From our first date, an evening flight over Galveston Bay, my wife Jennifer and I have always enjoyed travel in small planes. We try to get away as often as possible. Whether a weekend trip to the Texas Hill Country, New Orleans, or a week in the Rocky Mountains, trips in the plane are special to us. And it’s always fun to give Monday-morning trip reports to our non-flying friends, describing our 2- to 3-hour flights to scenic, fun destinations that would take 5 to 10 hours of driving or the better part of a day by commercial airliner.

Our latest adventure was a three-day trip to the Big Bend area of Texas. This is one of our favorite areas to visit. In many ways, it’s the opposite of Houston: sparsely populated, dry air, quiet, and amazingly scenic expanses. It’s a nice place to recharge after living the urban lifestyle.

We were traveling in our Lycoming-IO-360-powered RV-8. The winds were near perfect for the eastbound return flight. The higher the altitude, the better the wind speed. Knowing we would climb as high as possible on the flight, I put us both on oxygen as we departed Alpine.

About 45 minutes into the flight, as we were settling in at our cruising altitude, I recall looking down on the clouds covering some of the most desolate areas of Texas and thinking that having an engine problem out here would not be good. A few minutes later, it happened. No perceptible warning, just an instantaneous engine roughness and a noticeable slowing of the plane. Instinctively, I began making mixture adjustments, while cross-checking airspeed, altitude, and engine temperatures. At the same time Jennifer, sitting in the back seat, advised me in a firm voice that I really needed to stop doing whatever it was I was doing.

The flight from Alpine crossed some of the most desolate areas of Texas. After diverting to Ozona, the author spiraled down to the FAF, then flew the approach to Runway 16.

Seeing that my adjustments made no improvement, and letting the situation soak in for a couple of moments, I realized that this was indeed not my doing. We would be landing somewhere soon, and it would not be in Houston.

Diverting to Ozona

Planning the flight, I knew we’d be flying over the top of a solid layer for about one-third of the trip. Weather reports indicated the cloud cover was solid and ceilings low at 300-500 feet. But judging from the lack of precipitation on the radar, having onboard weather, multiple nav sources, and autopilot, I felt like it was an acceptable risk. If we had an issue forcing us to divert or turn around, we had 4 hours of fuel and several airports no farther than 30 minutes flying time off our route. We were good to go.

With the rough engine and slowing plane, I knew in fact that we had a problem, and this condition was not some exaggerated over-lean stumble. Now it was time to work through the emergency checklist. Recalling that part about being over a really desolate area, I first pressed the nearest button on the GPS. Ozona came up as the closest airport with an approach. First priority, head to the nearest good runway with an approach. That was 35 nautical miles away.

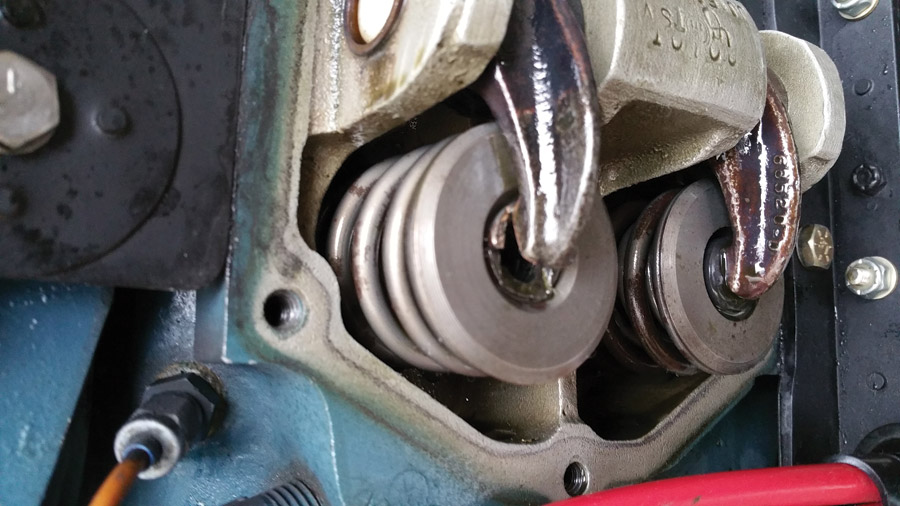

Inspection revealed that the number 4 intake valve/spring retainer keys had failed and the valve had floated loose in the guide. Eventually the entire valve train failed, leaving the valve stuck open.

I knew Jennifer was already anxious. You couldn’t miss the stumbling engine and reduced wind noise. Throw in the 50-60 heading change, and she knew this was not a good situation. I spoke up and told her we were diverting to Ozona and needed to make a precautionary landing to check things out. I didn’t mention the 35 miles and 300-foot ceiling below.

Established on a course to take us toward the runway, and after going through the emergency checklist with no improvement, I tried some minimal power, mixture, and propeller-speed adjustments. Recalling instances where flight crews had a flyable sick plane and made it totally unflyable by messing with it too much, I only made very small changes. There was no improvement, so I left things alone. I absolutely did not want to lose what power we had.

We were now a powered glider. It might work out if we stayed that way. Going through the mental calculation of RV-8 gliding performance, altitude, and nearest runway, the result wasn’t good. We absolutely would not be able to stretch a glide 35 miles without power. If the engine quit, we realistically had 10-12 miles glide range. So, it was time to think about Plan B. This meant landing on a road—if I could find one below the overcast. But it might also mean camping with the plane for the night, or at best, a 1- or 2-hour drive to a town. In either instance, I really had to let someone know exactly where we were located.

In cylinder 2 the tabs that secure the valve stem to the spring retainer were more than half worn away. Eventually, the valve stem became free of the spring retainer.

Calling for Help

Jennifer is a great flyer. We enjoy traveling all over Texas and the Southwest. She enjoys a little aerobatic flying and tolerates all kinds of turbulence, but she had never flown in this type of situation. Actually, neither had I. In 28 years of flying, I’ve always brought my plane home. She was really doing better than expected, but I knew the coming radio conversations would scare her. Her being really upset would only add more distractions at a time when I really needed to concentrate. So, I decided to switch her intercom audio off.

I dialed in 121.5 and called in the blind. After a few seconds, I received a reply. After a couple of exchanges, the very helpful voice on the radio let me know he’d copied my information and relayed it all to air traffic control. I felt relief hearing this. After another minute or two, my friend on the radio came back with a frequency for Midland Approach, where they were expecting to hear from us. I thanked him for his help, and let him know we’d be changing frequencies.

Failed intake valve spring retainer keys allowed the valve to become caught between the rising piston and the upper spring retainer.

I called Approach and advised that we were the Experimental that had called on Guard. I advised that we were direct to Ozona and would be straight in to Runway 34. He asked if we knew Ozona was overcast 300 feet, and if we wanted another airport. I told him quickly and without hesitation, we were unable and would be direct to Ozona. I could hear in his voice that there was no need for further explanation. He understood the nature of our situation.

I kept working on best glide speed while hand-flying the plane. Worried about not making it to the runway, I began looking for other options on the GPS moving map. I noticed a highway leading into Ozona from the south, so I veered east a little to intercept the road. It was a better option for landing than the rolling, rocky hills throughout this area, should we come up short.

My approach controller asked me the typical search-and-rescue questions. It was a bit unpleasant thinking about a bad outcome, but I knew it would be needed if someone had to come find us. Then he asked me to take down a number to call him after landing. Trying to write the number on paper, I realized my fingers really weren’t working very well. So I typed it into my phone. I didn’t feel that stressed, but obviously I was. This made me remember that I was still on oxygen. So I cranked it even higher. It may not be helping my handwriting, but it had to be helping my ability to think.

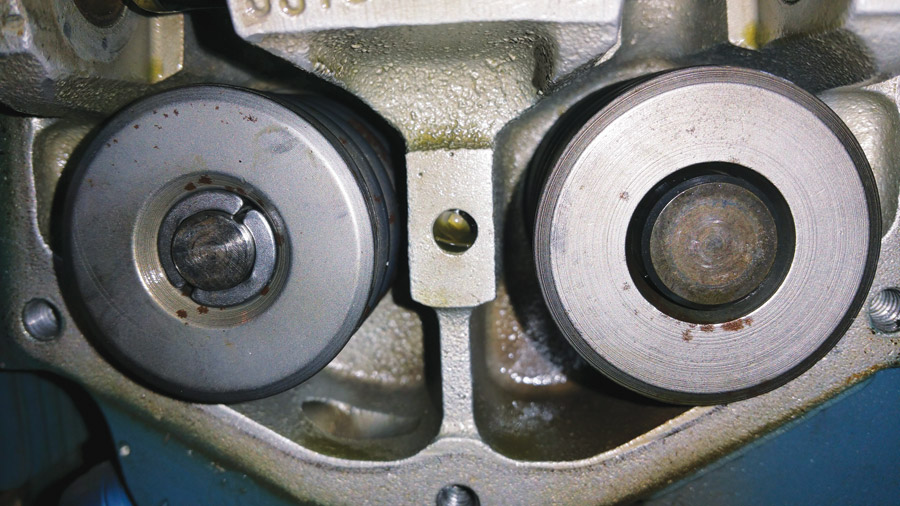

Compare the partially failed intake valve keys from cylinder 2 (left) to normal new intake valve keys (right).

Preparing for the Approach

There was not going to be a visual approach to any runway within 50 miles, being solid instrument meteorological conditions as far as we could see. With the current engine condition, Ozona was where we were going. So I pulled up the approaches. There was only one approach and it was to Runway 16. No approach from the south? Must be obstructions.

At five miles or so from Ozona, I realized we had sufficient altitude to make the field. One thing that was helping was the improving southerly wind. As we descended, it was switching to a very nice tailwind. This helped, but we still had the no-go-around approach to make.

Approach saw us tracking east of the airport, and asked about our intentions. I told him that with our current favorable altitude situation, we were going to be landing on Runway 16. We planned to fly to the final approach fix (FAF) and make a spiraling descent to approach altitude, then fly inbound. We had to make the spiraling descent because I did not want the engine to quit short of the airport while performing a normal, extended approach. We also had to lose altitude. I had considered spiraling down directly over the field, but with a 300-foot overcast ceiling, it was just too low to be safe.

Normal (top) and failed intake valve keys (bottom). Note that under normal conditions, the valve stem should project clearly by 1/16 inch or so above the keys.

Spiraling down to the FAF in the clouds may not sound like a good plan—but it was the best plan. I’d taught many multi- and single-engine instrument approaches, but I had never done one like this before. I sensed apprehension from my controller upon hearing my plan. Attempting to help him better understand the situation, I let him know I was rated and equipped. He cleared me for the approach.

With the understanding that we had surplus altitude, I began to decrease engine power abeam the approach end of the runway. The changes in engine operating conditions became evident. Vibration seemed more noticeable and temperatures were climbing erratically. I noticed the visual alarms on the engine monitoring system. I didn’t worry much about it. Actually, I had to ignore it. Just before beginning the spiraling descent, I consciously told myself that it was time to fly the plane—and there would be no missed approach.

One last item before beginning the final descent: I switched Jennifer’s intercom audio on and told her we were setting up for the approach. I gave her my typical get ready to land and tighten your seatbelts speech. She was pretty quiet as I switched the intercom audio back off.

Entering the Clouds

I knew that once we began the descent to the FAF, things would be getting busy and serious. I was still working on one unresolved question: Should I fly a steep final approach, or standard descent profile? We entered the clouds somewhere around 7000 feet after a half turn in the spiral descent. I began to get vertigo just after entering the clouds, but I reminded myself to begin scanning the instruments and fly the plane.

After two turns we rolled out on final, lined up pretty well, but still high. I remember recalling we were some 2000 feet higher than prescribed on the approach—but high was OK. Approach speed was also high, but I was concerned about the negative effects of reducing power and the engine possibly quitting.

Staying on course was not too challenging. The air was smooth, as you’d generally expect in low-overcast clouds. I scanned airspeed, altitude, track, and distance to the airport. Based on normal approaches flown in this plane many times before, things seemed to be happening slowly. The last leg to the airport was taking too long. I thought it must be the stress, so I wrote it off. In hindsight, I had not considered the 15- to 20-knot wind on my nose.

I knew the breakout altitude was somewhere around 300 feet above airport elevation. I had a good local altimeter setting, so I just kept descending and staying on course. At 400-500 feet AGL, I started noticing some features in my peripheral vision. Just as reported, at about 300 feet, we broke out of the clouds into 10 miles of visibility and a runway about one-half mile off our nose. I switched to local frequency and advised I was landing.

The landing went well. I consciously tried to ease it on smoothly for my wife. The engine wasn’t too happy, popping and making some pretty significant racket. At this time, the noise made me think it wasn’t fouled fuel injectors, and we had experienced some real physical damage to the engine. Reviewing the recorded engine information, I realized that I should have shut it down on the runway. The engine had been getting very hot on descent due to the altered air and fuel delivery conditions.

Welcome to Ozona

We stopped near the terminal, shut down, and got out. My wife wasn’t too happy at this point. She said the clouds scared her. With our feet firmly on the ground and the plane chocked, I told her it was all good. We’d just done what thousands of people do every day: make an instrument approach through the clouds. I didn’t think including the other issues would be helpful in calming her at this point.

I realized we were now in good shape standing there on the ramp, but my approach control friend was probably wondering if we were in a ditch somewhere. So I called the number he gave me. He answered, and I told him we were parked and in good shape, and that we really appreciated his help. He seemed happy to hear us calling and said he was glad he could help.

It was windy and chilly on the ramp, so I got my wife in a coat and blanket we were carrying. Then I turned my attention to the plane. Curious as to just what the heck happened, I began uncowling the engine and looking for issues. The first thing I noticed was oil on the belly and bottom cowling. Fouled fuel injectors usually don’t cause oil leakage. Great, did I have a hole punched in the crankcase? No. Following the oil, I found a very thoroughly bent number 4 cylinder intake valve pushrod and shroud. That was the source of the oil and surely related to the engine problems.

The wind was really whipping around, and it was chilly. I knew this certainly wouldn’t be fixed on the ramp today, so we closed things up, packed our bags, and tied down the plane for the evening. No rental or courtesy cars were available, so we accepted a ride into town to a hotel from the airport manager, Charles.

The next morning, after securing the only rentable ground transportation in Ozona—a U-Haul truck—we went back to the airport to do some airplane inspections before heading home. What I found was very interesting. It appeared that the number 4 intake valve/spring retainer keys had failed and the valve had floated loose in the guide. Eventually the entire valve train failed, leaving the valve stuck open.

This would take a lot more parts and tools than we had available, so we decided I’d return later to repair the plane. We secured the plane in a hangar and headed east on the 7-hour drive back to Houston.

Failure Sequence and Impact to Engine Operating Conditions

Disassembly and inspection confirmed that the intake valve spring retainer keys failed. This allowed the spring retainer to move upward, or away from the engine, along the valve stem. Eventually, the valve stem became free of the spring retainer. According to the engine monitor, I believe the valve floated freely for some 10 to 11 minutes. At this point, the valve was caught between the rising piston and the upper spring retainer. This caused the pushrod to buckle.

After this, the pushrod became clear of the valve lifter, but the valve was left stuck partially open, allowing gas from the number 4 cylinder to be pushed into and pulled from the engine induction system.

This alteration of the induction system caused significant problems with the other three cylinders, which resulted in the rough operation and low power output. Between the dead number 4 cylinder and the impact to the intake stream of the other three cylinders, I believe overall power was reduced by 40-50%.

When cylinder 1 is on the intake stroke, cylinder 4 is on compression stroke. Air is pushed from number 4 though the stuck intake valve into the induction system. This boosts air charge and slightly leans the overall mixture entering number 1. When cylinder 2 is on intake stroke, cylinder 4 is on the exhaust stroke. With both valves open, the amount of air being pushed into the induction system is reduced, but still acts to slightly lean the mixture entering number 2. When cylinder 3 is on intake stroke, cylinder 4 is on the power stroke. With a stuck intake valve, number 4 is now taking air from the induction system. This effectively reduces air feeding number 3, enriching it.

In summary, an intake valve failed in an open condition causes a hideous cascade of problems to the entire engine fuel/air distribution. The disturbance was so severe that at one point, cylinder 3 quit firing completely due to being overly rich. At another point, temperatures in cylinder 1 climbed very high due to a lean and overcharged mixture. The overall result was an engine running rough with severely reduced power and unstable temperatures.

The Other Cylinders

Inspection of cylinder number 2 revealed a partially failed set of intake valve spring retainer keys. The tabs that secure the valve stem to the spring retainer were more than half worn away. Cylinders 1 and 3 revealed no abnormal conditions. For reference, partially failed and normal intake valve keys are shown above.

Researching failure of intake valves on similar Lycoming engines, I discovered very few similar events—but I did find one documented in an FAA report from 2009. An O-320 had experienced intake valve spring retainer key failure. The failure was attributed to the keys. One major difference is the one documented in 2009 apparently did not result in pushrod and/or cylinder head damage.

How to Determine if Your Engine Has Failing Keys

If you have the style of intake valve with wedge-shaped retainer keys, there are two steps to take to make sure you do not have bad components. The first is very easy and takes just a few minutes per cylinder.

Remove the valve cover. Look at the amount of projection from the top of the valve stem to the top of the keys. The stem should project clearly above the keys by 1/16 inch or so. If the valve stem projection is less than 1/16 inch, or below the top edge of the keys, you should disassemble and inspect further before your next flight.

To perform a detailed inspection on the keys, you have to release the spring from the valve stem. Research “Lycoming Rope in Cylinder Field Removal of Valves” for more information on releasing the springs. Once you have this completed, look at the keys. The tab on the inside diameter surface, generally speaking, should be the same length as the groove on the end of the valve stem. If the key is not of sufficient strength or hardness, the tab will begin to wear away and eventually fail.

If in doubt, replace these with new items of known sourcing. Don’t just clean off some old, dusty ones out of the surplus Lycoming parts drawer. The damage that can result to your engine and impact to safe flying is significant.

Special thanks to Jeff Bertsch for flying me back to Ozona and helping with repairs. And for those of you who are wondering, yes, Jennifer continues to fly with me in our RV-8.