About halfway to Oshkosh last month, I started to notice spots of grease appearing on the canopy of our trusty RV-3. I’ve seen oil leaks before, and this wasn’t one of those – this was grease, and the only place that could come from was the prop hub. I’ve also seen grease leaks before, and one thing the do share in common with oil leaks is that a very tiny amount can look much worse than it is. So I wasn’t too concerned about it, cleaned the canopy at the fuel stops, and finished the tip to the show. Of course, I knew exactly where I could find the Whirlwind guys for the next week. AirVenture – what better place to have a technical issue?

Day one of the show I walked over to visit with Whirlwind, and met Chaz – the guy that put my prop back together after its last overhaul. I told him what was going on, and he first assured me that there would be no problem flying home. In fact, he said, the hub could run for a full overhaul interval without any grease at all if it had to. The hub of the three-blade Whirlwind 151 has no grease fittings anyway, so there is no way to add anything unless you start pulling covers. Chaz took the time to walk over to our parking spot and have a look. He gave each blade a little shake at the tip, and sure enough the blade with grease on the back had just a little tip motion. Nothing dangerous – but clearly (according to him) the cause of the leak.

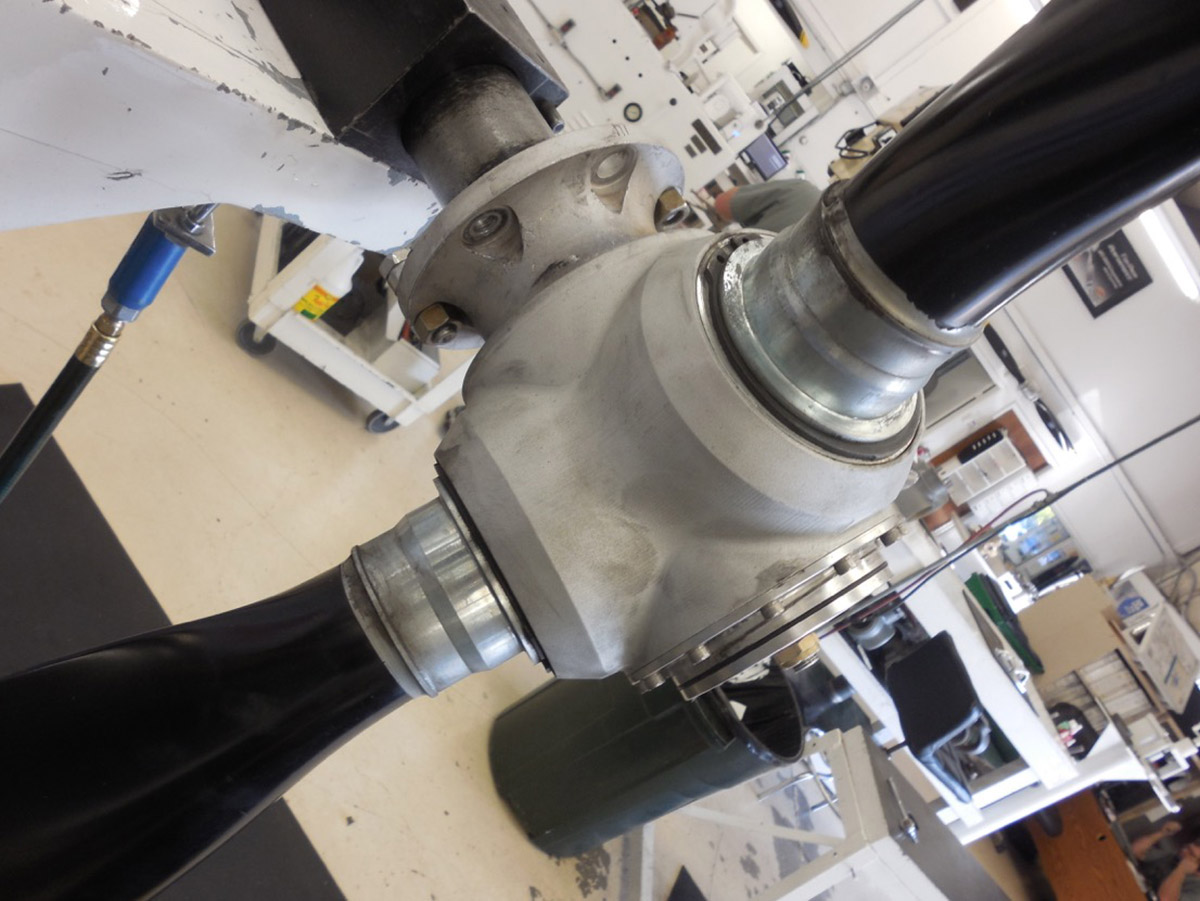

The blades on this prop (like many constant speed units), are inserted from the outside of the hub. Ball bearings are then put into the race on the blade ferrule, and the prop pulled back outward and secured with a snap ring. The ball bearings effectively create a larger diameter ferrule so that the blade cannot be pulled out of the hub by centrifugal force. The snap ring prevents the blade from going back in to the hub and releasing the ball bearings. In order to make the whole thing tight, shims are installed under the snap ring to put tension into the system. Each blade is shimmed individually at the time of assembly, and a record is kept of the build, so they can tell exactly what thickness of shim was used.

Chad said that if I was comfortable removing the snap ring and replacing the shim myself, he’d send me some so I could do it at home – he didn’t have any at AirVenture, and didn’t have my build sheet to see what was in there. In our case, the number 3 blade had been installed with a .057″ thick shim. He sent us the next three thicker sizes, just to make sure we’d have one that fit.

Sure enough, the shims showed up soon after I got home from the show, and after a wait to get a set of appropriately large snap-ring pliers from McMaster, I installed a .060″ shim yesterday, and took the plane for an hour flight today. No grease spots at all, and the blade tip doesn’t move. I’d call that a successful test! Great support by Whirlwind in this case, just as I have had before… and a chance to learn more about how this prop works, and how it is built.