The mighty P-51 Mustang is unquestionably one of the most iconic and famous

The mighty P-51 Mustang is unquestionably one of the most iconic and famous

aircraft of World War II. Born out of necessity in the tumult of war, the Mustang was, if not an immediate success, then definitely an enduring one once it got the more powerful Merlin engine. It was unparalleled as an escort fighter—fast, agile, fearsome. Eight decades after those first P-51s helped turn the tide in Europe, remaining flying machines soldier on in museums, airshows and the hangars of the few who can afford to purchase and feed one. Real Mustangs are not generally found among the common man. But if you really want to look out at those beautiful, tapered wings from a bubble canopy in a cockpit sitting high atop a slender, purposeful fuselage there are alternatives, including this one: the ScaleWings SW-51.

The Company

Design of the SW-51 dates back to the first proof of concept aircraft created back in 2013 by engineer Hans Schwoeller, a former RC model developer, along with a team of RC developers. The creation of the molds in painstaking detail reportedly took 16,000 hours to get every rivet head and panel line exactly right. Even though the body is rendered in carbon fiber, every rivet and screw visible on the original is replicated here. In scale. Imagine that.

The first example flew in 2014 and considerable time was spent perfecting the engineering. Extensive modeling and testing were performed using hydraulic load cylinders to confirm the strength of the structure. This was not just a case of loading up sandbags to test structure—this was an aerospace-quality project. Schwoeller met entrepreneur investor Christian Von Kessel in 2016, with Christian putting together a team of investors to move the project into kit production. While the company is primarily German, production of components (and assembly of aircraft) is done in Krosno, Poland, making this an international effort.

Von Kessel and fellow ScaleWings executive Sebastian Glueck brought the SW-51 mockup to Sun ’n Fun in 2022, generating tremendous interest. This led to demo flights of a finished airplane at AirVenture and the Reno Air Races later in the year. Arkansas aviation enthusiast Zak Heald and his partner Trevor Aldridge (a former Thunderbird) recognized the potential and offered to help market the kit in the U.S.

Heald and Aldridge are pushing for a program for individual builders to buy kits that meet the “51% rule” for Experimental/Amateur-Built licensing but also want to explore builder-assist programs. This could mean builder assistance in Europe or in Arkansas, though it’s likely it’ll involve Titan Aircraft in Ohio, which is helping with early kits. Still, the program simply isn’t firm at this time and is likely to evolve. We’re told that ScaleWings is dedicated to working within the rules set by the FAA and understand that if the initial kits don’t meet the E/A-B requirements, Experimental/Exhibition could be an option for early adopters. Still, ScaleWings is very early in the kit-defining process, so try to be patient!

The Aircraft

The legend of the P-51 means there are (and have been) many plans- and kitbuilt replicas over the years, from simple airplanes with VW engines up front to complex, high-end machines with custom V-10 engines on the nose. And everything in between.

What makes this latest entry in the Mustang look-alike contest special? Its carbon-fiber construction is a place to start. Making composite structural parts in female molds allows a surface finish that simulates every rivet and screw in the original Mustang. Painted properly, it is hard to tell that you aren’t looking at an aluminum airplane unless you knock on the structure and hear the difference. Remarkably, the molds for the SW-51 have every surface feature made into the mold individually with meticulous care, or so we’re told. When you look at the finished product, it shows flush rivets and screws that appear to have typical paint buildup in the dimples and in the heads of the Phillips screws. The simulation is remarkable. Even the rudder looks as if it is fabric covered, with rib stitching and pinked tapes—the whole nine yards. Just like a real Mustang.

But the beauty of the SW-51 is not just skin deep. Despite being conceived by a modeler, this is not a giant RC airplane. Looking through the CAD files, we see the result of extensive work to make the composite structure extremely strong, with the use of aluminum doublers and mating parts to make it maintainable. Attention to detail is evident when you see that the center wing section is designed to mount the landing gear and that the outer wing panels are removable—but with aluminum positioning parts and wedges to make the installation repeatable. Keeping the gear entirely in the center section makes removing the wings simple. The airplane remains on the gear so it can support itself and be moved around.

Re-creating the Mustang gave the SW-51 several advantages carried over from the original. Like radiator placement, which the SW-51’s Rotax 915 iS takes full advantage of. As every schoolboy knows, the P-51’s distinctive scoop houses the radiator for the Merlin V-12 engine—and the SW-51 uses the same scoop for the Rotax radiator, though it probably doesn’t give much of the thrust effect that is attributed to the original’s. Another gift from the original is the wide-stance main gear, which makes for stable ground handling. Since the original tailwheel mounts significantly forward of the rudder hinge line (whereas most modern taildraggers have it back by the trailing edge of the rudder), the ground handling is a little “different” but it’s not that hard to get used to, plus the robust wheel has a roomy fuselage in which to hide.

The SW-51 does use modern electric linear and rotary actuators to retract and extend the gear—hydraulics might be authentic but the all-electric system is cleaner and less prone to leaks. When we flew Serial #1, the inner gear doors had been removed for modification but rest assured that the commitment to an accurate replica is there to get the inner doors on the plane and working reliably.

It’s Not a Merlin

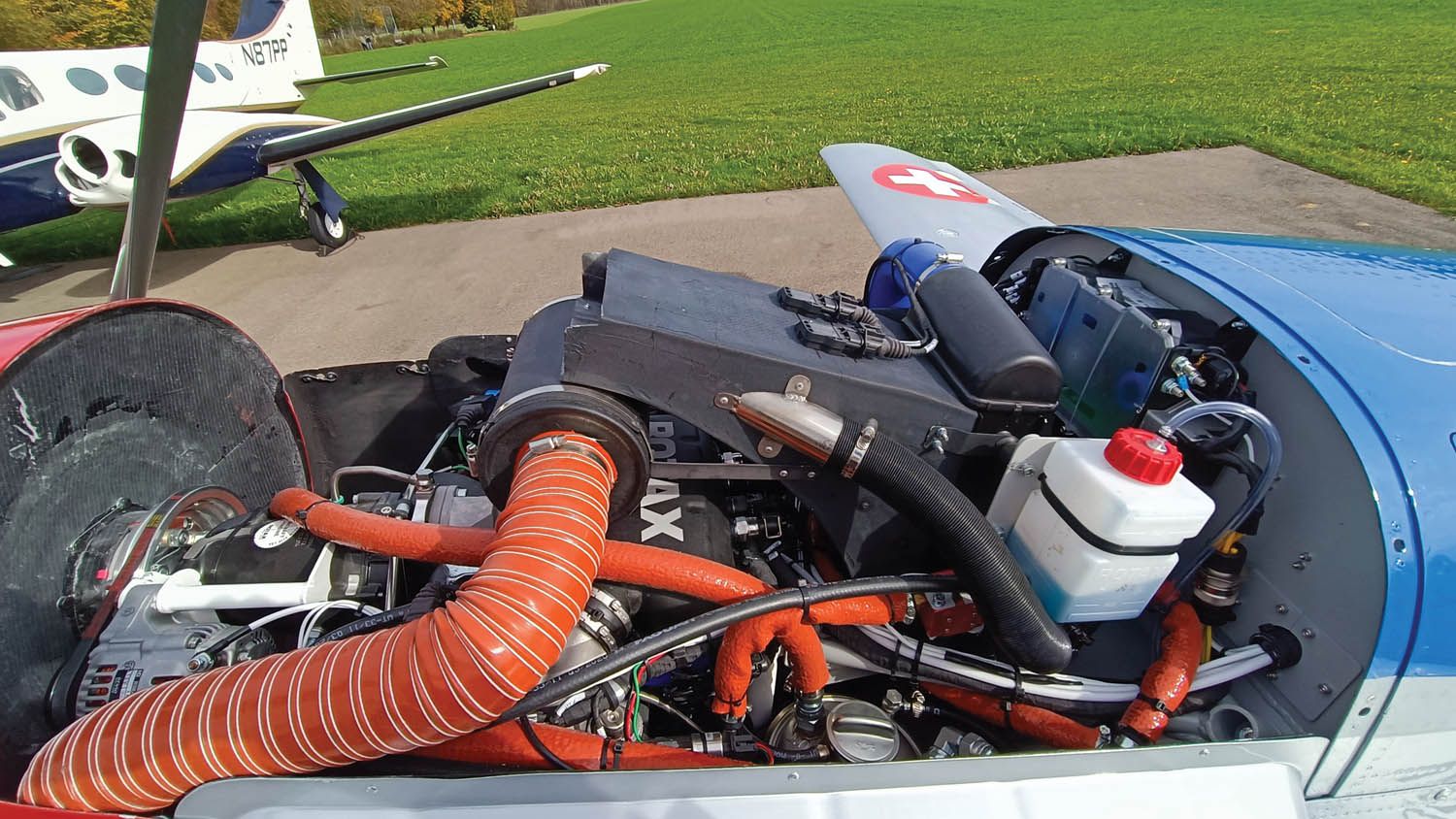

When you think of a Mustang, you don’t think of a high-winding, opposed-four-cylinder engine up front, but that’s what the SW-51 has: the modern, turbocharged Rotax 915 iS. Truth is, the Rotax fits the ScaleWings perfectly and provides more than adequate performance—but more on that later. For now, ScaleWings is happy with the Rotax, but no doubt somewhere along the line someone is going to want a bigger motor. The trick, of course, will be finding one that fits in the scale nose without needing bulges or bumps. The development team is looking, not because they feel it is needed but because it is inevitable that someone is going to want to hot-rod this little fighter and fly it at Reno. At least that is what we assume, based on an extensive knowledge of pilot behavior. After all, too much power is almost enough.

Ahead of the Rotax is an MT four-blade constant-speed propeller. Yes, it has four blades because, dang it, a Mustang needs four blades! But the prop currently installed looks a little, um, short. It is probably the only item on the airplane that isn’t to scale and ScaleWings knows it. There are props that would look more appropriate and probably give better initial acceleration and climb. However, the gearbox of the 915 iS can only support so much load and reliability is still king in the design process. So while it might look a little funny, the MT is safe and smart from a longevity standpoint. Still, ScaleWings is looking at possibilities for something more appropriate to scale.

Take a Walk Around

Many would argue that a P-51D (the bubble-canopy kind that the SW-51 emulates) isn’t supposed to have two seats. And if you’re talking about the stock WW-II fighter, you’d be correct. But the truth is that most flying P-51s have been modified with a rear seat, if only to carry someone willing to buy the gas for the guy up front! The SW-51’s canopy does look a little long and slightly flatish as a result, but it doesn’t really take away from the replica effect. The canopy does have an interesting motion—it slides back about 6 inches (and is intended to be flown that way, though the testing is still ongoing to prove that feature), then swings over to the side. Think of it as both a slider and tipper. The layout makes it easy to get in for both front- and rear-seat occupants.

Preflight is simple. Walk around and make sure that everything is connected securely but don’t be fooled when you get to the fuel caps. There are four fuel caps, but only one (the rear one) on each wing is real—the forward outboard one is there for scale. It’s a chore to get low enough to look up into the tailwheel well but it’s good practice to have a look. Check the radiator inlet under the belly and make sure you haven’t sucked up a plastic bag or a surprised squirrel. Unlike the real Mustang, there are no inlet or exit ramps to check. The SW-51’s are fixed, though it’s rumored that a larger-engine version could have active controls.

The airplane I flew did not have the inner gear doors installed, but if it did, there would be five actuators to check—one each for the main gear and tailwheel, and one more (each) for the inner doors. The linkage and drive mechanism for the inner doors was being revised at the time of our flight and the good news for pilots is that there is still just a single gear switch in the cockpit. There is also just a single release to drop all three wheels at the same time if the electrics go away.

Almost Ready to Fly

The first thing you notice when climbing into the cockpit of the SW-51 is that it is roomy—not quite as wide as an RV-8 at shoulder level because of the canopy shape, but close to that wide when you get below elbow level. It is certainly bigger than an RV-4, and the rear-seat passenger enjoys enough room for rudder pedals and a place to put things beside them between the seat and sidewall.

In both seats, the longerons feel higher than in many two-seaters, so be prepared for a little bit more work getting back out. The rudder pedals up front are adjustable, so the forward ’pit can handle a variety of pilots. Eye height can be adjusted with cushions, but the stock seat was perfect for a 5-foot-8 pilot like me. The closest comparable would be the RV-4, based on size, weight and, as we’ll see in a moment, handling.

Subsequent aircraft will be equipped with EFIS panels, but this one had steam gauges and electronic engine monitors and radios commonly used in Europe but little-seen in the States. Cockpit layout was fine but is going to be changed in future aircraft to clean things up and make use of lessons learned in testing. But we’ll describe the airplane we flew, which did the job just fine.

Panel instrumentation was simple, and all we really needed to know was where to find engine data—the airspeed and altimeter were obvious. Switches for the engine were standard Rotax 915 and monitoring was on a digital all-in-one display. Flaps are electric with Up, Flaps 1, Flaps 2 and Flaps 3 available with a flip of a rocker. The landing-gear retraction and extension was done with a single lever-locked switch for up and down. Emergency extension is performed by twisting a T-handle secured with a slender nylon cable tie—I determined in advance that it was more than adequate to hold it from turning unless I really, really wanted to turn it.

Let’s Start!

Starting the Rotax becomes easier for me with every new plane that incorporates the 915 iS—what once was foreign is becoming familiar! Turn on the master, both “lanes” and the fuel pump—lanes are what Rotax calls the independent injection and ignition channels and ECUs, which can operate independently and provide redundancy. Then hold the Start Enable switch to bring on the fuel pumps. Wait for the lane lights to go out and hit the Start switch—and the engine fires up. Wait until oil and water temps come into limits and you’re set to go. This wait, of course, takes longer than the time it typically takes to get a Lycoming or Continental ready to go, but that’s the nature of a water-cooled engine.

Prepping the airframe for flight takes almost no time at all—check the trims, flaps to one notch, latch and check the canopy—then sweep the cockpit or do a CIGAR check. The canopy can actually be left cracked open for takeoff, according to the factory, but since the airplane being used as a demonstrator is already privately owned, the U.S. reps are flying it conservatively—latched is one step further away from any potential of an accidental “deployment.” By the way, the canopy can be jettisoned with the pulling of two latches on the starboard side, away from the normal latch/unlatch controls—but we couldn’t figure out why you’d do that since the aircraft has a ballistic recovery parachute and you’d likely ride that down if you had a major issue.

Pilots will notice a few things different (not better or worse, just different) from the average Experimental low-wing taildragger. (I am talking mostly to RV drivers here.) The first is that the nose sits quite high—not just blocking the view forward a little but blocking it a lot. S-turns are pretty much mandatory as no one is going to be tall enough to crane their heads up to see anything out front. S-turning is a good technique to remember from your tailwheel endorsement anyway, so use it. Second, the tailwheel is mounted farther forward than you’re going to be used to. Almost all light airplane tailwheels these days are at the extreme end of the airplane, providing a longish wheelbase. The Mustang’s little wheel is mounted several bulkheads forward of the tail, making the wheelbase much shorter, and that changes the way it turns on the ground. Lastly, the tailwheel is steerable, locking or free-castering. The steering is really not very noticeable—the designers noted that you really don’t have enough authority to make a 90° turn off the runway—so it is only useful for an angled high-speed turnoff. The steering actually connects when the tailwheel is locked so it’s not really locked straight ahead.

The result of making this a scale model of the full-sized Mustang means that pilots will have to adapt to the steep nose angle and shorter wheelbase—but with the little taxiing I did and the single takeoff and landing, I didn’t have any trouble and felt that it would be almost natural after a little more time aboard. The thing to remember is that if you are taxiing with the tailwheel in swivel (to allow tight turns and ramp handling), the only real directional control you have is with brakes—so make sure they are working well.

Finally We Go!

When you’ve completed the preflight checks, it’s time to take the runway and get ready to depart. Because we had a direct crosswind of about 7 knots, I elected to take Trevor’s advice and roll the airplane straight, then lock the tailwheel before adding power for departure. With no one in the back seat, the tail came up at an amazingly slow speed, but visibility was quickly restored. This isn’t to say it is nose heavy—it’s not—the horizontal tail is just that effective. About the time the tail came up, the rudder was more than enough for directional control and the rest of the takeoff roll was smooth and easy to control. Those first few seconds just take a little glancing left and right to make sure you’re going straight.

Trevor advised getting the gear up and building up some speed before pulling straight back into the climb. This technique worked well, with an acceleration to about 100 knots before pulling into a climb at about 90. Vx is lower than that but I really didn’t feel like I needed maximum climb performance with a 5000-foot runway. In fact, we were off so quickly that I’d have been happy with the 2000-foot runway for departure—and probably landing after having done it a few times. Gear and flaps came up during acceleration and the electrics all worked fine.

The Rotax is easy to manage—the hydraulic prop is controlled by a quadrant lever (instead of the normal switch used with an electric prop often fitted to the 915), so it will be intuitive for most pilots. Pull it back from takeoff to cruise rpm and manage power with the throttle. The little turbo Rotax provides plenty of smash for routine flight. And while we didn’t try any aerobatics past a couple of wingovers, it was obvious that the airplane has the power to do fun stuff.

Let’s get the questions about handling out of the way. This airplane is a joy—the control forces are light but not twitchy and the harmony is almost perfect. This means that a given amount of force in either roll or pitch gives a corresponding rate in roll or pitch and the same force in either axis gives the same rate. Yaw was similarly natural, and I noted no situations where I had to compensate other than using a little rudder in high-pitch/slow-speed conditions, which is another way of saying that you need to hold right rudder in a climb.

We did a few military eights (essentially back-to-back wingovers) to check coordination and it was easy to keep the ball centered no matter the attitude or speed. A Chandelle was just as easily accomplished. A 60° steep turn provided a perfect buffet at the 360° point with little effort to hold altitude, so we reversed the turn and went the other way—and hit the wake again. Simply put, the airplane goes where you tell it to go and does what you tell it to do. No, it is not a fire-breathing vertical machine, but you’re unlikely to find any scale Messerschmitts to bounce, either. I’d expect loops and rolls—and the various combinations—to work out just fine.

Stalls—power on and power off—were unremarkable, except to say that you got a nice buffet warning about 5 knots before a very gentle, straight-ahead break. It honestly stalls like a Cub, letting you know it wants you to stop pulling back on the reins. If you don’t, it’ll gently drop its nose to pick up the speed it wants on its own. Trevor mentioned that no spin testing has been done, so we didn’t explore the boundary conditions of the stall with various banks and yaws. But straight ahead and typical pattern turns were just fine.

We did a few rudder kicks and slips up high and noticed no unnatural tendencies of the airplane entering or exiting the maneuvers—I wouldn’t hesitate to slip if I was high on final and needed more drag than I could get with the flaps. But I didn’t slip with the flaps all the way out, so I’d approach that with caution until someone who had done it tells you how it does. I will note that I have flown other warbird replicas that have had surprising handling characteristics in the stall or with slips because the airfoil didn’t scale well. Or maybe it did—fighters are built to be weapons platforms, not to be easy to stall. But the SW-51 is a pussycat in the slow-speed regime.

Visibility in the air is, as you’d expect from a fighter replica, quite good. Yes, we’ve seen better in airplanes with full bubbles and no windshield frames—but this is a scale model, so you’ll get what Yeager got over Europe and like it! The frames virtually disappear in reality as you look around them with one eye or another and the rest of the canopy is clear, so visibility mostly depends on the flexibility of the pilot’s neck.

It’s likely anyone building an SW-51 will be creating a pure-fun machine but it is not without good performance. We didn’t have much of an opportunity to check cruise speeds during the demo flight. But the factory quotes a best-case cruise of 180 knots true at 15,000 feet, which seems plausible given the SW’s performance down low and the 915 iS’s ability to maintain power at altitude. The two wing tanks carry 22.8 gallons usable, which is a little thin for the expected high-cruise consumption of around 8 gph, though econ cruise could get you closer to 6 gph.

With airwork out of the way, it was time to head back to the long, wide runway at Neosho, Missouri, where we were operating. There was no traffic but we did a standard traffic pattern rather than the tempting overhead break, just in case there was a NORDO Cub around. Gear came out as I entered the pattern and I dropped Flaps 1 abeam the numbers. Wanting a little time on final to see how it responded on the glideslope, I went a little longer than normal and after dropping Flaps 2 as I turned final, I added a little power to set up a stabilized approach. Trevor mentioned that Flaps 3 was all drag with no additional lift and suggested not using the position, so I didn’t. He also suggested a wheel landing, which he felt the airplane liked better. And since that is what I am used to in most RVs—for a long paved runway landing, anyway—I just carried the extra power and flew it on.

Control was excellent in the flare and after planting the mains, I eased off the throttle and let the tail come down. The locked tailwheel gave me confidence in a straight rollout despite the bit of crosswind. The only surprise came as I slowed below about 5 knots and unlocked the tailwheel in preparation to turn around on the runway. I swung a bit right to give myself room for the 180 and then as I turned around toward the wind, a gust on the rudder increased my turn rate and “helped” me come around almost the full 180°. If that hadn’t been my intent, I think I could have stopped it, but it was a little faster than I had planned. The short wheelbase made it feel just a bit different, but I wasn’t ready to stab significant amounts of braking on this first landing. In the end it worked out just fine. Pointed the right direction, I taxied back to the ramp and was happy to have looked out upon a Mustang-shaped wing.

Builders who sign on to be one of the early ScaleWings SW-51 customers will likely discover a company still figuring things out, with the inevitable bumps along the way, but the airplane itself is delightful. It looks 100% the part and the details molded right into the carbon fiber—along with the other thoughtful design touches evident throughout—will help make it the center of attention on any ramp. That the SW-51 flies well may be incidental to the insta-crowds that it’ll engender, but its performance, feel and attitude are a fitting tribute to arguably the greatest fighter of WW-II.

Very interesting. I think most of us dream of being fighter pilots and the scaled model makes it more achievable. Great article Paul!

Very cool article! Well-written and enthusiastic, it made me feel like I was right there with you.