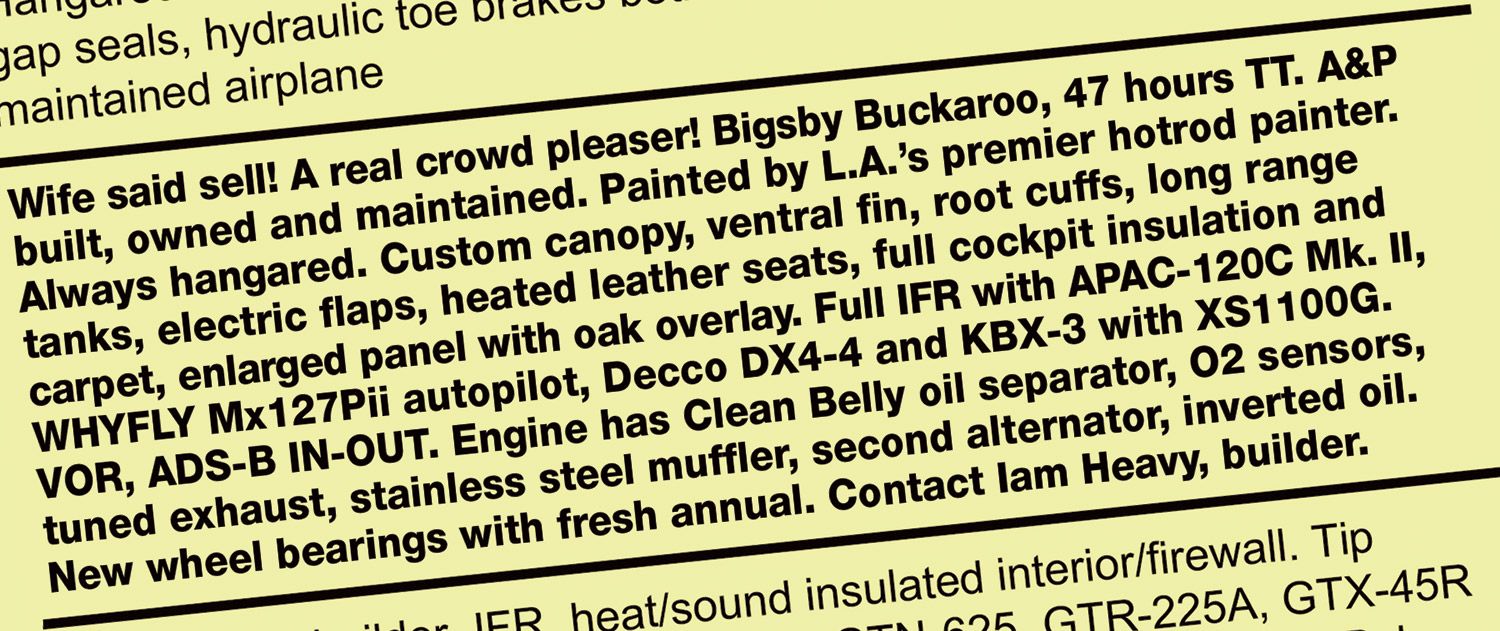

Classified ads for flying homebuilts boast of the meticulous workmanship and maintenance. The engine upgrades and professional paint are noted. A string of characters, which could make an impenetrable investment account password seem inadequate, describes the avionics. Pulsing landing light? Check! Always hangared? Check! To underscore how pampered the aircraft has been, a small detail (“new wheel bearings…”) from its last condition inspection is noted.

Classified ads for flying homebuilts boast of the meticulous workmanship and maintenance. The engine upgrades and professional paint are noted. A string of characters, which could make an impenetrable investment account password seem inadequate, describes the avionics. Pulsing landing light? Check! Always hangared? Check! To underscore how pampered the aircraft has been, a small detail (“new wheel bearings…”) from its last condition inspection is noted.

But weight. It’s missing. Weight, both empty and licensed gross, are almost always absent from an ad—perhaps because there’s too much of it? Those weights are important for all aircraft, but more so for homebuilts, which can vary greatly.

Empty Weight

For too many reasons to list, a homebuilt’s empty weight is at each builder’s mercy. An airframe burdened by too many trips to the custom-touch buffet won’t deliver the performance and payload capacity the designer intended. Every pound added to an airframe reduces the airframe’s useful load by an equal amount, or more, depending on the weight’s impact on the airframe’s center of gravity. Our seller, Iam Heavy, may have built his two-place Buckaroo for solo flight, intentionally sacrificing people capacity for creature comforts.

Compare the empty weight of the airplane you are considering purchasing to the designer’s specification. If it is greater by a questionable margin, investigate why. The factory-provided fabric baggage sling may have been replaced by aluminum. The airframe may have been beefed up (though I’d argue, burdened) with extra structure or thicker skins. The sleek tailwheel designed for the aircraft may have been replaced by a heavy unit from something else. Visible weight, like a packed panel or plush upholstery, can signal unseen weight additions.

To be fair, a designer’s published empty weight may be from a prototype that was completed enough to fly, but not representative of the airplane they display at shows. While an honest designer wouldn’t intentionally mislead on empty weight, their published number may not have kept up with a design’s changes or represent enhancements to the factory demonstrator. It’s also possible for a design to lose weight. A kit manufacturer may switch from fiberglass to carbon fiber cowling and fairings, or switch from lead-acid to lithium batteries. Therefore, a designer’s published empty weight should be accepted as a goal, not a given.

Design Gross Weight Vs. Licensed Gross Weight

A designer chooses every component based on a design’s targeted performance, gross weight, useful load and flight load factors (G’s). Their published specifications represent the design operated at or below the design’s published gross weight. But the Experimental/Amateur-Built category does not prohibit a builder from assigning an arbitrary gross weight when they license their aircraft. A builder might do this because they built heavy and increasing the licensed gross weight restores—on paper, but not in practice—the airframe’s useful load.

They may even have done it out of ignorance. For instance, a Sonex is an LSA when licensed at the designer’s 1150-pound gross weight. Some Sonexes have been licensed as high as 1320 pounds, the maximum gross weight allowed by the LSA category. A Sonex is no longer Light Sport eligible at 1320 pounds because its stall speed rises above the speed allowed by the category, pushing it out of the category. An individual who must fly as a Sport Pilot may not be aware they are flying illegally until their 1320-pound-licensed Sonex is ramp checked, or an incident/accident reveals they were not rated for the aircraft and insurance is denied. Worse, they may load the airplane beyond its intended gross weight and stagger into, and back out of, the sky. Ask a seller why they licensed their airframe above the designer’s specification.

Correcting the Licensed Gross Weight

While removing extra weight from an airframe may be impractical or impossible, correcting the licensed gross weight to match the designer’s intent can be accomplished through paperwork and piloting. The FAA defines a change to the licensed gross weight as a major change. (They do this by not defining it as a minor change.) An airplane’s specific operating limitations define the process for making a major change. In broad terms, the change requires a FSDO to assign a flight test area, logbook entries to place the airplane in Phase I flight testing, flight testing at the new gross weight (usually solo, for a minimum of five hours), recording the new performance numbers in the aircraft’s flight manual and updating the weight and balance report and aircraft data plate. In extreme cases, a new airworthiness certificate may be issued.

Cloud Pleaser or Crowd Pleaser?

To avoid the disappointment of buying a finished airplane that can’t serve your flying mission, focus early attention on an airframe’s empty weight and licensed gross weight, and its weight and balance report. Compare them to the designer’s specifications. Even with that information in hand, there remains one question. Is it accurate? Without weighing the aircraft and double-checking the arms, you won’t know. Take the empty weight on faith, but seasoned with a grain of salt. (Like pilots, airplanes can gain weight as they age.) It’s safe to assume if you seek a Buckeye Buckaroo, you seek the performance the designer intended, not one that asks you to leave your flying buddy waving from the ground. That crowd pleaser may be happier on the ground, in front of an adoring public, than in the air.

Good article, but one crucial piece of information is missing- where and/or how do we get our airplane weighed and balanced?

Hi Christopher,

Thank you for reading and commenting. You can weigh an airplane yourself using an accurate scale under each tire, or have an FBO or maintenance and repair facility do it for you. Each aircraft designer provides the method and information necessary to determine an accurate empty weight and empty center of gravity for their design. This information is typically included in the plans or flight manual. The key is to use scales that are known to be accurate, i.e., recently calibrated. Too often, bathroom scales are used by builders and those can be wildly inaccurate.

Blue Skies….

Kerry Fores