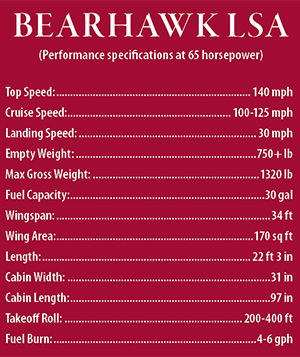

I’ve always had a soft spot for the classic light taildraggers. The Aeronca Champ, Piper Cub, Luscombe and others from the era offer beautiful lines, simplicity and reasonable cost of ownership. When I spend all day flying around in one of these beautiful antiques, I’m reminded that each also has its shortcomings. The Taylorcraft is fast but not very roomy. The Champ has more room, but it’s not able to carry much. The Cub looks great, but you have to practice getting in and out of it before you try to do either in public. Wouldn’t it be great to have an airplane with the allure and affordability of these classics, without compromising on performance or comfort? One hopeful candidate for this role is the Bearhawk LSA, the latest design from Bob Barrows.

Born to Be a Lightweight

Each airplane design starts with a mission, and the Bearhawk LSA was designed to be light. The empty weight of the prototype is a low 728 pounds, which didn’t happen by chance. It represents a culmination of weight-saving techniques that Barrows has collected over a building career that spans eight airplanes over 44 years. His two most popular designs are the four-place Bearhawk and the two-place Bearhawk Patrol. Those are known for their good performance and light weight, but the new LSA takes weight reduction to a new level. The Bearhawk LSA looks similar to the heavier and faster Patrol, but the LSA is a clean-sheet design, with the windshield being one of the only parts it has in common with the others.

The instrument panel is clean and simple.

The LSA heritage carries over from each of Barrows’ previous projects. Those who are familiar with his other designs will recognize the construction techniques, materials and the familiar Boston Maroon color scheme. The fuselage and tail surfaces are welded 4130 steel structures with fabric covering. The wing is made from 2024T-3 sheet aluminum with hand-formed ribs and layered spars. The ailerons are aluminum structures covered in fabric, and a single extruded aluminum strut braces the wing. Why are his airplanes built this way? It’s the best way he has found to keep them light, strong and simple.

Beyond those similarities, the LSA is a showcase of different techniques that save weight and improve performance. The hydraulically damped spring-strut landing gear operates as it does in the other Bearhawk designs, but the LSA parts are smaller and lighter. Barrows used Matco spun-aluminum wheel hubs and machined-aluminum brake calipers, saving about 5 pounds over traditional cast options. The 6.00×6 tires look small in an age where all of the cool folks have big bush wheels, but they are adequate for nearly any surface advertised as a runway. The smaller tires save weight and drag, as they should in an airplane where form follows function.

These lightweight Matco wheels and brakes save approximately 5 pounds.

Each of Barrows’ previous designs seems to fill a hole that he found in his own flying needs. They are all STOL capable, because he operates from a short field. The four-place Bearhawk helped carry heavy engine cargo (See About the Designer, below.), and the Bearhawk Patrol came from setting out to design the perfect transportation airplane for his type of flying. So what was the purpose for the Bearhawk LSA? That’s a short question with a long answer. Barrows says that he heard from many customers who liked the performance of his other designs but needed the flexibility of the Sport Pilot medical certification rules. His first solution was to suggest the Bearhawk Patrol could be built with a few modifications so it could meet the LSA definitions, but this wasn’t a great option. It would take serious builder discipline, and the finished airplane would lack some of the best characteristics of the Patrol. He knew that a clean-sheet design would make a superior airplane, but he also knew that he was happy to spend his free time flying his Bearhawk Patrol. He wasn’t motivated to invest the time needed to finish the LSA project. This conflict (and other factors) stretched a three-year project into an eight-year one.

The tandem cabin is a comfortable 31 inches wide.

The Light Sport Aircraft definition in 14CFR 1.1 shaped much of the mission of the Bearhawk LSA. For example, the tail control surfaces are neither mass-balanced nor aerodynamically balanced, and the ailerons are not mass-balanced. These omissions save 20 pounds, but they increase the risk of flutter at high speeds. To mitigate the risk, Vne is limited to 126 knots, which isn’t a problem when the maximum allowed level flight speed for an LSA is 120 knots.

By not including flaps in the design, Barrows estimates a weight savings of 20 pounds. Some onlookers have expressed concern about not having flaps, but Barrows says slow-speed performance is still excellent without them. In side-by-side slow flight tests with the heavier Bearhawk Patrol, the clean Bearhawk LSA was 4-6 knots slower than the flaps-down Patrol, Barrows said. The LSA has 10 square feet less wing area, but the more significant variable in this case is the Patrol’s 450 pounds of additional weight. The airfoil is also a factor. The LSA’s Riblett airfoil has a 6% camber, which is slightly more than the 4% camber of the Patrol. The advantages of the higher camber include more lift (especially at higher altitudes) and better low-speed performance. The disadvantages include a slight increase in drag and a slight increase in pitching moment. The increased pitching moment means that the horizontal stabilizer must be more effective, which is a process that also increases drag slightly. These drag increases are small, but they do add up to a slower cruise speed in the finished product. This is not a problem for the LSA, because any significant increase in cruise speed would conflict with the Light Sport speed restrictions anyway.

The horizontal stabilizer uses an airfoil cross section to improve effectiveness by up to 20%.

The Benefits of Simplicity

Barrows designed the LSA with amateur builders in mind, and one lesson from building the prototype is that 0.016-inch wingskins are just too thin. They are certainly strong enough to carry the loads of the structure, but even an experienced builder like Barrows had trouble making the wing profile as smooth as he would have preferred. The plans will call for 0.020-inch skins, which will add about 12 pounds to the finished wings but make construction easier. He estimates that 750 pounds is a realistic empty weight for a builder who works hard to keep the airplane light. To put that number in perspective, a Piper Cub usually weighs about 780 pounds empty, and a Champ weighs around 820 pounds empty. Both share a maximum gross weight of 1220 pounds. That makes the Bearhawk LSA’s potential useful load compelling. For a builder who doesn’t need to comply with the LSA maximum gross weight limit of 1320 pounds, the airplane can use a max gross weight of 1500 pounds and still be operated within safe margins. In either case, the useful load is higher than the comparable classics.

Continental engine compartment.

Engine size is one of the most important choices a builder makes to influence the empty weight of an airplane. By using a small, lightweight Continental, Barrows was also able to use smaller fuel tanks, which further save weight. In the first 25 hours of local test flights, Barrows said the total fuel consumption was 100 gallons, for a long-term average of 4 gph. The LSA’s two welded-aluminum wing tanks carry 30 gallons, which equates to 7.5 hours at a sightseeing power setting, or about 5 hours at an ambitious cruise power setting. There are few vehicles that can produce 25 mpg at 100 miles per hour, so the fuel economy is good.

Another great way to keep the empty weight low is to keep the airplane simple. The prototype has a sparsely populated instrument panel that meets, but does not exceed, the minimum requirements for day VFR flight. The space under the engine cowl is clean and simple, in part because the airplane has no electrical system. This simplicity also shortens the build time, which will be on par with something like a Wag-A-Bond or Pietenpol. As is often the case, build time and build cost are related. The Bearhawk LSA will take longer to build than a pre-punched aluminum kit, but it will also cost less to complete. A frugal builder could probably complete a Bearhawk LSA for less than the firewall-forward price for a Van’s RV-12 or RANS S-7, but the project may take twice as long as either of those options.

Barrows designed this durable tailwheel assembly, which can be scratch-built or purchased ready to install.

Building one of Barrows’ designs is not like building one of the modern RV-series kits. Those airplanes are known for clear and concise step-by-step instructions that have been tested and vetted by hundreds of previous builders. In a scratch-built project like the Bearhawk LSA, there aren’t any instructions at all. The plans include a short book that hits the high points of building techniques, but the builder must plan to spend some time working out the best way to reach the final goal. This initial investment of effort will pay dividends in the end to a builder who is empowered to make the replacement parts that he needs instead of purchasing them.

Currently the Bearhawk LSA is available both as a kit and as a scratch-built project. While a kit would obviously cost more to build, many builders find them a good value considering the time saved; perhaps as much as 70% of the build time on an airplane such as this can be saved when buying a QB kit. The LSA construction techniques are similar to the other designs. For the scratch-builder, the $275 plans price includes the hand-rendered drawings, license to build one airplane and the short book of helpful tips.

What will come next for the Bearhawk LSA? Barrows will continue to test the design, including flight with a larger engine. He’s working on a Continental C90-8 that will have a displacement of 200 cubic inches and over 100 horsepower. The airplane is a great performer on 65 hp, Barrows said, but he knows that inevitably builders will ask about a larger engine. Some will accept the 10-pound weight penalty for the boost in climb rate and cruise speed that the extra horsepower would allow.

For those in the market for a simple and affordable knock-around airplane that complies with Light Sport rules and can be built from scratch, the Bearhawk LSA is certainly worth a look.

For more information on Bearhawk LSA plans, call 540-473-3661. For more information on Bearhawk LSA kits, visit www.bearhawkaircraft.com, or call 877-528-4776.