company’s relentless development efforts that, some time ago, were forcefully directed by the faithful along the lines of, “Do what you want to the underpinnings, but always make it look like a Porsche 911.”

State of the art circa 2006, the avionics in Larson’s panel have held up well and provide excellent IFR capabilities. Dual Cheltons feature datalink weather.

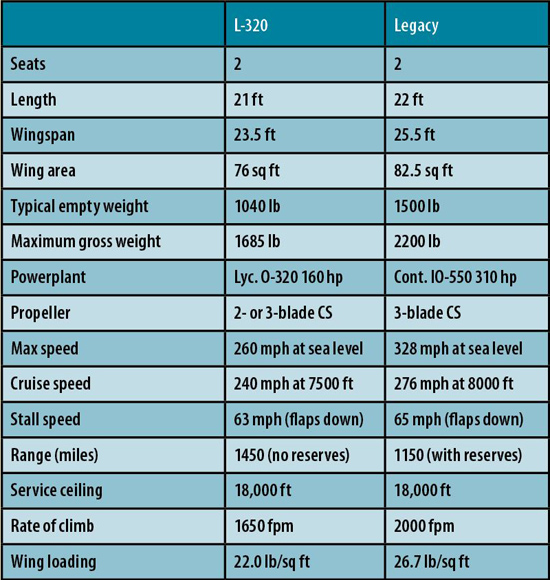

A parallel to the Lancair Legacy forms naturally. It’s true the two-seat Legacy, a thoroughly developed rework of the seminal Lancair 200-235-320-360 design, is less practical than the company’s own Evolution. The cabin is shrink-wrapped around its occupants, baggage needs to be soft-sided and light. Next to the larger, more broad-band Evolution, the Legacy seems tightly focused, and it shouldn’t surprise the curious that Lancair has sold far fewer of them recently than the newly minted model. (According to Lancair, the eighth Evo flew as of mid-May, with No. 9 ready to go “any day now.” A total of 37 Evos have been sold.)

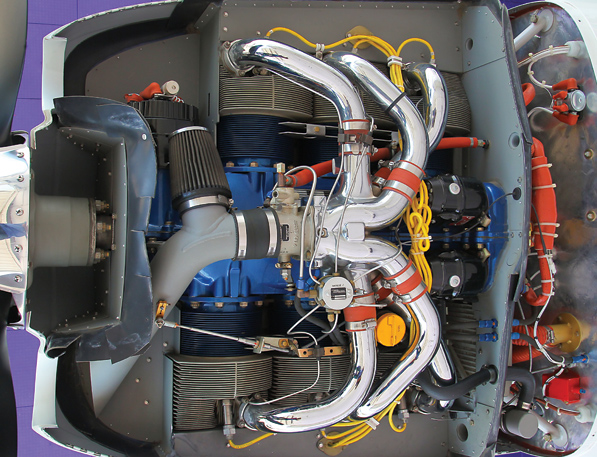

You don’t have to be a plane spotter to realize there’s a big honkin’ engine behind the Hartzell propeller.

Copy Machine

While the Legacy’s original design leveraged strongly off the first generation of Lancair two-seaters, it was substantially revised and modernized. For example, the retractable-gear version is almost all carbon-fiber composite, where the original was a mix of conventional fiberglass and Kevlar. In addition, the Legacy was designed from the start to carry the Continental IO-550 engine that was standard fare in the Lancair IV.

While the baggage area is reasonable for two, a ski tube (behind the circular cutout) can accommodate light, bulky items.

Seeing that the market for a fast, expensive two-seater could use a bit of invigorating, Lancair, in 2004, introduced a fixed-gear version of the Legacy intended to be lower cost, powered by a four-cylinder Lycoming, and made, again, of mostly fiberglass with some carbon-fiber reinforcements in key structural areas. The price difference wasn’t great enough to spur demand, so the retractable-gear Legacys outnumber their fixed-gear brethren by a substantial margin.

More recently, Lancair created and built two prototypes of the Synergy, described as a “Legacy fixed gear and a half.” Designed for primary training and funded by a contract with the Columbian government, the Synergy features a wider cabin, larger canopy, more wing area (for lower stall speed) and a larger horizontal tail. The first two were built at Lancair’s Redmond, Oregon, facility, but the remaining 23 ship sets were delivered to Columbia for local buildup. According to Lancair, a civilian version of the Synergy could be viable under better economic circumstances.

Right for the Mission

You might think that someone who flies an Airbus for FedEx would be predisposed to owning a large personal airplane that could haul stuff. In this case, you’d be wrong. Erik Larson undertook his Legacy project in 2006 because he recognized that the airplane fit his primary mission extremely well. “My wife, Terri, and I love to fly, and we have two sons in Northern California,” he says. (Larson bases out of the Carlsbad airport north of San Diego, California.) “We wanted an airplane that could get to them quickly, and make even day trips feasible.”

Erik Larson. Why is this man smiling? If you owned a Legacy this nice, wouldn’t you?

Larson began his search looking for an already built Legacy to buy, but there was nothing on the market at the time. “So I set about to build one. I really didn’t want the project to stretch over a long period of time. I had built a VariEze in the late 1970s and had it flying by 1980, so I knew about composites and how to plan a build.” But he also appreciated that the Legacy, with a more complicated airframe and the expectation of very sophisticated avionics, would be a different animal.

So Larson took advantage of as much assistance as the law allows. “I started with the week-long course at the Lancair factory,” he said. “It was fast-paced. We got a lot done in five days, closing out the wings, vertical fin, horizontal stab, and then attaching the stub wing to the fuselage. Using Lancair’s jigs was great, but we did almost nothing in terms of the systems.”

Layovers and Layups

That would wait until he got the airplane home. “I was fortunate to be fairly senior at FedEx and got to plan my layovers into San Diego. It made sense to bring the Legacy to Ron Gregory’s shop [R.G. Composites], which is just across the road from the Palomar Airport.” There, Larson worked regularly on the project and it took shape quickly. He continues to praise the quality of the kit, which might be expected when your previous experience is with glass over raw foam.

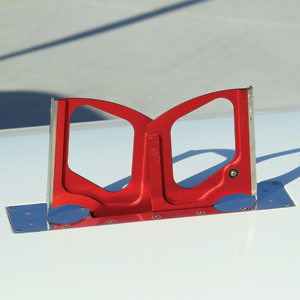

Precise Flight speed brakes make getting down from altitude a snap.

In Gregory’s shop, Larson used the talents of Doug Hughbanks for the avionics work. “I like the dual-screen Chelton system,” recalls Larson. “It was state of the art at the time. Of course, I got caught up in the Direct-To avionics fiasco [where the company principals left town with customers’ money], which cost us some time, as did delays getting the engine from Performance Engines.” In all, the project slipped behind schedule by three months, which isn’t much considering how far the average build gets pushed back. “I have to say that working with Ron and the guys was a delight, and it allowed me to split my efforts between the actual act of building and managing all the other aspects of the build.” Larson had learned the hard fact that only a portion of any project is in the doing. Much time is wasted tracking down parts, exacting delivery from vendors and the thousand other niggling aspects of the build.

Larson also credits Andy Paterson, who used to work for R.G. Composites before going out on his own. (His work was featured last year in KITPLANES®: See “Detail Man,” August 2010.) A lot of the fit, finish and detail in the project has Andy’s signature on it. Also on the list of credits are Melissa Shurmer (upholstery) and Alex Carrillo (paint). Carrillo is a well-known car painter in San Diego, so Larson had to take the Legacy to him in pieces.

Continental’s IO-550-N is among the best traditional aircraft engines at balancing power and fuel efficiency.

A Year, Already?

By pushing hard and using every available day off, Larson and the crew were able to finish the airplane in a year, a remarkable feat considering the scope of the project. Larson’s extensive flight experience—does 25,000-plus hours qualify?—gave him the confidence to do the first flight, but only after he’d worked out some dual time in another Legacy. “It went very well,” he says of the first flight from Palomar. “Only very minor issues. It did take some months to get all the avionics working properly.”

Walking around Larson’s Legacy is to appreciate the quality of his and his team’s work and the thoughtfulness in the execution of the few modifications. For example, a ski tube extends from the rear baggage bulkhead, perfect, he says, for the canopy cover or other light, bulky items. Boarding steps drop from the belly behind the flaps as part of the canopy-latching mechanism.

Leather-lined and swoopy, the Legacy’s interior coddles two fast-moving occupants.

Performance at Hand

For someone who flies an Airbus for a living, raw speed can fail to impress. But not here. “I’m totally thrilled with the airplane,” Larson says. “In the terminal environment, you’re flying jet speeds, close to what we do in the Airbus. Climb performance is great. We typically cruise-climb at 170 knots indicated [KIAS] and get more than 1000 feet per minute. Typical cruise, rich of peak [EGT] is 235 knots true [KTAS] at 11,500 feet. If I want to economize, I can run lean of peak and do 228 knots on 11.5 to 11.7 gph. It’s amazing. We’ve compared the trip to Northern California flying versus driving, and the Lancair consumes about the same amount of gas as a nice car. Plus we’re going so much faster.”

The Legacy features a larger wing than the two-seat Lancairs that came before, as well as additional fuel capacity, now 66 gallons.

One knock on the earlier two-seat Lancairs was fuel capacity, but the Legacy responds by having 66 gallons on board. That’s not a lavish amount for a 310-plus-horsepower engine, at least in terms of the endurance aloft, but the range is still respectable because of the airplane’s speed. “You must have a plan, know where you’re going to go,” Larson says, describing the need to remain ahead of the airplane. “It’s like a jet in that way, too. You can’t go up and not know what you’re doing.” Both the climb performance, which lets you get around weather and above much of the summertime turbulence, and the Precise Flight speed brakes, which allow rapid descents from cruise, increase the Legacy’s utility. “I can’t imagine flying this airplane without the speed brakes,” he says.

Superlative performance, excellent handling (see the sidebar “From the Flight Deck,” Page 12) and true utility are present and accounted for. What’s the downside? Only cost. To his credit, Larson didn’t dodge the question. “I have an investment of around $350,000 into this airplane,” he says, amazingly without a catch in his throat. (And in public, so his wife obviously knows already.) But he’s quick to turn it around, wondering what other airplane will do as much for the money.

Current prices for the Legacy kit are $71,500 for the basic airframe. Treble the cost as a rough estimate and you can see your own investment rise above $200,000. In truth, the Legacy is in a class of airplane where few owners skimp, so all-new, high-performance engines are the rule (there’s $60,000 to $70,000), as are top-line avionics, professionally applied paint and sumptuous interiors formed by those who do them for a living. Consider that a new Cessna 182 (with Garmin glass) is on the far side of $400,000 and that the well-equipped Cirrus singles passed half a million dollars some time ago, and look again at the wisdom of Larson’s investment. Put it this way: When he’s around his Legacy, he’s always smiling.

For more information, call 541/923-2244, or visit www.lancair.com.

Nafziger (right) and Larson get ready for their flight in the Legacy.