Van’s Aircraft has started production of its first-ever high-wing design, the RV-15. The company has begun manufacturing wing kits, which are expected to ship to builders this year.

On the opening day of EAA AirVenture 2025, Van’s began accepting orders for the RV-15’s wing kit. Deliveries are scheduled to start before the end of the year. The kits feature prepunched aluminum skins and structural components, assembled with blind rivets to reduce build time. Components will be pre-dimpled, and according to the engineering team, builders will not need to use a tape measure or any rigging because the focus is on “buildability” and ease of assembly. This elicited applause from attendees, and builders in the crowd were excited to hear about the improvements to the construction manuals which will include a bill of materials (BOM) for each step and shaded and colored views for quick identification of parts and task visualization. The company calls the instruction manuals “Lego-inspired.”

The 60-gallon fuel tanks will be built as a separate assembly, then added to the wing assembly. They are offered as a quick-build standard item and anyone who has dealt with Pro-Seal will appreciate this change.

The aircraft itself went through 29 iterations since 2021, and 21 of those were since 2024: 2 wing, 3 flap, 5 aileron, 8 tail, 3 rudder iterations.

“The RV-15 is a game changer for the backcountry flying community and Van’s Aircraft,” said Mikael Via, CEO of Van’s Aircraft. “Our design engineers have worked tirelessly to create an airplane that takes Van’s idea of ‘Total Performance’ into the utility category. The RV-15 has the ideal mix of very low stall speeds and docile handling that backcountry pilots love with unexpectedly high cruise speeds. The RV-15 is capable of cruising at 140 knots while also feeling comfortable on short, challenging remote airstrips.”

The wing kit is being offered at an introductory price of $19,650 and the company reported selling 20 wing kits in the first 30 minutes.

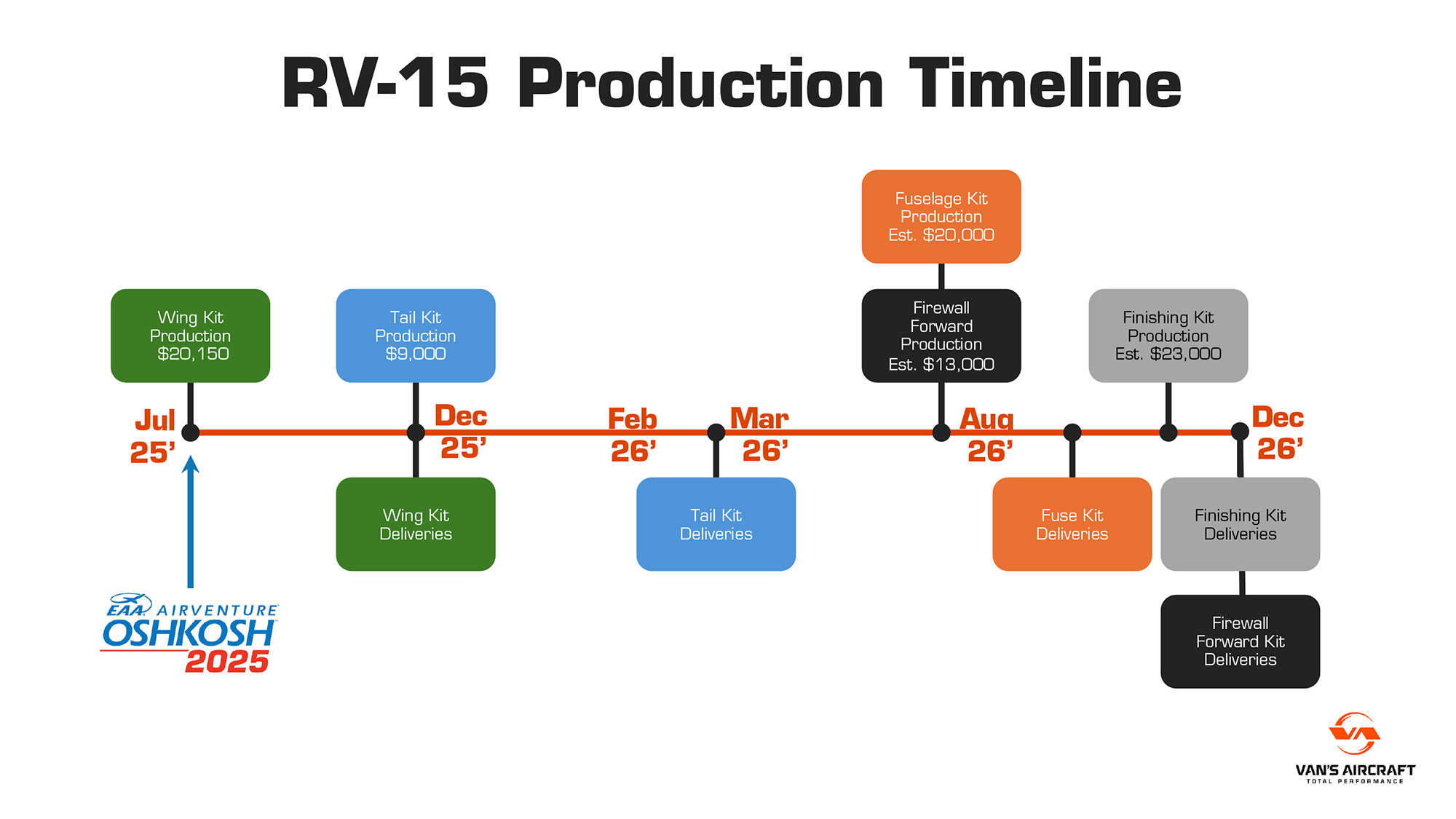

Production and Delivery Timeline:

- Tail Kits: Orders open in December 2025, with deliveries starting in March 2026.

- Fuselage Kits: Orders open in August 2026, with deliveries in October 2026.

- Firewall-Forward Kits: Orders open in August 2026, with deliveries by the end of 2026.

- Finish Kits: Orders open in November 2026, with deliveries by the end of 2026.

Estimated pricing for the remaining kits is $9,000 for the tail kit, $20,000 for the fuselage kit, $13,000 for the firewall-forward kit, and $23,000 for the finish kit.

Customers can place a wing kit order on the Van’s Aircraft website or in-person at Van’s booth at AirVenture.

The RV-15 shares few components with other Van’s RV models, incorporating new technologies for the backcountry market. Its patented articulated landing gear is designed for rough strips and benign taildragger handling. The flap design includes integrated vortex generators, hidden during cruise, to provide high lift and a high-drag configuration for steep approaches.

Chief engineer Rian Johnson was confident the airplane will have at least a 900-lb useful load and stall below 45 knots.

Current performance estimates:

- Useful Load: 900+ lb

- Stall Speed: < 45 kt at Gross Weight

- Speed: ~140 kt

- Seats: 2 Seats plus baggage

- Takeoff and Landing Distance: <400 ft

- Horsepower: 175 – 220 hp

- Engine: Lycoming IO-390

Van’s plans to move the tail kit into production late in 2025, with deliveries starting in the first quarter of 2026. Design work on the fuselage and firewall-forward sections will be completed in early 2026, with kit deliveries for those components scheduled for late in the year—a full year ahead of initial estimates.

The presentation this morning opened with Van’s CEO Mikael Via providing insight into the company accomplishments over the past year, and like last year, acknowledging the difficulties and missteps from the past that led the company to declare bankruptcy in late 2023. The backorder log has been significantly reduced – from $2.3 million in the spring of 2024, to about $190,000 today.

The warehouse and shipping operations have been improved with automation and new corrugated crates which saves builders an average of $200 per kit order.

The warehouse and shipping operations have been improved with automation and new corrugated crates which saves builders an average of $200 per kit order.