Surely no one would be tempted to straighten these badly bent blades, but even a slight bend is a cause for a professional prop shop to get involved. Gear-up landings are another major cause of prop strikes in certificated airplanes but are less common among Experimentals simply because most of them have fixed gear.

As soon as someone has a prop strike, the question arises, “Do I have to tear down my engine?” Unfortunately, most of the time the answer is yes. So, what is a prop strike exactly? Intuitively, it is when the propeller hits something. You may get some different opinions from a survey of your friends, but each major engine manufacturer has a definition of a prop strike that should be the beginning point of your decision process if the dreaded event occurs. Here is Lycoming’s definition:

A propeller strike includes:

• Any incident, whether or not the engine is operating, where repair of the propeller is necessary.

• Any incident during engine operation where the propeller has impact on a solid object. This incident includes propeller strikes against the ground. Although the propeller can continue to turn, damage to the engine can occur, possibly with progression to engine failure.

• Sudden rpm drop on impact to water, tall grass, or similar yielding medium where propeller damage does not usually occur.

Continental has a similar definition that is somewhat less wordy. Rotax has the briefest description: “A propeller strike is any incident while the engine is stationary or running which makes it necessary to perform repairs on the propeller.” Even though Rotax does not address an rpm reduction that does not damage the propeller, it seems prudent to at least consider such an incident to be a propeller strike with one of their engines.

Of course, as the owner of an Experimental airplane, you are not legally bound to these manufacturers’ service recommendations, but you are still responsible for maintaining your plane in a condition safe for flight. You will also have a lot of explaining to do to your insurance company if you ignore a prop strike that subsequently leads to a claim. The insurance company would much rather pay for the teardown and inspection than the loss of your airplane and maybe you and your passengers later.

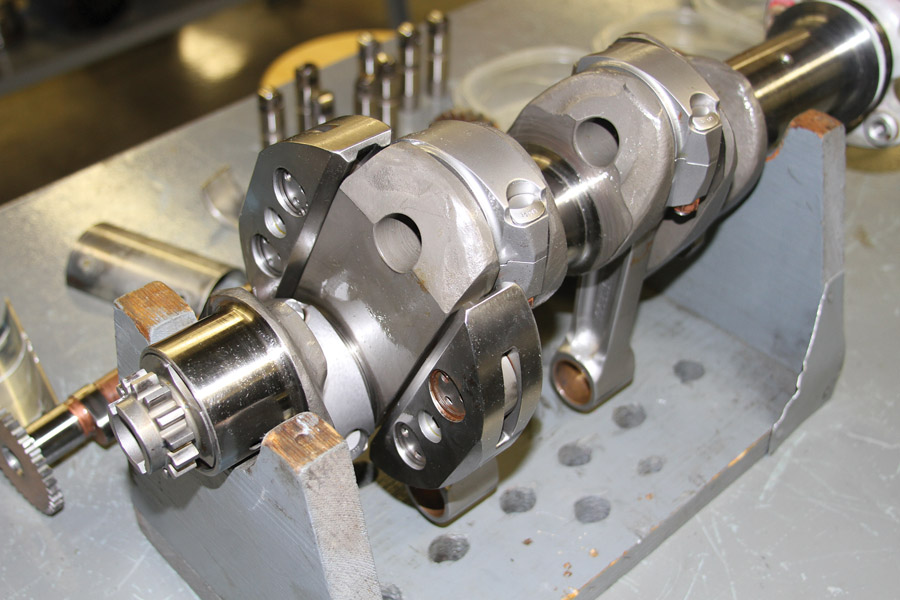

Any engine with movable counterweights must have these items carefully inspected and the pins and bushings replaced after a prop strike. An undetected failure of these caused a catastrophic engine failure in the author’s first plane. (Photo: Paul Dye)

Anatomy of a Prop Strike

Imagine your car rolling down the highway. If you suddenly run into something, you will most likely sustain some serious damage. Some of that damage may not be visible until you have someone really take a hard look at it. You may fix a bent fender, but there may also be damaged suspension components that require closer examination to find them. That is the same with an airplane engine that suffers a prop strike. You may be able to dress out the damage to the propeller and make it look pretty good, but other problems may be buried inside the engine that you can’t see without taking a closer look.

Visualize what is happening inside an engine right before a prop strike. Fuel is being rapidly burned inside cylinders where intense pressure drives pistons to turn the crankshaft. Pistons press down on connecting rods through piston pins. The rods convey that force to the crankshaft and then out to the propeller. The crankshaft also turns the camshaft and various accessory drive gears and the oil pump. All of these happily spinning and pushing parts can react poorly to any effort to force them to slow down or stop. Sometimes this results in an obvious failure, but sometimes, more insidiously, it can cause a stress fracture that will cause a failure later if it isn’t found in time. All of the moving and supporting parts of the engine are vulnerable to these stress fractures, even such things as the magnetos. This is why the engine must be torn down.

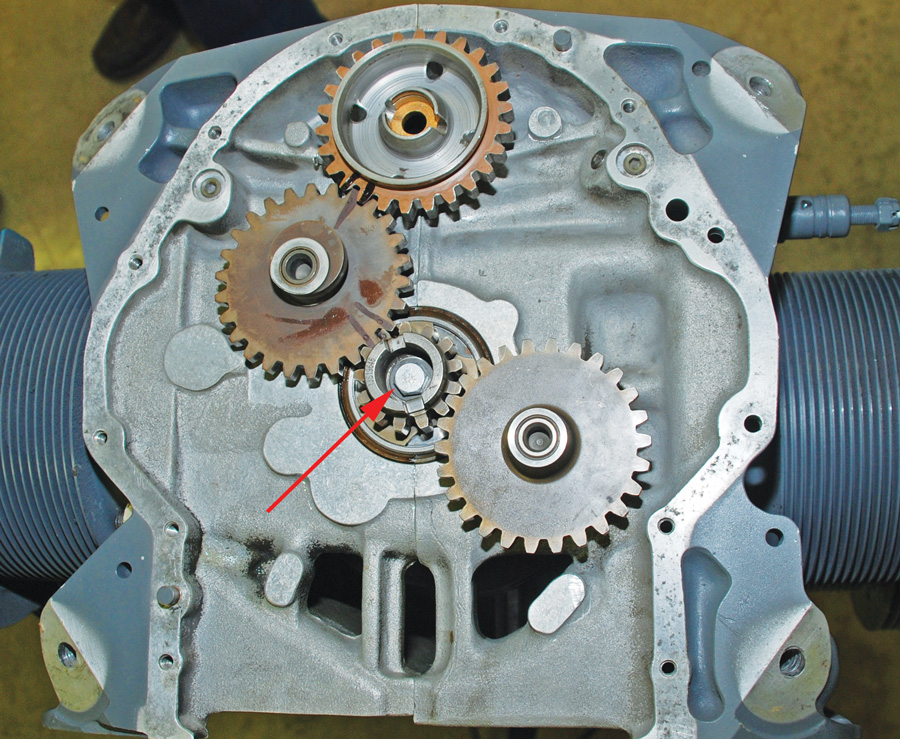

The bolt that holds on the gear that drives the camshaft and other accessory gears needs to be replaced after a prop strike no matter what. The gears need to be magnetic particle inspected to make sure they are not cracked. This engine is a dual-mag engine from the Lycoming engine school, so it lacks the second magneto drive gear found in most engines.

Rotax Engines

The exception to this general rule is the Rotax 912-914 series of engines. They have propeller speed reduction and clutch systems that usually protect the engine from prop strike damage, but does itself require a teardown and inspection after a prop strike. Rotax deals with this topic in their maintenance manual for these engines in Chapter 05-50-00, Section 1. Besides disassembling the gearbox and carefully inspecting it, the crankshaft must be checked for out-of-roundness to be sure that there is no more that .0031 inch of runout. If there is, the engine must also come apart for inspection and parts replacement. This is addressed in the Rotax heavy maintenance manual in Chapter 72-00-00, Section 3.9. These manuals are available online at the Rotax website. Most of the time the engine will not need to come apart, but you are still grounded after a prop strike until some serious work has been done.

Certificated and SLSA aircraft are legally bound to the Rotax factory requirements, but Experimentals are not. However, as stated before, it will be hard to make the case that you maintained your plane in a condition safe for operation if you do not follow these recommendations and something goes wrong later.

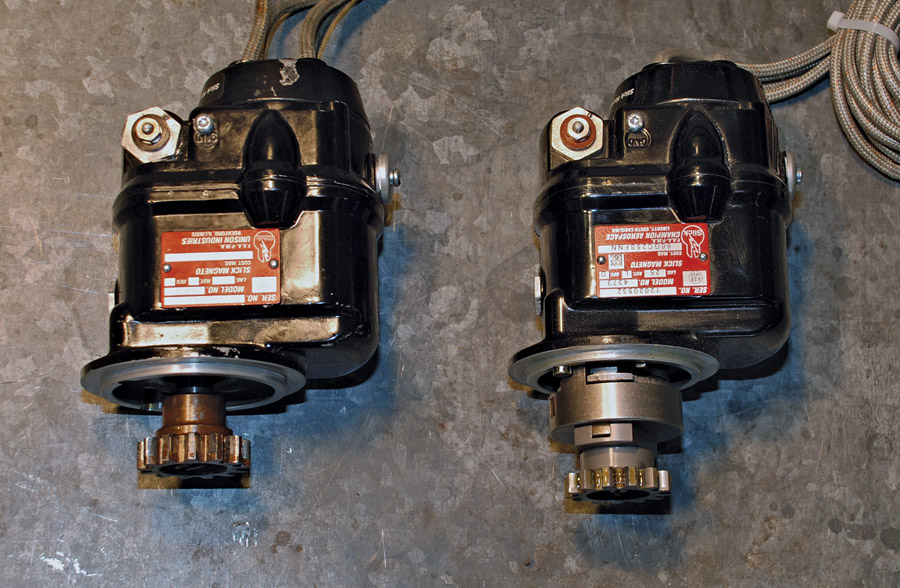

Even magnetos need to be checked out after a prop strike. The drive gears and impulse coupling are vulnerable to damage from a sudden engine stop.

Lycoming Engines

Lycoming deals with prop strikes in Service Bulletin SB-533C. This service bulletin is enforced on certificated aircraft owners through FAA Airworthiness Directive AD 2004-10-14. Lycoming’s service bulletin goes into great depth as to what needs to be inspected and how. It also addresses prop “strikes” that result in an engine slowdown without damaging the propeller such as might happen by hitting water or tall grass. Essentially, anything that causes a noticeable reduction in engine rpm or causes more than minor damage to the propeller calls for a teardown and inspection. This is regardless of the runout on the crankshaft. Crankshaft runout over .004 inch requires major engine work no matter what the cause, but that is a separate issue. The popular, but erroneous, advice that there is no need to take the engine apart if the crankshaft is straight is just plain wrong.

Areas of particular vulnerability in the Lycoming engine include the bolt that holds the cam drive gear to the end of the crankshaft and counterweight pins and bushings in engines that have movable counterweights. These items are routinely replaced after a prop strike.

Bad landings such as the ground loop that produced this disaster are a leading cause of prop strikes. The wood core construction of the MT prop probably helped to minimize damage to the engine, which checked out fine after a teardown. The problem was getting it to a shop from this remote location in British Columbia.

Continental Engines

Continental engines share the Lycoming’s susceptibility to damaged counterweight components from a prop strike. Accessory drive gears are also vulnerable parts that demand close scrutiny after a prop incident. Refer to Continental SB96-11B for more information.

My first airplane, a Cessna 205, suffered a catastrophic engine failure when the counterweights let go about two hours after a prop strike. This was back some 40 years ago when knowledge of the perils of prop strikes was much less common. An A&P mechanic had checked the runout on the prop after the strike and declared the engine fit for flight. He was hard to find afterwards when the airplane was towed back to the airport in pieces. Luckily, no one was injured in the emergency landing.

Field Experience

I don’t think there are any statistics on how many engines fail after prop strikes or how many damaged parts are found in a post-prop-strike teardown. Many people who have prop strikes simply ignore them and hope for the best. Sometimes that works out, and sometimes it does not. In the four cases of prop strikes where I knew the owners of the planes involved, two engines were torn down and had no damaged internal parts. One, the one mentioned above, had no teardown and failed shortly afterwards. The last one was a twin with Continental IO-470 engines that got two overhauled props and no teardowns after a gear-up landing. It flew fine for years afterwards with no apparent ill effects.

This small sample size doesn’t prove much, but it does suggest that not every prop strike causes major damage to the engine. On the other hand, one failure out of five engines is enough to make me reluctant to fly with a prop-strike engine that hasn’t been thoroughly checked out.

Larger main tires and a modified nosewheel fork gave the author’s Sportsman an extra two inches of ground clearance. This reduced the risk of a prop strike on the many dirt strips he has visited, such as this one at Coldfoot, Alaska.

Propeller Damage

A prop strike will almost always result in the need for a major repair or overhaul of the prop. This is not work that you can do, but must be done by a factory authorized repair facility. KITPLANES has an article [“Taking Care of Your Metal Prop“] in the February 2015 issue that deals with minor propeller repair and how to tell the difference between major and minor damage. But just to recap, major damage is when there is a gouge that is inch deep or more in the edge of the prop, or when there is a scratch in the face of a blade that is more than 1/8 inch deep. However, large areas of damage that are less than that should be checked out, too. Bent blades are also a reason to send the propeller into the shop. Pounding a bent prop back into shape yourself, even if it is just a bent tip, is a really bad idea.

In all cases, the manufacturer’s recommendations should be your guiding reference. With the advent of composite propellers, not to mention the continued existence of wood propellers, it is important to consult the most authoritative source when making your repair or overhaul decision.

Preventing Prop Strikes

As an airplane builder, the most important thing you can do to prevent a prop strike is to make sure you have adequate ground clearance between the tip of the prop and the tarmac. An absolute minimum of seven inches is required, but a more realistic minimum of nine inches is much safer. Selecting a prop that will leave you with good ground clearance, even at the cost of decreased climb performance, is a necessary precaution.

If off-airport or rough-field work is in your airplane’s future, it is a much better idea to build a taildragger than a trike. They have much better ground clearance (up to two feet), at least in the three-point position. Modified nose gear and larger tires can also increase ground clearance for a trike, but will likely take some extra work not included in the standard kit. I made such changes to my trike Sportsman and managed to get 11 inches of prop ground clearance.

Besides good ground clearance, the next best thing you can do to prevent a prop strike is to execute consistently good landings, since a great number of prop strikes result from ground loops or other landing mishaps. Lastly, know where you are taxiing or landing. Hidden obstructions can cause major damage, but even crossing a dip head on, rather than at an angle, can cause the prop to grind into the pavement.

Prop-Strike Engines

Value-conscious builders will sometimes be lured by the low price of an engine advertised as a “prop-strike” engine. These can be good deals if the seller will guarantee that the case and crank are still airworthy. Companies such as Wentworth will stand behind such a guarantee, but a private-party seller may be hard to find when you come looking for a refund after a crank turns out to be cracked. The reputation of the seller is vitally important with these engines.

If you hope to collect on such a guarantee, it is very important that you have the engine torn down and checked out right away. That doesn’t mean you have to do the expensive work of overhauling it, but it does mean that the necessary inspections should be conducted fairly soon after your purchase. It is not reasonable to expect a seller to stand behind an engine that has been in your possession for a year or two after he sold it. That said, such an engine may prove to be a bargain if you intended to overhaul it anyway. Just know what you are getting into.

For Rotax engine prop strike, it is necessary to check the crankshaft distortion check and out of roundness check.

CS distortion: max limit; 2 degree.

CS out of Roundness: 0.08 inch.

The value is mentioned in Heavy maintenance Book of Rotax engine. chapter 72-00-00 start at 3.9 as well as to check the serviceability of all accessories installed on engine.

The Gearbox with overload clutch is vvv important part that must deeply inspected. I suggest that replace it.

914 F2 engine installed on Denney Kitfox. aircraft crashed landing but the engine was safe. Engine thoroughly checked; found okay.

1. Crankshaft distortion checked. limit 2degree. Results Value. 0.0 degree.

2. Crankshaft out of roundness limit is 0.08 Result value 0.03mm.

Only Gearbox overload clutch damaged and new Gearbox with roller bearing installed. New engine suspension frame installed. All other things are found okay. you can tell the next acceptable Qualifications testing criteria? Should this engine require to test on Dynamometer?