Australia gives Experimental aircraft builders two interesting engine lines for their consideration: the Rotec radials and the Jabiru horizontally opposed powerplants. The main focus of this article is the Jabiru 120-horsepower, six-cylinder engine, but the four-cylinder version is also popular and quite similar except for the number of cylinders.

Jabiru appeared at Oshkosh AirVenture with its first engine in 1994 and introduced what is now the four-cylinder, 85-hp engine the following year. Since then, the company has sold about 3500 of those engines. In 1998 Jabiru began selling the larger 120-hp, six-cylinder model, with about 2600 of those engines now in use. It also produced an eight-cylinder version that just never caught on, with only about 100 units sold. Since their introduction, Jabiru engines have been in a constant state of evolution and improvement.

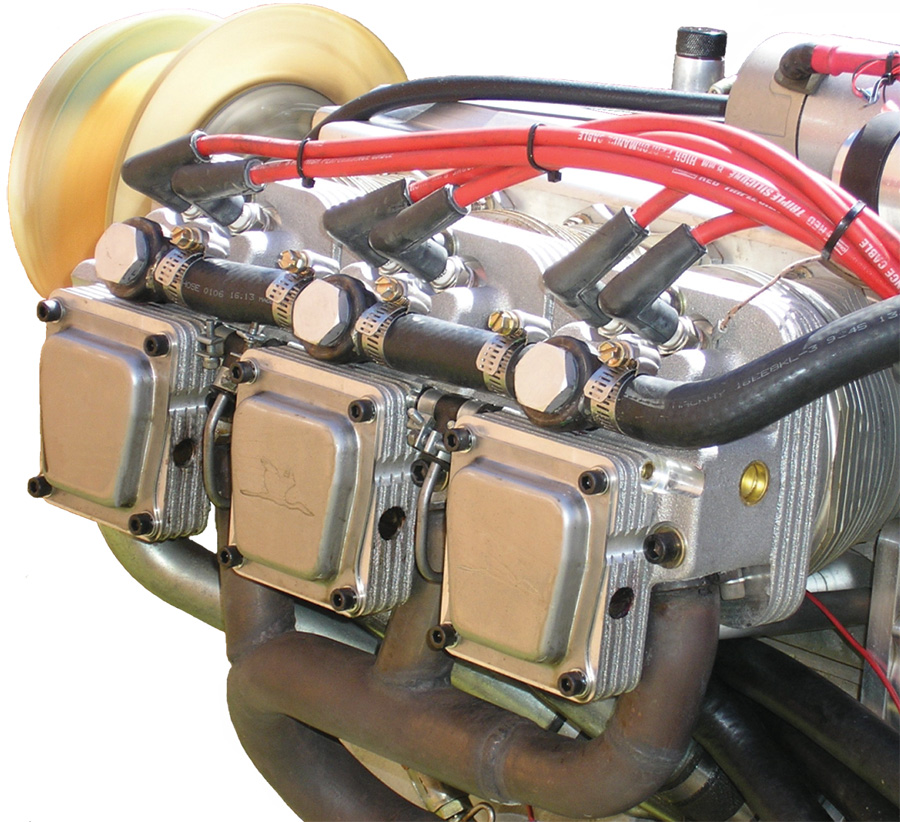

Jabiru engines have a distinctive appearance derived from an unusual manufacturing process. Most of the engine is machined from billet aluminum or steel, with only the sump pan being obviously cast. This allows improvements to be made easily with just the change of a few lines of code in the CNC machining program. This method of manufacturing also saves a great deal of money that would otherwise be spent on molds and tooling. On the downside, there are advantages to casting and forging that are lost with the billet method.

In addition to engines, Jabiru makes Special Light Sport Aircraft (SLSA, factory-built) airplanes: the J170-SP with the 85-hp engine and the J230-SP with 120 hp. This experience has taught the company much about how to set up, operate and improve its engines.

All of this notwithstanding, a number of amateur builders have struggled with Jabiru engines, their problems related to managing engine temperatures. This is unfortunate, because the engine serves as a viable alternative to the more expensive and less powerful Rotax 912 ULS, Continental O-200-D or Lycoming O-233-LSA. However, setting the Jabiru up properly can be a challenge, and it must be properly set up to function properly. Temperature management is critical for a long service life. The setup process begins with the understanding that the Jabiru is a unique engine and not a variation of the Lycoming or Continental.

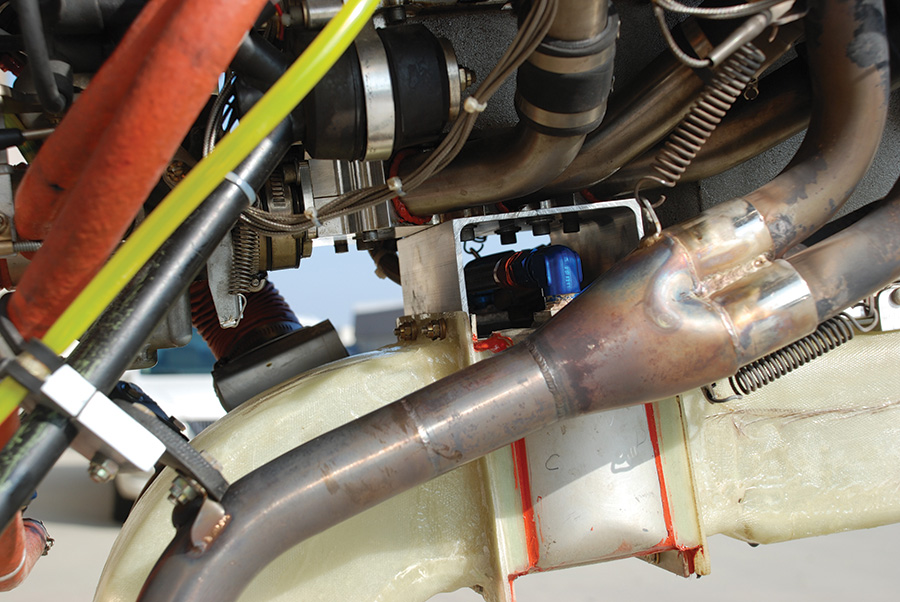

A large cowl exit allows cooling air to escape and better accommodates the oil-cooler exhaust duct. The duct exiting between the exhaust pipes is from the oil cooler.

Getting Air Through the Oil Cooler

As mentioned, controlling temperatures is vital to the survival of the Jabiru engine, and controlling oil temperature is a special challenge. Many kits come with oil coolers that are just too small, but this situation is improving as kit manufacturers get more experience with the Jabiru engine. As an example, the Texas Sport Cub requires an oil cooler normally used with a 180-hp Lycoming engine. Other airplanes with better aerodynamics and higher speeds may get by with smaller coolers, but as a general rule you will want to run the biggest oil cooler that’s reasonable to install.

In addition to getting a large oil cooler, you must pay attention to moving as much air as possible through the oil cooler. Some kits may work well enough as designed, but slower planes like the Cub require an aggressive effort to get sufficient air through the cooler. Each plane must be evaluated individually, but there are some key things to consider if oil-temperature problems persist. Oil-cooler air must enter from a high-pressure area and exit to a low-pressure area. If it does not, the air will not flow through the cooler, and the oil will not cool. This is obvious enough, but how one should go about achieving this is not always apparent.

In the case of the Cub, some extreme measures were required. The tip-off came from another low-and-slow airplane builder, Mark Marino, developer of the Hatz Bantam. His solution led directly to solving the Cub’s problem. He ducted air from the very front of the cowl, an obvious high-pressure area, straight to an oil cooler mounted below the engine. Exit air was then ducted to the cowl exit so that this air would not raise the pressure inside the cowl and thus impede airflow from the oil cooler or the cylinder heads. This modification alone produced a 30° drop in oil temperatures.

With the original Jabiru-powered Legend Cub (and Texas Sport kits), cooling air was brought in through a NACA scoop in the side of the cowl and then dumped into the lower part of the engine bay. Even though this approach produces good results on some other models, it did not provide sufficient airflow through the oil cooler on the Cub. The cowl exit air flow is also impaired by a high-pressure area that forms in front of the gear legs near the cowl exit, thus making airflow much more problematic. The gear legs could not be removed, so it was important to optimize cowl airflow in every other possible way. The Just Highlander and the Hatz have similar problems.

Builders of some airplanes have installed lips on the cowls in front of the exit to help lower the pressure and draw air out of the cowl in flight. Extending or further opening a cowl flap, if one is present, can also be helpful. Anything that eases the flow of air through and out of the cowl is worth considering.

Taming Cylinder-Head Temperatures

Anyone who has been through the installation process for a new Jabiru engine knows the cylinder-head-temperature drill. A plenum on each bank of cylinders directs air from the front of the engine down through the fins of each cylinder. Little deflectors must be installed in the plenums and then trimmed to balance the airflow to each one. It’s a cut-and-try process: You put in the deflectors and go fly, record the cylinder-head temperatures and then come back and trim the deflectors, making them shorter in front of the warmest cylinders. A few times through and you should have everything balanced fairly well.

Cylinder head temperatures are adjusted by trimming deflectors inside the Jabiru plenums to alter air flow to each cylinder.

Some added silicone rubber flaps were needed with the Cub to effectively channel the air over the rear cylinders. Just as with a Lycoming engine, it is important to keep the gaps between the rear baffles and cylinders fairly tight to force as much air as possible to flow around the fins on the heads and cylinders. The flaps were an important part of achieving this with the Jabiru. It was also necessary to add a deflector in front of the No. 1 cylinder head to prevent over-cooling. Each engine installation will potentially present different problems, so it is important to ask questions and be willing to try different strategies to find the best solution. One aspect to keep in mind is that Jabiru has much lower cylinder-head-temperature limits than Lycomings. You simply can’t let temperatures rise up toward 400˚ without doing something about it.

Some early Jabiru builders struggled with the factory plenums as they tried different configurations. With a larger base of knowledge now available, many of these problems have been solved. In all cases, an open mind and a willingness to try different approaches will help you through the setup process. Jabiru USA in Tennessee (www.usjabiru.com) seems to be pretty good at sorting out cooling issues in the faster airplanes, but Jabiru Pacific in California (www.jabirupacific.com) seems to be more helpful with the slower planes such as the Cub, the Just Highlander and the Hatz Bantam. Both distributors are helpful and friendly, but they have somewhat different customer bases and thus different experiences to draw on for future problem solving. Jabiru USA also has an informative three-day engine course that was previously described in the December 2008 issue of KITPLANES®.

If CHTs refuse to succumb to your efforts, there are now liquid-cooled heads available for the Jabiru at a cost of roughly $4,000 for a six-cylinder engine. These come from Rotec, the folks who make the small radials mentioned in the introduction. It is too soon to tell how these will work out in the long run, but they do hold great promise. Check out Rotec’s web site for more information (www.rotecaerosport.com/products/lch).

The Taildragger Tilt

Trigear airplane builders can skip this part, but if you install a Jabiru in a taildragger, you will need to change the oil dipstick before starting the engine for the first time. The problem is that when the engine is tilted back, as it must be when a taildragger is parked, the dipstick reads way low. Because this is not really a problem with Lycoming engines, it is not something that a first-time Jabiru builder would necessarily be looking for. This low dipstick reading will lead the new Jabiru owner to overfill the crankcase with oil, which will in turn cause the oil to be aerated or foamed by the spinning crankshaft in flight. Aerated oil does not cool well, resulting in high oil temperatures.

The solution is easy enough if you understand the problem. Just push the original dipstick rod out of the cap and replace it with a new blank piece of steel rod. Then fill the crankcase with the prescribed amount of oil. Insert and remove the dipstick and note the oil level. Make a mark on the dipstick with a file, and you are all set. Then it is just a matter of keeping the oil level on the mark.

Experienced Jabiru owners will talk about how many ounces of oil they use per hour, with the typical amount being about 2. A small amount of oil is usually added every so often to keep the level just right. When you only have a limited amount of oil, you do not wait until you are a quart low to add more.

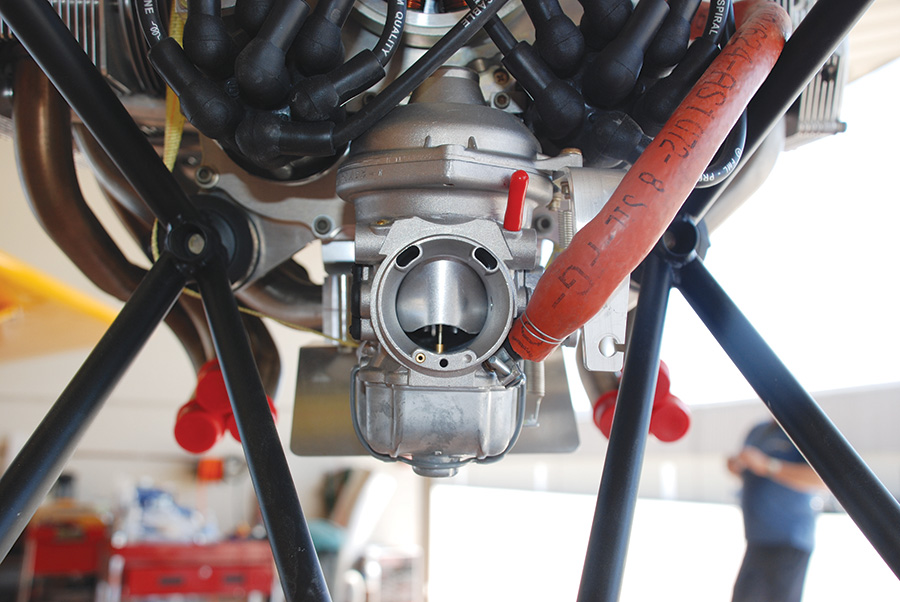

Bing, the Carburetor Jabiru Owners Love to Hate

The Bing carburetor found on Jabiru engines is a marvel as carburetors go, but Jabiru asks a lot from it. Jabiru specifies some fairly tight limits for exhaust-gas temperatures (EGTs), but the Bing carburetor has no manual mixture control. Furthermore, a single venturi must serve six cylinders. This does not make tuning easy. The trusty Bing will soldier on through all of this, though, if it has a little help. For one, the air coming into the carburetor needs to be relatively undisturbed, because an uneven flow of air through the carburetor will produce uneven EGTs. Some kit makers have done a better job than others in designing their intake tracts, so some builders have had to add straightening vanes leading into the carburetor, or they have simply had to tilt the carburetor a bit to even out EGTs.

Everyone loves to blame the Bing carburetor for the Jabiru’s woes, but in most cases the real problem lies elsewhere.

Even with a carefully designed intake tract it can be difficult to get good EGTs at all throttle settings. Sometimes a slightly different throttle setting or the application of some carburetor heat will be needed to tame an unruly cylinder or two that just seems to run too hot. You can change the jets in the Bing carburetor, but as a rule it is better to exhaust the possibilities elsewhere before exploring this option.

Users of aftermarket throttle-body fuel-injection systems report improvements in EGT spreads, but they still must work with the same intake manifold. This engine fairly begs for a fuel-injection system such as the one on the new Rotax 912 iS engine. In the meantime some builders have had good luck with throttle-body fuel injectors by Rotec or Ellison. For more information, visit www.rotectbi.com or http://ellison-fluid-systems.com. Their main benefit is that they allow for manual adjustment of the mixture.

An air dam is needed in front of No. 1 and No. 2 cylinders. An added small aluminum deflector plate helps prevent over-cooling of the No. 1 cylinder.

Cylinder Heads

Jabiru cylinder heads must be torqued after initial break-in and every 100 hours, but if battles with high CHTs extend beyond the break-in period, it is wise to check cylinder-head-bolt torque more frequently. The main problem is that the heads tend to lose their seal between the heads and the cylinders if the heads overheat. The most common point for this leakage is at the lower edge near the pushrod tubes. To help minimize this, it is best to always tighten the bottom bolt first as you work your way back and forth around the six head bolts. And since re-torquing the head bolts will almost always be done with the pushrods in place, it is wise to put each cylinder on top dead center before tightening the bolts. Otherwise, pressure from the pushrods pushing the valves open can produce uneven tightening of the bolts. Lycoming owners may be shaking their heads at this point, because Lycomings don’t have cylinder-head bolts, but the process is fairly painless once you get used to it, and it is a small price to pay for saving 30+ pounds of engine weight.

A Better Exhaust Yields Unexpected Benefits

Interestingly, the exhaust system can be a major cause of uneven EGTs. The six-tubes-into-a-big-can exhaust system that comes with many Jabiru engines leaves something to be desired. As part of the oil-cooler project on the Cub, we installed a Sonex exhaust system that yielded a great improvement in EGTs. This system consists of two three-into-one collectors and a bent pipe coming off of each collector (no muffler). Some modifications may be required to fit different airplanes, but this system greatly improves exhaust flow and has the added benefit of not leaking nearly as much as the standard Jabiru system. There is also good evidence that the freer-flowing exhaust helps the engine produce more power. Jabiru Pacific was a great help with this new exhaust system.

Props

Both the 85-hp and the 120-hp Jabiru engines have a maximum speed of 3300 rpm, some 600 rpm higher than the typical Lycoming engine. These engines are not happy swinging big props or turning at lower rpm. Jabiru has a maximum prop length of 70 inches that must be respected; a longer prop can over-stress the crankshaft and lead to a catastrophic failure. If most builders accept the maximum-length limitation, many do not quite embrace the idea that this engine likes to run at higher rpm. A propeller for the Jabiru should be pitched so that the engine will turn 3200-3300 rpm at full power in level flight. If it will not, it has too much pitch. While many people like to cruise their Lycoming engine at 2300-2400 rpm, the Jabiru is much happier at 2800-2900. Jabiru owners must simply recalibrate their comfort level up by about 500 rpm. It is important to find a throttle setting that brings EGTs and CHTs into the factory-recommended temperature limits and still makes good power.

Jabiru engines have their advantages and disadvantages, just like any other engine. They are fine-looking, smooth-running mills that are significantly lighter than either an O-200 Continental or the new O-233 Lycoming. They are simpler and more powerful than comparable Rotax 912 models, and they sound like proper airplane engines. On the other hand, they are less forgiving of setup errors and careless operation than their competitors and may take more tender loving care to keep them happy, but those challenges are not insurmountable. Jabiru engines have their own unique character that must be understood and accommodated. Happiness with the engine will likely prove elusive if you do not embrace that unique character and make peace with it.

![]()

Dave Prizio is a Southern California native who has been flying since 1973. Born into a family of builders, it was natural that he would become a contractor and spend his leisure time building airplanes. He has completed three: a GlaStar, Glasair Sportsman and Texas Sport Cub. He shares his love of aviation by flying Young Eagles and serving on the EAA Homebuilt Aircraft Council.

Well written Dave and thanks. I have a Camit Jabiru 6 cylinder engine and according to the instruments, it runs too cool. I wonder if the instrumentation could do this? I have each cylinder measureable with a 6 position switch. Would you need more details of the instrumentation or the engine installation ( it is in a J230 ) or what?

regards, Bruce Tuncks, Victoria, Australia.

Great article, thank you.

My 2200 is injected with an Airmaster constant speed prop. Max torque is at 2500 so I set the Airmaster controller to:

3,200 rpm Take-off

2,900 rpm Climb

2,500 rpm Cruise

I run wide open throttle until I am at cruise altitude then cruise at typically 23″ to 25″ depending on how fast I need to go.

Rotec water-cooled heads.

Regards Philip