My best friends in the shop are Mike and Cal. Mike is a Mitutoyo digital micrometer and Cal is an eight-inch Fowler X-Series digital caliper. Virtually every job starts and ends with one or both of those measuring tools.

Meet Mike (bottom), a one-inch digital micrometer and Cal (top), an eight-inch digital caliper. Note the caliper has a set of jaws for measuring outside (A), a set for measuring inside (B), and a depth probe (C).

The modern digital caliper is the latest in a long line of sliding jaw (one fixed and one moveable) rulers, dating back at least 2000 years. The big breakthrough came when a renaissance-era mathematician name Pierre Vernier invented a system that coupled a primary scale of graduations with a secondary “Vernier scale” of graduations. The secondary scale added the precision of two additional decimals to the primary reading. Soon after, the system was adapted to screw-calipers and the micrometer was born.

You can still buy direct-reading vernier calipers and micrometers, but they have largely been displaced by models with an electronic digital readout. Digital takes all the guesswork out of reading the tiny lines on the vernier scale. Even for old-timers (like me) who grew up with vernier mikes and calipers, the big display means we don’t have to get our close-up glasses to read the number. A few reasons to consider non-digital tools might be if you’re working in sub-zero weather conditions (which will freeze the LCD screen), or if you get a really good deal on a premium brand tool. As far as accuracy of measurement, there’s no difference. A digital display might have four or five digits right of the decimal, but for all practical purposes, they’re no more accurate than a vernier scale reading to three digits. People who do metrology for a living will tell you, don’t confuse resolution with accuracy.

Basic calipers come in sizes from as small as four inches (meaning a measuring capacity from 0 to 4 inches) to more than 20 inches. Six- and eight-inch calipers are probably the most typical. Standard calipers are capable of making outside, inside, and depth measurements.

You might come across different types of specialty calipers. Models with extended or gooseneck jaws could be for measuring odd shapes. Calipers designed for electronics are sometimes made of non-conductive plastic or composites. I’ve never had the occasion to need a special caliper. I use my eight-inch Fowler 99% of the time. My 12- and 20-inch calipers come in handy from time to time. But I loan them out to other people more often than I use them myself.

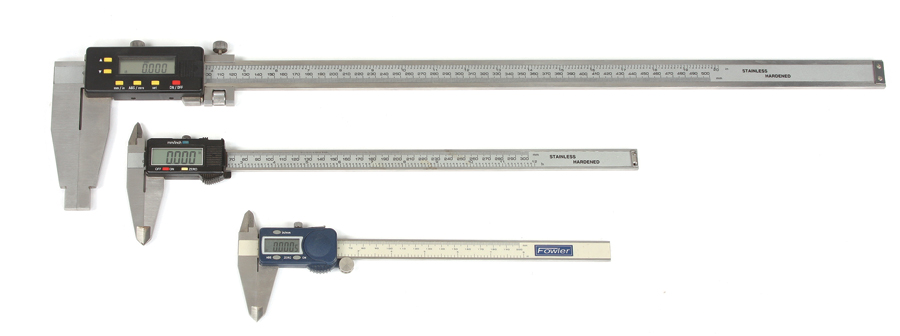

From the top: 20-inch caliper without the depth measuring feature, a 12-inch, and an 8-inch standard caliper.

Compared to calipers, micrometers have limited versatility but are more precise. Mikes are the go-to tool when doing precision lathe work. A good example would be when making a force-fit (aka press-fit) part. According to Machinery’s Handbook, the rule of thumb for force-fit components is 0.0015 inch per inch of diameter (with a tolerance of 0.001). In other words, if you need to turn a pin to force-fit into a 0.250 hole it should be 0.250 + (0.00015/4) = 0.250375, which we can round up to 0.2504. Such precision is possible with a good micrometer, but not with a caliper. Yes, the resolution of the display might extend four digits. But remember, resolution is not the same as accuracy!

The most common mike style is the “outside” micrometer, and the most common form is a C-frame with a 0-1 inch (0-25mm) range. “Outside” refers to the type of measuring that it will do based on the shape of the frame, anvil (stationary face) and spindle (moveable face). Since the anvil and spindle have flat faces, it is used to measure the outside dimension of a shaft, block, wire, etc. Some mikes have adapters or are specifically designed to measure irregular features. These include blade anvils for measuring grooves or V-notches to measure screw threads. You can also find “inside” micrometers. They are generally used for production applications and are not very common in the home shop. In a future column on boring holes and cylinders, I’ll talk about the different ways to measure the inside of a bore.

Most micrometer readouts or scales are based on 0.025 inch-per-revolution of the handle. While great for accuracy, it also means it takes a bunch of turns to move the spindle back and forth through the range (40 per inch, to be exact). The Mitutoyo micrometer shown in the photos has the Quickmike feature, which moves the non-rotating spindle 0.25 per turn (on most mikes the spindle rotates with the handle). This feature puts the mike on a near-par with calipers for speed and convenience—at least for making outside measurements on objects one inch or smaller.

Using a 1-inch gauge block, practice getting the feel that produces an accurate and repeatable result. Even with the clutch feature and a high-quality micrometer, the wrong “feel” can affect the reading. Granted, 0.0003 inch is hardly a problem for most jobs!

When it comes to calipers and micrometers, far more important than the number of digits on the readout is developing the right “feel” to get the most accurate readings. I’ve heard more than a few machinists say it takes years to properly use a caliper or micrometer. You can go a long way toward developing the correct feel by practicing with a precision gauge block. You’re not only verifying the caliper against the gauge block, you’re verifying your handling of the tool. Every caliper will be a little different. Play with the gauge block by putting it at the tip, the middle, or the base of the jaws, and see how much pressure is needed for each position to render the same reading. The same goes for the micrometer: Get the feel for what point of contact renders the gauge-block value. Many micrometers come with a clutching handle to prevent over- or under-tightening the screw. While this takes some of the guesswork out of how much pressure to use, even with a clutch feature, a fast or slow rate of closure can affect the readout.

It is always necessary to reset the zero on a digital caliper or micrometer prior to taking measurements. Before you re-zero, inspect the jaws or anvil surfaces for dust or dirt. They should be spotless. Even still, you will notice very often that when resetting zero, the previous zero-set may have drifted slightly. This is normal and could be due to thermal expansion or hysteresis in the electronics, or both. It’s nothing to worry about, as long as you reset zero frequently.

My 12-inch caliper is an inexpensive generic import from China. Although not quite as smooth as the Fowler, it’s quite accurate and, with good habits, just as accurate. The one-inch gauge block sells for about $30 and can also be used to verify the caliper jaws are parallel.

Calipers are relatively inexpensive. The eight-inch Fowler X-Series (for Xtra value) model is $70 or less from Amazon and other sources. Harbor Freight sells an imported six-inch electronic digital caliper for about $15, and they are often on sale for $10. The accuracy of the newest low-cost imported calipers is excellent. They are not as smooth in terms of the sliding parts, and the battery life is usually a few months instead of a year or more, but overall, they are a good value. The longer the caliper, the more the price goes up. I paid $80 on eBay for the 20-inch caliper shown here. New they sell for around $230. As long as the condition is good, there’s nothing wrong with buying used. Of course, you can pay a lot more for a new waterproof, shock-proof, super-caliper with extended battery life and wi-fi data link. But it might be a bit more than you need for a home shop!

Micrometers follow the same trend. A new Mitutoyo with the Quickmike feature is around $300. The same mike without the Quickmike feature is around $150. No-name or off-brand import models, with traditional 40 turns-per-inch spindle, start around $60.

![]()

Bob Hadley is the R&D manager for a California-based consumer products company. He holds a Sport Pilot certificate and a Light-Sport Repairman certificate with inspection authorization for his Jabiru J250-SP.