“I’m not a painter,” Tony Kirk said, and deciding on a paint scheme for his RV-7 was harder than building it. Repeating the red, white and blue Thunderbird scheme on his RV-6A, simplified by a painter who wasn’t comfortable masking all of the scallops, didn’t appeal. And then there was the question of who’d apply the paint? Kirk found the answers in the ubiquitous emblem of Van’s Air Force.

“I’m not a painter,” Tony Kirk said, and deciding on a paint scheme for his RV-7 was harder than building it. Repeating the red, white and blue Thunderbird scheme on his RV-6A, simplified by a painter who wasn’t comfortable masking all of the scallops, didn’t appeal. And then there was the question of who’d apply the paint? Kirk found the answers in the ubiquitous emblem of Van’s Air Force.

Curious to know if anyone had replicated the emblem’s transition from plans to reality in 3D, Kirk connected with its creator, Randall Henderson (see sidebar). “If no one has used it, it seemed like a great choice for me,” said Kirk, who worked in Van’s prototype shop and now is a member of the technical support team. “I’ve told people for years that if you want to get it done, stick to the plans. Now I tell them I stuck to the plans, and the plans are now stuck on me.”

While he may have stuck to the plans, Kirk’s life has followed a path less structured. “I’ve failed twice at retirement.” The first came after 34 years with the U.S. Postal Service in Toledo, Ohio. In between hiring on as a 19-year-old mechanic in 1979 and retiring as the fleet manager in 2016, he turned wrenches, worked the stockroom, repaired high-speed mail processing equipment and tested up to electronics technician.

When he retired, Kirk had been without an airplane for five years. In 2011 he’d sold his RV-6A to help son Kevin, a Toledo firefighter, buy a house five doors down from the family home in Sylvania, Ohio, a suburb of Toledo. Seeking a retirement project, he’d found a local RV project. Checking the RV-4 service bulletins on Van’s website, “I saw a help-wanted notice.”

Showing the ad to his wife, Jan, Kirk explained that “Van’s was looking for someone to work in the prototype shop, and I can do everything on this list. I’m retired, bored, with nothing to do, and your company has offered you an early retirement at the end of 2016. I’d like to apply for this job, but it would mean moving to Oregon. She said, ‘If you think you can do it, and you’d like to try, go for it.’ So, we did.”

Kirk’s weeklong audition in Oregon included Jan because Van’s knew that if she “didn’t buy into the move, I wasn’t going to be happy either.” Van’s president, Rian Johnson, picked them up in Portland on Saturday and showed them the Hood River on the way to the hotel. “We fell in love with the landscape, and we found a house to buy on Sunday,” Kirk said. He started his audition the next day. “Luck is when preparation meets opportunity. That’s the way my life has been, serendipity.”

COVID led to Kirk’s second retirement failure. “Van’s was a great adventure, and we loved [the Pacific Northwest], but we were just too far away from family. Three of our children are frontline workers [Kevin, the Toledo firefighter, and daughters Tracy and Lisa at ProMedica Toledo Hospital], and we felt we needed to be back there.”

A week after Van’s graciously accepted Kirk’s resignation, “they called with a job offer,” Kirk said, as they were packing for the move to Temperance, Michigan, 10 miles north of Toledo. “Yeah, we know you’re moving, so just shut up and listen for a minute,” they said. In the proto shop, Kirk did a lot of CAD work with the engineering staff, work he could continue to do from home, “and the tech support team could use someone with my knowledge on the telephone,” Kirk said. “I still do more engineering stuff here than I do tech support work.”

Moving Experiences

A Cub Scout penny-a-pound ride introduced Kirk to aviation at Toledo’s Express Airport. “I don’t remember much about it other than the pilot was talking about whiskey all the time.” Divorced, “in the late ’80s I was a single guy with custody of my two boys,” Kirk recalls. “Interested in computers since they were new, expensive and slow, I had an 8-bit Atari and a flight simulator program, so I was learning to fly that. That got me interested in building RC flying models.”

Looking up at his models, Kirk realized “they were having all the fun, and I’m still firmly on the ground. This ain’t working!” Looking into flying lessons, he saved a chunk of money and watched King videos. In 1990 “I started training in May and had my license in September with 46 hours in my logbook. I’m goal oriented.”

Kirk’s airplane building ambitions grew to full-scale flyers. Enamored with the Wheeler Express, he searched it out during his inaugural pilgrimage to Oshkosh in 1991 with his flying friend, Bob Terry. As they explored the flight line and exhibit areas, Terry suggested that they also look at RVs. Kirk looked again in 1992 and got a demo flight in Old Blue, Van’s Aircraft’s RV-6A. “That set the hook. I was totally RV after that and I started saving money for my kit.”

Kirk found and bought an RV-6 empennage kit in 1995, just before he met and married Jan, who had two daughters. “That empennage went in the attic, and we had a daughter, Kayla, and our focus was on raising five kids.”

Several years later he found an RV-6A kit with a finished wing and the fuselage metal still in the crate. Kirk made the first flight in 2005 and logged 720 hours in it before priorities changed and he sold it in 2011 to help his son buy the house down the street, “so I could have him and my grandkids in walking distance.”

Kirk moved to Oregon alone in September 2016 because his wife would not retire after 40 years of hospital administrative work until December. “We had to drive her car and a trailer full of stuff, but we weren’t going to do that in the middle of winter.” Waiting for spring was another measure of serendipity.

Before pulling the trigger on an RV-7 quickbuild fuselage that had suffered some transport damage on its way to the factory, Kirk found an RV-7 kit for sale in Flint, Michigan, 90 minutes north of where he and Jan would start her move to Oregon.

“Side-by-side seating is the best way to share the joy of flight,” said Kirk, who’s flown more than 175 Young Eagles and countless silver (and bald) eagles. “I didn’t want another RV-6 because it’s not match-hole drilled, and you spend an inordinate amount of time laying that out.”

And after he sold his RV-6, he’d logged several years in a friend’s RV-7. “A doctor, he didn’t have a lot of time to fly, so he said I could fly it to keep the oil circulating; just put gas in it when you’re done. I didn’t have my A&P yet, but he had his repairman certificate for the airplane and I helped him do his annual condition inspections.”

Pursuing the practical experience path to his A&P, proto shop supervisor Scott McDaniels endorsed his efforts. Kirk passed the knowledge exams and, back for Christmas in Toledo, took the oral and practical exams in Toledo with a friend, an examiner.

In late April, after he loaded the project, he picked up Jan and headed west. “When I got the kit, I told her it was going in the truck first, and what didn’t fit didn’t go. She wasn’t real happy about that, but we crammed the truck pretty full and got in everything we needed.”

Kirk had to fit the RV-7 into a single-car garage and work progressed slowly, especially during the summer. “The garage door faces west, and pointing the temperature gun one day, it was 157° F, too fricking hot to work on the kit. We also took time off to go places and see things—the coast, Crater Lake.”

Minimal Mods

Following his own advice, Kirk stuck to the RV-7’s plans. His few modifications focused on making life easier, like the Meske tip-up sliding canopy from Aircraft Extras. As it did on his RV-6, it made getting people and their baggage in and out much easier. Lightening the seat backs was not worth the time it took to create the holes with a Unibit and punch. “If you weigh all those aluminum disks, you have maybe 3 ounces. I’d save more weight if I didn’t eat lunch before flying.”

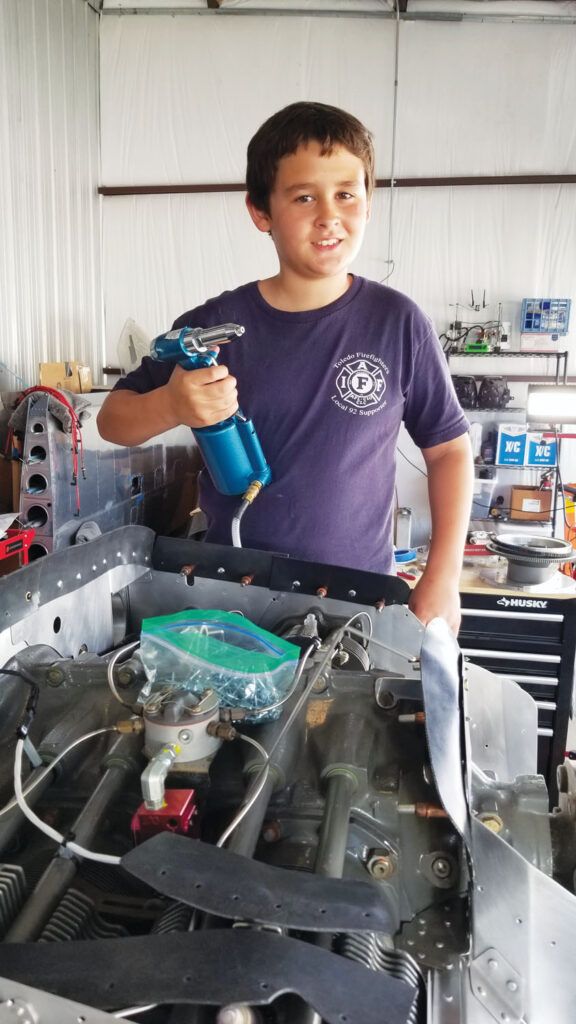

Not a fan of a field of circuit breakers “because they hardly get used, I’m happy with fuses,” said Kirk. To simplify access to the fuses, Kirk bent a module with a removable panel secured with nut plates. His 13-year-old granddaughter shows how to install them on Tony & Anna’s RV-7 Construction Videos channel on YouTube. Another video shows her removing the nut plates because Tony only measured the panel once, and it was too narrow.

Using an RV-10 mount, Kirk placed his oil cooler on the firewall and added a cockpit-controlled butterfly that adjusts the amount of cooling air and regulates the oil temperature. Kirk also made a spring-loaded dipstick door on the cowling. Painted on its underside is the powerplant, “Aero Sport Power IO-375 195 HP.”

This engine was another episode of serendipity. “I got it secondhand from Arizona Aircraft Salvage. It came off of a ground-looped Murphy Rebel; according to the logbook, it had 25 hours on it. I would have liked to have a constant-speed, but the engine has a solid crankshaft,” so it turns a fixed-pitch Sensenich metal prop. “On the other hand, I saved 40 more pounds and $10,000 by not buying a constant-speed prop and governor.”

Hanging this engine is the subject of another YouTube video. “I hear so many people talking about how many people and how long it takes to hang the engine,” Kirk said. “We hung it in about 12 minutes and had all four bolts tightened up. If you don’t have a 13-year-old granddaughter helping you, it might take a little longer.”

With his wife’s sewing machine, Kirk stitched his RV-6 interior. “I’d never sewed a darn thing in my life, but if other people can do it, I can do it. I’ll figure it out.” For the RV-7, he found a used industrial sewing machine in Oregon. Before deciding on the VAF scheme, he sewed a blue and gray interior. “I really wasn’t happy with it, but it was a good start.”

With the VAF scheme set, he sold that interior and started again. Starting with Van’s seat foam and patterns, he found the cowhide and all the necessary supplies at Perfect Fit, a great auto upholstery store in Portland. Knowing that at some point he’d return to the Toledo area, Kirk added heaters to both seats. They are controlled by a switch he added to the air vent module that also includes his headset jacks.

Mike Seager’s wife, Georgeanna, embroidered the VAF logo. “She has all the fancy machines, and I asked if they worked on leather,” Kirk said. “That was no problem, she said, so I took her some leather and she had the logo digitized, and they turned out great. But I knew I only had one shot to sew them in properly so they’d look right.”

Stahr Painter

With the VAF scheme set before he finished construction, Kirk had time to puzzle out the airplane’s planform paint. The emblem’s lightning-bolt transition from red reality on the left to plans on the right was the key. Deviating from the original, Kirk replaced the RV-4 with an RV-7 and he added a checkerboard rudder. “That’s been a Van’s staple since the beginning, but I didn’t want solid squares. Since they were on the plans portion of the airplane, I wanted them to look like an old-school, paper-and-pencil draftsman had doodle-sketched them on the plans while talking on the phone.”

Who would paint the airplane was still a vexing question. “Call a paint shop in July, and most of them will tell you they can schedule you for next June,” Kirk said. John Stahr’s plane was on display at the Van’s booth at Sun ’n Fun 2021, and Kirk rubbed shoulders with the airbrush master. “I thought it would be so nice to have him paint my plane, but I didn’t think it would be graphically or artistically challenging enough for him, so I didn’t approach him about it.”

Together again at EAA AirVenture Oshkosh 2021, Kirk described his red-and-white VAF scheme, adding that it was too simple for someone of his talent and asked him to recommend a painter. “John Stahr told me, ‘Oh, no, no, no! I’d really like to do that. I’ve been wanting to do that paint job for a long, long time. We can make it happen.’ He kind of twisted my arm, and it worked out that he could do it that year.” In October, “John Stahr and I painted the airplane in 10 days.”

After Oshkosh, Kirk refocused his construction efforts from the interior and wiring to everything that needed to be done before painting. “The rush was on. The fiberglass work hadn’t been done yet or the intersection fairings, and I spent a lot of long days getting ready for John.”

Heath Seckinger, a friend, pilot and paint wholesaler who owns NCW Enterprises, “really went out of his way to help me prepare,” Kirk said. Not only did he help pick the right red, he did some Bondo and prep work.

There are a million shades of red, Kirk said. Working with a DeBeer base and Matrix clear coat, he tested some pearl and metallic additives, but he went with “an unadulterated GM Torch Red, a spec automotive color, and a single-stage white because they would be easy to touch up.”

Securing N777RV had been another challenge. “Old Blue is N666RV, and I thought it would be cool to get N777RV for my -7,” Kirk said. An online N-number search led him to the Delaware Technical Community College. The registration adorned an A&P practice plane that would never again be airworthy. “It took me a year of back and forth for Delaware Tech to relinquish the number.” Kirk celebrated his acquisition by carving the N-number into the cowling’s aluminum hinge pin covers with a laptop-driven CNC kit. Stahr painted it on the fuselage using the checkerboard rudder doodle-shading.

Days before Stahr arrived, in his hangar at the Toledo Suburban Airport (DUH, in Lambertville, Michigan), Bill Sallee helped Kirk build a paint booth. “It was 12 feet wide, 10 feet high and 24 feet long. We used dimensional lumber and built it in 8 hours. I bought a dozen LED lights, and John was pretty happy with it when he got here.”

On the plans side of the scheme, all of the lines and nomenclature are painted, Kirk said. “John is a true artist, a magician.” To create the lines, he sprayed black zebra stripes over the rivet lines and then masked them with pinstripe tape. “I sent him parts of the plans so he could cut templates for the nomenclature and the arrows pointing to the part.”

Noting that they shared a simpatico work ethic, Kirk said he’d pick up Stahr, stop for breakfast and work all day. Kirk would fetch their lunch, and they’d work until 5, 6, 8 p.m. or later. “He’s smart, funny and easy to get along with. He has a dry sense of humor like I do. We were really in tune with each other. We even wore the same obscure fly-in T-shirt one day.”

But there were some surprises. “I have a smart device in my hangar, and I’d yell ‘Hey, Alexa, play Jimmy Buffett.’ John had never used anything like that. He was amazed, and before long he was making yelling requests to Alexa. Taking a break one day, Stahr was outside the hangar and he said, ‘There are the clouds I want to use [in the VAF emblem] on your wing.’ He got his iPad, took some pictures for reference and then freehanded them on my wing. He also said the plane needed a flag, and he’d brought a template for it.”

Stahr underestimated the amount of detail work, Kirk said, so he extended his stay by two days, and he shot the clear coat in a marathon session. “The last day we worked until 1:30 a.m. because he had to be on a plane home later that morning.”

“When you finish painting your plane, you need to balance your elevators,” Kirk said. The very forward edge of the elevator horn, which extends forward of the hinge line, already holds some lead counterweighting. “I was thinking of ways to tweak the balance, and I hit on the idea of casting my own lead weights and then turning them on my lathe to the weight I needed.”

Wiring Time

With the painting complete, Kirk finished building the airplane. “I did all of my wiring,” Kirk said. “It’s easy if you take your time to figure out how to do it.” This is the subject of another YouTube video, which emphasizes the importance of labeling each wire. He also built the wingtip LED lights from “really cool” kits from Flyleds in Australia.

Kirk also built the wiring harness and installed the avionics he found on Barnstormers.com. An RV-6 builder was selling his project as well as a suite of Garmin avionics still in the boxes. “It was a huge leap of faith, but I sent him half the money, and he send me half the boxes. After receiving them, I sent him the rest of the money and he sent me the rest of the boxes. It all worked out.”

In those boxes were a Garmin G3X Touch, a G5, GTR 200 com, GMC 307 autopilot, GDL 52 portable SiriusXM/ADS-B receiver and an EI Commander, which interfaces with the engine’s dual P-MAG system. “I sold a couple of the items in the suite and bought a Garmin GTN 625 GPS-only navigator. With one com radio and no ILS, the -7 is basic IFR; I’m not instrument rated, but I’d like to be, and I love the autopilot.”

“The airworthiness inspection was on my birthday, December 14, and I made the first flight on December 17, 2021, the 118th anniversary of the Wright brothers’ first flight. I completed the 40-hour Phase 1 testing in five weeks, and my only squawk was something I wired wrong on the ADS-B Out.” The plans for 2022 include a flight to Oshkosh, where Kirk’s RV-7 will be on display at Boeing Plaza on Monday and near the Van’s Aircraft booth for the rest of the week.

Photos: Tony Kirk and Maggie Lauderdale.

That is absolute genius! I hope I can see it up close at OSH.

Fantastic article, and as one of the three co-owners of Tony’s first RV6A it is great to get some more of the history of our aircraft (still in it’s Thunderbirds colour scheme). I even know what the rod behind the passenger seat is for now!