Translucent plastic panels are cut from 12-foot sheets of Suntuf, a durable polycarbonate material that is often used for greenhouses.

Like many young boys, I became interested in airplanes at an early age. I built quite a few model aircraft over the years. As I got older, one thing lead to another and about 20 years ago, I built a Challenger II kit airplane. After finishing that project and flying off the first 40 hours, I used a hangar that belonged to the EAA Chapter I’m a member of. But I soon realized a hangar of my own was a must.

I built a 32x40x12-foot metal hangar. Living in upstate New York in the winter, I soon realized that a hangar door was also a must. Upon pricing commercial hangar doors, I learned that I couldn’t buy what I wanted for much less than $9,000; so after researching all kinds of doors and reading everything I could get my hands on, I decided to build my own.

Living on Oneida Lake in upstate New York, author keeps his Challenger II on floats in the summer and skis during the winter.

DIY

I own a marina and as winter is my slow time of year, I spent most of it building the doors.

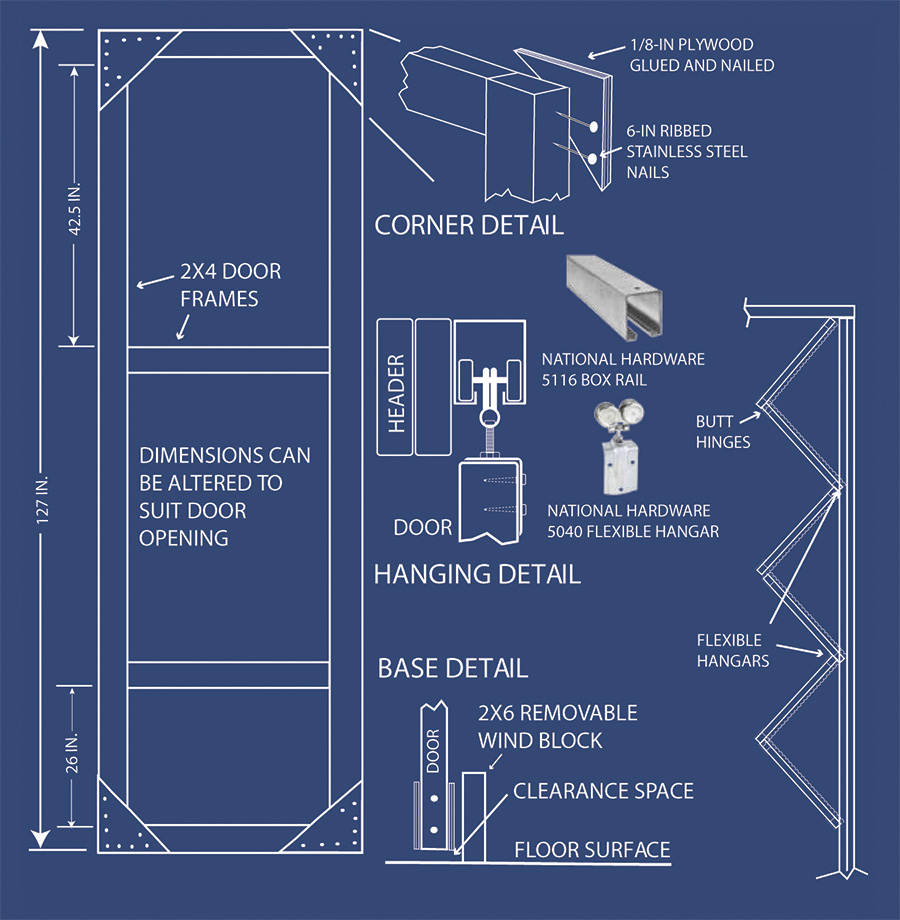

It was a learn-as-you-go project that turned out great. The design consists of multiple doors that hang from an overhead steep track. I built a jig to be sure the doors turned out straight and square. My hangar opening is 39 feet wide and 12 feet high, so I figured the sizes and made six doors for each side. I used 2x4s and glued gussets on all corners, using two 6-inch nails in each joint, as shown in the drawing.

I built a header to go across the hangar opening and beefed it up for added strength. I then installed a barn door track (purchased at Tractor Supply Co.) on the inside of that, so the doors would fold inside.

I then put one double set of rollers (also purchased at Tractor Supply Co.) on every other door. This allowed them to fold together so that they all pushed to each side. Each door has four hinges 3.5×2 inches, which I purchased at Home Depot for $1 each. The hinges that attach to the end wall have to be much bigger. After I finished building the doors, I put on a redwood stain and sealer before I hung them. I framed a doorway out of one of the twelve door frames to form a personnel door, to be able to go in and out without opening the whole set of doors.

Solar Option

After getting the doors all together, erected and working, I had to think about what to cover them with. I considered using steel, but then I discovered 12-foot sheets of clear plastic at Home Depot, originally made for greenhouses. The clear plastic is a corrugated polycarbonate called Suntuf and is virtually unbreakable. In fact, it has a lifetime limited warranty. The website is www.PalramAmericas.com. This plastic is nice to work with and can be cut with tin shears. They make three different grades. I used 20 sheets of the top-grade material at $30 a sheet.

The clear plastic allows the light to come in, making the inside nice and bright. My hangar faces almost due south, so that the sun shines in during winter, heating the entire hangar about 20 to 30 degrees warmer than outside. I plan to insulate it, which will make it even warmer. I also like to start my tomato plants in the hangar. They love the warm sunshine. Had great tomatoes last year. In conclusion, when all was said and done, the hangar doors cost me approximately $2,000.

Door frames are made from 2x4s fastened with six-inch stainless-steel nails. For additional strength, eighth-inch plywood gussets are glued and nailed at each corner. Butt hinges allow the doors to fold together.

Nolan Bradbury lives in upstate New York on Oneida Lake, where he operates a marina.

Nice door! Did you also build the hangar? Do you have plans for that? I plan on building a 40×40 hangar. I’m interested in the trusses as well.

Beautiful project.

Since all of the doors have the flexible hanger at the end of the door, when they are opened do they lean out? Or is the first penel fixed to the hanger to eliminate that?

Thanks for the info I am interested in a larger hangar door like this type that slides sideways: https://hangardoors.aero

do you think it would be possible to build this too?

I built my own overhead door with sliding door tracks, rollers and a Harbor Freight electric winch. Complete door cost about $1200. You can contact me for pictures. Also if you plan to build a hangar, build it 42 feet wide rather than 40 feet. I built mine many years ago at 42 feet and am glad I did. My Cessna 206 with wing extensions will fit but not in a 40 foot hangar.

[email protected]

Since I made my original post, I have had a number of people contact me requesting information and pictures of my door. I thought I would post a description. I have 20 pictures of the door but I couldn’t figure out how to post them so If you email me, I will send them.

It would be best if you came and took a look at the door. I am at the Ovid Airport, D82, Ovid, N.Y.

My door opening is 12 ½ feet high and 42 feet wide. I built it out of 2×4’s in 3, 14 foot sections using construction screws. I spaced the horizontal 2×4’s 2 feet apart for 24 inch fiberglass bats. I then screwed the 3 sections together and screwed 2×4’s on top and bottom full width but across the junctions of the 3 sections as splices. I bought the biggest Harbor Freight winch, It was 1320 lb using double line. I see there is a 1760 lb on Amazon. You could use any winch but the stronger winch the better so it is not straining. If you don’t have 120V at your hangar, you could use a 12V winch and batteries. I replaced the cable with 3/8 inch cable and used pulleys to give me a 3 to 1 advantage so there is less strain in the winch and the door raises slowly. My door takes around 45 seconds to a minute to open. I bought the sliding door tracks, trolleys cable and pulleys at Tractor Supply. I built the door around 2010 and cost me about $ 1200 for everything including fiberglass insulation and metal siding on the outside. I used 1/8 tempered hardboard on the inside but am going to replace it with fiberglass roof panels because the hardboard is too heavy. This door weighs about 1100 lbs, should be lighter when the hardboard is replaced.

There are 4, 8 foot door tracks that run from the front of the building back spaced 14 feet apart. There are 2, 8 foot door tracks that run vertical along the sides of the opening from top of door down. Tractor Supply has hubs that can be welded to sprockets or pulleys. I took a hub with ½ inch inside diameter and turned it down on a lathe so it would fit in the vertical door track and act as a roller to guide the sides of the door. I took the 2 brackets that come with the trolleys that would be used at the top of a sliding door and screwed them to the side of the door up 1/3 from the bottom and used a ½ inch bolt with the head cut off as a shaft for the roller inside the vertical door tracks. I fastened the vertical tracks to the sides of the opening with counter sunk screws and screwed 2×2 boards to the opening on both sides of the tracks to keep them from moving side to side. The trolleys have a pin and bolt that is used to adjust the height of a sliding door. I bought one of the long nuts and welded it to a big door hinge that I used at the top of the door. I would suggest you build the door with a 2 to 3 inch gap at the bottom with the adjusting bolt, nut hinge assembly at it’s longest adjustment in case your truss sags. You can use a rubber flap or seal at the bottom of the door. My truss sagged a little and I ended up having to cut a little off the bottom of my door. The lift cables are attached at the edges and junctions of the 3 sections at the same height as the rollers on the sides of the door. Use forged “I” bolts so the eye doesn’t open up under the strain of lifting the door. Cables run up then through pulleys above the door then back to pulleys then toward the center of the door then back to the 3 to 1 pulley cable arrangement to the winch. Pulley diameter should be 3 inch minimum. The 3 to 1 cable arrangement needs to be long enough so there is enough travel to lift the door. For a 12 foot tall door, you need an absolute minimum travel of 8 feet which is cutting it close, 10+ feet is better. I put the hinge hanger assembly at the top of the door on the inside so the door would hang toward the outside of the opening. When it is windy, the top of the door blows in a little. If the tracks were sloped up toward the back of the opening so gravity helped hold the door closed that would help. If the tracks could be bent downward a little at the opening, that would be another solution. The Harbor Freight winch has a hand control with the up and down switch that goes to a control box mounted to the winch. Take this control box off the winch and there are 2 wires running from the box to the winch motor. Mount the hand control, control box and plug in a convenient location next to an outlet. Splice in 2, 12 gauge wires, romex will work, from the control box to the winch motor. I don’t have stop switches on up or down so I painted yellow and red on the side of the door opening so I would know when to stop raising the door. When lowering the door don’t run the winch too far or the cable will unspool on the winch making a birds nest of a mess on the winch spool. When opening the door, bump it slowly until the top of the door starts to move inward so it doesn’t lift straight up and jam the trolleys in the tracks. This isn’t the best door in the world but a lot cheaper than a $10,000 bi-fold or hydraulic door plus sheeting and insulation. It has worked great for me. You are welcome to come look at my door or contact me if you have any questions.

John King

607-869-5601

[email protected]