There are all sorts of things I would like to know, but never take the time to learn – so much stuff, so little time… So I figure that some stuff will just have to wait until I need it. Such is the case of just how you mechanize a V-tail. You have two surfaces doing the work of three on a conventional tail – two ruddervators instead of two elevators and a rudder.

The ruddervators work like elevators in that they move up and down to control pitch – but they also move more in one direction than the other when the pilot pushes a rudder pedal. The two surfaces effectively “mix” the inputs from both pitch and yaw controls. Sounds complicated, right? So… how exactly is this done?

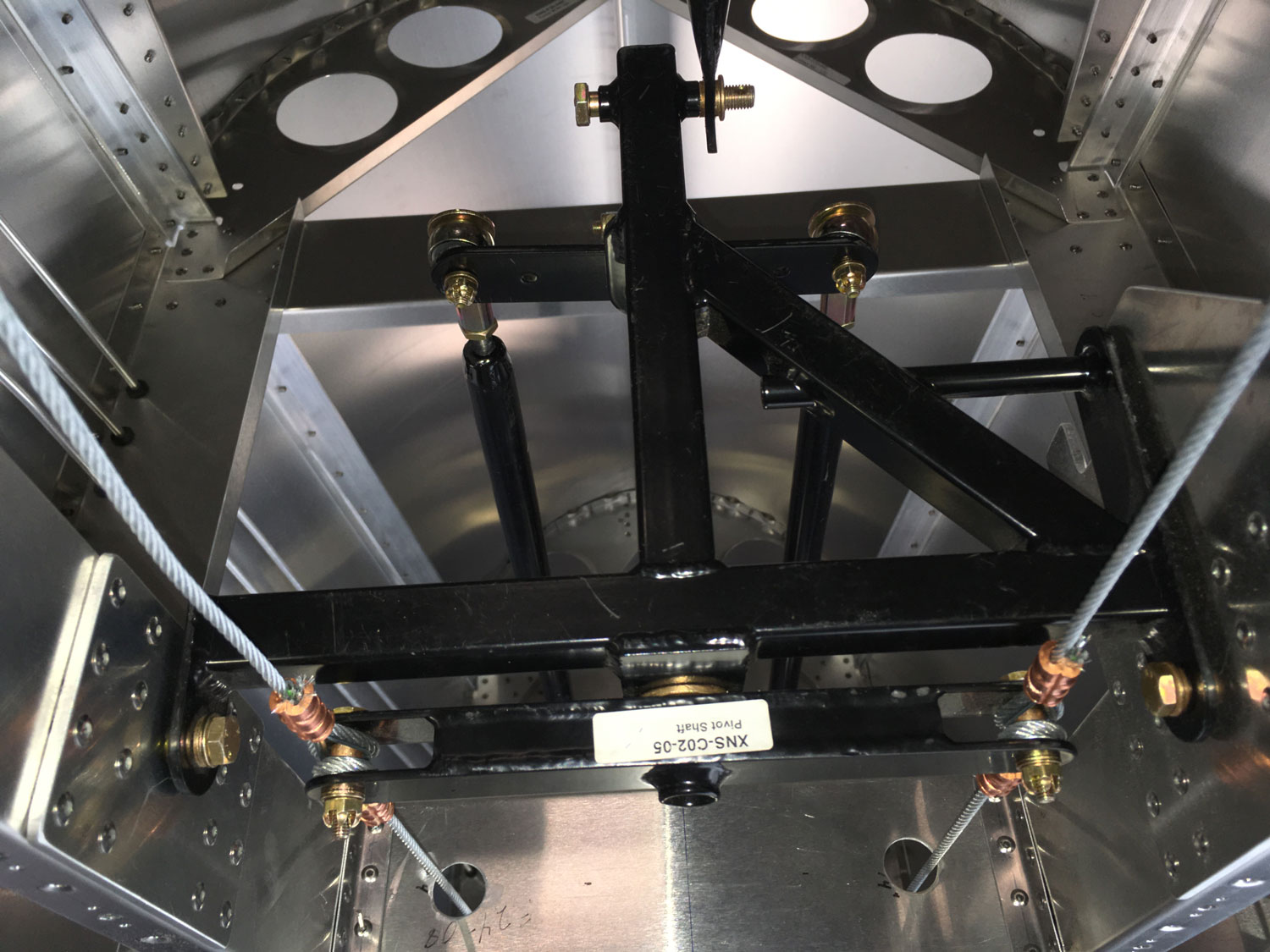

It turns out, the job is amazingly simple – you just use a–wait for it–mixer! I did the initial rigging of the controls (a fit-up, really–it all comes apart again, so don’t worry about the lack of nuts and cotter pins) for our “Y”-tailed Xenos motor glider last week, and finally saw just how the mixer works. Basically it is a vertical shaft that is mounted at the bottom so that it leans forward and aft with fore and aft stick (elevator) movement. The two pushrods for the ruddervators are mounted to a cross-bar at the top of this shaft, so if you ignore rudder, when the vertical shaft leans forward, you pull on both push rods, and this drives the ruddervators down. Now comes the genius part – the vertical shaft rotates with rudder pedal movement. In the case of the “Y” tail (with a tiny rudder underneath the V-tail), the rudder cables continue back to the rudder itself. When you push a pedal, it rotates the shaft as well as moving the rudder – this pull son one ruddervator pushrod, and pulls on the other.

The net effect is that you put in a bias on the ruddervators – one is now favoring “down”, and the other is slightly “up”. When you now work the pitch axis, they still move in the appropriate direction – just with them, both biased to create yaw as well.

Bloody simple, now that I see how it is done. I like simple–it doesn’t break!