Propellers have a large effect on the performance of piston-engined airplanes. One of the important decisions for a designer or builder is whether to use a fixed-pitch propeller or step up to the higher weight, cost, and complexity of a constant-speed prop in order to improve performance. Last month we looked at how the propeller absorbs power from the engine and converts it to useful thrust to drive the airplane through the air. We also saw how the power required to turn a given propeller varies with airspeed, and how that variation affects the thrust horsepower available from a fixed-pitch prop.

Fixed Pitch

A fixed-pitch propeller being driven by a piston engine behaves very much like an automobile that has only one gear ratio in its transmission. The fixed-pitch propeller can efficiently deliver the rated power of the engine to the airplane at the airspeed and rpm at which it was designed to operate (its design point), but the thrust horsepower it can deliver falls off relatively quickly as the airspeed varies from the design point.

At airspeeds above the design point, the propeller cannot absorb the rated power of the engine at the rated rpm of the engine. Accordingly, the engine cannot be run at full throttle at these higher airspeeds without exceeding its rated operating rpm. In order to avoid overspeeding the engine, we must reduce throttle, which decreases the power being delivered to the propeller, and hence decreases the thrust horsepower the propeller delivers to the airplane.

At airspeeds below the design point, the situation is different. The power required to turn the propeller at a given rpm increases as airspeed decreases. Accordingly, at airspeeds below the design point, the engine does not have enough power to turn the prop at the engine’s rated rpm. The prop will govern the engine down to a lower rpm. At this lower shaft speed, the engine will produce less than rated power, even at full throttle. The slower the airspeed is relative to the design point of the propeller, the more the prop holds down the engine rpm, and the lower the power delivered to the prop, and eventually, to the airplane.

Because of these effects the choice of pitch for a fixed-pitch propeller is inherently a compromise. If we pitch the prop to get the best cruise performance, its higher pitch tends to lug the engine down more at lower airspeeds, which hurts climb performance. On the other hand, if we choose a low-pitch prop that lets the engine deliver rated power at climb airspeeds, cruise performance will be severely reduced because the engine will not be able to deliver anything close to rated power at cruise airspeed without overspeeding. Accordingly, for most airplanes with fixed-pitch props, the prop pitch is somewhat less than optimum for cruise, but still higher than optimum for maximizing rate of climb. If the pitch is biased toward the high side to make the airplane faster, we call it a “cruise” prop, and if the pitch is biased down to emphasize climb performance, we call it a “climb” prop.

Speed Variation

A fixed-pitch prop is sensitive to variations in airspeed. Accordingly, the greater the variation in airspeed over the mission of the airplane, the harder it is to come up with an acceptable compromise pitch for a fixed-pitch propeller.

Early airplanes were relatively slow and had a relatively small speed range between takeoff, climb, and cruise. The same is true for modern ultralights. Since these airplanes fly at nearly constant airspeed, a fixed-pitch propeller works very well for them.

As cruise performance increases, the variation of airspeed between climb and cruise gets larger. At some point, the variation in airspeed between climb and cruise gets large enough that a single propeller pitch cannot adequately address the needs of the airplane over the entire speed range.

By the early 1920s the builders of racing airplanes began to run into this problem. By the mid ’20s, the top speed of the fastest racing airplanes was over 200 mph. In order to go this fast they had to have very high-pitch propellers. These worked well at racing speeds, but did very poorly on takeoff.

On some of these racers, the pitch in their prop blades was so high that the blades were stalled when the airplane was moving slowly. In this condition, the engine could turn relatively fast, but the prop produced very little thrust. It took a long roll for the airplane to get going fast enough to un-stall the prop blades. When this happened, the ability of the propeller to produce thrust increased, but the extra lift produced by the blades opposed the engine’s rotation enough to slow the engine down and reduce power. The engine rpm would actually drop at this point in the takeoff roll, even though thrust would start to increase. Because these racers had high-powered engines, they would eventually get off the ground, but their takeoff and climb performance was quite poor, and the takeoff roll was long in spite of their high installed power.

Modern single-engine light airplane designs span the speed range where the cross-over between fixed-pitch propellers being adequate and not occurs. A trainer or Light Sport airplane has a small enough speed range that a fixed-pitch prop will work fine. On a Cessna 150, for example, cruise speed is only about 25% faster than best rate of climb speed.

Cleaner, higher-powered airplanes can easily have cruise speeds that are more than twice the best rate of climb speed. As the variation between cruise speed and climb speed increases, the severity of the compromise inherent in a fixed-pitch prop also increases. At some point, a variable-pitch prop becomes the better option.

Variable Pitch

One of the parameters that determine how much power the propeller can absorb is the pitch angle in the blades. For a given blade shape and prop diameter, the greater the pitch angle the more power it takes to turn the propeller. By changing the pitch of the blades, we can adjust the propeller to absorb a given power at a given rpm. Early variable-pitch propellers had two pitch settings, a low (or fine) pitch setting for takeoff and climb, and a high (or coarse) pitch setting for high speed. Later, governors were developed that varied the pitch of the prop blades to keep the engine running at constant rpm. This allowed the pilot to choose the engine rpm by setting the governor, and then adjust power with the throttle. This constant-speed system is what is used on most airplanes today.

What a constant-speed prop does is allow the engine to turn up to its rated rpm at any airspeed within the airplane’s normal flight envelope. The governor adjusts the pitch of the blades to keep the rpm constant. When the prop is set to maximum rpm, the engine turns at its rated rpm. If the throttle is wide open, this means that the engine is delivering its rated horsepower to the prop. It is this ability to get full power out of the engine at a wide range of airspeeds that is the primary advantage of a constant-speed prop.

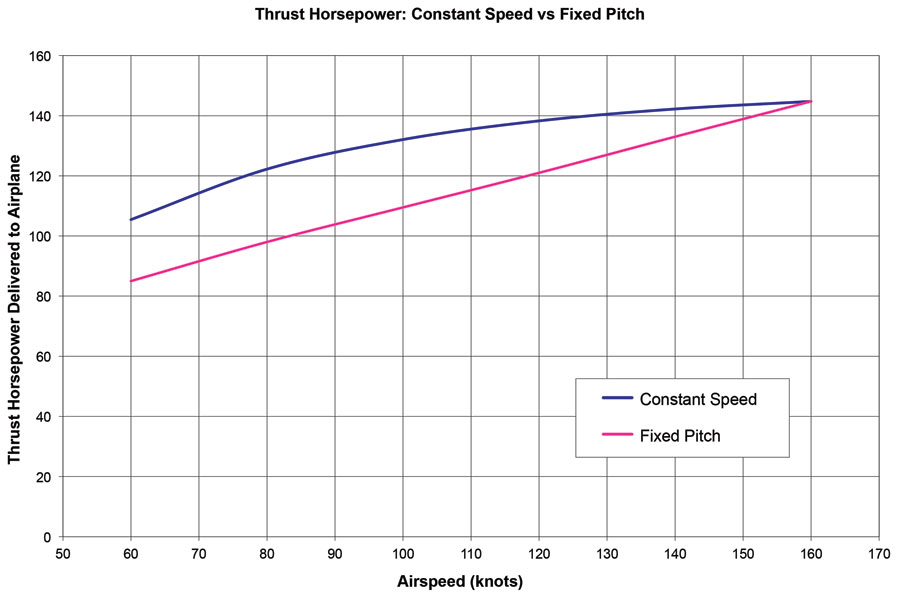

To illustrate the difference between fixed-pitch and constant-speed, lets look at Figure 1. This shows the thrust horsepower available from an example propeller. This prop was designed to absorb 160 hp at 160 knots.

The first thing to note is that there is no difference between the performance of the fixed-pitch and constant-speed prop at the design point of 160 knots. If the two propellers have the same blade shape, they will be essentially the same because the governor of the constant-speed prop will place the blades at the same pitch as the optimized fixed-pitch prop would have.

What is different is the performance of the two systems at airspeeds below the design point. The thrust horsepower available from the fixed-pitch prop falls sharply as airspeed is reduced. The constant-speed prop does much better at delivering power to the airframe at these lower airspeeds because, by adjusting the pitch to keep the rpm at rated rpm, the governor allows the constant-speed prop to absorb the full rated power of the engine.

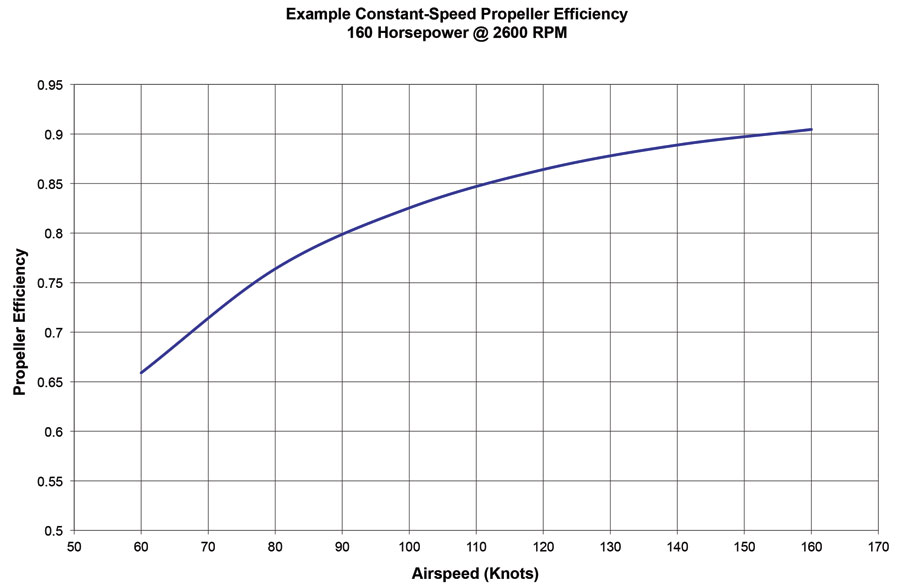

Notice that the performance of the constant-speed prop is not absolutely constant with airspeed. This is because, while the prop is getting full power from the engine, the propeller efficiency varies with airspeed. This effect is illustrated for our example prop in Figure 2. At lower than design airspeed, propeller efficiency degrades for two reasons. First, the ideal efficiency of a perfect prop decreases with decreasing airspeed. Second, the blades are shaped to be efficient at the design point, and while the governor can change the pitch of the blades, it can’t adjust the blade twist or planform.

Why Constant Speed?

Looking at Figure 1, we can see the primary reason to choose a constant-speed prop. If we look at a typical climb speed of 80 knots, we can see that the constant-speed propeller is delivering about 25% more power to the airplane than the fixed-pitch propeller. For a gross weight typical of a two-seat high-performance homebuilt, this difference corresponds to about 500 feet per minute of rate of climb.

What this rate of climb improvement allows the operator of the airplane to do is use a propeller that delivers maximum cruise performance while retaining acceptable take off and climb performance. A fixed-pitch prop can deliver the same cruise performance only if the greatly reduced rate of climb is still acceptable. If it is not, then the operator will be forced to use a lower-pitch prop that will compromise cruise performance to get an acceptable climb. As the top speed of the airplane increases, so does the magnitude of this compromise. When the performance of the airplane gets high enough, then a constant-speed prop becomes the best approach to using the cruise performance inherent in the design of the airframe, while still being able to take off in a reasonable distance and climb well.