The ignition system lights the fire that makes a gasoline engine (sometimes called a spark-ignition engine) run. The alternative is to use high compression to initiate the combustion process. Such powerplants are commonly called compression-ignition or diesel engines. Although diesel engines are emerging as alternatives to spark-ignition engines, they have not yet become widespread in Experimental airplanes.

Magneto Basics

The conventional way to produce spark for an airplane engine is by means of two magnetos. The magneto has a distinct advantage for airplane use because it produces its own power and does not need any outside source of electricity. A magneto doesn’t care if your battery is dying or even completely missing. If your engine is turning over, a magneto just keeps on making sparks. With two magnetos, the chance of having no source of ignition for your engine is quite small. With one magneto failed, the engine will not run as well, but it will still get you safely on the ground. If you start a flight with two good magnetos, it is extremely unlikely that you will fail to make it home because of an ignition failure. For all their shortcomings, this ability is a particularly endearing quality.

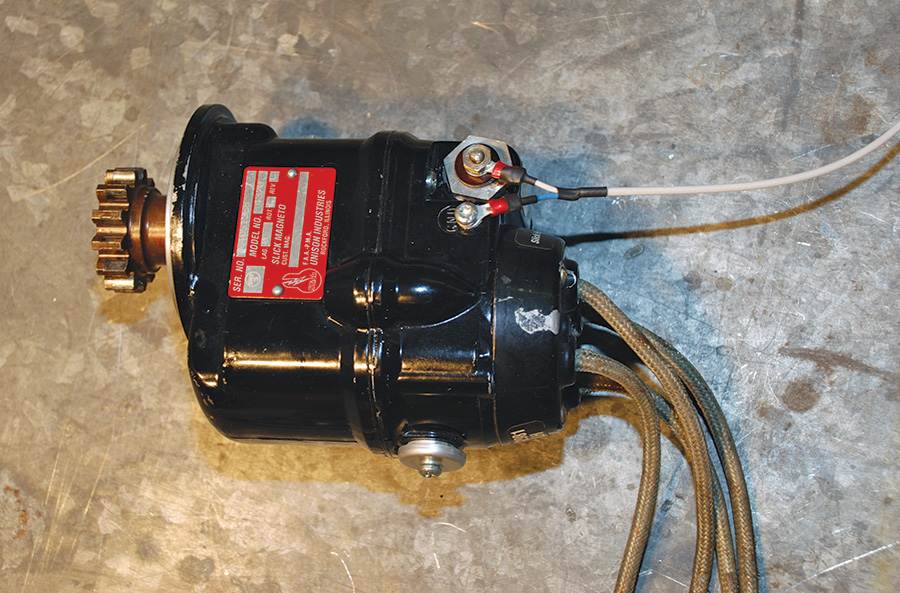

Magneto systems are simple, effective, redundant and safe, but unfortunately, a bit crude. They have fixed timing, which means they only have the optimum ignition timing for a narrow set of engine-speed and loading conditions. A typical airplane has its timing locked at 20-25˚ before top dead center, deviating from this only to start the engine. This is fine for some power settings, but not for others. Magnetos also have parts inside them that rub on each other and wear out. In fact, Slick, the supplier of many magnetos for new Lycoming engines and most engines destined for Experimentals, recommends overhauling its magnetos every 500 hours, at a cost of several hundred dollars each. Can you imagine a new car being sold today that needed to have its ignition system overhauled every 500 hours?

An airplane magneto is a small generator producing alternating current. The voltage produced by the magneto is boosted by a coil and switched by a set of breaker points. A rotor and distributor cap route the high-voltage current to the appropriate spark plug at just the right time, when everything is working properly. It is a fairly simple and certainly well-proven system, even if it is a bit inelegant by today’s standards. The main redeeming quality of a magneto is that it needs no outside source of power to work.

There are two types of airplane magneto systems in wide use, distinguished by how they work during the engine start-up phase: impulse coupling magnetos and retard breaker magnetos (sometimes called shower of sparks).

Impulse Coupling Magnetos

In the most common configuration, the left magneto (as seen from the pilot’s point of view) has an impulse coupling built into the magneto drive mechanism. The impulse coupling retards the spark timing to 0˚ advance (top dead center) to ease starting and avoid potentially damaging kickbacks. The impulse coupling also provides a little extra boost to the magneto by snapping quickly through the point of ignition when turning at start-up speeds. The standard Lycoming installation with two Slick magnetos uses an impulse coupling magneto on the left side and a similar magneto on the right, but without the impulse coupling. During starting, the right magneto is grounded out so that it will not provide power to the spark plugs connected to it. Once the ignition switch is released and returned to the “Both” position, the right and left magnetos fire together at the preset degree of advance recommended for that engine (20-25˚ BTDC).

Slick magnetos are quite common on four-cylinder Lycoming engines. On the right is a 4370 magneto, which would typically serve as the right magneto on the engine, and on the left is a 4373 magneto with an impulse coupler, which would typically be installed on the left side of the engine.

It is important to deactivate the right magneto during starting (unless it too has an impulse coupling) to avoid firing the spark plugs before the pistons reach the top of their travel (TDC). If the spark plugs fire too soon at the slow speeds encountered at engine start-up, the engine might try to run backward or kick back. This sudden reversal of crankshaft rotation could damage any number of internal engine parts and must be avoided. However, when the engine is running, the spark plugs need to fire before the pistons reach the top of their travel to allow time for the fuel-air mixture to ignite before the pistons begin their downward power stroke.

The advantages of the impulse coupling system are that it is simple to install, requires no battery (or, for that matter, any electrical system), works fairly well on smaller engines such as four-cylinder Lycomings, and is relatively inexpensive. The disadvantage is that it does not produce a very hot spark at start-up, because a magneto does not produce much power when it is turning slowly.

Shower of Sparks Magnetos

With a retard breaker or shower of sparks magneto system, the right magneto is turned off during start-up and the left magneto is switched on along with a separate device called a vibrator that retards the spark timing and produces a series (or shower) of sparks during start-up. This gives the engine multiple opportunities to fire on each cylinder. The advantage of the retard breaker system is that it produces a much better spark for starting because it is not dependent on the weak spark of a slowly turning magneto for power. The disadvantages are that it is heavier, costs more than an impulse coupling system and requires electricity to work the vibrator—no battery, no start. Because they produce much better sparks at starting, retard breaker magnetos are popular on larger engines. Once running, there is no difference in how a retard breaker magneto works compared to an impulse coupling magneto.

Magnetos are Always On!

Magnetos are always on unless they are grounded to turn them off. Therefore it is important that the wires from the ignition switch to each magneto are in good condition. These wires, called P-leads, must be grounded through the ignition switch when the switch is in the “Off” position. If a P-lead does not ground out its respective magneto, the engine could fire when the propeller is pulled through, with potentially disastrous consequences for anyone near the prop. Do whatever is necessary to avoid it.

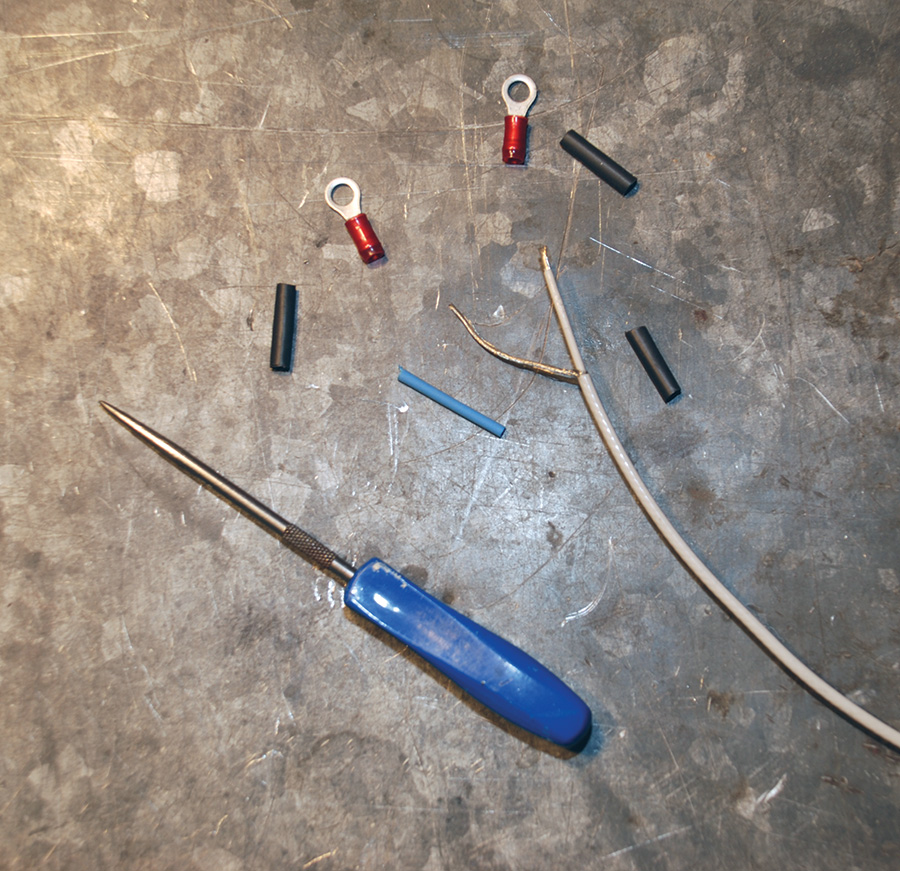

The P-leads also need to be shielded. One end of each P-lead shield should be connected to the ground and the other left free. This is to eliminate electrical noise or static caused by the magneto. We will talk about this more in the article on electrical systems.

To make a P-lead, first strip off about 2 inches of the outer insulation of some 16-gauge shielded wire to expose the shield. Use a pick to unweave the shield and roll it into a “wire.” Cover the shield wire with shrink tubing and install loop connectors. Use larger shrink tubing to reinforce the various joints.

The Ignition Switch

The lowly ignition switch does not get too much thought, but it can be the source of a number of problems. Its installation seems straightforward enough, but it is also possible to get it hooked up exactly wrong without even realizing it. The most common ignition switch in homebuilt airplanes is the ACS Model A-510-2K, which includes a built-in starter switch. This switch works well with impulse coupled magnetos, electronic ignition systems or retard breaker/shower of sparks ignition systems, but the wiring is different for each. Be sure to check the specific wiring instructions for your ignition system.

An important concept behind the switch installation is that when the switch is in the R or L position, the engine is supposed to be running on that magneto. Or, to put it another way, when the switch is in the R position, the left (L) mag is supposed to be grounded out, and similarly when in the L position, the right (R) mag is supposed to be grounded out.

If not for starting the engine, it wouldn’t matter if this were reversed, but for most Lycoming engines, the left mag has an impulse coupling that retards the timing to make starting easier. As mentioned, this means that for starting, the right mag needs to be turned off or grounded out. The ACS switch is designed to accommodate this, but only if it is hooked up correctly. Installed improperly, the risk of kickback is much greater, which can damage or destroy a starter motor.

If you look at the diagram, you can see the various terminals on the switch. Number 1 (marked R on the switch) goes to the right mag P-lead. If you have an impulse coupling in the left mag, another wire from the R terminal goes to the GRD terminal right next to it. This connection grounds out the right mag for starting. Number 2 (marked L on the switch) goes to the left mag P-lead. Number 3 (marked BAT on the switch) goes to the positive power supply. Number 4 (marked S on the switch) goes to the starter solenoid, and Number 5 (marked GRD in the center of the switch) goes to ground or negative.

If you’re not sure whether you have an impulse coupler in your left mag, the best thing to do is check the model number. Most new Lycoming engines for Experimentals come with Slick magnetos. The Model 4370 is the most common for the right mag (this does not have an impulse coupler), and the 4371 (20˚ retard) or 4373 (25˚ retard) mags are most common for the left (they do have impulse couplers). Some engines come with two impulse coupled mags, in which case there is no need to ground the right mag for starting. If you have Bendix mags, be sure to check the model numbers to verify that the left mag is an impulse coupled mag. If you are using electronic ignition to replace one or both magnetos, be sure to check with the manufacturer’s installation instructions for proper wiring.

Check the grounding of each mag before you try to start your engine. You don’t want to damage a new starter because you got the wires crossed. You can use a continuity tester or a volt-ohm meter to check for a short between the P-lead and ground on each mag while selecting L, R or Start. When you do, first remove the P-lead from the magneto, then check the continuity to ground from the magneto end of the P-lead to the engine case. Do this for each magneto. If you forget to disconnect the P-lead, you can get a false reading. Remember, the right mag should be grounded out when the ignition switch is turned to Start if you have an impulse coupling mag only on the left (pilot) side. The jumper wire from the R terminal to the GRD terminal next to it is what makes this work.

Each P-lead should be a shielded wire to help prevent static on your radios. Ground only one end of the P-lead shield and leave the other end of the shield free.

Electronic Ignition Systems

Electronic ignition systems have become popular aftermarket accessories for Experimental airplane engines and are starting to make inroads into the certified end of the business, too. As is true in many other areas of homebuilding, electronic ignition systems have often been developed by small companies catering to amateur builders, the units being mostly tested in the field in customer airplanes. This has gone better than you might imagine, but it has not been without some problems. The experience gained by these pioneers has resulted in some products that are now fairly well refined and are showing themselves to be reliable replacements for magneto ignition systems.

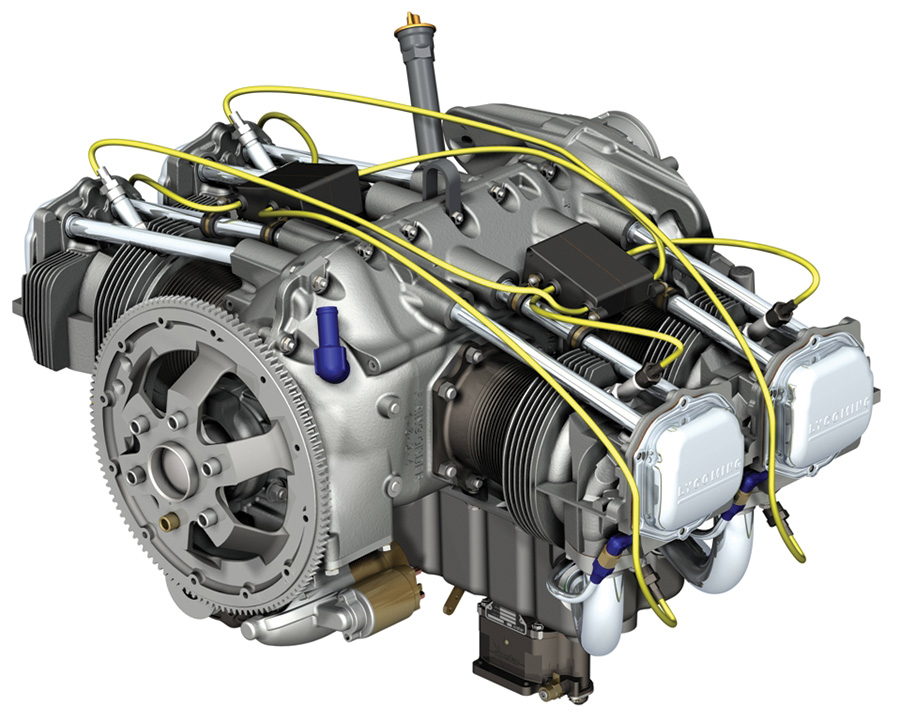

This new Lycoming IO-233 engine comes from the factory with dual electronic ignition. Note the coil packs attached to the pushrod tubes on either side of the engine. It only makes sense that we will be seeing more of this from Lycoming in the near future, but so far the company has made no such commitment.

Electronic ignition systems produce high-voltage electricity to fire spark plugs, but that is about the only thing they have in common with magnetos. Where magnetos generate their own electrical power, electronic ignition systems typically rely on external power. The exception to this is the P model by E-MAG Ignitions. It has a built-in tiny alternator to provide running power, but even it relies on external power as its primary power source for starting. Magnetos also use mechanical points to time their firing, versus the electronic triggers used by electronic ignition systems. Mechanical points wear out and go out of adjustment, but electronic systems do not have any wearing parts to be concerned with. Magnetos have fixed timing, but electronic ignitions have variable timing that can be optimized for engine rpm and loads. More sophisticated systems can even include items such as anti-knock sensors that can automatically retard timing to avoid dangerous detonation.

Electronic ignition systems are often paired with traditional magnetos in airplanes, typically replacing one magneto. These systems seem to work out fairly well, though future systems may simply eliminate magnetos altogether. The more advanced FADEC systems already do. The advantages of electronic ignition systems are better power and efficiency at altitude, more accurate timing and the ability to tailor the amount of ignition advance to the load and rpm of the engine in any configuration.

The most popular electronic ignition systems currently come from Light Speed Engineering and E-MAG (their P Model is often called a P-mag). Both are common on amateur-built airplanes. Electroair is another well-known supplier of electronic ignition systems, but until recently, the company was better known for its work with so-called alternative engines (Volkswagen, Subaru and Jabiru).

The LASAR system was an early electronic ignition system that was offered as a factory-installed option by Lycoming, but it has since fallen out of favor. It functioned reliably enough, but it never really delivered the benefits expected to justify its extra cost. The Champion spark plug people own the LASAR system now, but they have no plans to develop it further.

Electronic ignition systems offer the advantages of better starting and variable (and programmable) ignition timing. Better fuel economy and more power can result from these improvements. On the other hand, electronic ignition systems cost more initially, they require an outside power source to work (back-up battery), and many builders have complained about increased cylinder-head temperatures that can come from running more advanced timing at cruise power settings. You will need to consult with your engine builder to decide if the trade-offs make sense to you.

As electronic ignition systems gain more experience in the field, it is certain that they will become more refined and deliver a level of performance that magneto systems simply cannot match. It is not a matter of if electronic ignition systems will replace magnetos in airplanes; it is only a matter of when.

This is the complete kit to replace one magneto with an E-MAG P model system (sometimes called a P-mag). The E-MAG system contains a tiny generator inside, permitting it to run without battery power after starting.

E-MAG P Model

P-mag is a self-contained unit with an internal alternator to generate its own power after starting. In this sense, it comes the closest to being a direct replacement for a magneto. Currently they only have a system for four-cylinder Lycoming engines, but they are working on systems for dual-mag four-cylinder engines and for six-cylinder engines such as the IO-540 commonly used in RV-10s. The P-mag’s distinguishing feature, its ability to run without external power, has also been its greatest challenge due to the difficulties of getting power out of such a small alternator. It installs easily in the engine accessory case, where a magneto normally goes.

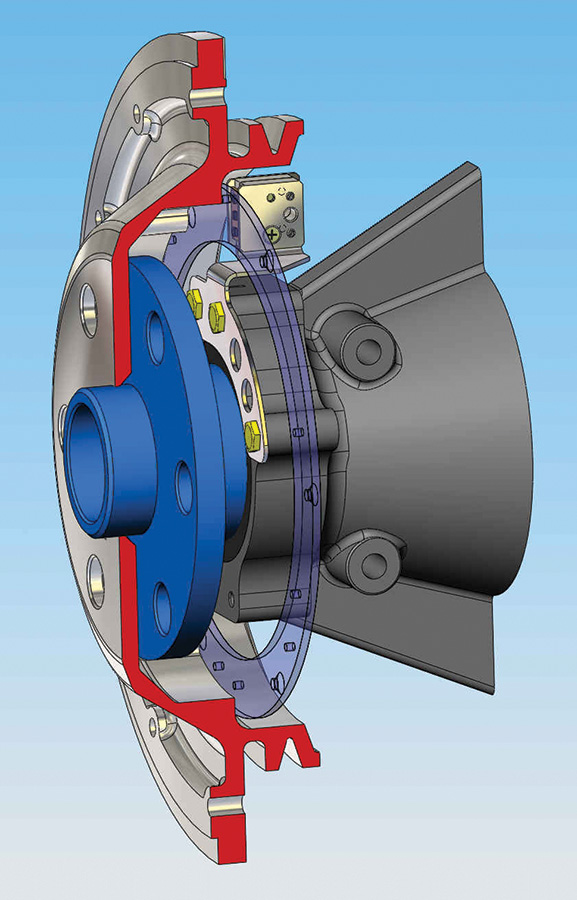

This is the Hall Effect sensor that goes in place of a magneto with one type of Light Speed ignition system. This sensor is an alternative to the crankshaft pick-ups used in other Light Speed systems. It allows installation of the ignition system without removing the prop and starter-ring gear support.

This cutaway drawing shows how the Light Speed crankshaft sensor mounts to the front of the engine. Note the ring attached to the inside of the starter-ring gear support.

Light Speed

Light Speed makes capacitor-discharge electronic ignition systems with either a Hall Effect sensor or a crankshaft trigger. The Hall Effect sensor unit fits into the accessory case where the magneto normally goes, but the crankshaft trigger unit has no moving parts except magnets attached to the starter-ring gear support. The magneto holes in the accessory case are simply blocked off with the crankshaft trigger system. Light Speed is moving away from the Hall Effect sensor systems because of their moving parts.

Since the Light Speed unit does not generate its own power for running, it depends on the reserves of the battery to sustain itself in the case of electrical failure. For pilots who want an extra margin of safety, a separate back-up battery can be installed. In that case, Klaus Savier of Light Speed Engineering recommends one of the new ultra-lightweight lithium iron phosphate batteries. These batteries hold their charge so well that they do not need to be connected to the airplane’s charging system, and a battery that will run the ignition system for several hours weighs less than 2 pounds.

Here are two pick-ups for a dual electronic ignition system by Light Speed. These are attached to the front of a Lycoming engine and will be triggered by magnets attached to the starter-ring gear support.

The Electroair ignition kit for a four-cylinder Lycoming. This setup replaces one of the magnetos. The ignition system uses a magneto timing housing that looks similar to the Light Speed Hall Effect sensor but operates very differently.

Electroair

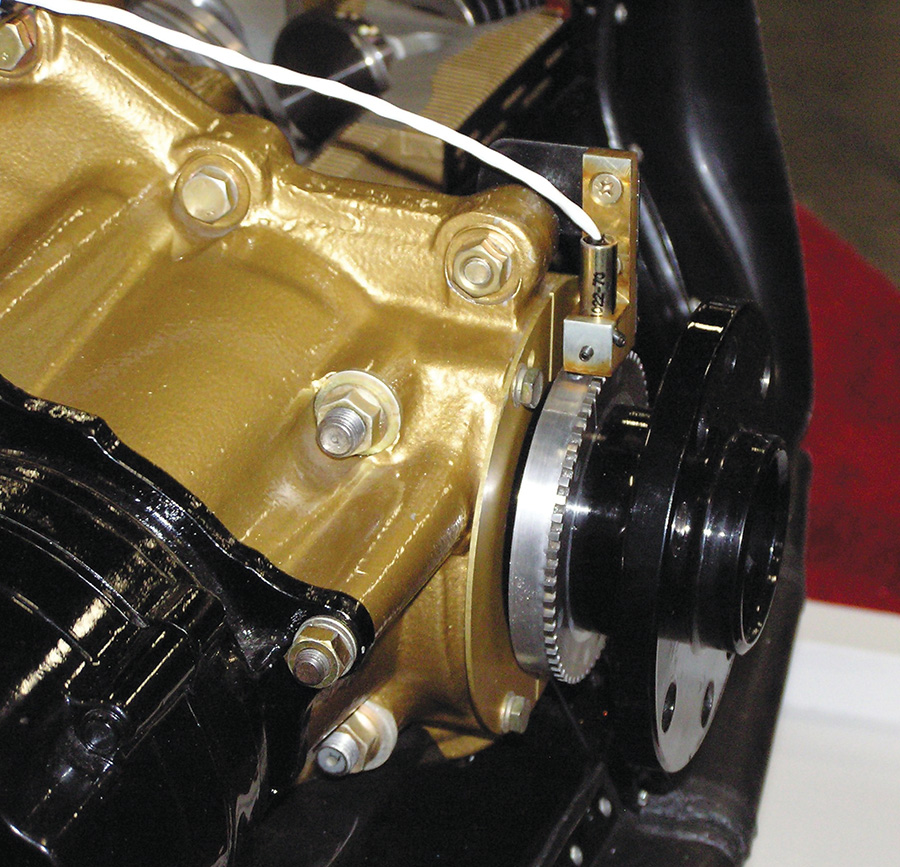

The Electroair ignition system is an inductive unit using a 60-tooth timing wheel with a single magnetic pickup. The timing wheel provides a high-resolution signal, which feeds continuous rpm information to the controller. For four-cylinder Lycoming engines, the timing wheel is enclosed in a mag timing housing and replaces the right-hand magneto; for six-cylinder Lycoming engines and all other engines, they use a crankshaft timing wheel with the pick-up mounted on a bracket. Electroair touts a 20˚ spark duration as a major advantage of their system.

This Electroair crankshaft sensor is attached to the front of a TCM IO-550 engine. The 60-tooth wheel attached to the crankshaft is a distinguishing feature of the Electroair system and allows for very precise ignition timing.

There are some interesting choices available when it comes to airplane ignition systems. Before you decide which one to use, do your homework. Talk to your engine builder, the various ignition-system manufacturers and other airplane owners, either in person or through one of the many Internet forums. Each system has its pros and cons.

Next time we will delve into electrical systems beyond the ignition system. This will involve two articles because there is so much ground to cover.