Working with little funding, fledgling devices not quite adequate for what they need to do, and learning the skills necessary to make a project successful while in the midst of making it a reality—things were the same fifty years ago for the average homebuilder as they are today.

But Fred To (pronounced Tow) is not the average homebuilder. Not many of us can say we’ve blown up an airplane with a leaf blower and pedaled it 20 feet in the air the length of a runway. Not many of us can say we’ve built a first-of-its-kind aircraft exploiting the oldest power source in the world. To has.

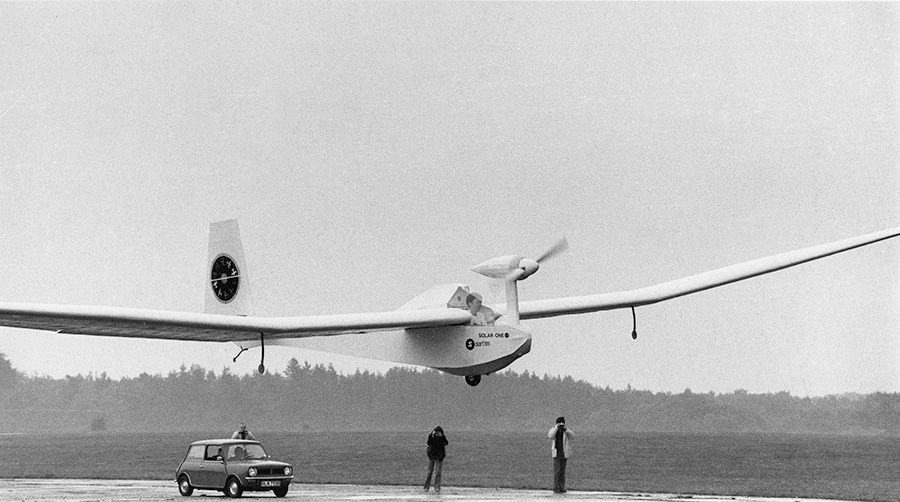

Solar One

Flight International of June 30, 1979 announced a flight of three-quarters of a mile for To’s Solar One, constructed of wood and covered (appropriately enough) with SolarFilm, a model-airplane product resembling a popular food wrap. Pulled into the air by four Bosch moped motors clustered around a single propeller, Solar One was powered by batteries charged by the light of the English sun. It performed well, considering the constraints under which it was made.

The magazine reported two flights, each the length of the runway. The first, piloted by Ken Stewart, reached a maximum altitude of 59 feet, took off at 18 to 20 knots (20.7 to 23 mph), and topped out at 35 knots (40.25 mph). The second, flown by Bill Maidment, reached 42 knots (48.3 mph).

Its sailplane-like configuration, 230-pound empty weight, and 260-square-foot wing with a 68-foot span, helped it fly on a mere four horsepower. The motors, chained together and providing torque to a 3:1 reduction drive, pulled a 5-foot, 3-inch diameter propeller at about 1100 rpm at full tilt, but slowed, Flight International explained, “as the batteries [became] exhausted.”

The batteries were minimal to the task at hand, consisting of 24 nickel-cadmium cells joined in series. The 25-amp-hour capacity provided enough power for the airplane to climb for about eight minutes, although they still held “enough useful energy for several more minutes,” as the magazine noted somewhat ambiguously.

To explained why he and the team made these demonstration flights over six months after the actual first flights. “We flew Solar One on one cold and freezing 19th of December 1978, much before the USA or anyone else flew. We kept it a secret as we had only managed a hop. When I read that Larry Mauro had claimed to be the first, we decided to announce our flight to the press; this was later in 1979.”

Fred To (left) and David Williams (right) show off solar cells to a team member. The number of cells was limited by To’s personal finances.

To relied on David Williams, who he describes as “a key figure in the design and building of the aircraft.” Pictures show To and Williams working in To’s garden shed workshop while farm animals frolic outside. To received mentoring from Frank Irving, a lecturer at the Imperial College aeronautics department, “excellent gliding pilot,” in To’s words, and contributor to the aerodynamic development of Formula 1 racers.

He also obtained counsel from Fred Militky, who with his partner, Heino Brditschka, had converted a two-seat motorglider into the world’s first human-carrying electric airplane in 1973.

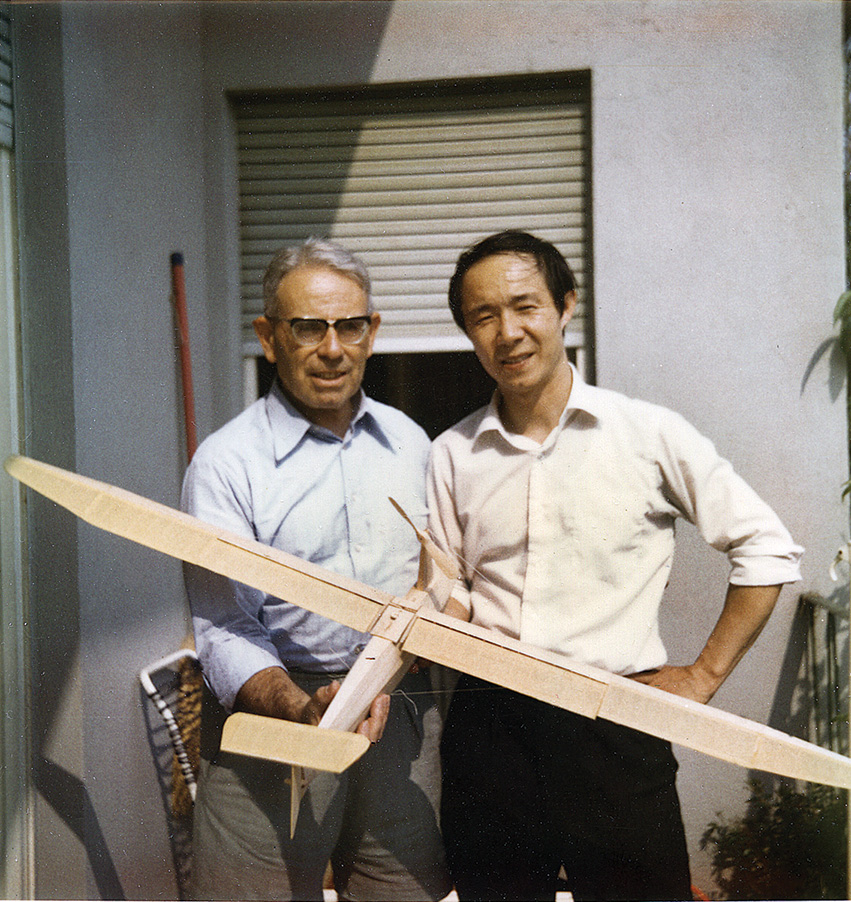

I noted in one exchange that Solar One looked a great deal like the Haessler-Villinger human-powered aircraft from the 1930s. To sent a picture of himself with Franz Villinger, a good friend, holding a model of Solar One. This resemblance may have led to the erroneous Wikipedia entry that To’s solar craft was derived from an original, but overweight, human-powered design. “Absolute rubbish,” To says. He designed it from the start as a solar-powered entity.

Ian Parker flies Solar One on a press demonstration day, not one particularly suited for demonstrating solar power.

To had approached DuPont in 1977 with the idea of a cross-channel solar-powered flight. DuPont elected to back Paul McCready and his Solar Challenger instead, forcing To to finance Solar One with his own money. This left him able to purchase fewer than half the solar cells needed for continuous cruise (NASA supplied Solar Challenger’s cells).

Franz Villinger, who with Helmut Haessler built a successful pre-war human-powered airplane, the Mufli, inspects a model of To’s Solar One—which bore a strong resemblance to the earlier HPA.

“We sat Solar One on the runway for some time before each flight attempt in order to charge the nickel-cadmium, on-board batteries,” said To. “I guess Larry Mauro had to do the same. That does not detract from McCready’s achievements. I think his team did give me some credit towards this flight attempt. Solar One was, of course, designed to cruise continuously under solar power; it had the right wing area to carry this off.”

The same airplane with today’s highly-efficient thin-film solar cells, much higher energy-density batteries and ultralight, permanent magnet brushless motors would undoubtedly achieve those aspirations easily. In 1979, lithium-ion batteries were still in laboratories, with Sony introducing them commercially in 1991. The highest-efficiency solar cells then were three-inch disks capable of capturing 14% of the energy that fell on them.

To later turned the aircraft over to the Cranfield aeronautical department for students to work on and later sold it to a friend. He has no idea where it is now.

Despite the groundbreaking firsts he achieved with Solar One, To is somewhat reserved about it all. He says, modestly, “I wouldn’t rank our flights anywhere as significant as the Wright brothers; what they did was ground breaking. Solar powered flight is about putting a few known techniques together.”

Starting off as an architect, To didn’t like that profession and taught himself to make movies, one of which “was a documentary on human-powered flight. That’s how I got into aviation,” he said. His fascination with human-powered flight led to a truly unique contribution to flight.

Phoenix, a 102-foot span airplane carried atop a compact car—one of the joys of inflatable aircraft. Left to right; Barbara Luff, Fred To, Beverley Poole, Ian Parker—pilot, Margaret McQuaile, unidentified.

The Phoenix

If not the largest, Phoenix is definitely one of the largest homebuilt airplanes ever, with a span of 102 feet and wing area of 1666 square feet. For comparison, an Airbus 320’s wing area is 1319 square feet and the Boeing 737’s is 1700 square feet.

Made of polyester film with lightweight sailcloth webs, Phoenix was initially slated to weigh a mere 85 pounds. Repairs and additions to the structure for aerodynamic improvements raised the final aircraft weight to 110 pounds, still astonishing for a flight vehicle of that size. Wing loading would be 0.066 pounds per square foot—more model-like than airplane-like. The Reynolds number at 8 mph was about 1.2 million, at the high end of human-powered flying machines, and was brought about by its wide chord.

Phoenix required 1/3 horsepower to turn its 18-foot propeller at 45 rpm and make 11 pounds of thrust, which allowed it to take off and reach its 8-mph cruising speed. To allow the pilot to concentrate on making power, the airplane had a total of 11 radio-controlled servos on its elevons, controlled by either the pilot or remotely controlled by an operator on the ground. To says it was a true fly-by-wire aircraft.

Mechanical connections between the pilot and control surfaces would have been problematic, since the wing expanded when it was inflated, the pressure causing the span to grow from its uninflated state.

The propeller was a marvel in itself, constructed as To notes, “like a giant model aircraft wing,” and weighing all of 6 pounds. Each trussed rib, made of balsa stringers, weighed about 1/8 ounce.

The airplane weighed roughly a few pounds more inflated than it did when flat, but the volume inside affected takeoff performance. The “huge mass of air trapped inside the wing…had to be accelerated also,” according to To.

Luckily, it was extremely stable, especially in pitch, allowing the pilot to concentrate on that all-important pedaling. Making its first flight on March 28, 1982, it followed with many short, but successful, flights (including two by To himself) at London Dockland, now London City Airport.

Derived from the Reluctant Phoenix, an earlier inflatable that To inherited from the late Dan Perkins, Phoenix followed the logic that Perkins had explored. He had noted that early HPAs fared badly in crashes, being reduced to spruce and balsa kindling on contact with the ground. Paul McCready had attempted to overcome this by simplifying the structure, but Perkins made it “bounce-able” and crash friendly.

Their huge sizes created storage and transportation problems for those rigid and fragile monsters, so being able to pull the plug, deflate the airplane and carry it on a typical small car was highly appealing.

Perkins had built four inflatables, with his last having a 31-foot wingspan and an empty weight of a mere 39 pounds. Flying in a large airship hangar, it made about 90 flights. The relatively short wing, with its high span loading compared to other human-powered aircraft, probably made the pilot work harder.

Expanding on construction techniques used by Perkins, To used a series of long inflatable tubes laid spanwise to define the rough wing shape, connecting them with upright webs of light sailcloth between the upper and lower wing surfaces, then wrapping the connected tubes with an outer polyester film sheath that gave the wing an airfoil shape. Even at that, as he discovered on a 20-foot test model, there was not a true curved outer surface, but many flat stretches between the intersections of the long tubes. That this would affect performance was verified in wind tunnel tests. To added chordwise airfoil-shaped stringers to smooth things and enhance aerodynamics.

It turns out that all this requires more precision than I had originally thought; tolerances for connecting parts properly needed to be less than 1.0 millimeter and alignment was a critical factor.

(Left image) Tape channels helped define width and depth of contact cement used to bond all seams. Barbara Luff, on the left, and a woman remembered only as “Emma” had answered To’s newspaper ad for “two wizards at the sewing machine.” (Center image) Activating contact cement with heat from irons. (Right image) Sewing pins much in evidence as ladies apply leading edge to 18-foot propeller.

Constructors needed to cut the material precisely, pulling polyester film or fabric from trays under the long work tables, then marking, cutting and aligning them to suit the dress-pattern-like drawings that Burt Rutan would emulate with glass fabric for his -Eze series of aircraft.

To make successful bonds between the different films and fabrics, To spent eight months devising and testing materials and techniques.

To’s friends defined glue lines by laying two strips of masking tape on either side of the line where a T-shaped bonding tape would be glued to the structure. They then spread a thin film of contact cement in place and used the masking tape as a guide and thickness gauge for the adhesive. By squeegeeing the cement between the strips of tape, they achieved a well-controlled thickness.

Solar Powered Aircraft Developments logo, worn by everyone working on the project. Today, there would be an Internet address instead of a phone number.

Mating parts coated with the contact cement were allowed to dry, making it possible to maneuver them into position without their immediately sticking to one another as usually happens with such bonding. Once oriented correctly, the pieces could be ironed together, activating the adhesive and making for a secure bond.

Despite all the care, there was a slight twist in the spanwise structure at the end, not a total surprise because of its 102-foot width.

To’s experience with this type of structure led to his designing and building several others under contracts to European companies. He notes one aspect of such structures—their transparency to radar—that would make them ideal unmanned aerial vehicles with true stealth.

One conclusion I’ve come to from my correspondence with To is that there really are no limits to what can be made to fly. It might take careful thought and planning, but there are seemingly always ways to use unlikely materials and achieve even more unlikely goals. What might seem trivial or playful can often evolve into something purposeful and even transcendent.

![]()

Dean Sigler has been a technical writer for 30 years, with a liberal arts background and a Master’s degree in education. He writes the CAFE Foundation blog and has spoken at the last two Electric Aircraft Symposia and at two Experimental Soaring Association workshops. Part of the Perlan Project, he is a private pilot, and hopes to get a sailplane rating soon.