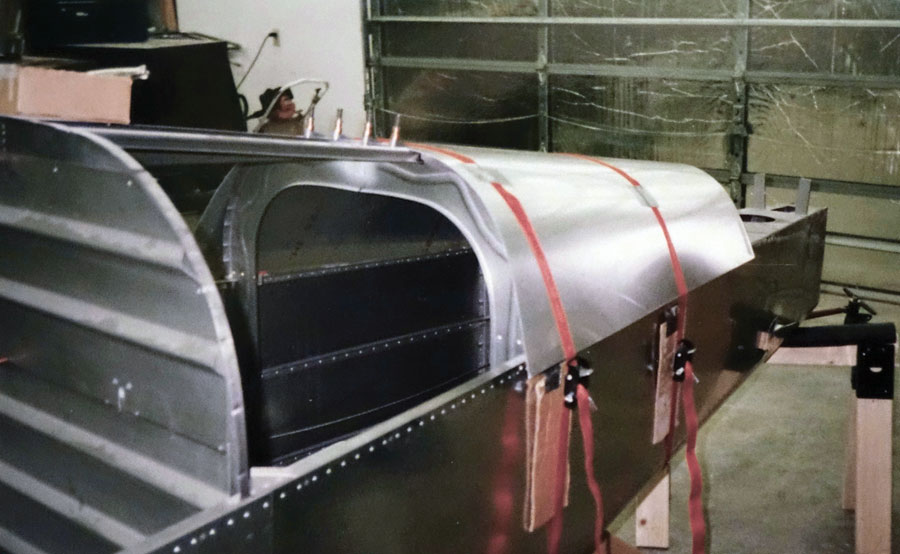

The author’s RV-6. At first he was hoping to buy a completed plane, but when Van’s introduced a tip-up QuickBuild kit, he decided to build instead.

I have been interested in kitbuilt airplanes for a long time. In 1971 I put a deposit down on one. That didn’t turn out very well at all, although I did better than many people by managing to get most of that deposit back. That sort of thing was not unusual in those days. There were many performance and delivery claims that were not founded in reality.

I started noticing the RV series of airplanes around 1996 and visited Sun ‘n Fun around that time to look at them. I was very impressed with the RV airplanes I saw. From chatting with owners I got the idea that Richard VanGrunsven was a man of integrity, and the airplanes did what he said they would do.

I also liked the fact that the airplanes were extraordinarily flexible as to what they could do, but were constructed out of very conventional materials with ordinary techniques. At that time the Rutan designs were very popular, and I had a friend who was building a Long-EZ. That is an impressive airplane that is optimized for speed and efficiency, but sacrifices short- and rough-field capability. The materials kits that were available at the time meant there was lots and lots of working with resins and lots and lots of sanding. I decided this was not the way I wanted to go. As it turned out, my friend developed a sensitivity to the resin that had unpleasant consequences. As it also turned out, the RV kits still have considerable resin work and sanding required.

So I decided I wanted an RV. Realizing that I have limited mechanical aptitude and skills, I started shopping for completed RV-4s or RV-6s. I was not able to find anything acceptable to me. Around this time Van’s introduced the first RV-6 QuickBuild kits. This was intriguing. I thought that maybe with that head start, I could pull this off myself, even though I live in an isolated area and would be very much on my own in the time before internet help. The trouble was, only the RV-6 slider was available as a QuickBuild and that wouldn’t do for me, so I continued to shop for completed airplanes.

Then it happened—the RV-6 tip-up QuickBuild was announced. I think it was that same day I heard about this that I sent off my order.

Even with a QuickBuild kit, there are still several skins that must be fitted, drilled, and riveted by the builder.

Building It

Having no place to build, I arranged to lease part of a television repair shop owned by a friend who is interested in aviation. What an adventure it was diving into this.

My tail kit had pre-punched skins only, and the QuickBuild kit was all old style, which meant the work left to me included plenty of cutting out skins and laying out rivet lines. I was the only one building in the area, and there was no online help available, so I tried to follow the construction manual. Even though that portion of the manual is quite detailed, there was a steep learning curve and many mistakes. As time went by it got easier, but I still spent more thinking time than construction time and found that when things started to go bad that was not the time to forge ahead; that was the time to start sweeping up aluminum shavings and go home.

I have a friend who is quite mechanically inclined, and he had a way of showing up just when I needed him. Despite my preconceived idea of a lot of riveting time, that was not the way it was. But when I did need a rivet bucker, George West would show up. I don’t recall ever asking him to come, he would just be there. The shop owner, Mark Snow, was also a great help. One RV wing is not terribly heavy, but when you are working on it, it needs to be flipped several times and that is best done with two people. After I got the control sticks installed, George showed up one night with some hand-carved cherrywood stick grips. Wow! I am using them and enjoying them to this day.

When I was thinking about how long the build would take, I read something that said if you decide to build and it takes three years, well, three years later you are that much older and you have an airplane. If you don’t build, three years still go by and you don’t have an airplane. Yes, but there are sacrifices. I am not married, but my social life did suffer as I spent about six days a week building. It was usually about 21/2 hours on weekday nights and 5 or 6 hours on one weekend day.

I struggled, learned stuff, made mistakes, and learned some more. By the time I finished, I knew something about aluminum construction, alloys, wiring, welding, silver soldering, panel layout, firewall plumbing, engine installation, and much more.

Even with all I learned, I can see how my airplane is still not up to the standard of newer ones in many ways. Most of that is because I do not have the amazing resources available today, such as Doug Reeves’ Van’s Air Force web site, which sets a very high standard for being informative and civil. The Matronics email list did come along during my build or shortly after, and it was a portent of what help the internet can be.

Flying It

So after about two years of all this, I had an unpainted, unfinished airplane that was ready to fly—and I flew it a lot. It was exhilarating. I had some time in airplanes of similar performance, but I couldn’t afford to fly those as my personal airplanes. More so, I would never otherwise have been able to fly an airplane with fighter-like handling like this. I was intoxicated. Just a thought seemed to be all that was necessary for the airplane to do what I wished. It reminded me of what I have seen with certain horse/rider combinations where the two become one.

Then, when I was out of Phase I testing, there was the travel. As a kid, my family would travel from Southeast New Mexico to Southern California. That was a long two-day slog in a sedan with seven people in it. Because of the heat, we would travel at night, but we would end up going through Yuma, Arizona, with temperatures around 100F at midnight with no air-conditioning. This trip became my standard, and I relished doing it in just part of a morning in the RV-6, cruising along in the cool air above 10,000 feet.

Locals in the Carlsbad, New Mexico, area now expect the author to keep them updated if there is a forest fire or flooding.

There were wonderful tours of the West. One time a bunch of us did this with four RVs and six people. We would fly somewhere like Hot Springs, South Dakota, spend the night with great people, and decide in the morning where to go next. Yellowstone? Glacier? Teton? I loved flying from Missoula, Montana, to Carlsbad, New Mexico, at 17,500 MSL with a 40-knot tailwind with one stop in Grand Junction, Colorado. I loved not having to worry about crossing the Sierra Nevada after spending so many years flying the western mountains in Cessna 150s and 172s.

Shiprock, New Mexico, got its name because early pioneers thought it looked like a giant 19th-century clipper ship.

Along the way I have landed at short and rough dirt strips, done plenty of gentle aerobatics, and greatly enjoyed some of the smaller fly-ins. I’m not an AirVenture kind of guy, but the RV LOE (Land of Enchantment) fly-ins, held for years in New Mexico, were right up my alley. I think it was at those gatherings that I first started appreciating what an extraordinary group of people the RV folk are—aerodynamic engineers, NASA people, test pilots, and all sorts of just plain interesting and competent people. These are people I would have had no chance of meeting without having gotten involved in the RV community. Yes, it isn’t just talk; this is a real community. This part of the RV experience is probably one almost no builders think of, but it turns out to be one of the most satisfying aspects of RV flying.

Maintaining It

The airplane has given very good service. Averaged out, the maintenance costs have not been significant compared to fixed costs like hangar and insurance. I had one condition inspection done by RV expert Randy Richmond of Fort Worth, Texas. I thought I had a cracked weldment (it actually wasn’t) in a difficult to access area inside the cockpit against the firewall. Randy worked on that and some other niggling items that needed attention. His very reasonable fee approached the cost of a normal annual in my previously owned Piper Pacer, which seemed to need new cylinders about every year. The RV’s Aero Sport Power O-360 engine has never been cracked open. I have replaced plugs, magnetos, and a fuel pump that turned out to be OK. Recently I swapped carburetors because of a leak, which a handy person could have easily fixed. Annual condition inspection costs usually run under $100, whereas with the Pacer, I felt lucky if it was under a few thousand dollars.

When the airplane was fairly new, a pilot was trying it and applied full rudder at a fairly high speed. After that event I found a skin crack in the rudder that I stop drilled. It has been stable for the last 14 years or so. That is the single airframe fault I have found. Since that time I guard the controls if I let a certified pilot try the controls. I have not found that to be so necessary with non-pilots who are not used to horsing around a factory airplane.

Early in the life of the airplane, I had problems with various cowl fasteners that I had to change. Many other people have had no problems whatever with those same fasteners. I also experienced problems with exhaust supports, which I used to pretty much rebuild every year. Larry Vetterman has improved the system since then, and with a newer design, I haven’t had problems in many years.

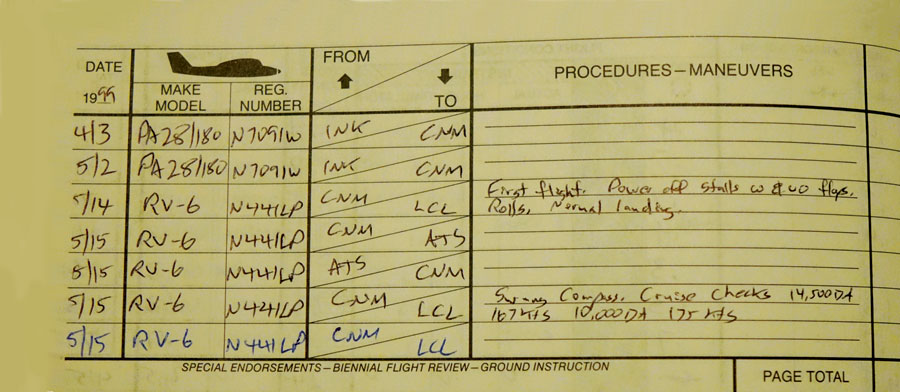

Logging the excitement of the first flight, then a few days later the satisfaction of seeing cruise speeds Richard VanGrunsven advised me to expect.

Enjoying It

As time goes by I have been traveling less and less, but I am enjoying the airplane as much as ever. What I do mostly is patrol my beautiful local area. I take pictures, give rides, and try to keep track of all the interesting things going on around Carlsbad. We have wonderful scenery in New Mexico, and one of my favorite things is to give rides through the Guadalupe Mountains, which are very near my home. The reaction is usually very gratifying. If there is a forest fire or flooding, I will try to get photos for the locals.

A Piper Cub would probably be more suited to what I do now, but I would give up that handling. The wonderful, light and frictionless feel has never gotten old, and it is so noticeably absent when I fly any other airplane. To an extent, it is absent in some heavy RVs I have flown. All that insulation, leather, and avionics does add up, and it affects handling and performance more than some may think. I said earlier that my airplane is not up to modern RV standards in many ways, but it is above modern RV standards in that it is simple and light. Experience suggests that is key to what I think is the core of these airplanes. They are capable of flying effortlessly and naturally in a way that no factory airplanes are able to, in my opinion.

I am very grateful to Richard VanGrunsven for how his designs have affected my life in so many good ways. I have expressed this to him a few times, and I get the impression he is very used to hearing it.