The Cassutt 111M is, in every sense of the word, a classic design. Small, sleek, and fast, the little one-place airplane that first appeared as the Cassutt Special in 1954 has been built by those who want to race—or just go fast on a few dollars—for over 60 years, yet still turns heads whenever it appears on a local airport ramp. Tom Cassutt’s design (based on Steve Wittman’s Buster) inspires; it speaks of speed and freedom, with just a little bit of danger thrown in.

If you asked for a show of hands at a homebuilder gathering, a majority would probably be waving their arms to indicate that they had built and flown model airplanes in their youth. U-control or R/C, many aviators got their start well before they could afford airplanes of a size that could actually take them aloft. And if you go back a few decades, many of those U-control airplanes looked like little single-seat racing planes—complete with a plastic bust of an aviator sitting under the bubble cockpit. These fast, maneuverable airplanes had many different names, but were referred to generally as “Formula 1 racers” because they looked a lot like the airplanes used for pylon racing that conformed to the International Formula 1 Rule book.

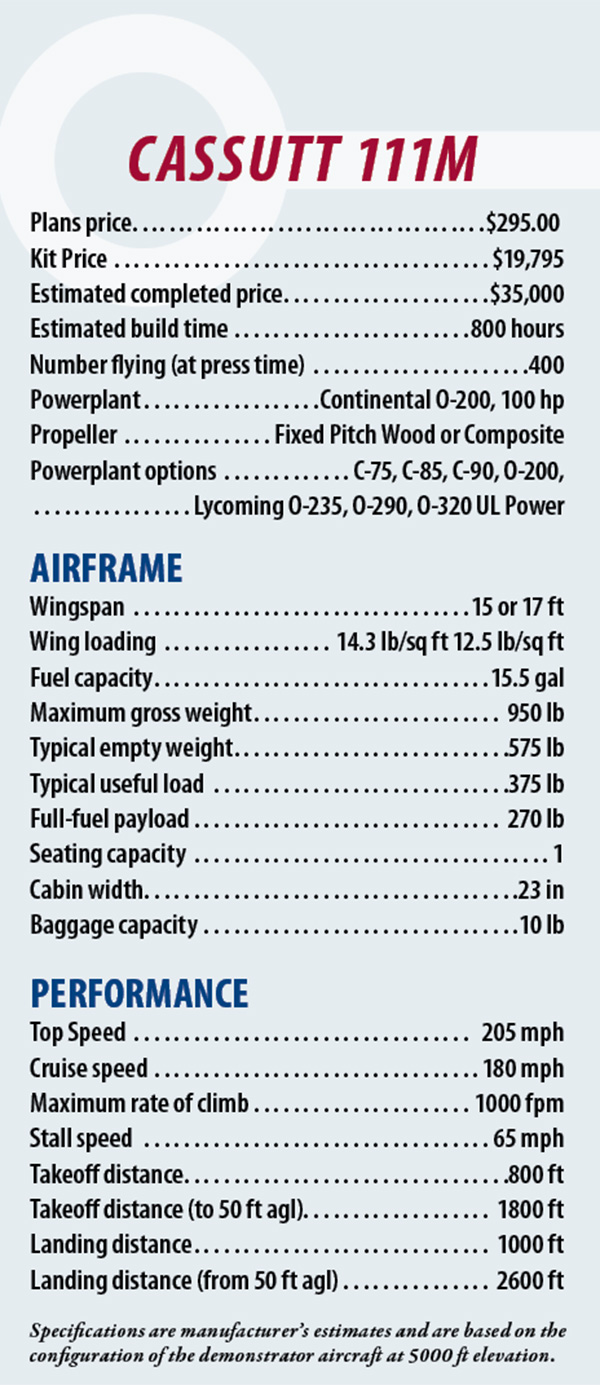

The Formula 1 rules were created to allow normal people—those without an unlimited bank account—to compete in pylon racing. The rules specify a small, C-series or O-200 engine from Continental Motors that is relatively inexpensive and found in large numbers. The small airframe must weigh no more than 500 pounds empty (no fuel, oil, or pilot), have a fixed-pitch propeller, and a wing area of at least 66 square feet. Fixed-gear only please, and pilots must weigh at least 160 pounds ready for flight.

The simple cockpit has only two switches—one for the left mag, and one for the right. Basic instruments include a sight gauge for the fuel tank.

This fairly simple set of rules is an attempt to create similar airplanes, so that pilot skill and racing experience play a large part in the outcome of the race—larger, that is, than the simple method of spending cubic dollars to race in the Unlimited classes. Since speed goes up with more horsepower, smaller wings, and lower weight, specifying these factors to equalize the field—at an affordable level—has been a good formula for a league that has survived the test of time. Still raced at Reno every year, the fields are usually full, and spectators of all ages enjoy the tiny airplanes that zip by the stands every September. In 2013, nine of the 15 aircraft registered in the Formula 1 class were Cassutts.

The license and rights to sell plans for the Cassutt were recently purchased by Creighton King of Salt Lake City, Utah, and he hopes to continue to provide builder support, parts, and plans to keep this enduring design going for those who still have that desire to go fast and do it on a budget. We recently caught up with King at his airport facility south of the Great Salt Lake, and took advantage of the chance to fly his aircraft, look at his facility, and talk about his plans for the future.

Classic Construction

The Cassutt was designed in a day when wood, steel tubes, and fabric still ruled the homebuilding world. If you wanted to build one from plans, the first thing you had to do was enroll in a welding class at a nearby vo-tech school or junior college. When you finished welding up the fuselage, it was time to dust off the woodworking skills and start on the Hershey-bar wing, cutting all of the little bits for ribs, gluing and tacking them together, and then covering the whole thing with plywood. Finally, the entire plane needed dope and fabric—classic construction for a classic airplane.

King’s aircraft has a slightly taller vertical fin than called for in the plans for added stability. Pitch trim is accomplished by adding or subtracting washers on the stabilizer attach points.

Today there are options for pre-welded parts, and there are fiberglass (and even carbon) parts that greatly simplify the cowling and transitions. Cassutt Aircraft is committed to making the building of a Cassutt simpler, and taking care of parts that require years of skills development to make. Getting pilots into the air faster is one of King’s goals.

The welded fuselage frame is covered in fabric, just as in the old days—but there are modern parts, such as fiberglass side panels (underneath the wing) and a glass cowl that flows around the engine. The single-piece wooden wing bolts onto the top of the fuselage structure, the spar being continuous from tip to tip. Modern racers have developed longer, tapered wings to replace the all-wood constant-chord model originally designed by Cassutt, but it is a safe bet that more Cassutts are flying with the Hershey bar than not; it is inexpensive and easy to build. Cassutt Aircraft is currently working on a carbon fiber tapered wing that will also hold fuel and should make for an interesting airplane when finished.

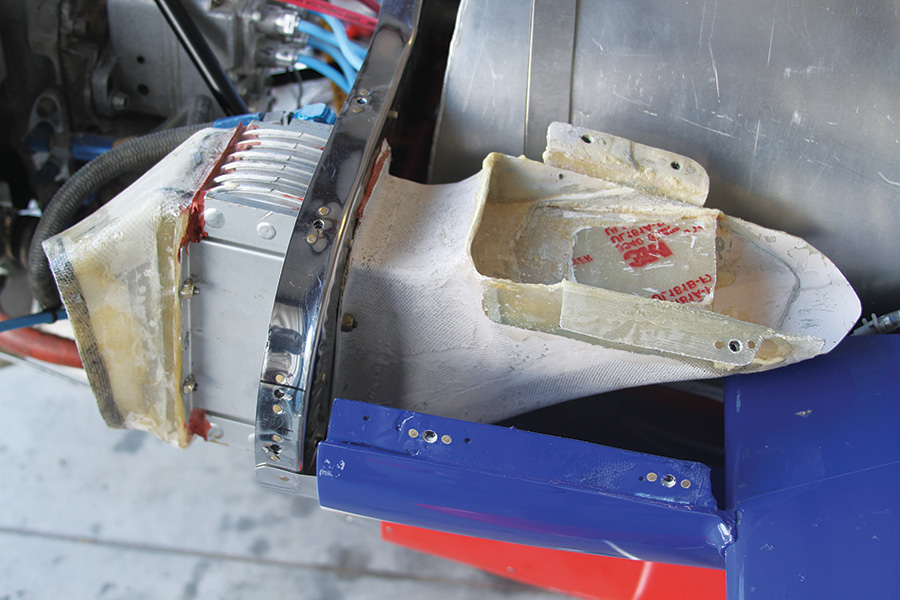

Oil cooler air comes from a scoop on the right side that is sculpted to provide better flow at slow speeds/high angles of attack. The outlet is above the wing at the root.

The tail surfaces are conventional steel tube and fabric, unbalanced with the fin extending over the rudder. There are no provisions for trim, other than adding or subtracting washers under the horizontal stabilizer attach points, so airplanes will generally be dialed in for a particular pilot weight. The ailerons are full span and slightly tapered towards the tip. They provide a brisk roll rate and good control.

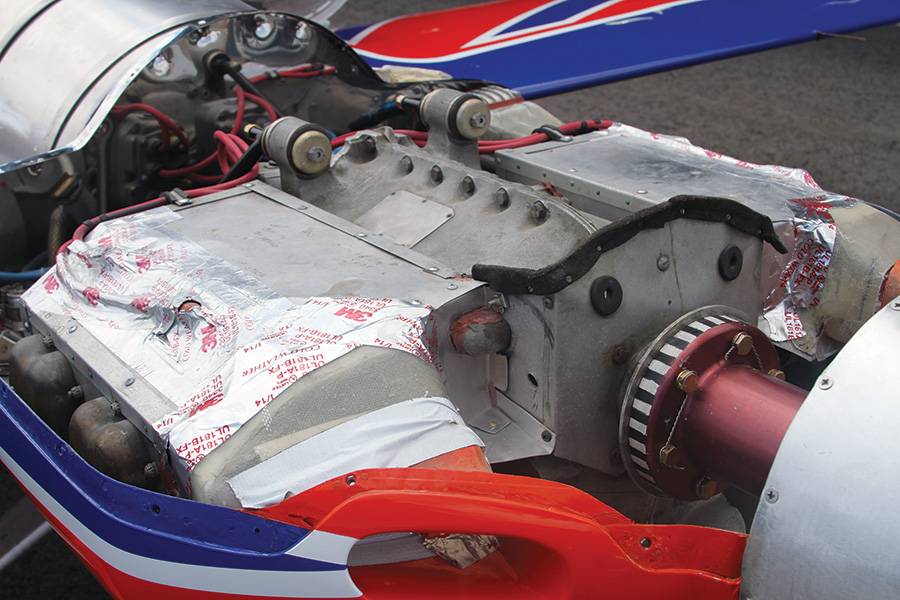

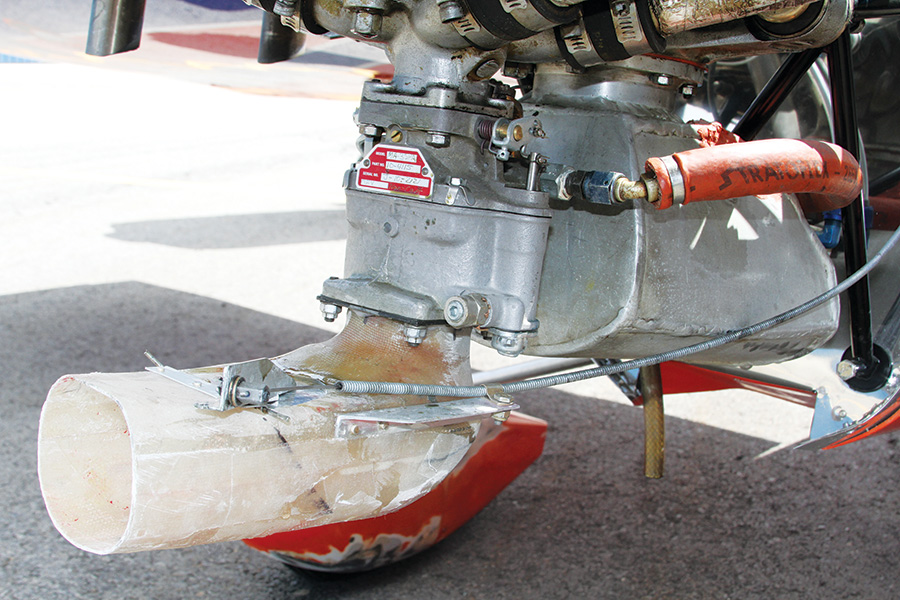

The landing gear is a single-piece steel assembly that bolts onto the fuselage frame with bolt-on axles. Five-inch wheels with compact tires are standard, and the brakes on the factory demonstrator were standard Clevelands—more than adequate for the job. Removing the cowling showed a refreshingly-simple firewall forward installation. The fuel tank sits ahead of the instrument panel and behind the firewall, and the O-200 engine had nothing attached but mags, a carburetor, and an oil cooler. The oil sump was custom-welded to fit inside the small, streamlined lower cowl, and a fiberglass air box joined the little snout to the carb. Individual left and right cooling plenums covered the cylinders and joined tightly to the front cowl inlets. Sealed with aluminum tape, they ensure that all the inlet air has to go over the cooling fins.

This unfinished Cassutt fuselage has been modified, but shows the basic construction of steel tube structure and fiberglass cowling.

The oil cooler was mounted to the firewall, with fiberglass inlet and outlet ducts cleverly designed to maximize cooling at slow speeds and higher angles of attack. The exit is on top of the wing on the left side, carefully faired to reduce drag. King said that, if anything, the oil is overcooled; he sometimes stuffs a rag into the outlet, or puts on a piece of aluminum tape to limit exit area in cool weather. The rag trick helps at lower power settings, and pops out when speeds (and engine energy) get to a certain point. CHTs are a moderate concern and are managed using mixture. For most normal flight regimes, they stay around 400° F, but at takeoff, they often climb to near 450—this is when full rich mixture comes in handy. King’s mixture control is mounted so that with your hand on the throttle, the palm can be used to twist the Vernier mixture knob to fine-tune the engine and cooling.

King added a cylindrical carb air inlet during his rebuild project to replace the former boxy-looking rectangular scoop.

The fiberglass air box matches the round inlet snout. Note the custom-made oil tank, shaped to fit in the compact Cassutt cowling.

The fact that the Cassutt airframe is traditional and simple probably accounts for the number of airframes that have been started over the decades. However, as is often the case with early plansbuilt airframes, a majority have probably not yet been finished, which means there are finds to be made in garages and barns around the country. So long as the proper material has been used and the work is of a good quality, these bargains could easily be turned into flying Cassutts with a little investment of time, money—and an old Cessna 150 as an engine donor.

The oil cooler installation on King’s airplane is so effective that he has to partially block it off in order to get temperatures up to operating values.

Factory Support— What You Can Expect

Creighton King is a man on a mission. The mission? Preserving the legacy of the Cassutt racer. His new company, Cassutt Aircraft, has purchased the rights to the plans, the parts inventory, and the jigs used by previous companies in order to perpetuate the factory support needed for builders to start—or finish Cassutt 111M aircraft (as well as the Owl Racer).

With the passing of the previous owner, the stock of parts and rights to the plans were in limbo until Creighton, a Salt Lake City native and airplane tinkerer from his teen years, offered to buy them in order to keep the design going. While he has yet to find time to move the entire inventory from its current Colorado location to his home in Utah, he has already been selling plans to new purchasers, and has a fair amount of Cassutt hardware taking up space in his hangar—along with a plans-built Super Cub and a Tri-Pacer. His recently-restored 111M, sporting race number 15, tucks in under the Piper wings on one side, while a long-range, big-engined Cassutt project lurks in the back, and yet another fuselage fills the last corner of the T-hangar.

The canopy latch system consists of forward and aft latches that operate independently—care must be taken to ensure they both catch.

Creighton is clearly committed to supporting these wonderful little toys—the “sport bikes” of the aviation world. Asked if he has any idea how many sets of plans have been sold in the decades the design has been around, he could only estimate “in the thousands.” The Cassutt is a small and simple machine that attracts dreamers as well as dedicated builders, and it is hard to know just how many uncompleted airframes are scattered about in hangars, garages, and workshops across the globe. Designed in the early days of plans building, many were started, but not as many finished, and this is a market that Creighton hopes to tap. He is looking to develop firewall-forward kits for those lucky people who have inherited an uncompleted airframe from an older relative who couldn’t quite get the details (those legendary last 90% familiar to all homebuilders) finished up. Even if he never sold another set of plans, the increase in flying airplanes would be tremendous if he could help get those already underway finished and airworthy.

If you find yourself with an uncompleted Cassutt, or want to start one, you can be comforted by the fact that Cassutt Aircraft plans to supply all sorts of parts and expertise to help get that machine into the air. Our visit confirmed that enthusiastic factory support is available once again.

The handheld radio antenna is simply stuck through the canopy vent—we assume that it would be stowed for racing.

Flying the Cassutt— the Need for Speed

Testing a single-seat airplane always presents certain challenges—not the least of which is that we have to learn everything we need to know from a pre-flight briefing—not from a qualified pilot sitting next to us in flight. In this vein, King shared his thoughts before we took his little orange bird aloft for the first time.

“I like to maintain 120 mph in the pattern, right through turning final. Some folks fly it slower, and that’s OK—I’m comfortable at 120. You’ll want a long shallow approach, and slow to about 100–105 over the fence, then let it slow down as you settle to the ground. The Cassutt won’t be stalled in a three point attitude, so you’re really going to fly it on in a tail-low wheel landing. At touchdown, push the stick forward just a touch to plant it, then let it slow down so the tail can touch.”

“The tailwheel is connected to the rudder with a solid link—no springs. So that is going to make it very sensitive on the ground. Then when the tail comes up on takeoff, there is a little bit of motion as you transition to rudder control because the rudder is small. It will fly away when it is ready, and you’ll want to climb about 120—just remember that speed, 120.”

The tailwheel is a modified Rollerblade wheel mounted to a spring. Steering is through a rigid rod bolted to the rudder—no springs here.

King has his mixture and throttle mounted on the left side, but the push-pull controls are in slightly unfamiliar positions: the throttle is below the mixture. He did this because, he says, he does a fair amount of mixture manipulation during flight to keep CHTs where he wants them to be. He does this with the palm of his large hand while manipulating the throttle. I found this a bit of a trick with more normal-sized hands, but one of the good things about the Cassutt is that it can be customized for the pilot by the builder—especially if they are one and the same.

King briefed me that the stall is fairly benign and straightforward; it shouldn’t be feared. Reading back through a previous review of the Cassutt in KITPLANES® (many years back), I found that the pilot considered it to be well-mannered in stalls, spins, and aerobatics. Since I was not planning on sampling spins, this gave me significant comfort that it wasn’t going to suddenly depart on me. With a good, thorough briefing on how to latch the canopy, I felt I was ready to go.

We repositioned the aircraft from its home field just south of the Salt Lake City International Airport to Bolinder-Tooele Valley airport, one mountain range to the west, situated in a smooth, flat valley on the south shore of the Great Salt Lake. This freed us from the constraints of the Salt Lake Class B airspace, and gave King a chance to warm the airplane up and make sure it was ready to go. Besides, remote fields without witnesses are always welcome when flying a hot-landing airplane for the first time.

Getting into the airplane requires a little bit of flexibility. Because the cockpit is forward of the trailing edge of the wing, and the trailing edge is actually full-span ailerons, you have to hoist your leg up and all the way into the cockpit in one big step. Fortunately, the lack of upholstery means you don’t have to worry about the seat, and assuming that you can get that first leg up, lowering yourself down into a seated position is not too difficult. These airplanes are generally custom-fitted to their occupants, so there is no seat adjustment, other than cushions. I found the relationship between rudder pedals and stick to be comfortable, so when I got my butt in the right place, all was fine.

I wouldn’t exactly call the cockpit comfortable; it’s more than adequate for racing or playing around in, but a long cross-country might be a challenge. The visibility is more limited than in many single-seat airplanes, partly because the canopy was designed to use a sheet of Plexiglas bent to shape, and partly because the pilot sits ahead of the shoulder-mounted wing. You kind of get the feeling you are peering out of a turret, rather than sitting with your head and shoulders above the airplane, as you would in a bubble-canopy aircraft. Frontal area means drag, and this is a racer, so some things have to be a compromise. In a race, you are probably more concerned about seeing who is ahead, and how you can get around them than you are with someone you have already put behind.

There are only two switches in King’s cockpit: one toggle for each mag. Along with the flight controls, there are mixture, throttle, and carb heat knobs, a handheld radio, and the canopy latch. No flaps, trim, or other complications get in the way. Starting it is a matter of having someone swing the prop—and if he is alone, King has rigged a small tow hook/release that can be used to hook the tail to a stake or post while starting. Once the engine is running, he can hop in the plane, pull the release string, and away he goes—clever, and far safer that trying to hand prop without being held back.

The O-200 started up on one pull after a couple of blades with the switches off to prime. King pointed out an important aspect of the O-200s used in racing: since they are turning very fast, the stock oil pump has a tough time keeping up, and the oil pressure runs extremely low at cruise power (or faster). I was glad he pointed this out, or I might very well have put it back on the runway on that first takeoff when I glanced at the gauge. Class rules require a stock oil pump, so there is not much that can be done, and the engines seem to tolerate the low pressure just fine.

The engines also seem to tolerate rpms that would drive a Cessna-150 instructor to drink. Because the props are so short, tip speeds are not as much of an issue, so it is not uncommon to be turning 3500 rpm in flight. Numbers like that are becoming more common to pilots who fly behind Rotaxes—but the Rotax has a gearbox to reduce the rpm seen by the prop. In the Cassutt, what you see on the tach is what you get at the prop—and it is fast! Idle was about 1400 rpm after start, and we secured the canopy carefully; there are two separate latches, one forward, and one aft, and it pays to take the time to get them both properly secured—and to have someone else verify that they are captured.

Taxiing takes a couple of seconds to get used to—the tailwheel being linked directly to the rudder gives very sensitive steering. Those who like tight, stiff tailwheel springs will feel right at home. Those pilots who prefer loose chains will have to get used to the instantaneous response. I adapted in just a few airplane lengths, but it pays to sample the steering cautiously the first time. The brakes were effective, but not overly so—a good match for the size of the airplane. I didn’t feel a tendency for it to get light on the tail during braking, even though our CG was at the front end of the box.

(The forward CG was primarily due to the fact that there is a heavy crush plate on the prop of King’s airplane to offset his size. Cassutts are set up for their primary pilot, and all others must adapt. In my case, we taped a small cylinder (it was half a ball-point pen) to the trailing edge of the elevator to act as a trim tab, and this worked fine in flight, but did little at low speeds. It was perfectly adequate for such a small airplane to fly it with constant stick forces, but if you had your own, you’d set it up perfectly with a little experimenting.)

With run-up complete and controls checked free, I taxied onto the runway, rolled the tailwheel straight, and pushed the throttle to the stop. The acceleration is not remarkable; the airplane’s fixed-pitch prop is designed for speed, not climb. Being used to constant-speed props, I was initially surprised at the lack of “get up and go,” but then, we got up and went! When the tail came up, there was just a slight bobble in yaw as I learned the feel of the rudder, but it probably wouldn’t happen the third time; the response is easily learned. Liftoff and initial climb/acceleration were flat, and once I had achieved the magic 120 mph number, we climbed out of the pattern to go sample the handing.

I could tell right off that the airplane is quick in roll response—the full-span ailerons give plenty of control in that axis. The airplane rolled significantly quicker to the left than to the right, and it felt more comfortable in a left turn, holding the bank angle very nicely. To the right, opposite stick was required in a 45° bank to keep it from significantly overbanking. But then again, there is no dihedral to the wing, so roll stability is going to be unusual. It was hard to judge pitch harmony with roll because of the nose-heaviness—the resulting forces tended to make it less responsive in the pitch axis, and it would be unfair to judge it in that condition.

Control was never a question, however, and the airplane is quite flyable. I slowed it down to about 100 mph a couple of times, just to see what it would be like during the descent to landing, and it still had positive control in all three axes. The rudder is effective, and pilots need to remember to coordinate their turns. A couple of wingovers proved again that the airplane was more comfortable going left than right, and the seat of my pants kept saying, “rudder, rudder, rudder….”

The large rpm range available was odd to someone used to operating a Lycoming (or Continental) between a flight idle of 700 and a redline near 2650. There was so much more throttle travel that it was almost disorienting when trying to set power for maneuvering. Minor changes in pitch without a throttle adjustment resulted in significant rpm changes due to the fixed-pitch prop, and an unfortunate in-flight failure of the tach drive cable left me blind to what the engine was doing, so I nixed the aerobatic and stall portions of the test card and returned to the pattern for a landing.

On our way back in to the field as a two-ship, I had gone to school on King’s altitudes and speed around the field. He suggested a pattern speed no lower than 120 mph, slowing to about 110 over the fence with a very low, shallow approach. I had difficulty getting myself that low before the threshold, but seeing as how we had 5,000 feet of concrete over which to float, it was not a significant problem. The float of the Hershey-bar wing was considerable—especially once I got close to the runway—and ground effect at speed became significant. The airplane was easily controllable, however, and we touched down in a nearly three-point attitude, after which control was quite positive, and braking was good. I didn’t look down at the airspeed at touchdown, but I expect that it was in the 80–90 mph range.

The gear seemed well-tuned to the airplane’s flight characteristics, and there was no significant bouncing or bucking—it just settled in nicely. The first landing I make in a new airplane is, unfortunately, usually my best, but in this case, that worked to my advantage, as I really didn’t want to continue without a tach (seeing as how the engine is turning so much faster than factory design speed), so my one landing was good, and I could quit while I was ahead.

Overall, the Cassutt is well and truly matched for what it was designed to do. It flies fast, and goes where you point it. It turns left with ease (the Reno Racing motto is “Fly low, fly fast, turn left”), and while I certainly wouldn’t call it a short-field airplane, it is easily manageable on a reasonable runway. Pilots who are willing to adapt to its speeds and quirks will find it fun in the way that anything with a little challenge is fun. It is honest in the true meaning of the word—it delivers what it promises, and doesn’t promise one thing and then do another. Treated with respect, it certainly would be a fun airplane to race.

Do You Want One?

Well that’s a silly question—of course you do! The question is, do you need one, and will it serve a purpose? You don’t have to plan on racing at Reno to enjoy building and flying a Cassutt. The existence of many unfinished airframes makes this a bargain for potential builders who simply want an airplane to fly. Granted, it is not going to be a daily cruiser—it is a performance machine that demands a higher level of skill than many might want to maintain—but this classic design is out there and waiting for those who want to give it a try.

Cassutt Aircraft is dedicated to helping people build and fly these machines, and while King admits that it is a niche market, it is a market that he believes in, and wants to support. If you already have another airplane with multiple seats to fly, and are looking for a unique project, the Cassutt is worth a look. Who knows, you might accidently have so much fun that you find yourself in the Formula 1 hangar at Reno some September, waiting to line up for the next heat.

For More information, contact Cassutt Aircraft at www.cassuttaircraft.com. For International Formula 1 Rules, visit www.if1airracing.com/index_htm_files/IF1_Technical_Rules_Rev2011.pdf. Visit the Cassutt Racer Owners Forum at www.Cassutt-Racer.com.