Fred Darnell and his wife, Pam, have always led an active life. Growing up in Crossville, Tennessee, they were high school sweethearts who went on to marry and have two children. Spending their youth in the hills of Tennessee, they acquired an appreciation for the outdoors and spent many hours backpacking, kayaking and just enjoying getting away. When their kids came along, they had to make some adjustments such as adding scuba diving to their list of hobbies. This story sound familiar so far? Of course it does.

Fred Darnell and his wife, Pam, have always led an active life. Growing up in Crossville, Tennessee, they were high school sweethearts who went on to marry and have two children. Spending their youth in the hills of Tennessee, they acquired an appreciation for the outdoors and spent many hours backpacking, kayaking and just enjoying getting away. When their kids came along, they had to make some adjustments such as adding scuba diving to their list of hobbies. This story sound familiar so far? Of course it does.

Flying was important to the Darnells. After going through the usual smattering of rental planes, and not finding one that was affordable and capable of transporting their growing family and all their outdoor gear, Fred Darnell came to the same conclusion most of us have: It was time to build his own.

His needs were simple. He wanted a plane that could haul his family of four, carry half the stuff in their house (you think this is a joke until you see how he packs), travel reasonably fast, and fly into and out of unimproved strips safely.

In the late 1990s, when he was selecting his kit, the market for four-place homebuilts was limited to the Murphy Super Rebel (SR2500), KIS Cruiser, Cozy Mark IV and the Comp Air 6. With safety and load hauling as his driving needs, Darnell selected the SR2500 after first seeing it at Sun n Fun in the spring of 1998. Safety was my number one concern, he said. From kit selection to installation of the fire extinguisher, safety was always on my mind.

Safety is an admirable focus, but he came back to the mission. My family enjoys scuba diving and backpacking, so I needed a plane that can carry a ton of stuff. The Super Rebel was a great choice, but he had only a few hours tailwheel time, and prefers tricycle gear airplanes. Thus, the journey to build a tricycle gear SR2500-a comparatively rare beast then and now-was on.

Kristen and Alex Darnell, ages 9 and 11, in 1999. Kristen is starting college in the fall, and Alex is an Army medic serving in Iraq.

When is a Moose Not a Moose?

Murphy Aircraft Manufacturing designed a large, rugged bush plane for the kit market in 1996. Located in Canada, Murphys design and marketing of a bush plane kit made a lot of sense. Somewhere in the early life of the design, Murphy realized that it could easily raise the gross weight to 3000 pounds but didn’t change the name. Shortly after, the Vedeneyev Design Bureau M-14 radial-a seven-cylinder, 360-horsepower beast-came to the North American market in significant quantities. (Incidentally, the sales and marketing of Murphy Aircraft has recently been taken over by Bob and Anna Patterson and is now called Patterson AeroSales. Bob Patterson worked as Murphys independent factory rep for more than 20 years, and Patterson AeroSales continues to manufacture and supply aircraft parts for new and existing customers, and these are available directly from the company. The factory is also continuing to provide technical support for builders, and looks forward to helping customers with their kit orders.)

After a few customers hung the Russian radial on their Super Rebels, Murphy became concerned about what impact this large engine would have on the airframe. The company also recognized the availability of the M-14 engine as an opportunity, and more customers might opt for this engine, which was relatively inexpensive in the late 1990s. Murphy then strengthened the airframe kit to accept the round engine and raised the gross weight to 3500 pounds. With the radial and round cowl, the Murphy Moose is reminiscent of a baby Beaver, and it captured the hearts of pilots who really wanted a Beaver but were on a budget. (Beavers and budgets are rarely associated without the word big attached.)

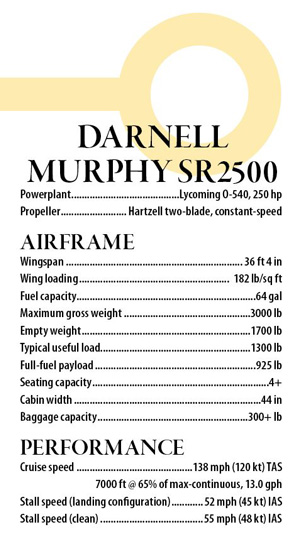

Darnells airplane is all of that without the round engine or cowling. It has a 250-hp Lycoming IO-540-C4B5 that spins a Hartzell constant-speed prop from a hurricane-damaged twin that was purchased from an aircraft salvage yard. It is fired by Bendix magnetos, and starting is helped along with a Unison SlickSTART booster. Where the flat Lycoming gives up that cool round engine look, it gives back in low weight, comparatively inexpensive purchase price, much lower fuel consumption and simplified maintenance. Its not nearly as sexy, thats true, but its a lot more practical for a regular guy on a budget.

Training Wheel?

Beneath that six-banger Lycoming is (gasp!) a nosewheel. Murphy offered the Super Rebel in tailwheel and trigear form, but few buyers opted for anything but the traditional taildragger. Darnell selected the nosewheel for some disarmingly simple reasons.

Even so, with close to 10 hours of tailwheel time, he thought the tailwheel transition training would not be an issue. The tailwheel Super Rebel is easy to handle on the ground, he says. But with safety in mind, I did not want to worry about possible ground loops, and the insurance rates for the tricycle Super Rebel are much lower. Also, the floor on the tricycle Super Rebel is level and flat [with the airplane on the ground.] In the event I need to sleep in there, I wont slide down into the tail cone. Even though Darnells plane is a trike, he installed the hard points for the tailwheel landing gear should he or a future owner ever want to do the conversion.

Selecting the Lycoming engine was easy, because 10 years ago not much was known about the Russian radial. Plus a certified engine/propeller combination could be serviced virtually anywhere he would land if he had a problem during a trip. Would he still go with the Lycoming if he were to start building today? Yes. The radial looks cool, but Darnell feels comfortable flying behind the big Lycoming.

Building Blocks

With his concern for safety, Darnell knew he wanted a dual electrical system to drive the electronics in his IFR-equipped Super Rebel. This led him to install a Grand Rapids Sport on the pilots side, complete with HITS (highway in the sky). On the right side is his engine monitor, a Dynon FlightDEK-D180 with an internal battery. Yes, the engine monitor is also his backup EFIS. With a background in software development, Darnell was afraid of having identical EFISes, so he elected to install systems from different manufacturers; that way, a software glitch wouldn’t take both units down at the same time.

The Super Rebels seats are so comfortable and spacious, it is almost like being in a movie theater.

Providing nav and com are a Garmin GNS 430W, Garmin SL40 com, Garmin GTX 327 transponder and a PS Engineering PMA6000M audio panel. The left wing supports a Dynon Avionics heated pitot tube with integral AOA. With capacitance fuel senders and gauges, dual batteries, dual voltage and amperage gauges, Andair fuel valve, Whelen strobes, and a Ray Allen trim system and stick grips, this is one well equipped bush plane.

Further, Darnell installed a Kannad 406-AF ELT and then went the extra step of installing Pacific Northwest Aero vortex generators on the top of the wings, bottom of the horizontal stabilizer and both sides of the vertical stabilizer to reduce the stall speed and improve slow-speed handling.

When it came time to run the headset connectors he didn’t want them sticking out of the panel where they could impale someone in an accident or simply be broken by a wayward foot. His solution was to install recessed fixtures (available from most aircraft equipment suppliers) in the floor. These protect the plugs and allow the cords to fall between the seats, providing a sterile cockpit.

Challenging Times

Over the 10-year gestation period of the project, there were challenges to overcome, the most memorable of which was when Darnell reached the section in the instructions for the fuel system. There was one line that read: Now might be a good time to think about your fuel system. With such skimpy guidance, he was required to study the fuel systems in Cessna 182s and 200-series aircraft, and he realized Cessna had made many changes to its systems over the years. He also used the expertise of the Technical Advisors in his EAA Chapter 309 and simplified the final plumbing just prior to moving his project to the airport. This was not easy, as half-inch tubing was used to feed the thirsty Lycoming. The good news is that with more than 70 hours on the plane, there have been no fuel-related issues.

With the fuel system in place, Darnell was looking around at the Spartan interior on his Super Rebel and decided some improvements were in order. He made custom interior panels out of fiberglass, which he then upholstered. He added a lighting fixture (out of an SUV) above the front seats, fitted with red lights for night flight and white lights for loading stuff after sunset. The front door panels have leather-covered armrests that hide NACA ducts for fresh air to the back-seat passengers. Covering the baggage compartment floor is a layer of rubber material commonly found in the bed of a pickup truck.

Big as a House

Accommodating such a large plane was challenging. Once he finished the wings, Darnell erected a temporary fabric garage behind his house to store them while he worked on the fuselage. With the fuselage on its gear, he found the vertical stabilizer was so tall it would not fit in his two-car garage, so he didn’t finish it until just prior to painting and moving the plane to the airport.

Darnell took his 25-hour Phase I test period seriously. After all, there aren’t a lot of Super Rebels flying, let alone trigear versions. To do his gross-weight testing he bought 12 bags of playground sand, each weighing 60 pounds. To this he added his 20-pound toolbox. The load was so heavy, he worried about damaging the suspension on his SUV during the drive to the airport. All that sand had it riding on its bump stops, and garnered quizzical looks from the airport bums watching him load bag after bag into the plane. But he just stood back and smiled, realizing that the SR2500 had fewer issues hauling that load than his truck had. Yep, the plane would haul a lot of stuff all right. Even with its tanks brimming, itll carry 960 pounds.

What Now?

Flight testing long since finished, its time for Darnell to enjoy the results of his efforts. Fly, trips and fun come next, he says. The Darnells have taken the plane from Charlotte, North Carolina, down to Floridas Sun n Fun, to Crossville, Tennessee, to visit family, and on numerous barbecue runs. If there’s one thing Ive learned about living in the South, its that Southerners don’t go for $100 hamburgers, but $100 barbecue is another thing entirely.

For more information, call Patterson AeroSales at 905/457-5238 or visit www.murphyair.com.

What’s the purpose of posting an article from 2009? Murphy Aircraft has been on a spiraling downturn since or before their 10 year absence from airshows. Now with the company entertaining sale of the company to the Chinese, where would that leave current or future customers? Not a company that I personally would purchase from with its ongoing turmoil IMHO.