Homebuilt airplanes are constructed, owned and flown for various reasons. For some, it is simple economics-they find that building and maintaining an Experimental is the only affordable way to own a plane. For others, it is a matter of obtaining the exact airplane that they want-and nothing in production exactly fits the bill. For still others, it is the notion of achieving some hitherto unknown breakthrough in aerodynamics, powerplant science or that quantum singularity drive that they have been tinkering with in the basement of the physics building for so long. Whatever the ultimate reason for deciding to go with an Experimental airplane, it is rare that a builder/owner/pilot doesn’t decide to put some personal "stamp" on the aircraft during construction (or afterwards)-little modifications that make the airplane unique, better to serve its intended purpose.

The Mach 3 XB-70 had to be flown VFR because it had no instrument approach capability. For its purposes, it didn’t need it.

It is on these "little modifications" that I wish to dwell for a while today, for within them we can oftentimes find reason for caution in the eventual use of the airplane. Intended use has a lot to do with what we build, and what we build (and how we build it) can have a lot to do with the safety of how it can eventually be used. I know that sounds like it was written by a mystic, and let me assure you, we are not going to go down that road. But we do need to understand that, plainly put, a simple modification can kill you.

Limited Utility Models

Truly Experimental airplanes in the aerospace world are generally extremely limited in the extent to which they can be utilized. In the heady days of the X-planes, for instance, most of the amazing aircraft flitting through the skies of the high desert were able to fly in VFR conditions only-many of them had a single UHF com radio and nothing at all for navigation. The X-15 had one of the world’s first and finest inertial reference platforms, yet it could barely stay aligned (and useful) for the 10 to 20 minutes it took for the aircraft to fly from northern Nevada back to the Antelope Valley-and it basically took Mark 1 eyeballs and ground vectoring to find the landing site. Similarly, the XB-70 bomber-turned-research plane (it started out as a bomber, but the program collapsed under the weight of politics), that remarkable Mach 3 monster, had to be flown under visual conditions because it didn’t have any sort of instrument approach capability that could be relied on. But to complete the programs for which they were intended, neither airplane needed more.

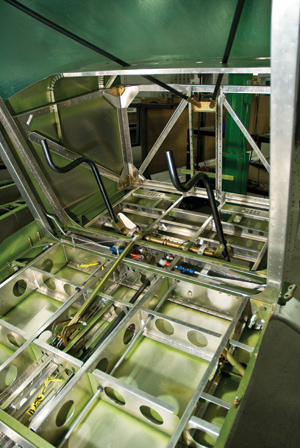

When you start, an airplane is just a bunch of parts, some built by the factory, and some with your own hand. A successful, long-lived, safe aircraft becomes a matter of attitude.

Overly Unfamiliar

What do these icons of Experimental test flying have to do with our little single-engine homebuilts (even the fast ones)? Well, we need to remember that homebuilts are, by their nature, custom-built and unique. It is rare to find two identical machines, even if they are built in the same shop by twin brothers. What this means to us as operators and pilots is that there are always going to be components and/or systems that have little time in service to prove themselves. This, in turn, means that reliability cannot be assured based on test results. Many times, homebuilders put things together on the TLAR ("that looks about right") system. Unfortunately, the reliability of that method has not proven to be good in the history of aviation. Strange things happen in a world where vibration occurs all across the spectrum, aeroelasticity can change the shape of things at the microscopic level, and load paths that seem intuitive and obvious sometimes take entirely different routes through the structure than we expected. In short, when you make a modification to a known component or system, you are (Ta da!) experimenting.

"Great," I hear you saying. "Any more obvious announcements you want to make? Or can I go finish this little fuel line I was making?" Well, not so fast. Just stop and read a bit more, please. What is it that makes some experienced pilots treat airplanes like cars? Quick-what was the make and model of the last car you rented? Heck, I’d be surprised if I could remember the last rental car company I used. The car had a steering wheel, key and pedals-I made it go and returned it with a full tank of gas. Many folks deeply involved with aviation do the same thing with airplanes. Certainly airline pilots fly different machines every day, identical in all but serial and registration numbers. And working GA pilots have to "go get that Cessna that got left at XYZ by the student who got weathered in." Cessnas? They all fly alike-just go pick it up and bring it home. Pretty easy to do, and pretty safe as well, because we know that they are all built alike, and that there are hundreds of thousands (heck, probably millions) of hours of experience with the systems configuration of each model. They all have identical fuel and electrical systems. Their structures are identical. The way they fly is well-known. When there are failures, they are common and understood. Their reliability is hard to exaggerate; aside from vacuum systems, you can pretty much rely on the fact that they will keep running-even in the clouds-to get you home. Yes, there are statistical anomalies that have led unlucky pilots to an untimely arrival at a random spot on the earth. But generally speaking, we have a large experience base that says they are reliable.

Tackling the Less Well-Known

Experimental airplanes, on the other hand, are not such well-known quantities. The stock Lycoming or Continental engine, if maintained to its original type certificated configuration, is well understood. The sheer millions of hours of accumulated operation time has worked out the kinks and developed into a reliable package. But when you change the configuration even slightly, you open up a potential Pandora’s box of unknowns. Ever wonder why an Experimental engine and/or prop combination means more Phase I time? Well the measly extra 15 hours isn’t much, a halfhearted attempt by the FAA to underline the fact that configuration changes may affect reliability.

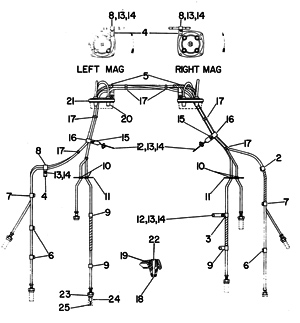

What kind of changes are we talking about? Well just about anything from the way a fuel or oil line is routed to the materials from which they are made. Did you know that ignition harness support is called out specifically for each certified model of engine? Right down to the number and location of bolts and nuts holding specific Adel clamps to identifiable locations. Primer lines? Specified. Safety wire? Specified. Each configuration is known down to the last detail so that we can count on the data obtained from thousands of units in the field to build a database of reliability information. Our Experimentals? Well, they are horses of a different color.

This Is a Test

Let’s just concentrate on the firewall forward for a minute. There are many other examples to be found in the airframe, but limiting the field might help us understand the concept. How many times does the average builder refer to the instructions on how to route an oil or fuel line? How many of us add useful things to our system such as fuel-flow meters? With no specific guidance to tell us where and how to mount the transducer, we have to make up something that looks good and conforms to what we have read in the best references we have-AC43.13, the Bingelis books, EAA tutorials. Using these materials, we can conform to the best shop practices and techniques, but we still don’t know the vibration environment that we are creating. Will the device be shaken to pieces because the mount has a resonant frequency that we didn’t anticipate? Will the fuel line that we fabricated be up to that unknown vibrational environment? Will the device be affected by heat that we didn’t anticipate in this previously unexplored location? There is no way of knowing for certain, except by testing.

How much testing? Well, we might compute the worst case vibration as a function of the frequencies available in the average engine configuration-multiples or fractions of the engine rpm, for instance. If we then figure out the amplitude of the vibration and the amount the device might move, coupled with a knowledge of the material characteristics, we might determine a limit life, which could be off by a factor of two or four. Analysis is fun, but testing is better. Will it last 10 hours? How about a hundred? And can we, by inspection, determine if it is in good shape and safe to continue in service? These are the kinds of questions asked by manufacturers when they test aircraft systems for production machines, and they look at thousands of hours of test data before committing to an answer. Ever wonder why a TBO is specified at 2000 hours for some engines, or 1000 hours for a prop? Those are the outside limits for which the engineers are willing to state that the reliability is acceptable without a complete teardown and inspection.

Ignition harness and lead assembly for Lycoming installations. No reason not to follow the manual here.

Managing Risk

So what does this mean to us, the builders and operators of Experimental aircraft? It means that we need to consider our modifications to basic designs when considering the risks that we take. Flying a highly modified airplane in day VFR conditions with good emergency landing sites underneath us at all times? Good risk management. Taking that same airplane, with highly modified systems whose reliability is unknown into situations where we have little hope of survival if the engine quits? That’s a different matter. In fact, I would argue that the reason I am comfortable flying IFR in a single-engine airplane (under some conditions) is that I understand the reliability of the aircraft, its engine and the necessary systems. Production aircraft are known quantities. Experimental aircraft built to known configurations that have been duplicated many times and have built a database of hundreds of thousands of hours are riskier, but acceptable. Highly modified aircraft, or even those slightly modified with new ideas? Well, I would have to be convinced by actual flight and test data that the reliability is there before I’d put myself in a situation where I would be depending on that reliability.

I have a lot of Experimental avionics in my airplane, but I’m set up with triple redundancy and unlike systems, so the statistical odds of ending up IFR with nothing to use to find my way home in an upright condition is very small. My firewall-forward configuration? It is as much like a factory airplane as I can assure it to be. I only have one way to stay aloft over hostile terrain, and I want it to be as reliable as possible. Minor changes-a hose rerouted here or there can cause vapor lock-may have disastrous effects on reliability numbers. Changing a clamp location can affect vibration loads. And don’t even get me started on things rubbing and wearing holes where they should not be. I flew my airplane with a "bone stock" configuration for a couple of hundred hours before I took it into IMC-and even then, with higher than normal minimums at both ends and en route. I didn’t want to be stuck with no place to go.

Experimenting is valuable-it is how we advance. But we should not expect an Experimental airplane to be as reliable as those production airplanes that we learned to trust (somewhat) until our new mounts have proven themselves by flying enough hours to show that they have no hidden traps or pitfalls that can put us in a dire situation. The good side of this is that finding out requires us to fly more to build up those hours and learn to trust the aircraft. More flying is always a good thing, don’t you think?

![]()

Paul Dye is an aeronautical engineer, commercial pilot and avid homebuilder with 30 years of leadership experience in aerospace operations and flight testing. He is also an EAA tech counselor and flight advisor who currently flies an RV-8, which he built, and is working on an RV-3.