Another day, another workshop! Yesterday I headed over to the Sheet Metal 101 class with Louise, who’s obviously graduated from the beginner course, but wanted to get a better feel for how the regular sheet metal practical is presented as opposed to the women’s one we attended on Monday.

We sat for a half hour long presentation, which covered everything from aluminum strengths (6061 versus 2024, that sort of thing) to different types of rivets (Series 470 vs. 426). The speaker also emphasized the importance of safety. We learned we’d be setting both universal and countersunk head rivets.

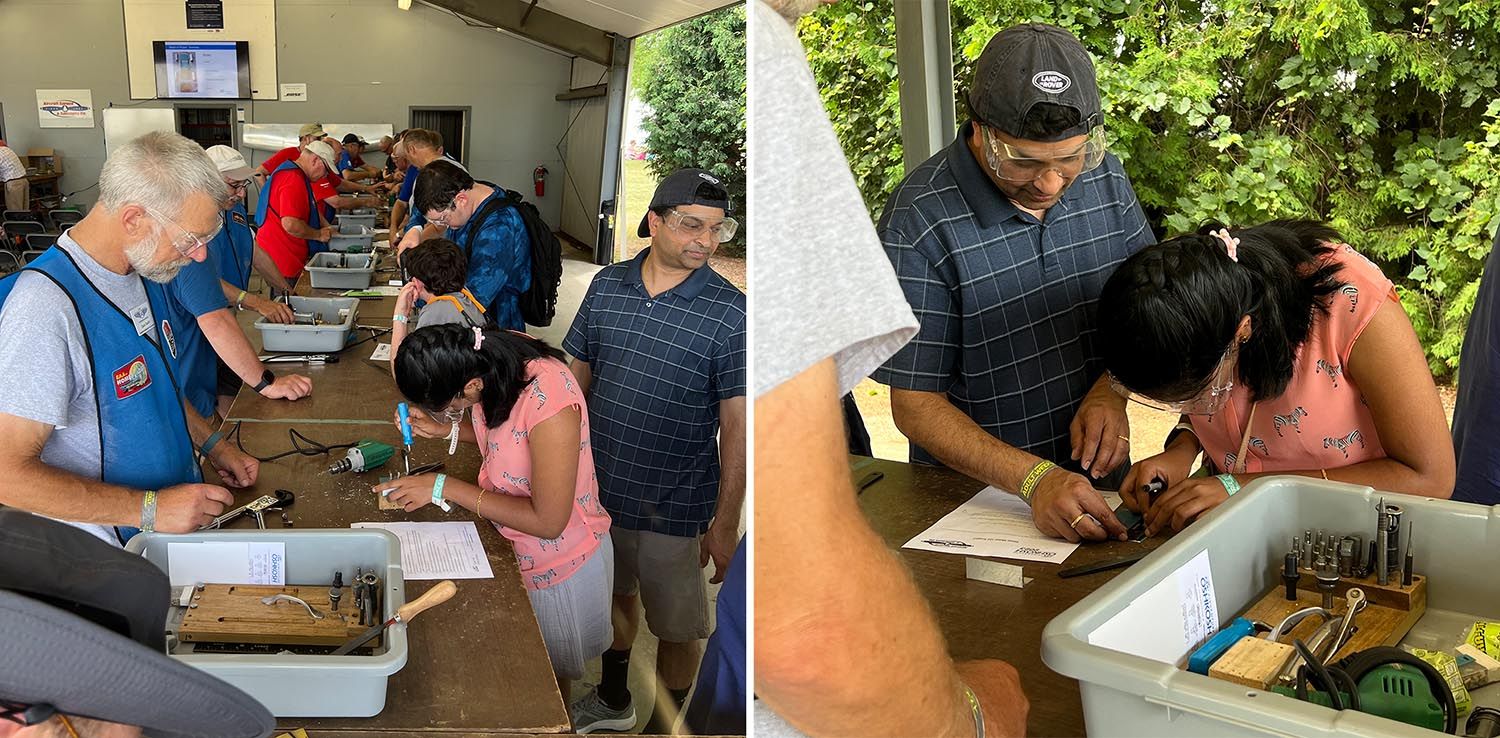

After Monday’s lesson, I was familiar with drilling and deburring, but in this class I learned to dimple using dimple dies and countersink holes with a caged countersink. I also learned to squeeze rivets (I’m weak—I see a pneumatic squeezer in my future, or y’know, pull rivets…) as well as use a rivet gun and bucking bar, which I had one of my helpers hold. It was a great intro course that lasted about an hour and 15 minutes—a good first step stone for anyone interested in building an aluminum airplane. It was also nice to take a break from walking.