After months or even years of research, you have decided to build a kit aircraft. With hundreds of kits to choose from, how do you decide which one to build? Easy. Just gather all of the information about all of the different kits, compile it in a list, pin it to the wall, and throw a dart at it.

But seriously, one of the best ways to get started, in addition to your own research online and elsewhere, is to find out what the locals fly and why. They will offer advice, opinions and their experience. This doesn’t mean you have to build what they are building, but it is a great way to glean information to help with your decision-making (and they may be a source of future building assistance). If you haven’t already done so, read the trade magazines and attend airshows and aviation events.

With this information in your grasp, it’s time to determine your own requirements for an aircraft. Don’t know what they are? Ask yourself a few basic questions to help narrow the scope.

Pilot Type

Consider what kind of pilot you are and how you will use your plane. Your “pilot personality” will help inform what type of kit to buy. Are you a low-and-slow weekend pilot? Do you like to fly high and fast? Maybe you are after the ultimate vertical-roll performance. Whatever you plan on doing most of the time, make sure your kit is designed for that purpose.

Here is where many people get off track. They buy the kit based on what they want to do with the aircraft at the extreme rather than what they will do the most. You want to buy a kit that will serve what you do 90% of the time. I hear from customers all the time about how they want a plane for an extended, once-a-year vacation. However, in reality, they need a plane they can use every weekend or even every day.

Before you buy a kit, get a demo ride in the aircraft. You need to make sure that you fit and feel comfortable in the aircraft of your dreams. Many times you can get your first flight at an airshow with the factory demonstrator. But don’t make that the only ride; see if you can get a flight with an owner in your area. Most owners are happy to share the experience with an interested person. Just don’t forget to pay for the fuel!

Type of Flying

How many people will you take with you? Take a look around and see how many two-seat aircraft are being built. This should be a hint. Most people fly in an aircraft solo or with one other person. Sure, there are families that need more seats, but how often? If you need more than two seats, there are certainly four-seat designs available, but this will often increase the expense of building and operating because of bigger engines and greater complexity.

Do you want a high wing or a low wing? I grew up learning to fly in a Cessna, so I like high-wing aircraft. Most people I meet end up flying an aircraft like what they learned in. I’ve owned Pipers, a Grumman, a KR2 and biplanes, but I still like high wings the best. In my mind (and as I age), I think about the difficulty of climbing over the wing and sliding down into the cockpit compared to sitting on the seat and sliding my legs in. And it’s not just me; what about my passenger? I know owners who have had to change from a low-wing, bubble-canopy aircraft to a high-wing Cessna style because their spouse could no longer get into the aircraft.

The insurance-oriented side of me also thinks about the ease of egress in an accident. The typical accident in a tailwheel aircraft is a ground loop, nose over. Will I be able to open the doors or the canopy to get out if I am upside down? None of us expects to have an accident, but it does happen.

And here’s one of my favorite pieces of advice: “If you fly over water, fly a low wing because it floats longer. If you fly over trees, fly a high wing to see between the trees when you crash.” You may be laughing, but in some ways this does make sense.

Majority Rules

How much do you fly? For years, 55 hours a year has been the average. Only 55 hours! It’s not surprising that when times are tough (high fuel prices, interest rates, unemployment or whatever), the hours flown in a given year go down. I see pilots flying light twins and heavy singles less than 25 hours a year. How can you stay proficient in a complex aircraft at 2 hours a month on average? You can’t, so it’s important to look for an aircraft that you can continue to fly even with high fuel prices or when the economy falters.

While we’re on the topic of not flying, many kit aircraft have the option to build them as a tailwheel or a tricycle gear. The macho in me says build the tailwheel; the lazy in me says build the trigear. The accountant I married says build the simplest and the cheapest. So what’s less expensive to insure? That’s the trigear. Fixed trigear aircraft are almost always 10-15% less to insure than a tailwheel aircraft (or a retractable-gear aircraft for that matter). For the best insurance rates, remember the K.I.S.S. rule about keeping it simple. That’s a great thing to remember when picking a kit too. If the aircraft is too difficult to fly, too complicated or too expensive, many of you won’t fly it much, so choose a different kit.

Storage is a big fixed expense for an aircraft. Hangar space nearby can be at a premium. Maybe you need to think about an aircraft that allows you to share a space with another aircraft owner. Folding wings may cut hangar cost, but they can reduce your actual flying time if it’s a complicated process.

Motivation

Building an aircraft can take a long time. The average kit airplane takes three to five years to build, and five to seven years is not uncommon. You will need to motivate yourself to go to the shop and start drilling holes and pounding rivets (or laying up composites or sawing wood) with no one else making you do it. I added a better stereo and a furnace in my shop so that I could work year-round, and it still didn’t motivate me to buck rivets.

You also need to think about what kind of tools, equipment and experience you have. While some people have a well-equipped shop and lots of knowledge and mechanical ability, others have limited resources and skills. You might be great at metalworking but bad at woodworking. Know what your aptitude is and opt for that type of construction. The easier the construction method, the faster you can build. All right, a few of you may like a challenge and want to learn a new skill. Just make sure you can get the help you need so that acquiring those new skills doesn’t frustrate you to the point of quitting the project.

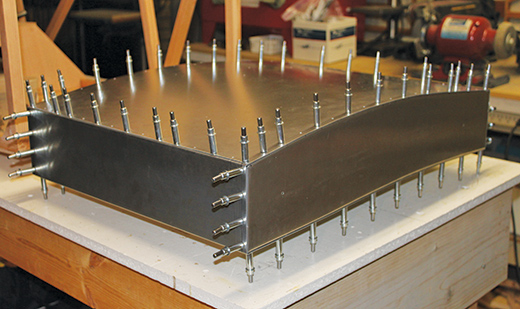

Got enough tools? Buying the kit is just the start of your expenses. Make a list of the tools you have and compare it to the tools you need. Make sure the tools are included in your cost to build. Many items are reusable, like the Clecoes holding the sheet metal in place. By the time you are done, you’ll have boxes of assorted Clecoes lying around. What to do with them when you’re done is another issue…guess that means building another aircraft.

How Do You Build?

If you aren’t good at working by yourself, or you don’t have the room and tools you need, a good option may be a builder’s assistance program. Yes, it costs more because you have access to the facility’s staff and tools, but it saves money and time because you won’t need to build the jigs or buy the tools. And you get help and motivation to complete the project. This head start should also mean it takes less time for you to complete the project. Builders in a community situation (builder-assistance program or a group build) often have a better success rate.

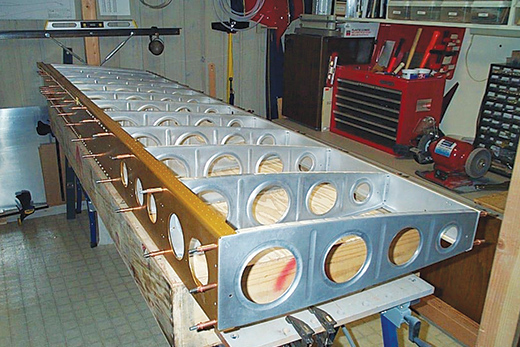

In addition to the tools, do you have the space? If you don’t have a workshop big enough to build the components, plan ahead. Once the wings or the fuselage are ready to assemble, you might want to move your project to a new location. Maybe a builder’s assist shop would be cheaper than knocking out a basement wall to remove the wings. Seriously, it really does happen!

Now How Much Would You Pay?

What does it cost to buy, build and operate the aircraft you want, and can you afford it? It doesn’t matter what aircraft you select, it won’t fly if you can’t pay for it. So this factor pretty much trumps everything else.

Will you need to borrow money to buy the kit all at once, or will you pay as you go? If you pay as you go and don’t buy the complete kit initially, you could fall prey to the “failing company syndrome.” If the manufacturer goes belly up, the kit may never get delivered. Look at the history of the aircraft manufacturer, and be aware of the risk.

Ask for personal referrals if possible and lurk on relevant Internet forums to see how the builders like a given company. But be careful. The Internet is a wonderful source of information, but it is also rife with misinformation.

No time? No patience? Take a look at a different kind of aircraft to build. Remember Erector Sets? Para-planes and weight-shift trikes are more of an assembly than a manufacture. Not to say they are any less complicated, but they don’t always require the manufacturing and building of components, just the bolting together. Is it less of a project? It flies, doesn’t it—who cares?

Proximity Is Key

After the kit is built and flying, can you afford to rent the hangar and feed the engine? If you can’t get a hangar close to home, maybe you need to buy a kit that can withstand the weather and be tied down at the local airport. If the closest hangar is an hour or more away but you can tie down at a grass strip 30 minutes away, maybe you should build an aircraft that can be tied out and flown off grass. The farther you have to drive to fly your aircraft, the more it costs and the less you will fly it.

In my seminars, I tell people to leave their personal preference (emotion) out of the decision until they figure the cost. Going through the process detailed here establishes the category of aircraft to consider. It has always been interesting to me that in most cases, this category will be a two-place, fixed-gear aircraft. Even though manufacturers continue to expand their product lines with bigger, more complex and faster designs, the most common category remains two-place, fixed-gear aircraft.

All the time, frustration, skinned knuckles and bruises are worth it when you open the hangar door and see the aircraft that you built waiting for you. OK, so maybe it’s not as much satisfaction as actually flying your aircraft that you built. Either way, the end result is something only a builder will know.

Operating Costs

Wise shoppers will learn how to calculate the operating cost of an aircraft, which is what it takes to fly and maintain an aircraft. This doesn’t include storage, insurance or the purchase price.

For years, the general rule for a simple single-engine aircraft is two times the fuel burn. For example: A 180-horsepower engine burns 10 gallons an hour, and the fuel cost is $6 per gallon, so the aircraft should operate for about $120 an hour. Building your own aircraft might save on your maintenance, but there are still fixed costs such as insurance and variables such as fuel and oil. With this formula, you can walk down the flight line at an airshow and estimate what each plane costs to operate. The more complex and bigger the plane, the higher the multiplying factor. Heavy, complex, single-engine aircraft mean three times the fuel burn, light twins mean four times the fuel burn, etc. Get the idea?

Options in the Category

Let’s say you want to build a popular, simple, fixed-gear, fixed-propeller, two-seat, all-metal aircraft, so you might pick a Van’s RV-7A. This aircraft has good all-around performance, reasonable operating cost and decent resale. Your calculations might be $120 an hour to operate, but an RV-7A may cost $100,000 when all is said and done, and that’s more than you can spend. What do you do?

You’ve decided you want that category, so maybe you should look at a Thorp T-18. Same type of engine, same type of construction, same operating cost. What’s different? The Thorp is an older design, and it might not be quite as fast or look as smooth, but it’s still a two-place, fixed-gear, side-by-side aircraft and you can be in the Thorp for less money.

Hold on to your hate mail! There are always exceptions, and there will always be a better deal somewhere. The concept is to establish the category and then start looking for the different models that fit that category.

Lastly, never buy an aircraft or a kit without trying it on for size and getting a demo flight. And remember that factory demo planes are usually well equipped and well maintained. You should also visit with owners of the aircraft you’re considering. Airshows such as AirVenture and Sun ’n Fun are great opportunities to see large numbers of the same models. Joining builder groups and forums will help you learn the ins and outs of building and the problems builders encounter. When I bought my first KR2, I discovered that the stock retractable gear was hard to operate, the center stick gave the most room in the extremely small cockpit, and if there was any sort of header tank, it was in the way of my toes when my feet were on the rudder pedals. This information came from those already flying the aircraft. Make sure you talk with people who have built and flown what you want to build and fly. And make sure you talk to people who are not trying to sell their aircraft.

If you don’t like doing the same thing over and over, like making ribs or drilling thousands of holes, maybe there is a quickbuild kit that’s got all that repetitive stuff done. Building an aircraft requires doing the same type of thing over and over, and that’s OK—you’ll be good at it when you are done.

Reality Dose

Once you complete these steps, ask yourself what you really want and what you are willing to sacrifice to get it. Know what your mechanical abilities are and your ability to pay without significantly changing your lifestyle or habits. I promised to quit going to Starbucks every morning for coffee, which could save me a lot of money. But in reality, I probably won’t stop. So when you tell yourself all the things you will do to get the plane built and cover the costs, be realistic.

Building an aircraft can be a long but enjoyable process, so you need to bring your family and friends into the sacred “builders circle.” If you don’t, you might not see them for years, and that’s not the way to sustain the relationships you value. Besides, it’s often more fun to build with someone than to go it alone.