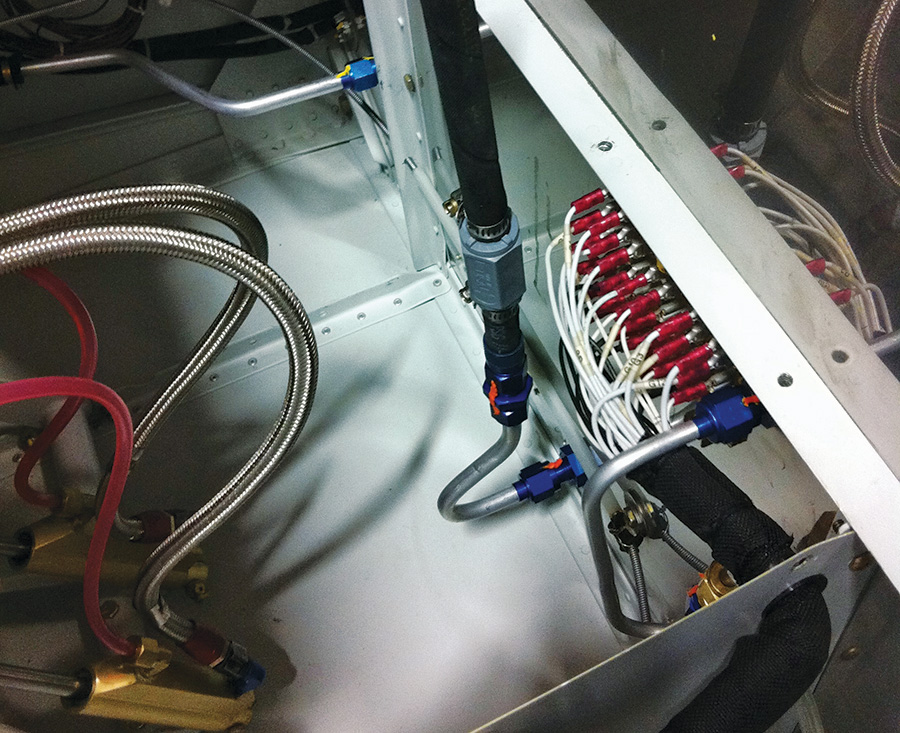

It’s going to fit! The first step was placing the smoke tank into the front baggage compartment with the tank bracket and all the lines in position.

As a child, the white line extending behind some airplanes while doing aerobatics excited my imagination and prolonged my joy of seeing them dance in the sky. Naturally, visions of passing the same sensation on to other children watching me fly aerobatics drifted through my mind as I built my Van’s RV-8. So, I designed the electrical system and developed a list of needed equipment, including the smoke-pump. But at the time, a smoke system exceeded my budget. Build now and improve later is my personal rule, so I limited myself to putting in a spare circuit breaker, knowing quite well what the spare was to be used for. After building the plane, making the first flight, testing, flying, and enjoying it for 100 hours, the right time came to install the smoke system.

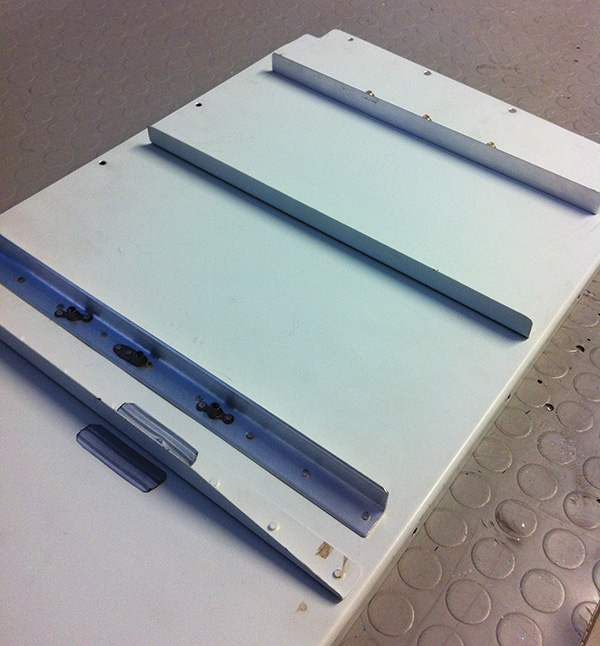

Starboard side stiffener and a removable tank bracket arrangement will hold the port side stiffener.

The summer flying season was in full swing, so despite the joy of building stuff, I wanted something ready—plug and play—and proven. I chose a straight-forward approach with the SA-100H model from Smoking Airplanes, LLC. The level and non-continuous inverted, positive-G flight smoke system kit carries the politically correct name: VCAS (Visual Collision Avoidance System).

Planning

Smoking Airplanes sells kits or components without the tank, but a little “brain scratching” demonstrates that the kit is a convenient choice—saving time and probably money. After studying the kit options, I started planning my installation.

What’s included in planning? Well, weight and CG are fundamental factors. The smoke system consists of a tank containing smoke oil, with a good electrical pump activated by a relay-controlled Microswitch. I had two possible positions for the tank: rear or front baggage compartment. The rear baggage compartment provides the opportunity to install the larger tank (5.5 gallons), but Smoking Airplanes has a low-profile tank (3.5 gallons) that fits perfectly into the RV-8’s front baggage area and results in easier and quicker installation and, particularly compelling to me, removal. I chose the front baggage area option.

The port-side tank bracket has three notches that will slip under these large washers, allowing the tank assembly to slide during installation and removal.

Van’s recommends a limit of no more than 50 pounds in the front baggage compartment to stay within their design limits; the kit, including tank, pump, and 3.5 gallons of smoke oil, weighs 37.15 pounds. It passed the weight-consideration hurdle, so CG calculations with a simulated full smoke tank became the next exercise. Flying solo with 25 gallons of fuel in the airplane proved within the aerobatic weight and CG limits. Sharing a smoke ride with a friend could remain within limits by carrying only 15 gallons of fuel or avoiding a full charge in the smoke tank.

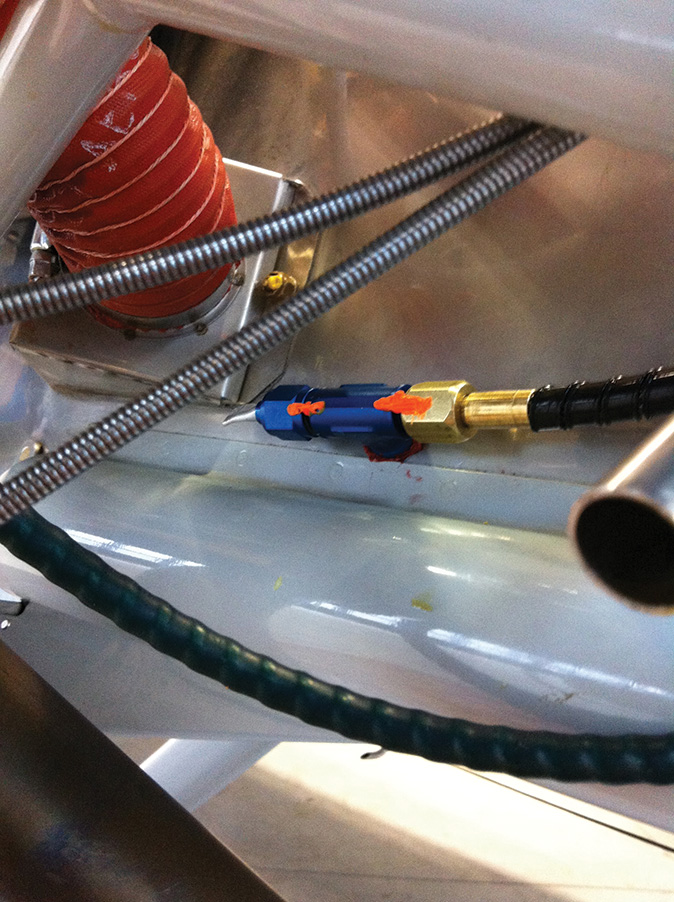

A small hole drilled into the firewall provides a place to attach the kit-provided long pop rivet, which acts as a mount for the vent line.

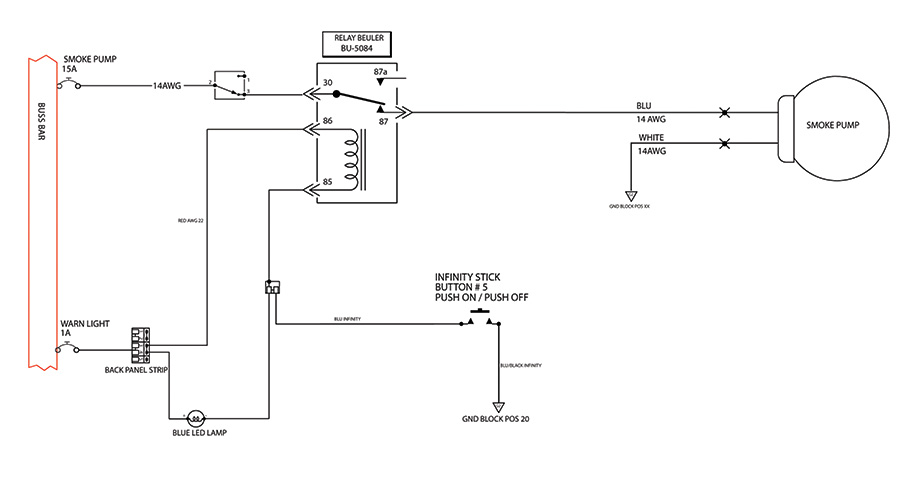

Planning also included decisions on the placement of all other elements of the system. One must install a specific circuit breaker and a master smoke switch. Pushing the button causes the pump to build pressure into the line, while the mixture valve controls the amount of smoke oil sent into the injectors, which are placed in the hottest spot of the last exhaust tube. A red LED light confirms “Smoke On.” Big smokers will probably like the optional second injector.

Baggage Area Installation

To prepare for installation, I studied the manual named RV-8 Front Baggage Area Installation, where everything is well explained. To begin the installation, I put the tank into the front baggage compartment with the tank bracket and all the lines in position. The internal tank pickup (suction) must be toward the rear of the airplane for best results. I wanted a clean routing of the hoses, so I paid close attention to the potential tank position.

I prepared two baggage floor stiffeners for the tank-attach brackets. Three plate nuts hold the starboard side stiffener, and a removable tank bracket arrangement holds the port side stiffener. I made three notches in the port-side tank bracket, which mounts on the baggage floor under a large washer in a bolt/large washer/spacer/nut combination, so it can slide during the installation and removal.

The smoke tank must be vented and, in my installation, drilling a small hole into the firewall to mount the kit-provided plug for the red vent hose (a long blind rivet) seemed the easiest way. If a problem arises with this arrangement (e.g., smoke oil creating a mess on the firewall), it will be easy to build a vent tube along the firewall that extends to the bottom of the aircraft. Please note, however, the vent line must go outside the aircraft with a fully-inverted smoke oil system.

I decided to plug the oil mixture valve directly to the pump exit, so the valve regulator will be easily accessible through the front baggage door. I also added a hole to the baggage floor for the oil line. To remove the smoke tank, I unscrew the clamp of the oil mixture valve, remove the red vent hose from the internal firewall plug, and remove the three bolts in the right-side tank bracket. It takes less than five minutes.

Using a vertical line from the hole in the baggage floor, the author prepared a contoured curve in a 3/8-inch diameter soft aluminum tube and installed the AN815 flared union fitting.

I wanted to stay in the vertical line from the hole that I had put into the baggage floor, so I prepared a contoured curve in a 3/8-inch diameter soft aluminum tube and installed the AN815 flared union fitting to connect the aluminum tube to the hose AN fitting coming from the one-way check valve (gray) already installed by the factory. Then, I cut the needed length of the supplied black pressure hose to extend from the mixture valve through the baggage floor.

The bulkhead fitting should be mounted low on the firewall, lower than the injector. Choosing to mount the kit-supplied tee bulkhead fitting for a future double injector configuration, I attached it to the firewall through a Unibit-created hole and sealed it with high-temperature RTV. I had to close the unused exit, but didn’t have an AN929 flared tube fitting cap. I have a lot of scrap fuel vent line pieces in my shop, so I took a short ¼-inch tube of soft aluminum and flared one side of the tube for the standard AN818 nut and AN819 sleeve. The other side of this short tube was sealed and crimped in a bench vise.

Attaching the oil mixture valve directly to the pump exit allows easy access to the valve regulator through the front baggage door.

I plan to install the second injector after testing the first one. The resulting smoke system installation doesn’t interfere with any moving parts of the aircraft.

Firewall Forward Installation

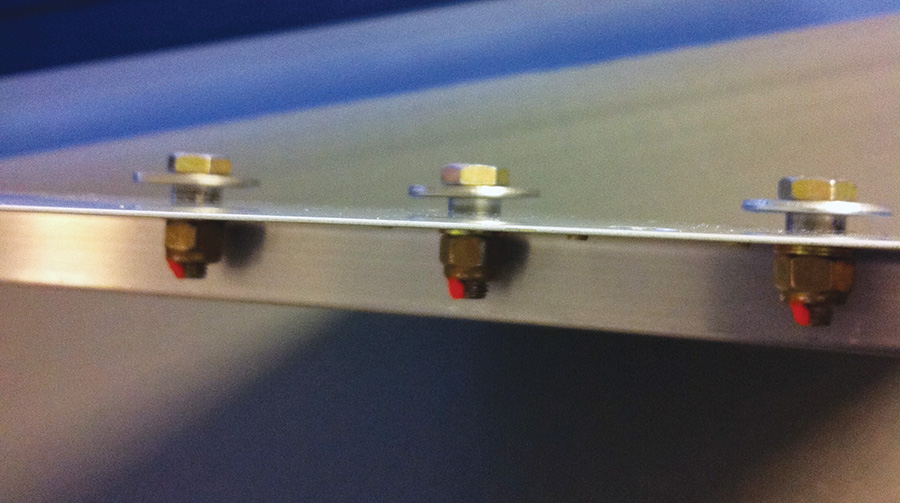

Obviously, options for the position of the bulkhead fitting and hose routing are more limited when working with a flying aircraft than during an initial build. I studied the potential routing of the hose that will go into the injector, made measurements, and included a 24-inch long braided stainless steel hose with the kit order. Following the kit instructions, I used a Unibit to drill a 3/8-inch hole into the top of the exhaust pipe just aft of the “Y” from the number 2 and 4 cylinders to place the primary injector. Where possible, the injector should stay higher than the bulkhead fitting for a cleaner smoke trail cutoff that keeps residual oil in the braided hose from dripping into the exhaust pipe once the pump disengages. Two hose clamps maintain the injector in its position, and a safety wire is installed to keep the injector body in the exhaust pipe if the injector mounting plate weld fails.

The stainless hose must have sufficient slack for engine movement. I protected half of the hose with a high-temperature spiral wrap (in order to avoid friction with the fuel line) and supported it with an MS21919 DG clamp placed on the engine mount. The hose makes a sump between the bulkhead fitting and the injector in order to maintain a cleaner smoke trail cutoff when the system turns off.

The complete, plug-and-play Smoking Airplanes electrical kit makes installation of the electrical system easy, although one can organize the components according to personal preference. With the standard installation, the smoke system operates two ways: pushing the momentary remote switch or putting the three-way switch on continuous mode. (Safety Note: Leaving the smoke system in “On Continuous” during high-risk flight and aerobatics isn’t recommended due to the possibility that the smoke oil pump could run continuously after a crash. Smoke oil burns, and such an incident contributed to a recent fatality.)

A black pressure hose provided with the kit will extend from the mixture valve through the baggage floor.

Although the kit provides a complete electrical system, I chose to partially follow my own way. A switch on my Infinity stick grip, in addition to a master smoke switch on the side-switch panel, gives an electrical signal to the relay that turns on the smoke pump. I have a blue LED light just in front of me that informs me that I’m making smoke. My system is protected by two aeronautical standard Klixon circuit breakers: 15 amp for the smoke pump and 1 amp for the blue LED light and relay activation.

Testing the Smoke System

With the cowling off and after filling the smoke tank with the right oil, I put a can under the exhaust pipe-injector junction. A helper was useful here. With the oil mixture valve opened one turn, I switched the system on for 15 seconds until the oil drained steadily from the exhaust pipe. I checked that the blue LED was on. After switching the system off, I confirmed that there was no leak. Before the in-flight test, I double-checked that all controls and control surfaces didn’t interfere with this new installation; a ground test was executed, always with the oil valve opened one turn. Lacking any leak in the system, I did the first “smoking” flight. For setting the oil mixture valve properly, you need a spectator. It’s the perfect moment to enlist the help of some hangar bums. When they think that you had a great smoke trail and you notice very little oil, or no oil, on the belly, you’re done with the adjustment. Opening the mixture valve ½ turn proved perfect for my RV-8.

The primary injector fits into a 3/8-inch hole drilled into the top of the exhaust pipe just aft of the “Y” from the number 2 and 4 cylinders.

Two hose clamps maintain the injector in its position, and a safety wire is installed to keep the injector body in the exhaust pipe.

The hose makes a sump between the bulkhead fitting and the injector in order to maintain a cleaner smoke trail cutoff when the system turns off.

The smoke system plumbing was carefully checked before flight to ensure it didn’t interfere with the rudder pedals and brake lines (left side of picture).

Smoke in flight is really fun, and intercepting your smoke trail during a cloverleaf is priceless. But, during this fun, always remember—fly the airplane first.

A video of the author flying aerobatics in his -8 using the smoke system is available at http://vimeo.com/68380783.

The kit-supplied tee-fitting attached to the firewall through a hole sealed with high-temperature RTV. To close the unused port for the second injector, the author squeezed and sealed a short 1/4-inch tube of soft aluminum installed in the tee with a standard AN818 nut and AN819 sleeve.

Photos: Francesco Dante and Luca ‘Luke’ Perazzolli