The VariEze looks and sounds futuristic now, in the 21st century. Just imagine the impact this shape had on homebuilders back in 1975. It must have seemed straight out of Star Wars!

Not only its appearance, but also its moldless foam-and-fiberglass construction was revolutionary in an era when amateur-built planes materialized only after years of gestation from plans, not from the kits that have since become commonplace. Prior to the VariEze, available materials were just glued wood, welded steel tubing or riveted aluminum. Then up popped Burt Rutan with this amazing design that could be carved quickly from hot-wire-cut foam sheets and blocks covered with a thin layer of glass cloth and resin. His claim was that it would be “VariEze to make.”

Not only was his unconventional two-place pusher canard simpler and cheaper to build, but it also flew almost twice as fast as anything else did on what was then the lowest-power aero engine available. No wonder rows of VarieEzes dominated the homebuilders’ rallies of the 1980s. But where are they all today?

Steve Brown’s and Mike Roper’s example, based at the Biggin Hill airfield in Kent, U.K, is possibly one of the best. This being their second VariEze, they incorporated all of the lessons learned from their first project, including all known improvements, while concentrating particularly on lightness and clean aerodynamics. The result is superb, lightweight (670 pounds) for such a well-equipped example, and with a perfect shape, minimal filler, minute control gaps and a glossy finish.

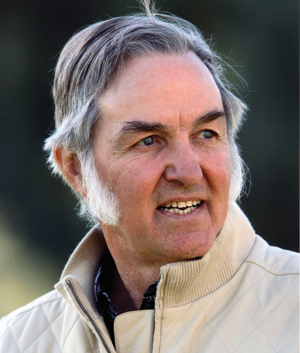

Steve Brown’s example incorporates all of the lessons learned over the years and may be one of the finest examples built.

Brown has also gained maximum thrust from the nominally 100-horsepower Continental O-200 engine by increasing its compression-ratio from 7.1:1 to 8.2:1. A beautifully carved Hertzler Silver Bullet carbon-sheathed wood propeller and pressure-recovering spinner complete the ensemble.

The long canopy swings up and over to the right for boarding, to be held securely in position by a gas strut. When empty, the VariEze’s center of gravity is exactly over its mainwheels, so to prevent inadvertent upsets, its noseleg is retracted for parking. Rear-seat entry is simplest with the nose down, but still not super easy. It involves stepping up onto a tiny fuselage-side plate and lifting your leg over the leading-edge root extension (where the fuel is stored) to reach back and step down into the narrow cockpit.

A gas strut holds the canopy securely for boarding.

The rear-seat passenger has a removable sidestick but no throttle, rudder pedals or instruments, though the passenger does have a direct-reading wing-tank fuel gauge tube at the elbow. I got my first familiarization flight from this position, and found it fairly comfortable once I was in place despite its narrowness, and with surprisingly good all-round visibility into which the foreplane obtrudes less than it does for the front-seater.

A direct-reading wing-tank fuel gauge is elbow high for the rear-seater.

There is no luggage compartment, because the engine occupies the space behind the rear-seater’s head, so any bags must go beside and underfoot, reducing the already limited room. It is also important that this stuff does not obstruct the exposed air-brake linkage running down the rear left of the front seat back. A few small items may also be stowed in the pyramidal front seat headrest, which doubles as rollover protection. Some builders have made external, under-wing baggage pods.

With a maximum weight of 1100 pounds and generous 36-gallon tanks, the VariEze is somewhat restricted in its lifting ability, and other, heavier examples must be severely curtailed. Brown and full fuel weigh 350 pounds, leaving just 80 more pounds available if he wants maximum range. However, we were able to load 20 gallons of fuel—enough for 4 hours of flying with reserves.

Let’s Get Started

Entry to the pilot’s snug cockpit is easier, and can be effected with the noseleg extended if the passenger is already in place, or if you’re careful to keep your weight on the airframe as you board. Some examples have an electric nosegear motor so that both occupants can get in and then raise the fuselage to level, but like most owners, Brown omitted this system because of its weight. Both occupants have a noticeably reclined seating position, with their legs well forward and their heads just above the close-set cockpit sills, a consequence of the smallest possible cross section having been chosen for maximum performance.

Starting an O-200 is never difficult, and though pusher installations are notoriously prone to overheating, there should not be a vapor-lock problem in this application; the fuel system is entirely gravity-fed from both the 33-gallon wingroot tanks and a 3-gallon fuselage reserve/header tank. The fuel valve is a rotating lever under your right arm, and twists through 180° for the main tanks, or just 90° for the header, where it sticks up under your wrist, reminding you not to take off in this configuration.

The only oddity is remembering to look back over your shoulder for inquisitive bystanders before shouting, “Clear prop.” After pressing the starter, the Continental engine kicks into life with the typical bark and throb of a high-compression powerplant.

Taxiing can be another matter. The VariEze has no steering, merely a fully castering nosewheel, so directional control is all by differential braking; the wingtip rudders are no help, because they are well-displaced from the propwash. The best technique seems to be to ensure the airplane is pointing in the right direction with the nosewheel centered before you board, and then to get it moving under power before steering with gentle dabs of brake in the required direction. The brakes operate directly from each rudder pedal after a small amount of travel. You must take care not to ride them, particularly when taxiing downwind when there is no cooling airflow, because the wheels have close-fitting pants.

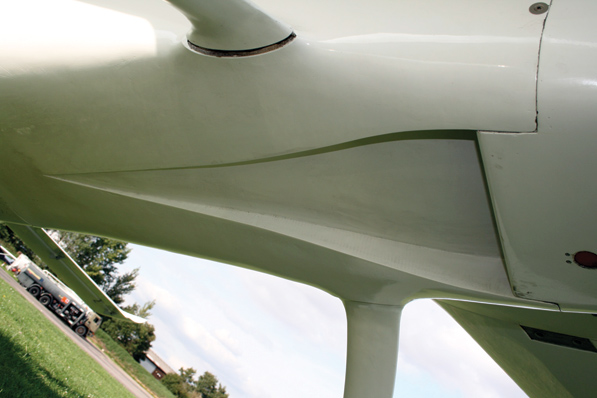

Aerodynamic devices help control spanwise flow.

In addition to the usual consequences of brake overheating, the S-glass composite legs, if they get too hot, can sag. This is easier said than done, because pedal pressures are light, and both rudders can easily be fully deflected together. This taildragger pilot’s feet tended to press too firmly, too often. One big advantage of this system is the ability to turn tightly in confined spaces, around one wheel if necessary, provided you use a good blast of power at the same time.

The seating position in both front and back is noticeably reclined. Comfy or cramped? It’s in the eye of the beholder.

I thought the suspension seemed a little on the bouncy side, while the small wheels and high-pressure tires transmitted rumbles through the airframe. The 5-inch mainwheels with special, undersize tires and a 4-inch nosewheel are obligatory, as anything more conventionally sized causes landing-gear resonance. With such small wheels, this is definitely not a rough-field airplane, though Brown says that thanks to the nosewheel’s guard, there is no problem with stones being flicked up into the pusher propeller.

Ready for Takeoff

Pre-takeoff checks are conventional with the exception of setting the spring-bias pitch trim so that the trailing edge of the narrow-chord elevator immediately ahead of you is deflected three-quarters of an inch down. The canopy can be held slightly open by its secondary latch for occupant cooling, so it is important to ensure that it is securely latched before takeoff, but there is a simple spring-steel safety catch to supplement the dual, over-center latches that clamp it down on to the fuselage sides. A warning light and buzzer remind the forgetful.

Once the canopy is shut, I find my headset keeps touching it, and though this gives me the best possible forward view, I do intermittently receive a few odd buzzing noises in my cranium. The owner’s manual insists the pilot’s head must be within an inch of the canopy before takeoff, so that requirement is certainly fulfilled.

Some builders have installed an electric nosegear motor to keep the fuselage level while boarding, but Brown and his partner decided against it due to weight.

Brown emphasized the one flying limitation, which is that the canard must never be raised above the horizon when near the ground, both for fear of getting into a high-drag, low-performance regime, and because of the prop tips’ and wingtips’ proximity to the ground in a nose-high attitude. Entering the runway, we roll forward a few feet to center the nosewheel.

Opening the throttle produces an uncharacteristic snarl from the little Continental (soon left behind as we accelerate) and an immediate smoothing in its rotation as the rpm increases. We surge forward enthusiastically, and I intermittently tap first one brake and then the other to keep us somewhere near the centerline until the rudders start working aerodynamically at around 40 knots. At 50 knots I raise the nose a touch, being startled at first by the elevator’s sensitivity, and to my shame, inducing a brief PIO as I try to skim the nosewheel just above the runway surface while we continue accelerating. We lift off at around 70 knots after a run of a little over 600 yards in calm 70° F conditions.

The VariEZE uses a carved Hertzler Silver Bullet carbon-sheathed wood prop and pressure-recovering spinner.

Performance by the Numbers

As we climb away, I have to concentrate hard on not over-controlling in pitch when I remove the locking bungee with my left hand and wind 10 easy turns on the noseleg crank until it is retracted. I discern no pitch change during this operation, after which securing the handle again with its bungee loop allows me to concentrate better on the airplane’s handling and performance.

I was immediately struck by the poor control harmony, with an extremely sensitive elevator but heavy and sluggish ailerons and intermediate-weight rudders (remember, there are two of them). However, once our speed builds up to 110 knots, the roll control greatly improves, and I saw a climb rate of around 1000 fpm on the vertical speed indicator, remarkable for such a low-powered two-seater at maximum weight and more than double an identically powered Cessna 150’s performance. Only slight right rudder pedal pressure is needed through takeoff and climb, just as in any other American-engine airplane, but less so.

Once above 1000 feet, I reduce power a little and keep the speed up at 110 knots for good cooling, which has always been a problem area for pusher aircraft. Brown’s cowlings are a later design, optimized for minimum drag with maximum cooling airflow delivered by a wide NACA duct under the belly, so our temperatures and pressures remain within limits.

However, the aircraft later sat on the ground for half an hour before the photo sortie, allowing the engine to become heat-soaked, and requiring several minutes of low-level, low-powered cooling flight before we could climb through the turbulence to 3500 feet.

At 4500 feet, a maximum cruise setting of 2500 rpm results in cracking 151 knots TAS at just 4.2-gph consumption with the mixture leaned. This improved economy over standard is another result of Brown’s high-compression conversion, and gives him an incredible 7.8 hours flying with 45 minutes’ reserve, for a most impressive still-air range of 1180 nautical miles! Reducing rpm to 2380 at 1500 feet decreases consumption to 3.8 gph while knocking back the airspeed by only 6 knots to 145 knots true, meaning you can now fly 1250 n.m. in 8.6 hours. Economy cruise of 2250 rpm, as well as being quieter and smoother, extends endurance to 9.25 hours and range to nearly 1280 n.m. at 138 knots. This is no less than 53 mpg at a whopping 160 mph—what efficiency! All these figures would probably be solo of course, because of the weight limitation.

This is the VariEze’s natural attitude when in repose, with the noseleg retracted.

Got It Handled

Handling in the cruise is better, though the ailerons are still much heavier than the elevators, making it difficult to prevent small pitch excursions when making significant roll inputs. Rolling to the right is particularly difficult because you have to operate the sidestick backhanded.

The sidestick in the front seat position. The rear seat has a removable one, but no other controls.

Our formation pilot found station keeping tricky at the 70 knots imposed by our camera ship, and he frequently had to resort to bringing his left hand to help the right when turning away from our Cessna 120. This poor lateral control is probably due to the small ailerons, fitted well inboard on the wings, presumably because they would cause too much flexing if they were bigger or set farther out, but it can be improved by appropriate use of the rudders.

Those small tabs are the rudders, which operate independently.

I also found the dual, winglet-mounted rudders a bit difficult to get used to. I guess I habitually clamp my feet fairly firmly against rudder pedals to increase the effective fixed fin area for less fishtailing in conventional airplanes, but doing this in the VariEze merely results in excess drag from having both rudders somewhat deflected against their return springs. The best solution almost seemed to be to keep my feet off the pedals altogether, and they are hardly needed for coordinating turns up to quite a high roll rate, as the swept wing confers strong roll/yaw coupling.

Nevertheless, stability is good in all three axes, though I felt the aircraft was slightly less stable in pitch than I would have preferred. Flying through light turbulence led to an odd little elevator feedback through the stick so that it bobbled back and forth against my gently clasping palm as the airframe nodded its way through the bumps.

The VariEze’s all-round visibility is superb, particularly in turning flight, with the small exception of directly ahead and down, where the canard gets in the way. The passenger also has good visibility, better than in its Long-EZ successor with its bigger wingroot leading-edge extensions. Airflow sound levels in cruise are low, thanks to excellent canopy sealing and the aircraft’s super clean lines; what little engine noise there is blows away behind you. The generous canopy provides both occupants with plenty of warmth, even in winter (there is no heater), while a well-positioned air vent above the front panel can be adjusted to blow a stream of cooling air right in your face.

The Canard Conundrum

One well-known drawback of canards is their tendency to abnormal behavior in pitch if the foreplane becomes wet or gets covered in squashed bugs. Brown explained several reasons for this, foremost among them the poor profiling of the canard’s airfoil by less than meticulous builders. The Long-EZ has an optional improved Roncz section on its foreplane, and some VariEze builders have adopted this. However, Rutan has not approved it, so Brown and Roper would not use it. Brown assures me he has flown in rain, and suffered no more disconcerting effects than a slight change in pitch trim.

Brown and his partner have kept the foreplane true to Rutan’s original design.

A locking bungee holds the noseleg in place until 10 turns on the crank either retract or lower it.

Prepare to Land

It takes us some time to slow down after reducing power, further testament to this airframe’s exceptionally low drag. Once flying slower than 120 knots the nosewheel can be lowered, while the airbrake can be extended below 90 knots. At more than 95 knots its spring-loaded, over-center mechanism succumbs to dynamic air pressure and snaps back shut, so this is really a device for increasing the descent angle rather than for reducing airspeed.

Eventually, we get below 100 knots and the ailerons are back in low-effectiveness mode. Canard types are deliberately designed such that the foreplane (a lifting surface) stalls before the main wing in all circumstances, so there is always a pitch-down rendering their minimum flying speeds higher than the same wing could produce with a conventional tail, but preventing a true main-wing stall.

In the VariEze’s case, the minimum speed I achieve is 52 knots, though holding the sidestick fully back against the stops to get it takes a massive, wrist-aching effort. As I hold it there, the airplane nods up and down while the airspeed needle swings back and forth between 50 and 60 knots. This is called the “pitch buck” and is gentler than on the only other canard type I’ve sampled, the Velocity. There is no sign of a wing drop, presumably thanks to the vortilons and trailing-edge flow-straighteners on the outer wings, and though roll response is now positively ponderous, the ailerons do still work. Brown explained that those vortilons and flow straighteners not only improve roll control, but they actually reduce the VariEze’s minimum flying speed. Nevertheless, a glance at the VSI shows the hidden danger of a descent rate that is off the clock.

All engine cooling comes through a belly scoop. Builders have tried various permutations of this inlet.

Sideslipping should be attempted only with extreme caution, as it is possible to stall a winglet in a steep slip, inducing a sharp departure from controlled flight into a tight spiral for several seconds. Recovery merely involves centralizing all controls, but may result in as much as a 1500-foot loss in altitude. On the other hand, being so clean, the VariEze glides well, a 10:1 glide angle being quoted with a windmilling propeller at 80 knots.

Back in the pattern, and slowing below 100 knots on downwind, I crank down the nosewheel to get that out of the way and secure its bungee, further reducing to less than 90 knots on base leg and extending the airbrake. This is somewhat awkward, because the lever comes up and backward under your left armpit. But it is not hard to move and there is no perceptible trim change with it out, only a slight airflow burble. Turning toward the airfield, I throttle back to 1300 rpm to give us a gentle 400-fpm descent at 85 knots.

In the narrow cockpit, all of the controls come readily to hand.

Flying down a straight final approach, you can clearly see the threshold over the foreplane plus some of the undershoot, though downward visibility is not as good as it is in many more conventional types. It is relatively simple to maintain the required 85-knot airspeed and a steady glidepath, and only the tiniest wrist movements are needed for minor adjustments. Accurate speed control is essential in such a slippery airframe if you don’t want to gobble up the runway in a long float, but I found it to be no chore at all.

Brown tells me to check the descent and then hold the attitude, allowing the airplane to settle, and once again ensuring the foreplane does not rise above the horizon. This is a jet-like technique, to which I am no stranger, so I find the flare, brief hold off and landing simple. Luckily, by the time we get back to base the crosswind has decayed, so there is little need for maneuvering in roll or yaw, which I might find more challenging; with the nose raised, the tips of those swept wings come close to the surface, making accurate wing leveling vital.

As it happens, the actual touchdown turns out to be a non-event. Letting the speed dribble back to 70 knots as we cross the airfield boundary, I raise the nose the required 3° (the necessary amount if you’re flying a standard 3° approach), ease the throttle closed, hold my breath, and wait until our mainwheels scuff the surface with a musical double chirp. Brown is kind enough to say it’s a good landing.

Squiggling along the centerline slightly as I try to equalize my differential braking while holding the nosewheel off the runway to less than 50 knots, we gently roll to a halt with light braking in perhaps 1500 yards. This could have been at least halved with more practice, better technique and harder braking, and Brown claims he regularly stops in 1200 feet with any sort of a headwind. Nevertheless, this is not really a short-strip or a rough-field airplane.

Taxiing back, Brown routinely leaves the airbrake extended to afford some protection for the propeller, something he does not do when taxiing out for fear of inadvertently attempting takeoff with the brake extended.

Canard Converts

So, again the question: Why don’t we see so many canards around these days? Well, they may just all be away, roaring around the continent, because high-speed, long-distance cruising is their forte.

Or it may be the construction. Modern homebuilders probably prefer today’s quickbuild kits to this once-revolutionary but now comparatively laborious method. However, I suspect the true reason they may have become less common is simply that Burt Rutan stopped selling plans for the VariEze in 1984, though he continued to provide support for those who were building.

Whatever the reason, Brown is clearly a canard convert, and he is very proud of his superb example, rightly so. It is beautifully built and performs astoundingly well on such low and economical power. I’ll let him have the last word, as he compares it with his previous version: “There’s a massive difference in performance; it’s miles better.”

![]()

Bob Grimstead is a 21,000-hour retired jet driver turned aviation journalist and aerobatic display pilot, who has flown 250 different types and written more than 180 articles on them. Two of the four airplanes he owns have VW engines.

Great article! One thing to keep in mind with VariEzes is that Rutan has published and never rescinded a service bulletin that limits them to 2.5g positive and 1.5g negative due to inconsistent spar cap properties discovered in customer-completed aircraft. That doesn’t mean that any particular aircraft is questionable, but it is a thing to be aware of. Note that the later LongEZ is not subject to this limitation.

http://www.cozybuilders.org/Canard_Pusher/RAF_inspection.pdf

–Bob K.

Amusing to read 1st photo caption, since Varieze came 2 years before Star Wars. It was certainly a dramatic airplane then, but so was the KR2.

I sure am tired of seeing Rutan being described thusly: “Rutan pioneered foam-filled, fiberglass-skinned composite construction for his 1975 prototype 1835cc Volkswagen-powered VariEze, . . .”

I’m as much a fan of Burt as anyone, however this foam and fiberglass type of construction was first introduced to the aviation community by Ken Rand and Stuart Robinson who introduced the KR-1 in February, 1972. The following summer, Ken took N1436 to Oshkosh, creating a sensation. The KR-1 was followed by the two-place version, the KR-2, which debuted at Oshkosh in 1974, a full year before Rutan introduced the VariEze.

From Wikipedia: “The design has proved popular, with 6,000 sets of KR-1 plans and 4,500 sets of KR-2 plans sold by 1979.[1] From these, over 200 KR-1s and 350 KR-2s were flying by 1987.” Plans and kits are still available today and it remains a very popular homebuilt.

Ken, an aeronautical engineer with Douglas Aircraft in Los Angeles, died in 1979 flying his turbocharged KR from Van Horn, Texas (a fuel stop) non-stop to Los Angeles where the worst winter storm in memory was raging. Descending through clouds, he iced up and fatally crashed near Victorville. Had he lived, he might well not be so overlooked in articles such as this one.