For the first powered airplane flight, flown by the Wright brothers in December 1903, historical records show both the distance flown, 162 feet, and the elapsed flight time, 12 seconds. Not many pilots today keep an ongoing record of how far they have flown in any given flight, or the total distance flown to date. But a record of flight time per flight and total flight time to date is considered such a standard measuring criteria of piloting experience and qualifications that every pilot wants to keep some reasonably permanent record of that time.

Beyond an individual pilot’s personal desire to maintain a record of flight time, federal regulations require it. Certain flight-time records must be kept in order to qualify for higher ratings, to fly certain types of aircraft, or to fly in certain flight conditions such as at night or under instrument flight rules.

It is also necessary to keep track of airframe and engine time in service. Without this information, it is extremely difficult—if not impossible—to properly maintain an aircraft and keep it in airworthy condition. Let’s take a look at some of the most common devices used to keep track of pilot and aircraft time.

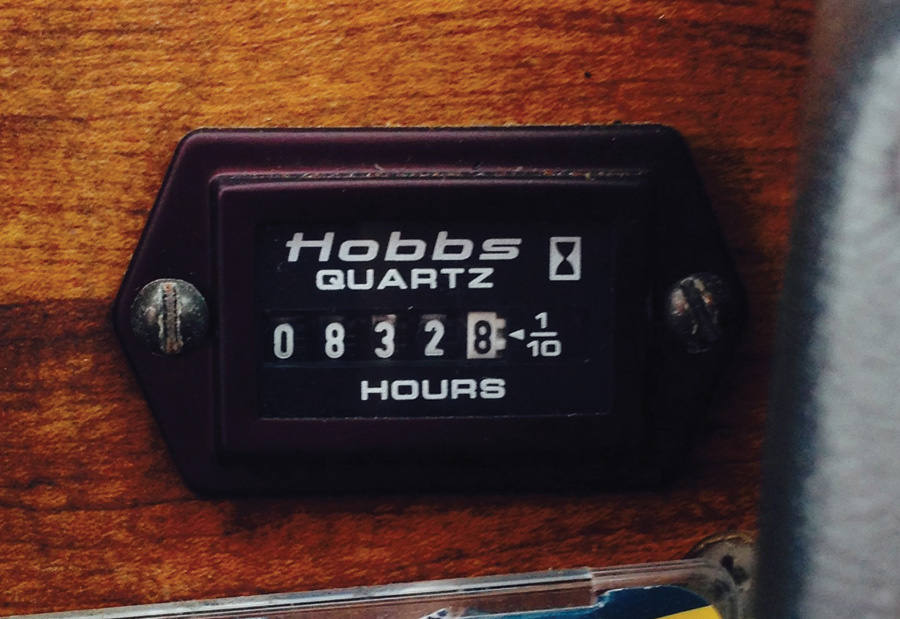

Hobbs meters are quite common in rental aircraft, but the time they record is not exactly in synch with pilot flight time as defined by the FARs.

Hobbs Meters

John Weston Hobbs (1889-1968) invented the Hobbs meter, an electrically driven, elapsed time recording device. There are still indeed actual Hobbs meters that can be obtained for installation in homebuilt aircraft. The generic term, Hobbs meter, is also used for similar devices from other manufacturers.

A Hobbs meter is commonly turned on and off by sensors that detect engine oil pressure, air pressure, or landing gear contact with the ground. Hobbs meters can also be controlled with a manual switch.

Time in service, with respect to maintenance records, is defined in the FARs as the time from the moment an aircraft leaves the surface of the earth until it touches down at the next point of landing. Therefore, if a Hobbs meter is installed so that it runs and records elapsed time whenever the aircraft is airborne, i.e., landing gear not in contact with the ground, it will provide an accurate and regulatory compliant record for all components on the aircraft, such as the engine and prop, that require a record of time in service.

It might also be convenient and reasonable for the pilot to use that very same recorded airborne time as pilot flight time, but it will not be pilot flight time as defined by the federal regulations (see sidebar).

Creating a record of engine or aircraft time in service by having the Hobbs meter record elapsed time whenever the engine is producing oil pressure is a very common practice for rental aircraft. However, it is not in compliance with the federal regulation for time in service. It will also hasten the arrival of the time due for overhaul of the engine or the work on any aircraft components that require maintenance based on time in service.

The mechanically driven hour meter on a tachometer is unable to accurately record either pilot flight time or time in service as defined by the regulations.

Tachometers

A common device for recording elapsed time for service purposes is a tachometer that is mechanically driven by engine rpm. An Experimental/Amateur-Built aircraft operating under day VFR conditions only is not required to have a tachometer. But the operating limitations of that same aircraft operating at night or under IFR do require compliance with FAR Section 91.205 paragraphs (a) and (b), which state that a tachometer must be installed.

The primary purpose of the tachometer is to inform the pilot of engine rpm at any given moment. But somewhere along the line, tachometers also began to display the total time of engine operation. The elapsed time display on the instrument requires a conversion ratio of instantaneous engine rpm into elapsed time of engine operation. If, say, 2000 rpm were chosen as the standard mechanical revolution rate to convert into one minute of elapsed engine operating time, then any engine operation at less than 2000 rpm would generate less than one minute of elapsed engine operating time, and any operation at an rpm greater than 2000 would generate more than one minute of elapsed engine operating time. Therefore, any mechanically driven engine tachometer that includes a time readout can’t accurately record either pilot flight time or time in service as defined by the regulations.

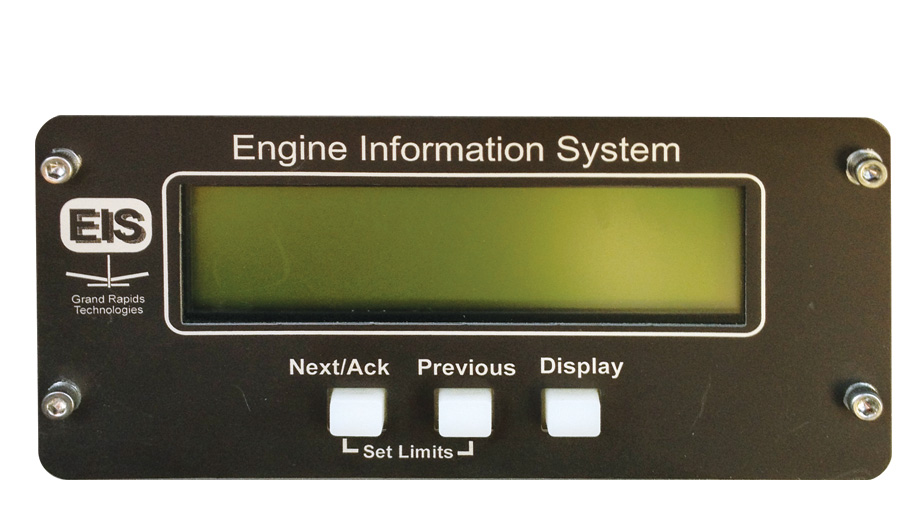

EFIS and EMS

Now we examine what the digital age has to offer for meeting the homebuilder’s automatic time recording desires. There is a wide variety of digital EFIS (Electronic Flight Instrument System), EIS (Engine Information System) and their associated displays and software available to the homebuilder. That variety, along with the ability to modify the manufacturer’s initial software in some cases, makes an exact comparison of one airplane’s time in service or pilot’s flight time record to another airplane’s time in service or pilot’s flight time record a very difficult and complex problem. The probability that either an EFIS or EIS could be programmed to automatically record elapsed pilot flight time in exact compliance with the defining federal regulation is very remote. However, with research and understanding, an EFIS, and even an associated transponder that incorporated an elapsed time recording capability, could possibly offer a convenient means of automatically recording time in service.

The probability that either an EFIS or EIS could be programmed to automatically record elapsed pilot flight time in exact compliance with the defining federal regulation is very remote.

So what can the homebuilder and pilot do? Here are some suggestions:

Don’t obsess about creating and comparing elapsed time records with other airplanes and pilots. Many people are not recording pilot flight time or time in service the same way that you are, and neither are they in exact compliance with the defining regulations.

Do explore the sophisticated record keeping systems that are available and then select equipment and a method of documentation, simple or complex, that seem to reasonably fit both your, and the federal government’s, elapsed time record needs, and stick with them. Be consistent in how you gather and record elapsed time so that you can view and show the results with some confidence.

One example: The choice for the pilot of one digital EIS-equipped airplane was to just record “tach time” from the EIS for both pilot flight time and time in service. The EIS software generated zero elapsed time anytime the engine rpm was less than 1500 rpm and real clock time in hours and tenths any time the engine rpm was above 1500 rpm. Recording the EIS-provided elapsed tach time for both pilot flight time and engine time in service short-changed both of these times since for some amount of airborne time while practicing landings in the pattern, the engine was below 1500 rpm and the EIS was therefore not generating any elapsing time. These inaccuracies were considered minor and acceptable because the method was consistent and greatly simplified the record keeping in both elapsed time categories.

Finally, be both wary and charitable of someone else’s time claims and don’t make a big deal of it unless you are billing or getting paid by the hour and minute.