The success of the P-51 in WW-II is legendary. The underslung, ventral radiator scoop is probably its most recognizable feature, and most pilots have heard the stories about how efficient that radiator system is-perhaps even producing thrust under some conditions.

Back in WW-I, designers of aircraft with liquid-cooled engines didn’t pay much attention to ducting radiators. The radiator began to present a more sizable drag penalty as speeds slowly worked upwards in the mid-1920s. Designers knew the basics by this point: Mass x momentum loss = cooling drag. So, how could mass flow be reduced while still cooling the engine, and how could they reduce the momentum loss of the cooling air? The Schneider Cup racers mainly adopted surface conduction cooling (flowing coolant by the aircraft skin) starting in 1925 with the winning Curtiss R3C. The surface conduction layout was impractical for warplanes and civilian aircraft, however, being vulnerable, heavy, and complicated, so a better solution was sought.

While others may have been contemplating improved radiator designs, it was British scientist F.W. Meredith who first theorized on paper and showed mathematically that it should be possible to not only offset most of the drag of a radiator installation, but possibly produce some thrust by shaping the duct properly and utilizing the added energy of the cooling air exit stream through an adjustable nozzle. His paper was published on August 14, 1935, and much later, his theory became known as “The Meredith Effect.”

The paper used some simplifications and assumptions, which we know not to be valid today, but the report garnered interest on both sides of the Atlantic. In Germany, B. Gothert generated a paper on aircraft radiators dated September 10, 1938. His work was from practical wind tunnel experiments with both hot and cold radiators, and heated simulation grids. Meredith’s theories were mostly validated by Gothert’s actual measurements.

While both papers discussed virtually every consideration imaginable with regards to drag, viscosity, separation, heat transfer, and wakes, they seemed more interested in developing equations to explain every facet of the physics, rather than building and testing actual radiator duct designs which could be used on real aircraft. That being said, these men were both math guys first, and their work was leading edge at the time.

Early Examples

Designers in England took heed of Meredith’s ideas, and ducted radiators appeared soon after on the new Hawker Hurricane and Supermarine Spitfire. Wing-mounted, ducted rads also replaced the original under-engine rad on the BF109 in late 1938, perhaps due to Gothert’s work earlier that year. All these designs had moveable exit doors to control mass flow and cut drag.

The Spitfire and BF109 designers seem to not have had a good understanding of duct dynamics, however, and both suffered from inlet air separation due to the obtuse angles the air was forced to turn between the inlet and rad face, a consequence of having very short ducts. The BF109E duct design gave way to a more complicated design on the F models, having an internal “boundary layer” bleed, movable inlet lip, and double-split exit flaps at the trailing edge of the wing. The G model discarded the bleed, probably because it couldn’t have worked properly due to separation well prior to the rad. Meredith had already noted that efficiency of the rad would be compromised, along with added drag, if inlet separation occurred. The designers seem more concerned with reducing rad frontal area than making sure separation didn’t occur. Despite this, both designs managed to get by in the deserts of North Africa and other hot climates, and both performed well for the times, offering a 100+ mph leap in speed over the biplanes they replaced.

The BF109 and Spitfire rad duct designs couldn’t have produced cooling thrust though due to their inefficient inlet and diffuser designs. Most of the drag reduction on the majority of WW-II fighter designs was simply due to the rad exit doors, which lowered mass flow through the rads in cruise and high-speed flight.

Wing leading edge intakes with buried rads were developed on aircraft like the Westland Whirlwind and Mosquito in the 1938-1940 era. These presented no additional frontal area, but didn’t have very favorable exit geometry and used rather restrictive core designs. Still, these showed lower drag than under-cowl designs when fitted to aircraft like the Hawker Tempest.

Another innovative design of the time worthy of mention is the French Bugatti 100P racer, which was being designed to break world speed records. Their approach was different in that the radiators were totally submerged in the rear fuselage, and air was taken from inlets on the V-tail leading edges, forward through exotic ductwork, then turning to exit from fixed louvers in the wingroots. The designers, however, failed to understand the momentum loss resulting from turning the cooling air 360 degrees through the long ductwork, and the significance of having a variable area exit and the exit smaller than the inlet. This design was finalized around September 1937.

The most uncompromised and functional layout was probably on the British Napier-Heston T.5 race plane, also designed to take the world speed record. Design work was begun in mid 1938. Much of the cooling system layout was done by ducting/cooling expert Arthur Hagg, an ex-deHavilland engineer. The T.5 featured a mid-fuselage-mounted ventral radiator scoop with boundary layer scupper. The exit ducting ran the entire length of the aft fuselage to dump on either side of the rudder, just below the stab. This layout gave the length to construct an ideally shaped diffuser and nozzle for the least losses and drag of any design before or since. The T.5 had all the right stuff to break the speed records-diminutive size, huge hp, ejector exhaust, laminar type airfoil, ultra-smooth finish, and low-drag cooling system. Unfortunately, it overheated on the initial test flight in June 1940, either due to a leak or undersized radiator and ducting, and was written off in a hard landing.

Cooling the P-51

In the U.S., Curtiss and North American were watching European fighter design and thinking about putting Meredith’s ideas into use. In 1940, the P-51 designers also prioritized the cooling system to make best use of the Meredith Effect. The NA-73X prototype had movable inlet and exit doors on the rad scoop. Eventually, a revised, fixed inlet was used with a boundary layer bleed, based on wind tunnel testing of a full-scale P-51, minus outer wing panels. This was to determine a cause and fix for inlet separation in the rad scoop, which was accompanied by a serious, audible rumble. The long duct of the P-51 was a big improvement over the short ducts used on the Spitfire and BF109. It also integrated oil and intercooler functions like the T.5.

Despite the fact that many tests were run by North American with regards to cooling drag, there is still extensive speculation today as to what drag reducing benefits the P-51 actually enjoys due to its design and the Meredith Effect. Some say the P-51 could offset up to 90% of the cooling drag, others variously insist it produced a net thrust of 250-400 pounds. Calculations with wild assumptions abound on the Internet, but I’ve never seen a definitive answer with real flight test data.

The Quest for Truth

The question has always intrigued me, so when it came time for a major overhaul on my Subaru-powered RV-6A, I was determined to build an efficient ventral radiator scoop like the P-51 to replace my kluged and much-modified initial attempt from 10 years earlier. I wanted to instrument the scoop and take actual in-flight measurements to at least prove if the basic Meredith Effect was real or not, even if I couldn’t test an actual P-51 to settle that age-old debate.

The Radiator

If we look at a modern radiator, most consist of two tanks connected by flat tubes to carry the coolant. The tubes are thin to break the coolant into many small sheets. This increases surface area and thermal gradient. Between the tubes we have very thin fins, which serve to increase surface area even more. Many fins are pierced or louvered to create turbulence, which helps “scrub” the surface for even higher heater dissipation. The cooling air flows between and over all this structure, dissipating heat from the coolant. The modern aluminum radiator is very efficient at dissipating heat per unit volume compared to an air-cooled cylinder. A small radiator like mine (17.6 x 6.75 inches) has a total surface area of over 3200 in2. In the WW-II era, radiators often used a very different honeycomb construction, which presented far more drag than the tube-and-fin types common today.

The radiator can dissipate more heat if the coolant is hotter and the inlet air cooler. This is called delta T, or the difference between the coolant temperature and the inlet air temperature. It’s generally not practical or good for the engine to increase coolant temperature over 230 F, and we can do nothing to control the inlet air temperature on a hot day. We are forced to work within these constraints.

The Duct

The purpose of the duct is to streamline the external flow around the rad as much as possible, slow down the inlet air without separation to recover as much pressure as possible at the rad face, while equally wetting the entire rad area. The flow is then converged with a smaller cross section downstream to gain back exit velocity. We can also incorporate a variable exit door to throttle the mass flow through the rad and increase exit velocity even more. The door allows us to increase flow in the climb and on the ground while decreasing it in cruise. Lower velocity through the tubes and fins equals lower drag.

The RV-6A was never designed for a liquid-cooled engine and even less so for a ventral radiator scoop. The design considerations were numerous, and I often thought I’d never finish what I started.

I was determined to improve on the P-51 design. My design goals were a bit different from North American’s as I needed to have extended ground cooling on a hot day-something the P-51 cannot do. I used a relatively large inlet of 29.5 in2 to accomplish this and placed the rad much further forward, based on CFD analysis. This increases delta P from the prop blast at the inlet during ground idle conditions.

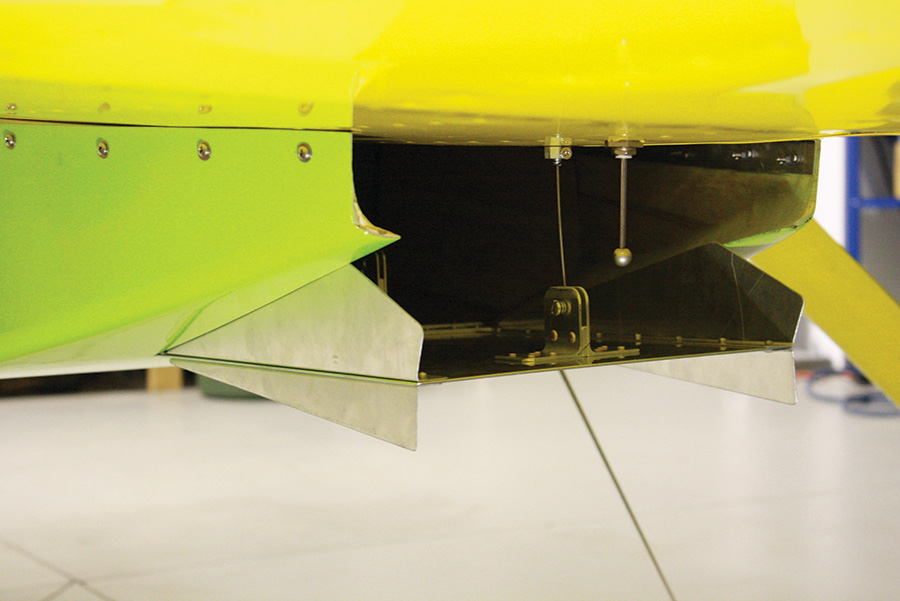

I wanted to have the inlet transition air smoothly to the rad face without separation. The duct would not have the rad tanks exposed to the airstream, as this would cause high drag and turbulence. After experimenting with wool tufts while feeding the inlet with air from two high-capacity centrifugal blowers, it was found that separation was occurring about two-thirds of the way down the diffuser where internal divergence exceeded seven degrees. This was expected from previous experiments. Guide vanes were then installed in the diffuser to smoothly direct the flow into the rad matrix. Apparently the WW-II designers never thought of this simple idea, although the Bugatti 100P did use guide vanes on its inlets.

I have minimal skill at composite work, so it was a time-consuming and painful exercise for me to build the duct from scratch. I used a balsa core, glassed on both sides for strength. Coolant tubes were run outside the diffuser so as not to impinge on smooth airflow to the core. The tanks on the downstream side of the rad were faired into the duct wall to reduce turbulence, and the rad support structure was faired into both the inlet and exit sides, so only the core matrix was touched by the air. Most designs don’t take this type of care. The P-51 and most P-51 replicas don’t have smooth transitions or shapes here, so they will have turbulence in these places.

Measurement

Aerodynamics is a complex field and some things are notoriously hard to model or calculate-like radiators and ducts for instance. There are so many interconnected considerations and effects that it’s actually much easier to instrument the actual part and go fly it for the most accurate data.

I wanted to measure inlet and outlet pressures, inlet and outlet temperatures of the air and coolant, plus exit-air velocity. I had most of what I needed around the shop from previous projects-temperature sensors, an ASI, and sensitive pressure gauges. I also wanted to take some video of wool tufting to see what the airflow was doing in and around my duct.

Flight Testing

I love flight testing and learning new things. After extended ground running to validate ground cooling and test the rebuilt engine and other new systems, the next step was to make sure the duct didn’t change the excellent RV flight characteristics. I couldn’t note any changes other than the cooling margin was much better than the previous setup (which had no fewer than four submerged heat exchangers!).

The ground cooling was excellent. I idled for over 45 minutes at +80 F OAT. The coolant temperature didn’t climb further after 30 minutes, just sitting at 195 F.

Next flights gathered initial pressure recovery and pressure delta data. Ram recovery peaked at 84% with the door closed. Other data points showed a maximum rad efficiency of 92%. Video data followed, which uncovered the fact that the door-actuating mechanism was not stiff enough to keep the door fully closed in flight. I revised the system to solve that problem and started to collect momentum data.

One of the big problems, as far as collecting data, was that the engine now ran too cool. I couldn’t get the coolant temperature above 160 F in level flight, even with the door closed. Calculations showed at lower speeds (hotter air exit temperatures), the best I could do for momentum recovery was about 93%. I had to raise the coolant temp to measure what effect that would have, so I blocked off the cabin heater core which doubles as a secondary heat exchanger. This raised the coolant temperature to around 180-185 F. I was quite excited to see the temperature delta at 125 F and a high speed reading on the rad exit ASI. When I ran calculations later on the ground, they showed a maximum of 104.4% at 80 KIAS. The cooling air was exiting faster than the TAS of the aircraft, proving that Meredith was correct 79 years ago. The strongest factor was temperature delta. I could not correlate his theory that the effect would be stronger at higher airspeeds. In fact, the opposite was true according to my data. Higher speeds resulted in lower outlet temperatures, which reduced the expansion effect in the nozzle. Just for interest’s sake, opening the door fully dropped momentum recovery to as low as 59%.

The magic figure to reach velocity parity at the exit was a temperature delta of 120 F. With higher coolant temps, even higher velocities might have been measured. However, Gothert’s data showed a decrease on core drag up to a certain temperature due to reduced air density from heating and, at a certain point, higher drag, when the air expansion within the rad core caused increased turbulence downstream.

I made no attempt to measure the drag of the scoop externally; my only goal was to see if net thrust was possible as Meredith had theorized. The aircraft is around 6-8 knots faster than before, but many external and internal changes were made to other scoops and heat exchangers, so no valid conclusions can be made as far as what parts had what effect. I am happy with the speed increase for whatever the reason though.

What about the P-51?

I’ll speculate that for various reasons, the stock P-51 probably didn’t produce any net thrust, but only flight measurement could ultimately confirm that as fact. The stock radiator is very restrictive due to its design and depth. This would result in a much larger pressure drop compared to the modern rad designs we have today. There is also likely to be inlet separation due to the larger angular change from the inlet to the top of the rad with the relatively short diffuser. On the plus side, it is running higher coolant temperature than I was, which could offset some of these factors.

Race P-51s like Strega use a much longer and shallower scoop with revised exit door geometry and much smaller inlet without the boundary layer scupper. They also probably use a modern rad design. Their speed secrets are kept hidden from view on the tarmac. Strega is in a different speed realm from my RV and uses water spray bars to cool the rad, plus has to fight considerable inlet temperature rise from the high speeds lowering delta T substantially. I’d speculate that Strega enjoys cooling thrust due to these modifications. I’d love to instrument it or any P-51 to see the true story.

Conclusion

My testing shows that with careful design and attention to detail, a properly ducted rad can offset all internal cooling drag. We see most homebuilt aircraft with liquid-cooled engines fitted with some truly awful and inefficient radiator setups. When cooling drag accounts for between 15 and 25% of total airframe drag, you’d think designers would pay more attention to this aspect. Maintaining cooling air momentum is free speed. I hope this article inspires builders to think more about their cooling system designs.

Cooling efficiency can be further enhanced by using a double core “counter cross flow” radiator, as advocated by Paul Lamar. I’m working on a project CH-640 with a rotary powerplant.

Actually no. This is a common misconception. This strategy reduces the Delta across the cores which would result in a drop in heat transfer rate.

Thank you for this very informative fact and data driven design work. I have also been somewhat surprised at the lack of real test data available for these style radiators. As airframes get more efficient, the cooling drag becomes an increasingly large percentage of the remaining drag, and more work definitely needs to be done in this area.

Glad you found it informative. I was able to quantify some sizing data at least applicable to this class of aircraft. At the time I built my plane 17 years ago, I too could find no useful data for sizing rads so did my own experiments.

This was a great read for somebody just curious what the Meredith Effect is. Well written and a well done engineering project. Just the project as executed was a success. That you also saw some positive results is the cherry on top. Nice job, I’m glad it worked well for you.

Thank you. It took a while to do all this. Glad it was useful to you.

Hey great write up on a hard to find Topic. Defnatly helped me with my masters Thesis, TY!

I also found some great research on the topic : https://www.researchgate.net/publication/253649721_The_bonus_of_aircraft_piston_engines_an_update_of_the_Meredith_effect/link/0046351fa125b4ad8a000000/download

Also a good read 😀

Ross

Really enjoyed your research cooling system integration and Meredith effect, particularly the empirical work and proof

With regard to WWII and P51s, Spits and Mosquitos benefitting, we should bear in mind a couple of things… scale effects improving matters; higher Reynolds Nos.

And most importantly the regime where greatest benefits perhaps were felt, would be in yhjnvsir and very cold inlet temperatures I.e. high altitude cruise.

Combined with ejector exhaust mass flow (momentum thrust) and rapidly reducing propeller efficiency, irs been suggested 1/3rd or more of total thrust may ge coming from these two sources.

The exhaust ejector thrust has been documented from testing at the time in some sources I’ve read. I don’t have the figures handy but seem to recall it was 60- 100 pounds on a Merlin, depending on altitude, power setting and type of stacks used. Fairly significant up high.

Thanks for putting this together, it was a pretty good read even for an amateur.

Do you think this effect could be implemented in race cars? The biggest hurdle i can think of is just finding enough space for the inlet and outlet and making sure theyre long enough to be effective.

Thanks for this info.

It make me wonder about the P-51H

With its longer ducting.

I would think some effect it has on the P51 B,D was positive at least to off set drag.

Remember the Reno racers are using steam

And the rad is to condense it back to water

Some dish soap is used to brake surfaces tension of the water .

There is no definitive flight test evidence that cooling drag was offset on the stock B and D model P51s and doubtful also on the H models. The rad cores are very deep on all of these (10-12 inches) so the momentum loss is huge.

Most Unlimited Reno racers use spray bars to put water on the front race face which then flashes to steam going through the rad. This wouldn’t condense until it exited the duct.

Redline Water Wetter is sometimes used to reduce coolant surface tension.

I did a couple vids on liquid cooling which you may find interesting : https://www.youtube.com/watch?v=pf1D6GVlNGA&t=14s

https://www.youtube.com/watch?v=GGXXEgqhmmc&t=1102s

No the steam leaving the engine the condensed at the bottom of the rad ,

Spray bars of water would help the condenser work faster . You came see the vapor trail when there using the spray bars.

The reason there using the steam-water system is to save the weight in water..

Remember the Super marine S6B used steam and the He100 as well but the wings where the surface .

Buy the way Thanks I will read your stuff

So? What’s your verdict on radiators in the wing like the mosquito? If done right are they viable? Do they have the potential to be better than the body mounted ones? How much of an impact would they have on the wing itself?

The leading edge rads don’t add any frontal area or more external wetted area so that in itself should produce less drag on that front, however, none I’ve seen have really good exit geometry so momentum recovery would be less than good ventral designs like on the Martin Baker MB5. Overall I could only guess that the LE rads might produce slightly less drag overall. It would be a really time consuming thing to prove through flight testing or CFD even.

The Mosquito, Hornet and Tempest I didn’t seem to suffer any big ill effects on the airfoil, having the rad inlets on the leading edges. Piping coolant to wing mounted rads is harder, especially if fuel is held inboard. The wing structure to allow airflow through the rads and still keep it strong enough would also be challenging (a big hole in the spar). The Whirlwind used a truss made of streamlined tubing here.

The basic idea has to work. A jet engine has an inlet, pressure rise, heat addition, and nozzle. The only things different here are the numbers. AT P&WA we dumped engine compartment cooling air overboard through a nozzle for a small gain. With variable areas, a computer controller to adjust them, and a lifetime of testing you should have this fairly well optimized.

Ross, An excellent article with collected data! I’m discussed several of the Reno cooling systems there while crewing for a friend in the Sport Class. Nice to see your conclusions from your in flight data. I also think that you have done well to show that your ling systemsallow you to have a sagnifigant ground run without o verheating! If you have ever flown into Palo Alto, and then heard the ATC Cessna November 10 CPM you are 15th for takeoff in sequence! most people don’t start their engine until they are about 5th in line! I have enjoyed whenever you have given us an update on the RV6. Thanks again for this article, there is always speculation about the effect, but you have given us some solid data. Thanks Ross.

Bill J.

Excellent work and article!

Curious as to what engine cowl cooling ducts and their area if any were used to manage the cowl temps?

Standard Van’s inlets, one feeds the intercooler, other feeds the oil cooler and redrive.

Is there any application of the Meredith effect to auto racing? I was thinking in terms of reducing the inlet opening to reduce drag and exhaust(blowing) outlet to increase cooling efficiency.

Probably only a formula car with long side pod rad ducts could recover some momentum but the effect is so small on cars which have much higher drag than airplanes. Probably not worth the effort. Exhaust energy can and has been used to pull more air though the ducts and especially pumping diffusers for higher downforce but perhaps it doesn’t create any more thrust than just facing the exhausts aft.

F1 cars have evolved much smaller inlets over the years as designers discovered you don’t need massive ones with well designed ducts. Would be an interesting experiment if you can figure out how to quantify the gains or losses.

I built a counter-flow radiator inlet air moves from front to back and coolant moves from back to front) 6” diameter by 18” long. It consists of 56 tubes 1/2” diameter it provides for both coolant and oil cooling. The front is fitted with a 3D printed “multi nozzle (56 intersecting conical ducts) to direct air into the tubes. Engine is a Madza 13b with the Tracy Crooks PSRU. I would include photos but see no way to attach images in this venue.

How did you manage the scoop sizing?

You can check out two YouTube videos I did. Search RV6EJGUY, Vids #101 and #102.

Hi

Loved your article it way above my engineering leve now at 82 yr age . However it still makes my mind active . Today we fly giant 1/4 scale Rc war birds we are now contemplating an “ H model P 51. The belly scoop represents significant drag if not an open passage. We have no plans in any Meredith effect purely drag reduction our planes are noe belt drive electric so almost no heat involve what ever comes in the chin scoop is more than enough to cool batts and electric motor we have plans to duct this out the belly scoop the duct will be quite smooth as it will be molded fiber glass . We are most interested in scale appearance an drag reduction this plane will be in the 110 mp range of it went a little faster it won’t hurt feelings it’s still within “ scale” speeds as observed by judges since they know these were very fast planes in their day . Sometimes if something just looks s” scale “ it’s considered scale laughably so this is our intent . There are few plans for them “H” model so we are evolving our own based on various prints we can get internally the cockpit has many pictures so we can detail thy easily it just the basic plane we really need we have pretty good “D” plans that we can modify I don’t see we’l among other things but I act as instructor more than builder now . The H” belly scoop exit door is our weak information point now so any help would be greatly appreciated.

Thanks in advance