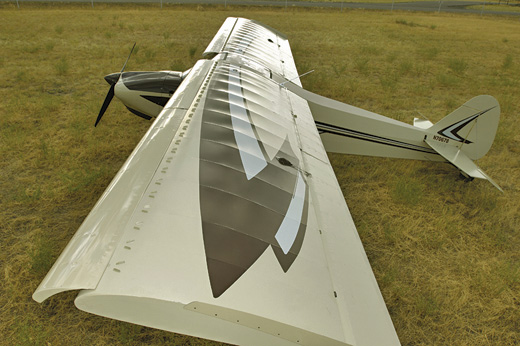

Backcountry Cubs makes a very traditional Super Cub complete with rounded wingtips. This serves as the foundation for the highly modified Mackey SQ2 and a number of possible iterations in between, depending on what options the builder selects.

In an age of 300-knot homebuilts and fast-glass certified airplanes that seem to practically fly themselves, there remains a deep and abiding interest in unadorned, basic aviation—flying low and slow to places that are not served by large paved runways, or even any runways at all. Such aviating is the province of the Super Cub and its ilk. It is no wonder that a host of airplane kits are available to meet this demand.

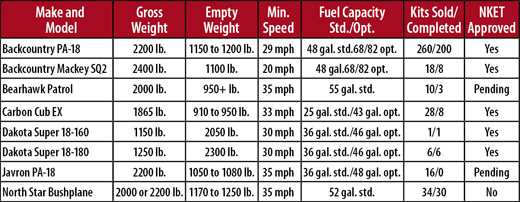

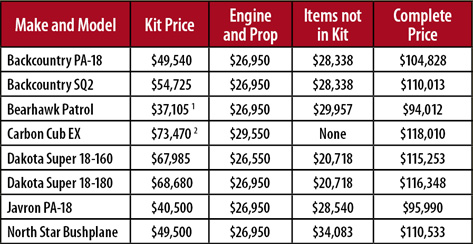

We previously looked at the LSA-eligible Cub kits (KITPLANES®, March 2011, “STOL Brothers”), so this time we’ll compare the Super Cub kits and those that provide similar features. These are heavier planes with gross weights ranging from 2000 to 2400 pounds and typically 180 horsepower engines. They do not struggle to carry two good-size adults and meager fuel, with no payload left for so much as a toothbrush. These aircraft carry a half-ton of fuel, gear and people to remote places with names like Kantishna, Cold Foot and Johnson Creek. With only one exception, these planes are recognizable as Super Cub variants, and they have all grown out of the hard-working Super Cubs that continue to ply the backcountry of the world as they have for the last 60 years.

After an extensive search, we found these kits worth considering for the would-be Super Cub builder. Backcountry Super Cubs has two models: a PA-18 clone and the Mackey SQ2. Bearhawk has its new Patrol, the least Cub-like of the group. The CubCrafters Carbon Cub EX can do double duty as a Light Sport Aircraft or a full-size Super Cub, depending on gross weight used. Custom Flight Ltd. makes the North Star Bushplane, a PA-18 clone with its own improvements. Dakota Cubs also has two models, the Super 18-160 and the Super 18-180. Javron Inc. makes a PA-18 clone, in addition to a number of other Cub-clone models.

As Javron builder Bill Rusk says, “There must be a lot of interest in building your own Super Cub, because there sure are a lot of people making kits for them.” Indeed there are. With all these choices, which one is right for you? Why should you consider one over another? And why is there so much difference in the cost of the kits? All good questions. We hope to answer them for you.

Flying into grass strips and pitching a tent makes the Super Cub experience complete. Here a standard Backcountry Super Cub is being used for just that purpose.

Backcountry Super Cubs

Backcountry Super Cubs traces its origins to the Smith Cub kits, which then became Turbine Cubs of Wyoming and later Backcountry Cubs. So in one sense it is a new company, but its roots go deep. Through the various name changes they have produced some 260 Super Cub kits, about 200 of which are flying. Their PA-18 look-alike is a classic Super Cub with a group of improvements that have come to be known as Alaska mods, which include 3-inch longer gear legs, some added bracing to the fuselage, increased gross weight and a larger baggage area, among others. The wingtips are also squared off, which allows the installation of longer flaps and ailerons than would be possible with the standard round wingtips of the original Super Cub. A 4-inch wider fuselage is also available as an option, as are leading edge slats for the wings, which come standard on the SQ2.

The Backcountry Mackey SQ2 is the high-performance version of the Backcountry Cub. Note the sloping engine cowl made possible by the lowered engine mount. This permits better visibility when flying at low speeds and high angles of attack.

The Mackey SQ2 incorporates many more modifications to the original design. A wide fuselage and leading edge slats are standard, as is a carbon-fiber cowl with a lowered inline-thrust motor mount. The gross weight gets bumped up to 2400 pounds and the baggage area is increased even more. Backcountry’s claim to fame is its castering leading edge slats that actually move as the angle of attack of the wings changes. This produces what the company calls an “unstallable” wing and gives the SQ2 a reported minimum-control airspeed of 20 mph, about half of the original Super Cub’s 43-mph stall speed. This is standard on the SQ2 and optional on its Super Cub.

The Backcountry kits include most of the items you need to assemble your plane, except for the engine, prop and firewall-forward accessories. They also do not include tires, upholstery or rear seat controls, and like most of these kits, the fuselage and other steel parts are not painted or powder-coated. Fabric covering materials and paint are also not included, as is typical for all of these kits except the Carbon Cub. The wings do come pre-assembled, which is a real time-saving feature, and a number of options are available at extra cost, such as a one-piece, left-side cabin door, auxiliary fuel tanks and rear-seat controls. Backcountry has a detailed assembly manual posted on its web site, and it is constantly being updated. The company also hosts a builders forum where customers can ask questions and share information.

Note the leading-edge slats on the Mackey SQ2’s wings. The company calls the wing “unstallable.”

The base kit for the Super Cub is $49,540, and $54,725 for the Mackey SQ2. The extra cost of the SQ2 comes from the slotted wings and the carbon-fiber cowl. Backcountry will cover and paint your plane for an additional $20,000, if you come to the factory and do a minimal amount of assembly work necessary to offset the 51%-rule credit needed to make the FAA happy.

Bearhawk Patrol

The Patrol is the least Cub-like of these kits, but its basic size, layout and performance make it a reasonable choice for someone who wants to build a tandem two-place utility airplane. The fuselage is tube and fabric just like a Cub, but the wings are all-metal with aluminum skins. It also is the only one in this group that does not use the original Super Cub USA 35B airfoil. The flush-riveted wings and modern aerodynamics give the Patrol the best cruise speed of the group at 140 mph. With this cruise speed it still manages a respectable 35-mph landing speed, which bests a stock Super Cub but trails most others in this group with their many high-performance modifications. With an empty weight of 950 pounds for a minimally equipped example and a 2000-pound gross weight, its huge 32-inch-wide cabin will haul a respectable load.

A Bearhawk Patrol ready to cover. It is usually much easier to run as many of the internal systems as possible before covering the fuselage with fabric. Unlike the other kits considered, the Patrol has metal-covered wings.

The Patrol kit generally includes all of the parts you need that are distinctively Bearhawk, but it does not include most off-the-shelf parts readily available from Aircraft Spruce or Wicks. One exception to this general rule is the windshield, which is listed as an option even though it is obviously required and uniquely Bearhawk. The company also does not offer a swing-out engine mount or auxiliary fuel tanks, even though most of the other kit manufacturers do. The standard fuel tanks are very generous at 55 gallons total, and most people manage to live without swing-out engine mounts, so these will be minor issues for most builders.

The four-place Bearhawk has been around for some time, but its smaller brother, the Patrol, is fairly new, at least in kit form. For this reason, only about 10 kits have been sold with one complete, plus two that were scratch-built from plans. The Patrol kit comes with both plans and a manual that is almost complete, but early builders have relied heavily on the manual, which is available on the company’s web site, for the four-place Bearhawk. Builders can get extra support from Yahoo groups dedicated to each type of Bearhawk kit.

Who knows what adventures are in store for Bearhawk Patrol builder Ferguson Aldridge. Parked on a farm strip, his new plane awaits its pilot.

Patrol kits are available either as a quickbuild with the fuselage completely welded ($37,105) or as a basic kit with some welding still left to do ($30,825). Both include wings that are substantially complete except for installing fuel tanks, wiring and closing out. National Kit Evaluation Team (NKET) approval as an amateur-built kit is pending, awaiting completion of the assembly manual (as of this writing).

CubCrafters Carbon Cub EX

We looked at the Carbon Cub EX when we previously compared Light Sport-eligible Cub kits. In that comparison it was at the top of the class in this field with its outstanding quality and impressive performance, but it achieved that at the cost of being the heaviest plane in a group that already fights empty weight at every turn. At a gross weight of 1320 pounds the Carbon Cub became something of a super single-seater. However, with no changes to the airplane except some paperwork, the gross weight can be raised to 1865 pounds, at which point the Carbon Cub becomes a contender with the somewhat larger Super Cub derivatives. Using a realistic minimum empty weight of 910 pounds, it sacrifices about 100 pounds or so of useful load compared to some of the competition, but many builders may find that its good points outweigh this small deficiency. Certainly there are some distinct advantages to being 300 to 400 pounds lighter, while hauling almost the same payload.

Although factory-built (SLSA) Carbon Cubs far outnumber customer-built Experimentals, CubCrafters is dedicated to making the best Cub kit possible. Shown here is a homebuilt Carbon Cub EX.

The Carbon Cub kit is by far the most complete kit of the group, including virtually every part you need to build the airplane, even fabric covering, and the engine and propeller, if you choose. Prewired instrument panels are also offered in various forms, if you so desire. The only thing not included is paint.

Two things set the Carbon Cub apart from the competition: the completeness of the kit and the price. The three sub kits cost $21,660 each and provide all of the parts for the wings, the fuselage and what the company calls a finishing kit. After that you can purchase a firewall-forward installation kit for $8490, a special lightweight CC340 engine that makes 180 horsepower for $27,500, and a Catto composite propeller for $2050. Finally, a VFR instrument panel and the related wiring come in at $14,990, and you get a grand total of $118,010. After you spring for a nice paint job and deal with your state’s tax man you only need to add several hundred hours of your own labor to be flying the plane of your dreams.

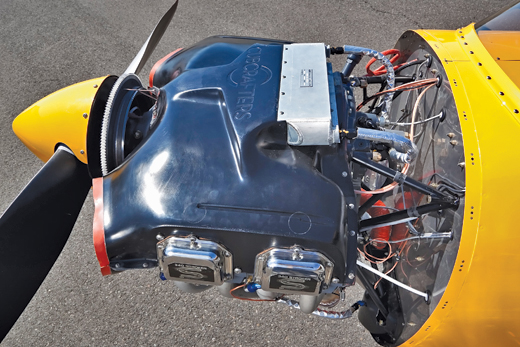

CubCrafters’ impressive 180-hp CC340 engine plays an important role in the company’s quest to make the Carbon Cub as light as possible. Cooling is provided by a slick looking carbon-fiber plenum that forces the maximum possible amount of air over the custom-built engine.

At first that price seems like a real jaw-dropper, but you are not likely to build any of these kits with the same features and a new engine for much under $100,000, no matter how good of a bargain hunter you are. For instance, Amy Gesch, director of marketing for Dakota Cubs, estimates that the company’s Super 18 kit will cost about $98,400 to complete with a used engine, no radios and no paint. The real advantage with the Carbon Cub is that you do not have to shop for anything. You just open the box and the assembly manual and get to work. The disadvantage is that there is not much flexibility in how you put the plane together, except for the radios, the size of the tires you use and the color of the paint. Many people will like that, but others will not.

Another view of a customer-built Carbon Cub.

The Carbon Cub comes with a 28-inch-wide fuselage (4 inches wider than a stock Super Cub), and its adjustable seats will fit almost any size pilot. (Jim Richmond, the owner of

CubCrafters, is a big guy, so he made sure his planes will fit just about anyone.) The stall speed is listed at 33 mph, and the maximum cruise speed at 125 mph. The kit comes with a detailed assembly manual.

Custom Flight Ltd. North Star Bushplane

Custom Flight Ltd. of Ontario, Canada, makes the North Star Bushplane and has for 20 years. This is a low-key operation that appeals to experienced Super Cub pilots. What owner Morgan Williams lacks in flash and salesmanship, he makes up for with quality workmanship and dedication. He sticks pretty close to the basic Super Cub formula, but does make a few distinctive changes. The North Star fuselage is 2.5 inches wider than standard, and the top of the fuselage is flat instead of ridged like a standard PA-18. The ailerons and flaps are also larger than stock, which is typical of this group. The North Star comes with 52-gallon fuel tanks standard, with no option for extras.

A North Star Bushplane sporting small tires approaches to land on pavement. While it is not the preferred venue for the North Star, this design will handle it with aplomb. No doubt this builder is just getting in some practice while awaiting the arrival of some “real” tires.

The North Star empty will come in at 1170 to 1250 pounds, depending on options and gross weight selected, which can be 2000 or 2200 pounds. The higher gross weight requires some extra reinforcing. Stall speed is 35 mph, and Williams lists the cruise speed at 98 mph with a climb prop and 31-inch tires. These speeds are pretty typical for the PA-18 lookalikes in this group that do not use slatted or slotted wings.

One place where the North Star really shines is in the assembly instructions. In addition to a manual and assembly drawings, the kit comes with videos to walk the builder through each step of the building process. The wing video alone runs six hours. So far 34 North Star kits have been sold, with 30 completed.

Many North Stars end up on floats. Rigging the floats and running the cables and hydraulic lines before covering the plane make this work much easier, but then the floats and wings must come off for covering and paint.

The North Star kit is $49,500, and excludes readily available hardware items. The NKET has not evaluated this kit for amateur-built compliance, but there is no reason to believe that the FAA would not accept it as amateur-built. It just makes for some extra work to prove it.

The Dakota Cub Super 18.

Dakota Cub Aircraft

Dakota Cub has two models of its Super 18, one dubbed the Super 18-160, the other the Super 18-180. They use the 160- and 180-hp Lycoming engines, respectively, and have different empty and gross weights. The 160 weighs about 1150 pounds empty with a gross weight of 2050 pounds, and the 180 is about 100 pounds heavier with a gross weight of 2300 pounds. Extra fuselage bracing and more heavily reinforced wings allow for the added weight in the 180.

Dakota Cubs distinguish themselves from the others in this group with their slotted wings. These slots near the leading edges of the wings allow the Dakotas to be flown at outrageously high angles of attack, and thus very low speeds. Landings at 30 mph are possible with the Dakota Cubs, but extremely low speeds do need a fair bit of power to control the sink rate. These Cubs are derived from certified airplanes, so every part is covered by an FAA parts manufacturing authority (PMA) or type design. This ensures a level of quality control and documentation that Experimental-only manufacturers are not required to meet.

A Dakota Super 18 on 26-inch Alaskan Bushwheels shows off its patriotic paint job.

The Dakota Cub’s massive flaps combined with the leading-edge slot setup make for impressive STOL capability.

The Dakota Cub Super 18-160 sports the economical Lycoming O-320 engine making 160 horsepower. Many Super Cub drivers prefer the lighter 160 over the more powerful but heavier 180-hp Lycoming.

Cruise speeds fall in the 100- to 120-mph range depending on the tires and prop installed. Fuselages come 4 inches wider than Super Cub standard, and the landing gear is 3 inches longer than standard. Other typical Alaska mods can also be found on the Dakota Cubs. The company also now makes a Light Sport-eligible version of its Super Cub, which was not yet available when the previous comparison article ran. It is now ready to sell to builders looking for a 1320-pound gross weight Cub.

So far Dakota Cubs has sold one Super 18-160, which has been completed, and six Super 18-180s, all of which are now flying. In addition, it has sold a number of certified planes and a large number of parts for use on certified Super Cubs. In fact, selling its slotted wings to Piper owners has been the mainstay of its business for some time, with its foray into the kit business being much more recent. Dakota kits come with a detailed assembly manual, plus supplemental materials developed from the wing sales program. Kits cost $67,985 for the 160 and $68,680 for the 180.

A Dakota Cub with the Alpha Omega Suspension System (AOSS). It was developed by Burl’s Aircraft in Chugiak, Alaska, and features low-rebound polyurethane “pucks” inside the canister. The system is designed to soak up the bumps of landing on a rough strip, enabling bush pilots to get on the brakes quicker and reduce the abuse the landing gear takes. AOSS is an option on Dakota Cub kits.

The Dakota Cub has a cavernous cargo area that extends well aft of what is found in the standard Super Cub.

Javron Inc.

Javron builds Cub components for others and has for some time, so it was fairly easy to transition into the complete kit market, which it has just recently done. Its focus is on reproducing the Super Cub in its purest form. Owner Jay DeRosier incorporates some of the popular modifications, but believes that the original Super Cub is a pretty good airplane just as it is. This approach allows him to produce a very light and original looking and flying airplane. The Javron Cub comes with a gross weight of 2200 pounds and an empty weight of 1050 or 1080 pounds, depending on whether the builder chooses the standard 24-inch cabin width or the 28-inch width so popular with Experimental Cub builders now. A bit more weight can be saved by going with the lighter 160-hp Lycoming O-320 engine. He also offers a choice of traditional rounded wingtips or squared-off wingtips, which allow for larger flaps and ailerons resulting in a somewhat slower landing speed.

Javron owner Jay DeRosier reports that Jay Hansen of Iowa has his Super Cub replica just about ready to fly. He used a Turbine Cub’s fuselage (manufactured by Javron) and many other Javron parts to put his project together. Other, more completely Javron Super Cubs are progressing, but are not as far along as Hansen’s “almost-Javron” airplane.

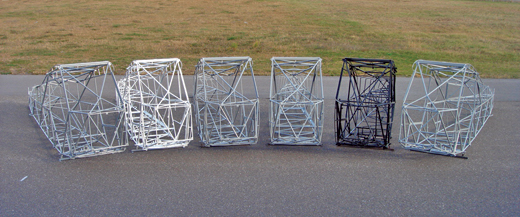

Six Javron fuselages, all welded and painted, sit on the pavement outside DeRosier’s shop ready to ship to customers. Builders will soon be using them to put together Javron Super Cubs.

A pair of Javron wings is ready to ship to a builder. These sport the traditional Super Cub round wingtips. There are a lot of parts in these wings, so having them pre-assembled in factory jigs saves the builder a lot of time.

Javron’s attention to maintaining original PA-18 standards makes for a plane that flies as much as possible just like a Piper Super Cub. This means some in this group will fly slower and land shorter, but the performance of the original Super Cub has a long history of being up to the task of bush flying all over the world. The Javron certainly matches that performance with a package that solves many of the minor deficiencies of the original design, and its focus on keeping things light has an advantage that is not completely reflected in advertised speed numbers. Given the same horsepower, a lighter plane will accelerate and decelerate more readily, but even if a heavier plane has a lower stall speed, its weight may negate some if not all of the benefit of that lower stall speed. In other words, it may take just as much room to take off and land as the lighter plane with the somewhat higher stall speed.

The Javron kit sells for $40,500, with a number of options available, such as squared-off wingtips, a choice of door and window configurations, extra fuel and even a cargo pod. Like most kits, off-the-shelf items are mostly excluded. Javron has sold 10 kits, with six more on order. In addition, Javron made components for Smith Cubs for many years and can borrow from some of that much longer history for itself. Javron is working on developing an assembly manual, but for now builders need to rely on widely available Super Cub drawings and Javron’s detailed hardware diagrams. Final NKET approval will have to wait for the completion of the assembly manual.

What’s Not in the Kit?

With the exception of the Carbon Cub EX, no other kit manufacturers offer their customers engines or props. CubCrafters does because its lightweight engine is such an integral part of the company’s overall strategy to keep weight at an absolute minimum. Available engines run the gamut from O-320 and O-360 Lycoming Thunderbolt engines to custom engines by vendors such as Mattituck, Barrett Precision Engines and Aero Sport Power. Used Lycomings will run anywhere from $10,000 to $15,000 or so, depending on their time in service and general condition. It is worth noting that buying a used engine is not for the impatient or faint of heart. It is hard to get a really good used engine and easy to get a really bad, used-up engine. That said, you can save some serious money if you know what you are doing or have a knowledgeable friend who can help you.

New engines in this size range will run from the mid-$20,000s to about $30,000. Some good examples at the low end are the 150-hp Aero Sport Power O-320-D2A at $24,500, built with mostly ECi parts. At the high end you’ll find the Lycoming Thunderbolt YO-360-A1A with roller tappets at $29,250. Custom modifications and fuel injection will add to those prices. A popular choice with the Backcountry Cub folks is the Aero Sport Power O-375 engine making 195 hp for $26,700. These are just a few examples, though. Shop around and see what suits your budget and flying requirements.

Again, only CubCrafters offers a prop with the kit, so with anyone else you will need to buy one. The available offerings range from wood and composite fixed props by Catto and other small vendors, starting at about $2000, to Sensenich fixed metal props at about $3000, up to a constant-speed propeller by Hartzell or some nice but pricier models from WhirlWind or MT-Propeller. Expect to pay $6000 to $7000 for a new Hartzell prop and upwards of $10,000 or so for the composite props by MT or WhirlWind.

Hardware and miscellaneous items can range from near zero for the Carbon Cub to thousands of dollars for the other kits. Engine accessories such as oil coolers, baffles, cabin heat valves and fuel lines will cost several thousand dollars more. And you don’t want to forget things like instruments, strobes, upholstery and a battery. This is where that $100,000+ completed price comes from; it adds up fast. In each case it is important to determine what’s included and what’s not before making a final decision. A low kit price does not necessarily result in a low final price.

Comparing Features

Reducing these planes to numbers on a chart is at once too tempting to avoid and too misleading to let stand without comment. Gross weight is a useful number when you need to legally cram a large amount of gear into your plane and survive a ramp check, but an impressive gross weight number does not get your plane off a sand bar in the afternoon as the river starts to rise; a low actual weight and a low takeoff speed do.

Empty weight varies more from plane to plane depending on your equipment and attention to detail as you build than the differences between most of these kit manufacturers. Minimum speed is a tough number to compare, because it is not measured to any standard. How slow you can fly depends on the aerodynamics of each plane to be sure, but it also depends on weight, power and pilot technique. However, everyone likes to talk about it, so we list it here.

Fuel capacity is useful if you need to fly somewhere with no fuel and get back again in unpredictable weather, but to be honest, topping off your tanks when you can carry 82 gallons of fuel is something you would seldom do. Kits sold and completed tells you something about how long a company has been around. It also gives you some idea of how much help you can count on from other builders. Lastly, NKET approval means the FAA has approved the kit as complying with the majority amateur-built rule (51% rule). This approval makes getting an Experimental/Amateur-Built airworthiness certificate easier. Without this approval you can still get through the process, but you will have to do some extra work, because you will have to make the case for amateur-built status on your own.

All of these numbers come from the respective manufacturers, and they have not been independently verified. They can serve as a good starting guideline, but before making a purchase as substantial as this, it would be wise to check things out for yourself.

Enjoyed your article can I just scratch build a airplane I get a set a plan which airplane would you suggest I like that ask you to SQ2 But he’s like a real good one what do you think it would cost if I build one from scratch I can weld and gig

There is so much more to building a Supercubs than welding the fuselage. The wings probably present the biggest challenge to a builder unless you are. Willing to live with wood wings.

I do not have good information on the cost of scratch building such a plane, but it may be possible for around $50-60 K if you got a used engine and minimal instruments and radios