Of all the ways to get an RV to VNE, nitrous oxide injection is one of the more exotic. Something of a forbidden fire in the hot rodder’s bag of tricks, building big horsepower from nitrous is on one hand so easy engine builders say it’s your engine on drugs while more experienced practitioners get a little quiet when recalling fireballs and torched pistons. But to the high priests chanting the proper incantations, nitrous seems a short path to the winner’s circle.

Of all the ways to get an RV to VNE, nitrous oxide injection is one of the more exotic. Something of a forbidden fire in the hot rodder’s bag of tricks, building big horsepower from nitrous is on one hand so easy engine builders say it’s your engine on drugs while more experienced practitioners get a little quiet when recalling fireballs and torched pistons. But to the high priests chanting the proper incantations, nitrous seems a short path to the winner’s circle.

It’s not so bad as all that when used, er, responsibly, and so we were cat-curious during the 2019 Reno pilgrimage when Todd Rudberg qualified his RV-8 at a heart-fluttering 277 mph. That’s an average speed in level flight around a turning course, mind you. It’s also the fastest lap we can find for an RV airframe at Reno, which means Todd has outpaced even Bill Beaton’s supercharged 540 Harmon Rocket around the pylons. That’s saying something.

Turns out there’s nothing overwhelmingly sleek about Todd’s airframe, either, which if straighter than normal and aside from a custom canopy and a few other detail improvements is at least visually the same ’ol bus 1500 other RV-8 builders are enjoying. So most of that speed seems to be coming from a fairly regular Ly-Con IO-390, a good constant-speed and enough blue bottles to recreate a full season of Sea Hunt.

Furthermore, a quick glance at Mr. Rudberg’s plane shows a level of execution that typically follows developed thinking, and this is the case with Todd, who thanks to a CFI dad, can’t remember a time outside of aviation. Originally starting out in the Marine Corps PLC program but quickly moving on to a career in aerospace engineering, Todd is a major player at Electroimpact in Mukilteo, Washington. There he puts his physics degree from the University of Washington to excellent use in robotized carbon fiber wing layups along with multiple other highly automated procedures for outfits such as Boeing, Airbus and Bombardier. Electroimpact machinery is currently building the spar and skin on the Boeing 777X wing, for example, so clearly Todd has the brains and resources for a little fun at Reno.

Todd originally built his RV-8 as transport to visit his children after divorce separated his family. And while that worked, he’s since cooled on the idea of flying IFR over the Cascades in little single-engine skeeters. Instead, his association with the Blackjack Squadron formation team lead him to Reno pylon racing in 2017. Jeff LaVelle, a Sport Class front-runner, is also a Blackjack Squadron member, and it was he who gave Todd the push to Reno.

Comprehensively Wrinkled

Just after his introductory year at Reno, however, Todd had an impactful meeting with a herd of runway-crossing elk in December 2017. He nearly escaped unscratched, but by just nicking one elk he lost a prop blade and suffered a nasty, gear-failing ground loop. In the resulting total rebuild his RV-8 was named Undaunted for its ability to rebound from the elk disaster, plus it gained several racing-bred improvements to the cowling, spinner and wing roots.

“Rebuild” is a bit light duty. As the elk-bit airplane was comprehensively wrinkled, Todd ended up buying an untouched RV-8 kit from a fellow with second thoughts on aircraft building. That kit was in upstate New York, and Todd ended up working with Wilson Champ in Pennsylvania on melding the original and new parts into what’s really a new, straight RV-8.

Working within his busy schedule, Todd made six 10-day trips to Pennsylvania, working very long days to put the aluminum together. Essentially a building partnership, the build with Wilson proved a great collaboration. “He’d have parallel but better ideas,” said Todd. “It was the funnest partnership I’ve ever had.” Avionics were handled in Washington by Todd and crew chief Colin Hover, and when the airplane was complete Todd and daughter Sarah flew it home via Nashville, New Orleans, Sedona and, appropriately enough, Reno. Not quite incidentally, Sarah just graduated from the family alma mater, University of Washington, as a mechanical engineer and Todd’s other daughter, Rebekah Horch, crews on the race plane as well.

For power, Todd knew he wanted a 390 Lycoming and nitrous combination. Because he regularly flies his -8 as daily transport and for formation flights, he wanted the RV-8 as stock as possible, ruling out turbos or big six-cylinder engines. That would conserve weight and preserve the pleasant Van’s handling because the nitrous system is designed to remove easily when not pylon racing. As Todd put it, “When I take the nitrous system off of that airplane, it is just a sweet-flying RV-8. It does have extra power from that IO-390 and it’s clean. But other than that, it’s a stock airplane that climbs at 2500 feet per minute or maybe more and cruises at 200 knots or 230 mph naturally aspirated in an altitude range of 5500 to 11,000 feet.”

Therefore, nothing overly special was done to the core engine as nitrous works best when assisting a well-developed naturally aspirated engine. Todd had Ken Tunnell at Ly-Con build his 390 Lycoming, noting, “You got to call Kenny if you are going to be racing.” Compression was set at 10:1 with Ly-Con’s NFS pistons, plus, “Kenny did whatever he does on the camshaft,” including diamond-like coating (DLC) the cam and lifters. Bendix mechanical fuel injection is used.

Adding Nitrous

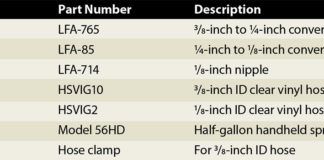

Because Todd knew the common automotive nitrous kits were not up to aviation hardware standards or designed for long-duration use, he wanted to design and build his own custom nitrous system. “Since I was building the airframe almost from scratch already, I knew the weight and balance down pat, and I knew I had capacity for about 200 pounds back there [in the rear passenger seat]. So I went with the biggest bottle—20-pound bottles.” He calculated, “I could make big power for 10 minutes, and in qualifying I can make more than that [for a shorter period of time].”

Todd’s machinist background was handy when whittling out various small parts such as the nitrous manifold in the back seat. He admits there are a few commercially available Nitrous Express parts in his system, and that as a sponsor and from a hardware standpoint they’ve been a big help. But mainly he’s breaking new ground in running nitrous for such long durations. This includes the additional, standalone fuel system using NASCAR-quality Brown & Miller Racing Solutions lightweight hoses.

Operationally Todd’s system is purely mechanical with valves opening the separate nitrous and additional fuel systems. Each system is independent of the other and manually controlled, so this is at least simple engineering, especially on the nitrous side. All four bottles feed into the single manifold, and from there forward to the engine’s primer ports. A single needle valve from Nitrous Express allows manually tuning the nitrous flow. Todd runs the bottles to approximately 75 percent empty, which is when nitrous flow slows non-linearly as bottle pressure drops. Jetted for a 100-hp power boost there is, as calculated, about 10 minutes of nitrous on board.

The extra gasoline is also added mechanically by controlling fuel pressure at the regular Bendix system’s nozzles via another needle valve. “I monitor fuel flow and EGT to determine the proper fuel pressure setting…I am targeting a fuel flow to set the power and nitrous amount to maintain a mixture. It’s a lot of headwork and takes some hand-brain coordination. I bypass the RSA-5’s fuel system when in the race configuration. Adjusting fuel flow manually is tricky and the control is sensitive.” Indeed, to the point where Todd is considering a move to electronic fuel injection and incorporating the nitrous assist’s fuel needs into the EFI’s programming. This would greatly reduce his workload while racing, keeping his head up and out of the cockpit.

As if to illustrate the point, Todd got a little behind on his engine management during a heat race last year and sneezed the engine. Sneeze is the racer’s euphemism for an induction backfire (think gasoline bomb), or as the engineering-oriented Todd recalls, “Sneezes are high-energy events and should be avoided at all costs. It did no damage other than kill my fuel servo and scare the crap out of me. I saw the cowl expand and orange plasma escape through the cowl seams at the firewall. The motor would start and idle fine, but would not make any power and ran very lean and rough if you opened the throttle. Kenny really supported me…and overnighted mags and a fuel servo to me. However, by the time they arrived, another racer offered to let me use his fuel servo for the duration of Reno.”

Other Factors

Another racing consideration is the on-off nature of nitrous. Without the “squeeze” Todd’s RV-8 indicates 180 knots at normal rpm, which is a bit light when gaining speed with the larger-engined, sleeker airframe competition prior to the start. Going down the starting chute, speeds can be high—perhaps a worrying 300 mph (260 knots)—which doesn’t bother the Glasairs and SX300s, but even the most gung-ho RV driver squirms at such velocities.

Todd works off of indicated speed in knots when racing and has a personal limit of 235 knots IAS for the airframe, a speed he can likely exceed in level flight, much less coming down the starting chute. Therefore, at the start he has a power setting in mind, but then the pace plane might bring the field steeply down the chute one time and not so steeply the next. In short, Todd can be a busy, conflicted man at the start as he fiddles with his power knobs.

Also worth mentioning is the cost of nitrous. It’s an old saw in racing that nitrous systems are inexpensive to install compared to a turbo or supercharger, but after consuming enough nitrous the calculus goes the other way. Todd used literally over a ton of the stuff while testing and calibrating his system prior to Reno and goes through 10 bottles during race week. A volume discount arranged with Central Welding in his Seattle hometown helped with his first 3000 pounds of nitrous, and now with the initial testing completed he doesn’t need quite so much annually. Luckily crew chief Colin has a hazmat-endorsed driver’s license so the team can legally transport such large volumes of nitrous.

Finally, as with any power adder, Todd’s Lycoming heat-rejection needs have risen greatly. He answered with a homegrown water spray bar system added after the 2019 Pylon Racing School. This simply spritzes water on the outside of the engine increasing cooling via evaporation. The plastic water tank goes in the nose baggage compartment (a smoke system lives there when not racing) supplying the five gallons of water expended per race. That’s in addition to 60 pounds of nitrous, so Todd starts his races heavy—“weight is good coming down the chute”—and finishes noticeably lighter.

While we don’t expect to see a rash of bottle-fed RVs at the next pancake breakfast, racers such as Todd are pioneering a modern nitrous reprise that could be useful to the sportier among us. Coupled with electronic controls it seems a plausible burst of power for when turbos and blowers are a little too much.

Photos: Tom Wilson

Very cool article. I find it interesting with the Lycoming 390