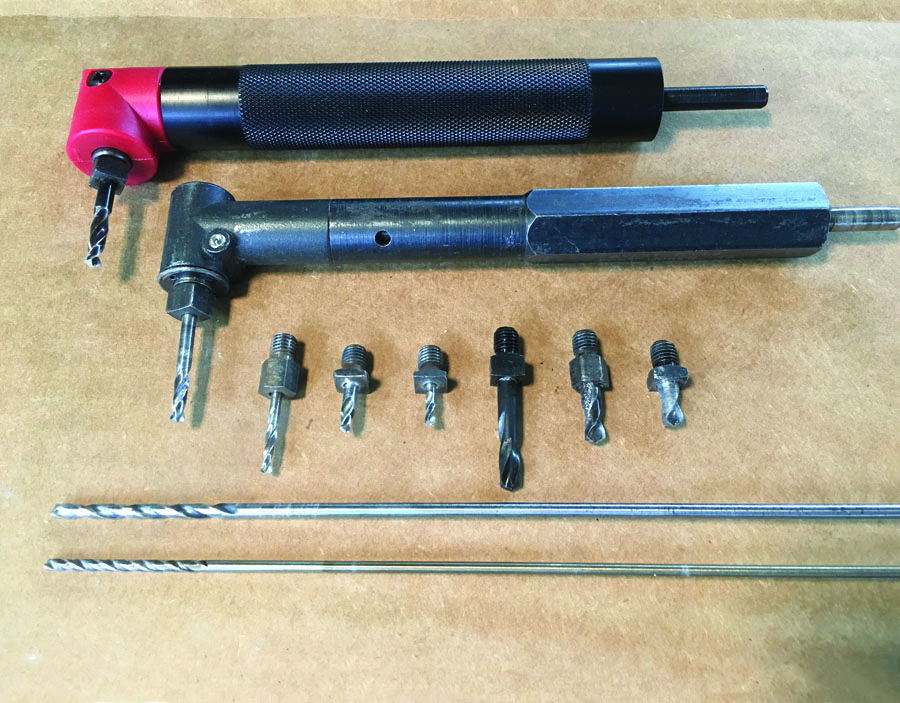

Top to bottom: the inexpensive Tight Fit drill, a typical right-angle drill attachment, short drill bits used with right-angle drills, and foot-long drill bits.

Drilling hundreds of holes is typically a mundane task while building our aircraft. Whether using an electric or air-driven drill, the drilling process is usually stress free. But every once in a while, we are confronted with a scenario that restricts our drill bit from getting a straight shot to the desired hole location. A sense of panic or frustration sets in as we cannot get our drill properly positioned. If we try to cheat and drill at an angle, this often results in a ruined part or, at best, an oblong hole.

Maybe only a handful of situations during the aircraft build pose these “impossible” drilling scenarios, but each needs to be addressed properly. We must use the tools that are made for drilling in tight places. Fortunately, there are a couple of affordable tool options available for this purpose. The least obvious, least expensive, and most surprising solution is the foot-long drill bit.

The foot-long drill bit excels by simply keeping the drill motor far away from the target hole. This is often all that is needed to prevent interference that would otherwise prevent a straight shot to the desired hole location. These long bits are available in the popular sizes we use for making rivet holes. The flexibility of their long length allows you to flex the shaft with your fingers around barriers as needed.

The right-angle drill is the ultimate tool for tight drilling locations. It is available either as an attachment to your conventional drill motor (best value) or as a self-contained unit in either electric or air-powered format. Combined with special drill bits, they provide a reliable solution to the most challenging drilling locations. Most right-angle drills of the style shown here share a common style of drill bit: one end has a 1/4-inch 28 threaded shank, and the cutting end is available in many popular diameter sizes and lengths.

Either a foot-long bit or a right-angle drill attachment makes accurate drilling possible in restricted locations.

Since the right-angle drill attachment is only occasionally used in a project, builders may not want to invest in the somewhat high price of these tools (approximately $100-$250). A company called Tight Fit makes a nice economy model for about $40. The internal parts wore out in my Tight Fit after my second aircraft build, but it was well worth the value in getting all of my next-to-impossible holes drilled properly. The more expensive, durable models will last a lifetime, and many come as a kit with popular drill bit sizes included.

Drilling with a right-angle drill attachment takes a little practice—it is easy for the bit to catch in the hole as it breaks through the material. This is often due to not keeping the bit perpendicular to the material, as it is hard to judge with the bit length being very short. Letting up on the pressure as the bit breaks through will definitely help. These tools and their drill bits are available from your favorite aircraft tool supplier and the likes of Amazon.com.