The more your build—or modify or maintain your Experimental—the more you come to understand the need for specialist tools. Sure, for the most common items, basic tools will do. And, as in this case, where electrical wiring is concerned there can be a world of difference between the cheap tools and the stuff the semi-pros use. That difference can help make your work better and much more consistent—as well as quicker.

What follows is the collection of tools that always seem to be on my bench or roll-around project cart when wiring is involved. My tools carry some custom marking. For example, I put a small red Sharpie mark on the slot for 22-gauge wire in my Ideal stripper. There’s also a silver mark on the correct die for the first Molex crimp. This trick can help cut the time it takes for repetitive tasks and improve your accuracy.

End or Flush Cutters

Nothing more frustrating than to pull your arm back through some small access point in the instrument panel to see you’ve been cut raw by the tang ends of zip ties. A good set of end cutters is useful for not only trimming the tails off flush with the clamp but for removing old ones. I’ve used these Hakko miniature side-cutters for some time with great luck. Buy a three pack because you’ll be tempted at least once to use them for something bigger than they can handle and a dented or bent side cutter is next to worthless.

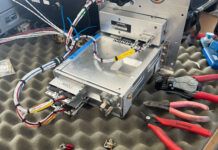

Molex Crimp Tool

Like many builders, I have a love/hate relationship with Molex’s lightweight plastic connector series. Truth is, I find the lightweight versions really useful. When I installed my new Garmin GTR 200 com radio, I didn’t have everything to connect to it, but I stubbed out four audio sources (two in, plus music in and recorded audio out) and the RS-232 data. The smaller Molex connectors (with the 0.062-inch pins) are perfect for this, especially since you can order the pins and sockets for exactly the wire gauge you’re using. The trick to happiness here is the right crimper tool, which I bought from B&C Specialty Products many years ago. The BCT-2 ($39) works wonderfully on these smaller Molex pins and sockets.  I’d tried several “off the shelf” crimpers but this is the only one that performs consistently well, making the double-inverted-U crimps accurately, even on the thinner insulator found with Tefzel wire.

I’d tried several “off the shelf” crimpers but this is the only one that performs consistently well, making the double-inverted-U crimps accurately, even on the thinner insulator found with Tefzel wire.

Incidentally, the official Molex extraction tool is good but fairly expensive. These have worked well for me.

Ideal Stripmaster

A wire stripper is arguably one of the most important of the wiring tools. I’ve tried a bunch, from a pull-style stripper, common plier-type stripper and others. The best by far is the Ideal Stripmaster. Understand that there are several versions of the Stripmater but the one you want is the 45-097, which I also purchased from B&C for $69. It has the correct dies for the most common Tefzel wires you’ll be stripping. (In fact, in my recent project, I’d say 90% of the wires are 22 gauge.) Once you get the hang of using the Stripmaster, it’s easy to correctly strip the right length of insulation for D-Sub pins, Molex pins and sockets, butt and ring terminals plus much more. A wire stop tool is an add-on but with some practice you’ll get good estimating the proper amount of strip for the terminal at hand.

D-sub Tool

Face it, working with D-sub connectors can be frustrating. I’ve lost track of how many of those red/white (or green/white, for high density) tools I’ve bent or otherwise obliterated while trying to extract seated pins or sockets. Yes, it could be my caveman-like approach but these tools have always vexed me. Not this one. I happened upon this while perusing Amazon and it’s likely to be available under various brands, but mine is the JReady and has worked beautifully for some time. The trick is, as you may know, to use the tool to insert directly into the back of the connector and twist to release the pin or socket. Any angle can bend even this tool and only frustrate you. And while I really like this tool, I can’t seem to find its equivalent for the high-density pins used on some Garmin equipment.

Ratcheting Crimper

Here’s another one of those slight extravagances that pays back with time saved and better-quality work. There are a bunch of these on the market, but I found this Klein version at my local big-box store and it’s performed well for years. Once set up, you’ll get consistent crimps in insulated terminals every time. (Doesn’t mean you shouldn’t pull-test them, but anything to improve your consistency is a good thing.)

Coax Stripping Tool

I’ve had this Knipex tool in my kit for many years. It’s designed to strip coaxial cable in one motion. Using three blades, it strips the outer sheath, the braid and the insulation around the center conductor. While each blade can be adjusted for the depth of cut, I’ve left mine set so the center conductor is slightly shallow, which gives me the chance to finish the cut manually and inspect the center conductor carefully. If you cut into the center conductor, the pin for the BNC or TNC connector might not seat properly. I’ve used this tool for years and it still cuts well. By the way, use the RG-58 setting to cut the preferred RG-400 coax.

Coax Crimping Tool

This is another tool I bought from B&C and it works splendidly well with the common BNC and TNC connectors you’ll find in aircraft. Plus, B&C has a simple tutorial on its website on how to use the tool.

Wire Spoon

Another one of those tools you don’t know you need until, well, you need it. We’ve all finished up a harness, tidy and neat, only to discover there’s one more wire to add. The Wire Spoon allows you to sneak a wire into an existing harness without too much drama. Be careful, though; the tip is sharp enough to pierce skin. Ask me how I know…

Another one of those tools you don’t know you need until, well, you need it. We’ve all finished up a harness, tidy and neat, only to discover there’s one more wire to add. The Wire Spoon allows you to sneak a wire into an existing harness without too much drama. Be careful, though; the tip is sharp enough to pierce skin. Ask me how I know…

Please double-check links for “Ratcheting Crimper”- the URL points to the D-sub pin extractor (which I ordered, thank you!)

Thanks, Ron. We’ve fixed the link.

That type of side cutter seems very common but does not last for me. They always seem to bend and the cutting edges go out of alignment. Nothing good happens after that. I stick with the side cutter concept but aim for something with a more robust pivot point. They are often targeted at modelers for plastic sprue cutting. Something more like this:

https://www.amazon.com/dp/B099J9TN2T/?th=1