Engine designer and industry consultant Andrew Higgs has joined with Sport class air racer Karl Grove to form AC Aero USA LLC. The new company combines Higgs’ engine design and manufacturing capabilities with Grove’s marketing background to deliver premium engine parts for Lycoming-type engines along with several all-new Jet-A burning engine models.

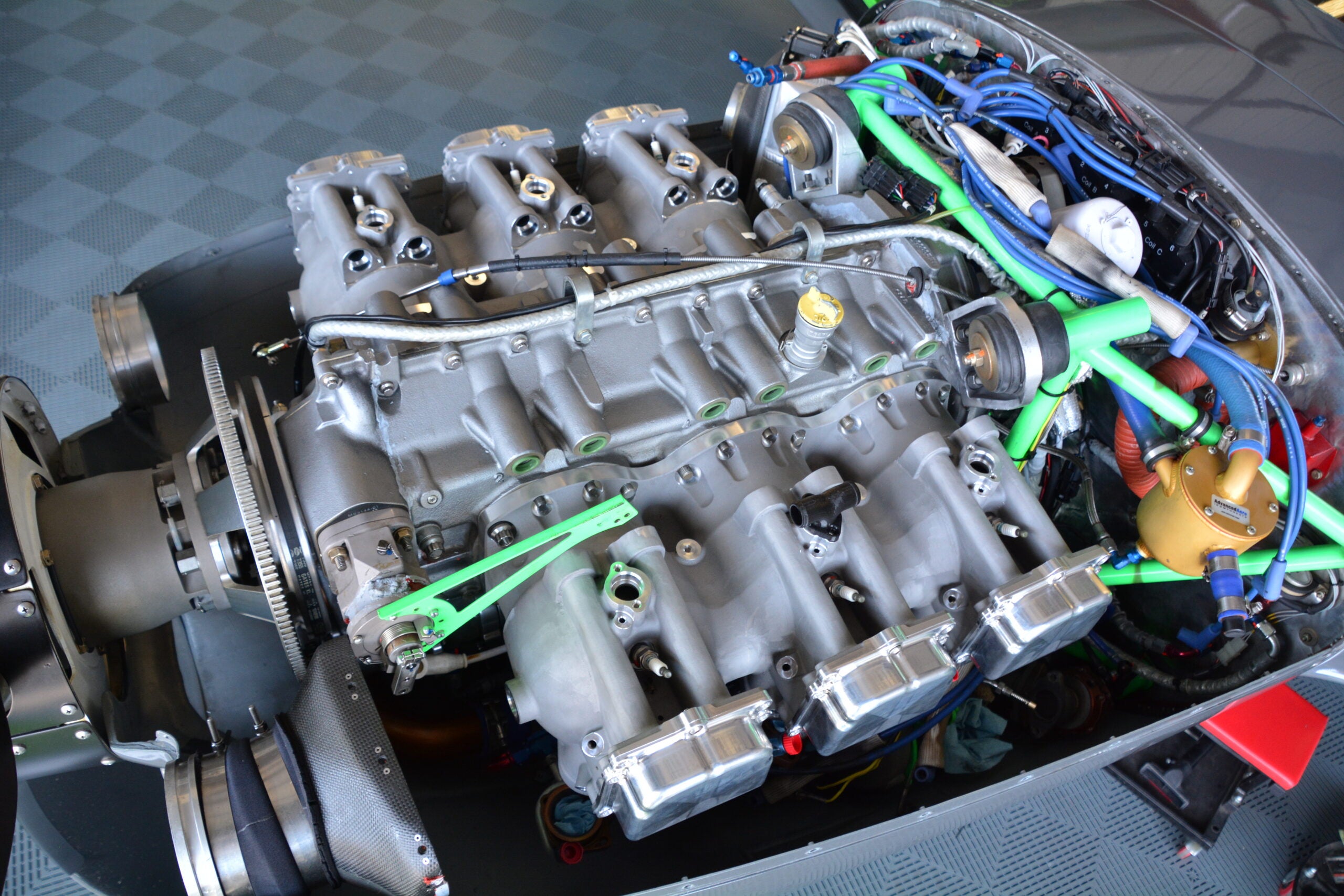

Previously Higgs marketed a line of upgraded air-cooled Lycoming cylinders under the AX50 name. Those cylinders are now out of production, replaced by AC Aero’s new line of liquid-cooled cylinder banks. That is, the liquid cooled cylinders are cast as assemblies of two or three cylinders for use on four- and six-cylinder wide-deck Lycoming based engines. These assemblies feature increased diameter cylinder bores for a displacement increase and are known as Gladiator cylinders for four-cylinder engines and Centurion for six-cylinders.

AC Aero is also offering stroker crankshafts under the Legion name. The Legion and Gladiator/Centurion offerings may be combined for hefty displacement increases. The 540 Lycoming can reach 660 cubic inches, for example.

For even more Lycoming-based power, AC Aero has an RS line (Race Specification) of complete, custom-built racing engines. These turn the Lycoming-architecture 360 four-cylinders into 440 cubic-inch engines; 540s become 660 cubic inches, both with liquid cooled cylinders. All RS engines are pure custom units, typically bristling with specialty options.

To ensure quality control, AC Aero is establishing a series of build centers worldwide. The first center will be on the US west coast and will handle sales, parts installation (engine builds) and servicing. No parts will be sold outside of the build centers, so owner installation is not an option. Customers can ship their engines to the build center; AC Aero can develop an engine from scratch or a flying airplane can be brought to the build center. As the liquid-cooled cylinders require a radiator and completely different under-cowl detailing (no air baffles, for one thing), the installation on currently flying aircraft will involve a fair bit of fabrication. Not quite incidentally, the liquid-cooled cylinders are a few pounds lighter and each bank is a half-inch narrower than stock air-cooled Lycoming jugs. This should eliminate cowling width concerns, although one would expect to pick up a few pounds after installation is complete with coolant and radiator.

Given the racing pedigree of the company owners it’s no surprise the new cylinders are designed for high cylinder pressure. Grove says the Centurion banks are rated to run at a continuous 110 inches of manifold pressure.

Legion long-stroke crankshaft kits are scheduled to begin delivery by the end of July. Liquid-cooled cylinders are to follow “four to six weeks after that,” so call it August and November 2020, respectively. AC Aero is currently taking reservations at no charge. A deposit will be required once a serial number is generated when the customer’s cylinders are ready, with full payment upon engine delivery.

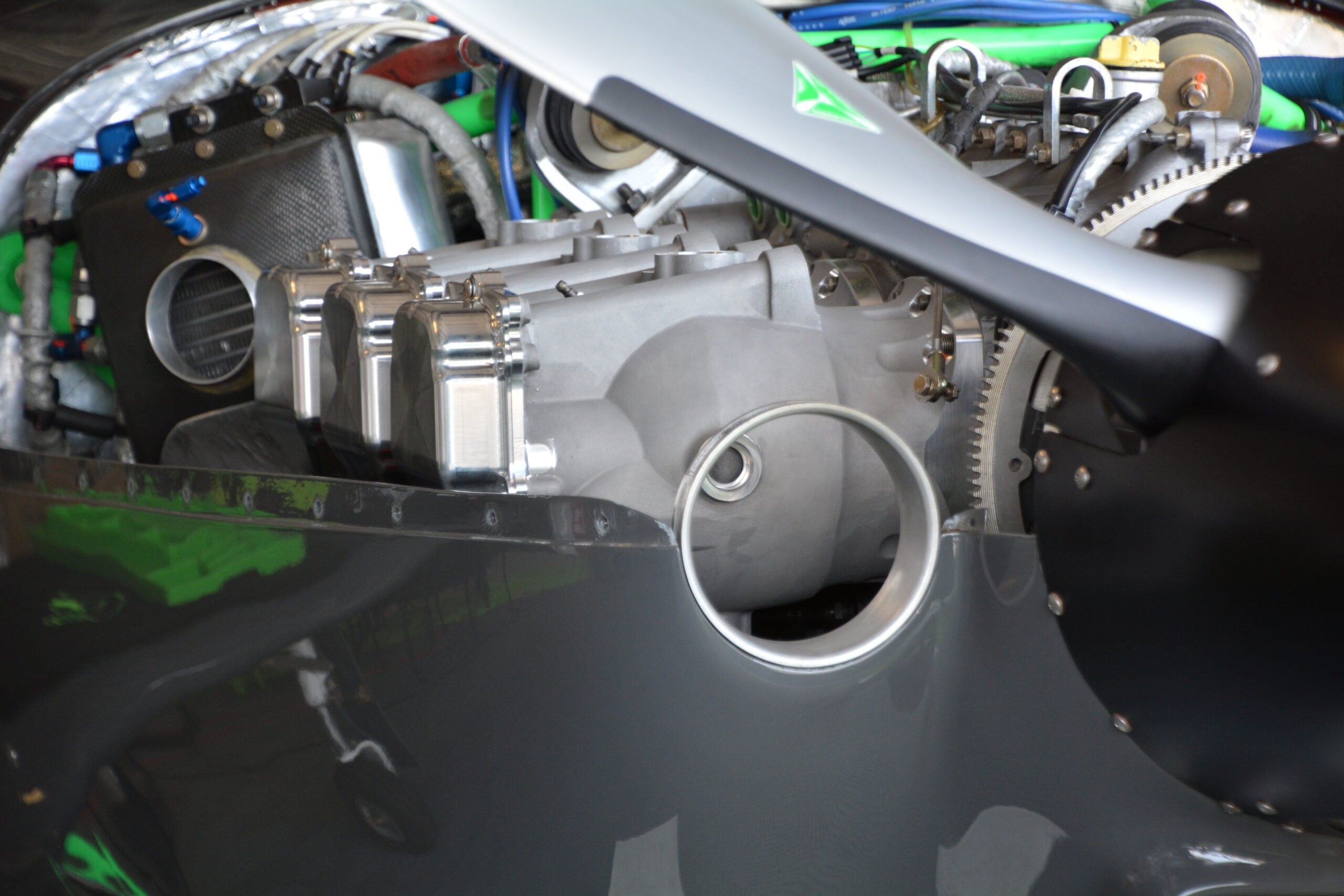

More information, including some pricing, regarding AC Aero’s “Lycoming Solutions” can found on the company’s website. But there is more, much more. AC Aero’s ambitions extend far beyond hopped-up Lycomings. Higgs has apparently developed an innovative method of combining two- and four-stroke engine cycles in a new-design cylinder using an unusual piston dome shape to arrive at a liquid-cooled cylinder featuring two-stroke style intake and exhaust ports and spark plugs (as you’d expect in a gas engine) but burning Jet-A fuel. The cylinders are designed to work on a full pressure oiling crankcase, contrary to typical two-stroke architecture. This basic cylinder design is being packaged in a variety of inverted V-4, upright V-8 and 1000 cubic inch V-12(!) architectures, all under the Higgs Diesel name and sold through AC Aero. We’ve yet to delve into the details of the new Higgs cylinder design, but its combination of Jet-A fueling, greatly reduced parts count (no valve train) and compact dimensions could prove revolutionary.

Dear Tom

Traditional air cooled engines, such as the Lycoming IO-360 and IO-540, suffer from detonation at high manifold pressures and, to combat this, run at low compression ratios and rich mixtures using fuel to cool the pistons and cylinders.

The primary benefits of the liquid cooled Gladiator and Centurion cylinder banks are that they have a modern combustion chamber design which permits much higher compression ratios, I believe up to 10:1 on MoGas.

This increases power and reduces specific fuel consumption. The liquid cooling can permit lean mixtures at high power outputs.

The secondary benefits are no cylinder head/barrel joint to fail, increased rigidity of the crankcases, less wear and longer life, tighter tolerances, reduced oil consumption, reduced cooling drag and elimination of shock cooling.

It is a shame that neither Continental nor Lycoming have done any real innovating since the 1950s and, although focused on racing, I believe that Andrew Higgs will drag these Lycoming engines into the 21 st Century.

The Jet-A engines are technically 2-strokes, however, they use a stepped piston which means 2 sets of piston rings so that the crankshaft can run plain bearings and there is no carbon contamination of the oil which will have a very long life. There are no camshaft, lifters, valve gear or valves to be manufactured or to fail.

The Jet-A engines are intended to compete with small the medium sized turbines on power, size and fuel type but beat turbines on specific fuel consumption at high power by and thrash turbines fuel flows at low power and idle and a fraction of the acquisition cost.

They are modular but cylinders work in pairs, so the architecture is Hawk V4 (350 HP to 500 HP), Eagle V8 (700 HP to 1,000 HP) and Condor V12 (1,000 HP to 1,600 HP) the numbers being normally aspirated and turbocharged and, yes, the Condor is a Beast!

Experimental aircraft builders will be most interested in the Swift FL150 130 HP and Falcon FL200 250 HP miniature lightweight V4 engines with multi-fuel capability.

These will outperform the Rotax 912iS and 915iS engines, ULPower engines and also most 4-cylinder Lycoming engines on power, prop noise at 2,000 rpm, fuel consumption, fuel cost per gallon, durability, dimensions and weight.

http://www.ac-aero.com/wp-content/uploads/2020/05/ac_FALCON_2020_R00_051820.pdf

The next 12 months are going to be really exciting and I wish Andrew Higgs the best of luck!

Now this is what a 21st Century aviation engine should look like! It is amazing that they can run on both Jet-A and mogas. I certainly hope they succeed!

Where on the west coast will the service center be?

AC Aero has not yet said where the west coast service center will be as they are still finalizing the arrangement.

More efficient diesel packaging is the age old proven junkers design As per the never yet brought to market https://www.geminidiesel.aero/index.php/aviation/gemini-100

Darn it.