I’ve always loved tools. As a boy I studied the Sears and Roebuck newspaper ads (“This 100-piece Craftsman tool set only $39.95!”), and as a teenager I spent more than a few paychecks there. I still page through the latest tool catalogs as soon as they arrive, carefully considering the usefulness of every offering.

I’m not alone in my fascination. Tools are fundamental. Type the single word “tools” into Google, and you’ll get 826 million results, only a few less than “food” (936 million) and “sex” (1.04 billion). It was once believed that tool use was unique to humans, perhaps the defining trait which allowed us to dominate the other animals. Then, in 1960, pioneering ethologist Jane Goodall observed a chimpanzee fishing in a termite mound with a stick. It wasn’t the use of the tool that so electrified the world. It was the realization that the chimps were purposely making tools, stripping leaves and chewing the ends of the sticks into fans in order to catch more termites.

As it turns out, a great many animals use tools. We’re merely the most talented of the hominids, the one with a real flair for using tools to create new tools. It’s a handy skill if you happen to be an animal who likes airplanes…and it proves you’re at least as smart as an ape. Well, at least that ape at the airport who blows dirt into your hangar.

Modified Tools

The lowly wrench is probably every builder’s first adventure in toolmaking. They’re often ground to fit into a tight spot, bent to clear an obstruction, or lengthened to reach into a recess. A few variations are shown in figure 1. Experienced builders pick up junk wrenches at flea markets and yard sales, just so they are not tempted to chop up their polished and plated favorites from the Snap-on truck.

The import tool store is another good source for raw material; that’s where I found the three cheap cast copies of high-quality forged hammers shown in figure 2. These hammers have one great virtue—as throwaways, you won’t hesitate to grind and sand the faces into whatever shape you need to finish the task at hand.

Additions to Tools

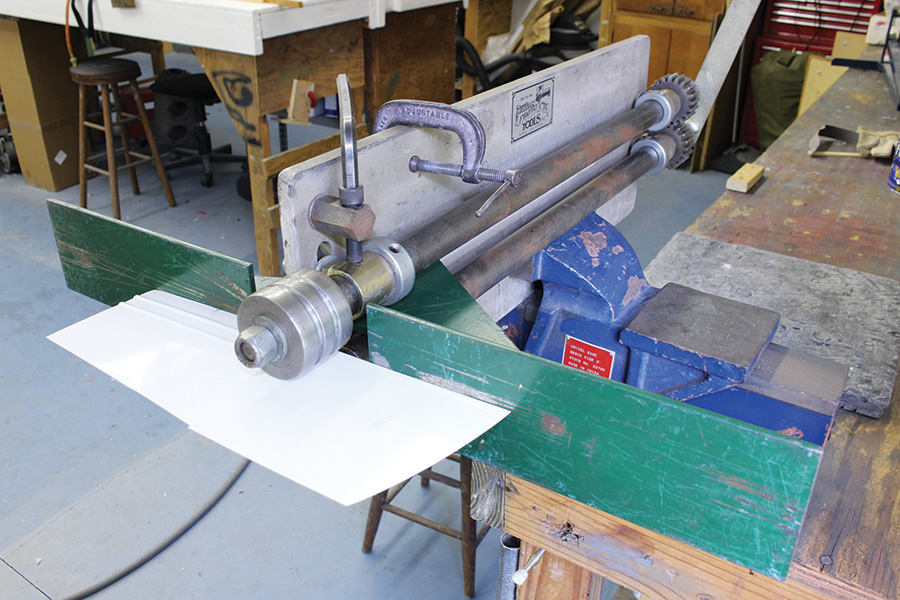

The smart hominid knows even the best tool can sometimes be improved with an accessory. Take a traditional bead roller like the one shown in figure 3. Adding a guide fence ensures the rolled bead will be perfectly straight, and at an exact set distance from the edge of the panel. The fence is simply clamped to the back of the beader frame and slides to any position. The set distance can be as much as 16 inches.

Do you have an engine stand loafing around in the shop between builds? Fire up the welder and put it to work as a tailwheel stand as shown in figure 4. All it takes is a length of heavy threaded rod, two big nuts, a small section of plate, and some angle iron to make a wheel cup. The threaded rod allows perfect longeron leveling, the wheel can’t escape the cup, and the wide base makes it all very stable. You can even crawl into the rear fuselage without fear.

Found Tools

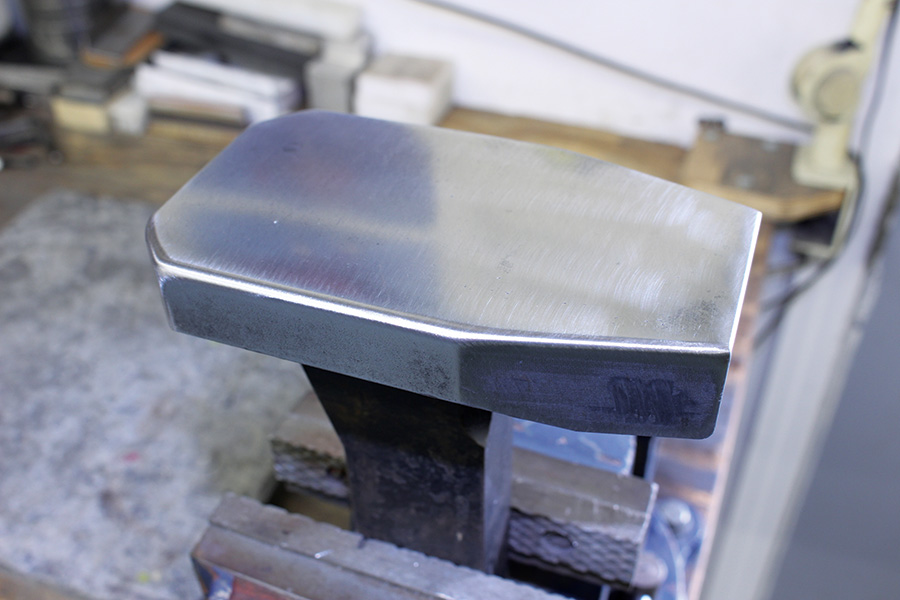

Some of the best stuff is found in the junk pile. The other less talented apes didn’t think it was useful, so they threw it away. Consider the chunk of steel shown clamped in a vise in figure 5. Metalworkers call this a “head.” It is used something like an anvil; metal is formed over it with a hammer. I have no idea what this piece of steel once was, but I keep the 1-inch thick top surface polished, with smooth edges. It’s perfect for tweaking a part or planishing a dent.

I’ve found it pays to make friends with the manager at the local scrap metal yard. Scrap is bought and sold by the pound; some very interesting material can be purchased for a markup measured in pennies. Your goal is to be the guy he calls when a nice chunk of 6061-T6 round, or an interesting machine, comes in the gate. You’ll need a place to store scrap; I’ve found a roll-around rack like the one in figure 6 works great. The rack itself can be built from scrap, including the industrial caster wheels. You might be surprised at how many projects I start with a quick survey of my scrap bin.

Now take a look at figure 7. You’re probably focusing on the bead roller, but don’t overlook the massively mundane. See the one-foot square lead block on the benchtop? I’ve had it almost 40 years. Let’s say I want to center punch a small part in preparation for drilling a hole. If I rest the part on the lead block, it doesn’t bounce when I hit it.

“Mass tools” can be invaluable. Among other favorites, I have a 2-inch x 6-inch aluminum plank 5 feet long, and a 3-foot x 3-foot steel plate ¾-inch thick. The plank is a perfectly straight, stiff base for fabrication. The plate serves the same way, most recently to jig an engine mount.

Tools Made Cheap

I’ve never understood why some tools are purchased rather than made. It must be a monkey-see, monkey-do thing. Take for example a ring compressor. The store-bought version is really just a fancy way to clamp a sheet metal band around a piston so the rings are squeezed into the grooves. So why not just use a sheet metal band like the one shown in figure 8? You can spend the money you save on bananas.

Ever feel like pounding the snot out of something? For metal stretching on a shot bag, nothing beats a big wooden mallet like the one in figure 9. Grab a hardwood block, round one face, and stick a handle in it; any handy tree limb will do. Now hit the sheet metal as hard as you can. Every big whack knocks a dent in the sheet, stretching it. Later all the dents are blended together, the result being a dome in the sheet. See the pretty nylon hammer (for fine work) next to the wood mallet? It’s easy to afford because the cost of the big hammer is exactly zip.

We install lots of small AN fasteners, and sometimes they need a little tap to slide home. A brass hammer doesn’t make them ugly, and it is non-sparking, a nice feature for airframe work. In this case you need a little brass hammer, which is as simple as adding a handle to a short length of brass rod. You can see the one I made in figure 10.

The other tool in the same photo? It pushes pop rivets into tight holes. The large round handle lets you push in a few hundred without making your palm sore, like a pop rivet puller tends to do. The shank is end-drilled for a slip fit on the rivet mandrel.

Next time you’re at the flea market, pick up a few old screwdrivers; they’re great toolmaking material. Figure 11 shows a long screwdriver that’s been converted into a spark plug boot puller; just heat the end, hammer it flat, bend it over, and file a half-moon. The screwdriver in figure 12 has been transformed into a carefully shaped pick for extracting a propshaft seal without damaging the engine case.

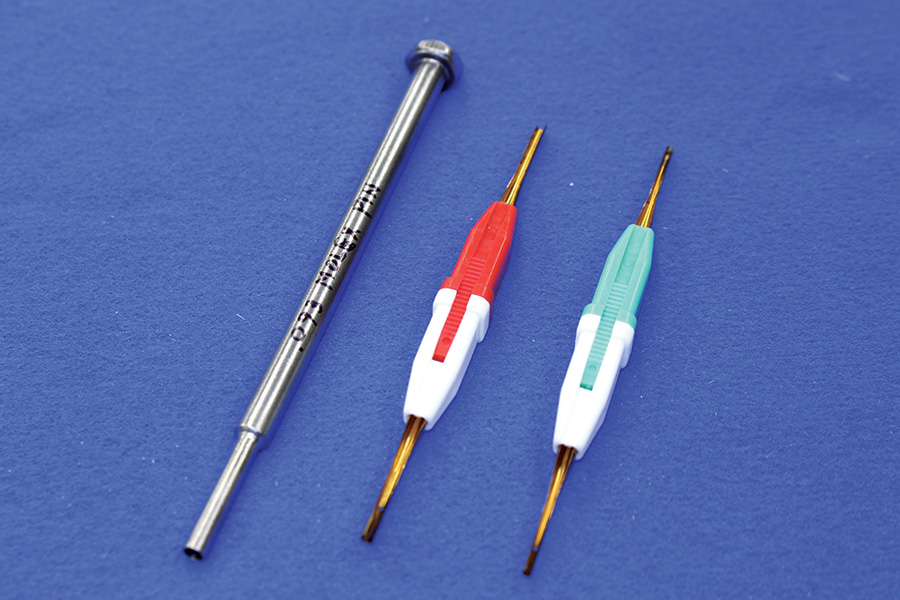

One Sunday afternoon I was almost done with a wiring job when I realized I had pushed a 0.093-inch Molex pin into the wrong hole. The baboons would no doubt order a Molex pin extractor, wait a week for delivery, and waste $15. This human chucked a ¼-inch bolt in the lathe, drilled the end with a 3/32-inch bit (0.09375), and then cut the OD. The pin was out of the connector in less than five minutes, and of course I kept the tool. It lives in a padded drawer with its fancy cousins, the D-sub pin extractors. You can see all three in figure 13.

Want to check main bearing clearance in an assembled engine case, but don’t have a really good bore micrometer, or the means to calibrate it properly? Sidestep the issue with a gauge plug like the one in figure 14. Mike the crank journal, then lathe cut a plug with the identical diameter. Both measurements are made with the same outside micrometer, so calibration is not required. Slide the plug into the assembled bearing, then measure the clearance directly with an ordinary feeler gauge. It’s so simple even Bonzo could do it.

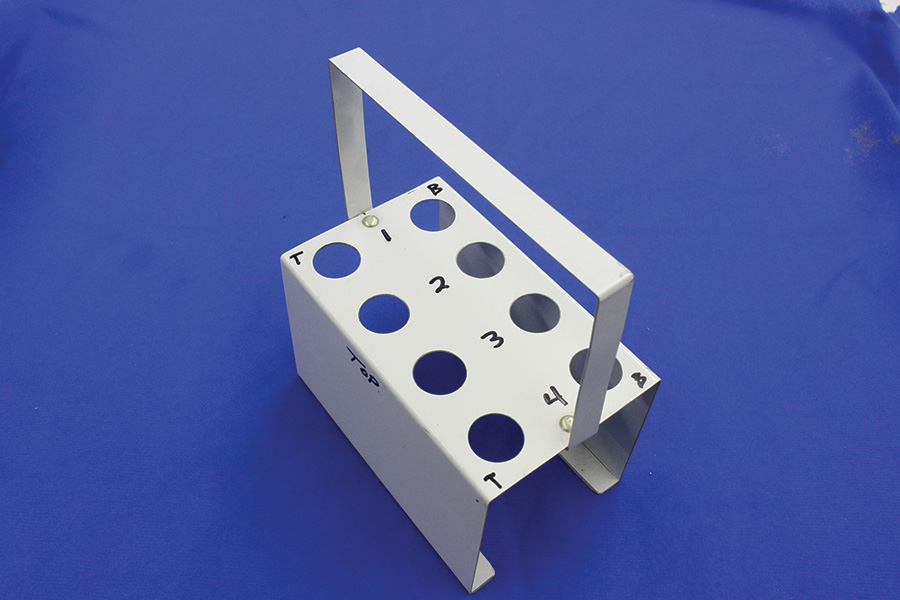

OK, now it’s time for a shame test. See the spark plug holder in figure 15? If you bought one of these, your hominid card is officially revoked. For penance you must catch and eat a termite.

Custom Tools

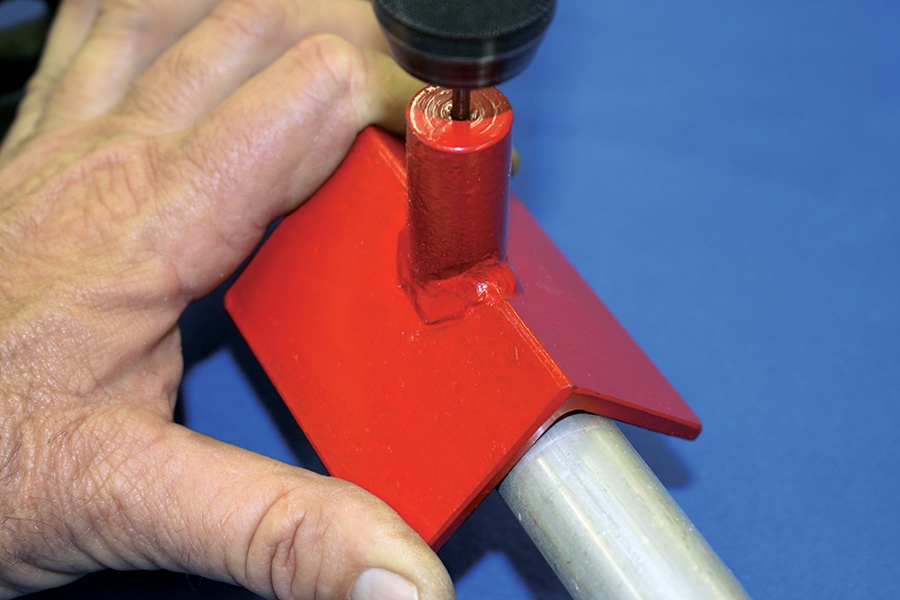

Figure 16 shows a drill guide every homebuilder should have. It centers on a tube, and guarantees that paired, opposing holes are perpendicular to the long axis. It’s easy to make; start by welding a length of solid steel rod to a clean section of angle. Now bore a 0.125-inch hole down through the rod with the angle sitting on a drill table known to be perpendicular to the drill chuck. Be sure to bisect the apex of the angle. To use it, merely rest it on the tube and drill pilot holes with a 0.125-inch bit.

Care to guess what the simple device in figure 17 is used for? It checks the leakdown rate of the hydraulic units found in valve lifters. The operating principle is simple enough; a given weight acting via an arm of known length results in a specific pressure on the hydraulic unit (represented in the photo by a white spacer). Just fill the lifter with fluid, insert it in the jaw, apply the weight, and time how long it takes to go flat. There are leakdown specifications, but mostly we just want to be sure all the installed lifters are the same. This homemade tool makes a bad apple quite apparent.

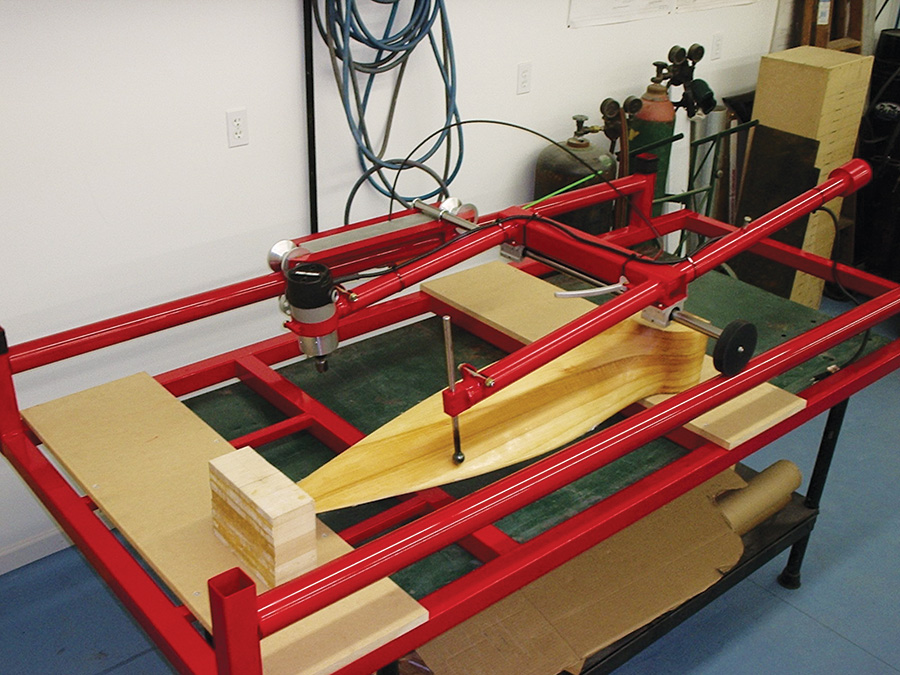

Some great tool ideas are, umm, borrowed. I needed to carve an identical pair of rather large custom props. It seemed easiest to carve one single master blade from softwood, then use a duplicator to carve the maple props. So, with a tip of the hat to the good folks at Gemini (yes, I called them first), I built the rather large prop duplicator shown in figure 18. It was as much fun as building the props themselves, which in turn was necessary to build the airplane. There’s an anthropology lesson in there somewhere.

Hard Tooling

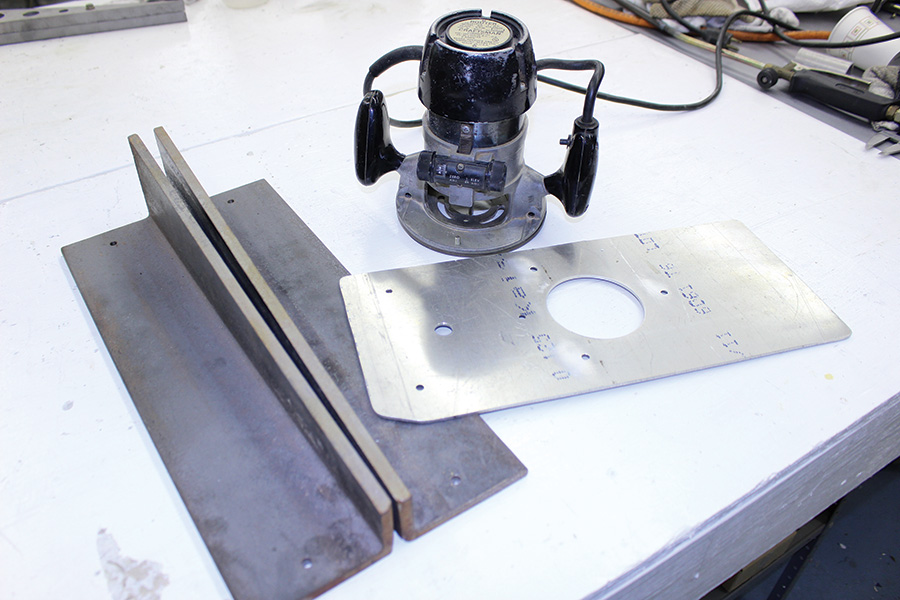

Figure 19 shows scarf guides milled from two big sections of steel angle. They get clamped on each side of a spruce or fir spar blank. The aluminum plate gets attached to the router baseplate, and serves as a bridge between the guides, suspending the router bit above the wood. Simply slide the router assembly up and down the guides, cutting the perfect scarf.

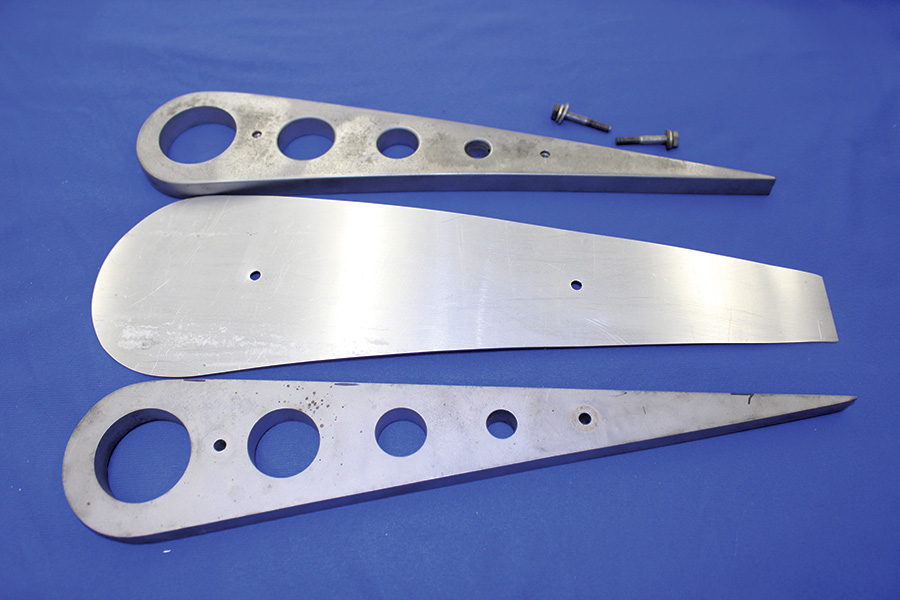

If you’ve built a metal airplane from scratch, you know that traditional aluminum ribs are shop-made with hammer forms. Wood forms work in a pinch, but these days it’s not hard to find a machine shop with CNC water, laser, or plasma cutting capability. Lay out the exactly shape in a CAD program, take your thumb drive to the shop, and come home with good steel forms. The forms shown in figure 20 bolt together, which is very handy compared to the usual C-clamps. The aluminum blank in the photo is a master, something to trace around with a Sharpie so the real rib blanks can be laid out on a sheet. Of course the blanks could also be CNC cut. Why not? CNC seems to be the hot tool for really smart hominids.

For sure I’m not the smartest monkey in the troop; anyone can whip up a tool. When none of the standard methods look like they will work, let your mind run on what might work, however unusual, and then make what you need. You’ll find most solutions are not complex. More often than not, it’s merely a matter of quickly making something you’ve seen elsewhere, but don’t happen to have handy. That’s the mindset; lack of a tool is not a reason to halt your progress. It’s an excuse to make something cool you may use the rest of your life, and take great pleasure in it every time.

Have fun!

I got tickled at your solution for removing the errant Molex pin. I have sections of collapsible antennas in my tool box for just such occurrences, or for when I need to ‘adjust’ the wiring profile of a plug. One size is for the male pin and another for the female.