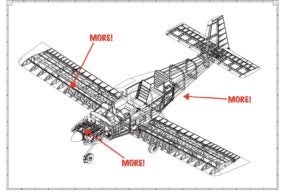

One of the most desirable and intrinsic benefits of building your own airplane under the Experimental/Amateur-Built rules is the ability to deviate from the plans and make changes to your kit as you go. Historically, this approach could entail anything from slight changes in hardware and equipment to much bigger stuff, like different airfoils or other major structural variations. When the airplanes were simpler and slower, and when builders were more likely to have a grounding in aircraft design or construction, this kind of mix-and-match attitude was more common.

The upside is the opportunity for experimentation. The downside is that no two of any given design may be the same—they might not fly the same, have the same stall characteristics or even reveal the same performance. Assuming the original designer was thoughtful and smart, at least the first versions should have been vetted for the big things—that the wings stay on or an incipient stall doesn’t turn into a frightening and unrecoverable snap spin. But then every modification away from that original version carries the potential to make the airplane better, but also to make it worse. Only a really diligent flight test program can reveal which way the airplane moved along the safety spectrum, and even then you might not completely know how the design has been changed by your modifications.

Today’s builder is sometimes derisively referred to as “an assembler,” as though completing a well-designed and well-implemented kit is somehow a lesser endeavor. But the truth is that modern kits are better than they ever have been, both from a design standpoint and in terms of execution by the kit maker. It’s easier now to build a “fully conforming” Experimental whose performance, safety and handling qualities will closely align with the factory prototype and, very likely, the airplane you first flew as a demo that got you started in this process.

Weighty Measures

There are modifications big and small in our world. During the discussion of the Van’s RV-15 in our October issue, Paul Dye mentioned that some RV-6s had their maximum gross weight upped above that set by Van’s. In part, this was a misstatement on our part—we said some were near 1800 pounds when the original was set at 1600 or 1650 pounds—and not intended as an endorsement of the practice. Yes, the builder is the manufacturer and many change things like the gross weight somewhat arbitrarily. Some, instead, just choose to operate well over the listed max-gross weight and hope their insurance company won’t decline to cover incidents or accidents while being flown over the limit.

The mods issue has been growing over time and prompted Van’s to issue Service Letter SL-00062 in mid-September relating to airframe mods:

“Every modification carries with it certain unenumerated/unknown/unevaluated risks, and any individual change or combination of changes may result in the introduction of new or additional risks and/or defects in the resulting one-off aircraft design. Van’s Aircraft does not evaluate, review, test, approve, or in any other way provide its support for deviations from its published and maintained aircraft designs. Any changes, enhancements, or modifications made by the builder, owner, or any other person are made at that person(s) own risk, and the person(s) making the changes, as well as anyone who operates the airplane at any point in the future, bears the responsibility for evaluating, understanding, and accepting any consequences of such deviations from the aircraft plans.”

No Simple Answers

Deviating from the designer’s recommendations for things like gross weight (or even CG range or fuel capacity) can be a slippery slope. I had intended to do the subject justice in this space, but as I got deeper into the possible interactions of the aftermarket mods and the original airframes (multiplied by the different kinds of airplanes out there), it became obvious this is not a two-page deal. So look for a much deeper dive on the effects of mods to common kits in a future issue.

I’ll wrap up here by reiterating that every time you move from the way the original kit was built—excepting, of course, alterations made by the designer over the course of the model’s lifespan—you’re in new, untested territory. What’s more, you have to be on the lookout for combinations of mods that may or may not work together, or whose combination turns a potential problem into a persistent one. Experimenting is a fantastic freedom to have, and it can be exhilarating for the right individual. But there’s really no such thing as a plug-and-play modification. Not here in the real world.

Finally, G100UL Approved

I’m happy to report that as of September 1, 2022, the FAA has approved GAMI’s supplemental type certificate so that owners of certified aircraft can use its G100UL unleaded avgas. The FAA signed off on the STC after months of delay.

After AirVenture, GAMI was to have meetings with FAA management to answer the few remaining open questions on the fleetwide STC. This they did, at the insistence of FAA’s head of the certification office, Lirio Liu. Within a couple of weeks, FAA HQ signed the STC paperwork that the Wichita Aircraft Certification Office has had ready for months. The sky didn’t fall.

Now GAMI can continue getting manufacturers involved, ramp up efforts with distribution partner Avfuel and hope to see G100UL appear at local airports. GAMI has an agreement with a California flight school to run G100UL exclusively, so that will help with additional field experience. (And Swift has a program with the University of North Dakota to run its 94UL, which will help tell us how much happier our engines will be without lead.) No doubt G100UL’s rollout will be a gradual, careful process, but with this regulatory hurdle cleared, we’re finally on the road to a viable replacement for lead in our high-octane fuel.

One thing I’ve learned about designing airplanes is that somethings are easier and simpler than the common person thinks. But at the same time other things in aviation the common person would think is no big deal, can have huge consequences, or result in a more difficult analysis to determine the impacts.